WASTE-TO-ENERGY: A PROMISING MARITIME TRANSPORT TECHNOLOGY

Dr. S. Thangalakshmi 1 ![]()

![]() ,

Dr. K. Sivasami 2

,

Dr. K. Sivasami 2![]()

![]()

1 Faculty - Electrical, School of Marine Engineering and Technology Indian Maritime University, Chennai Campus Chennai, India

2 Associate Professor & Head, School of Marine Engineering and Technology Indian Maritime University, Chennai Campus Chennai, India

|

|

ABSTRACT |

||

|

Everything in the world, including the shipping industry, is powered by energy. There are numerous advanced energy-generation strategies, but it would be greatly valued if energy could be consistently derived from ship waste. Waste disposal is a difficult task in the shipping industry, so many studies are being conducted to find better ways to dispose of waste. According to regulatory agencies, India has a large source of both industrial and urban organic waste. The shipping industry, like any other, necessitates massive amounts of energy. On a daily basis, a massive amount of waste is generated, ranging from small crafts to ultra-large vessels (aerobic as well as anaerobic). So, there is a significant opportunity for capturing the energy from this waste, and both the difficulty of waste disposal and the depletion of conventional energy sources can be effectively addressed concurrently. This paper examines various means of generating energy from waste. Furthermore, the current state of Waste-to-Energy (WTE) in our country and around the world is discussed. Motivation/Background: There is a perennial need for energy in all industry. This energy is pivotal in marine sector. There is huge amount of waste disposal into sea and IMO is keen on pollution control and de-carbonization. So, converting the waste serves two purposes viz. pollution control and green energy generation. Method: Various techniques for generating energy from waste had been discussed. Results: Waste-To-Energy is still a relatively unexplored technology in the shipping industry. Large cruise ships generate massive quantities of waste. This in and of itself represents a large avenue for WTE as a source of renewable energy on board ships. There are very few manufacturers venturing into the WTE segment to create power from ship waste. Scan ship, a Norwegian ship waste management system manufacturer, has established a system that uses microwave-assisted pyrolysis to transform carbon-based waste generated on ships into biofuels. Conclusions: WTE is also

a relatively new concept in the shipping industry. Countries such as Norway,

which is successfully operating WTE plants on land, are progressively

migrating the technology and paving the way for others. More initiatives like

these can radically decrease the amount of waste that ships discharge into

the sea, resulting in a more comprehensive ecosystem for all life forms. |

|||

|

Received 02 April 2022 Accepted 05 May 2022 Published 21 May 2022 Corresponding Author Dr. S.

Thangalakshmi, thangalakshmiprakash@yahoo.com DOI 10.29121/IJOEST.v6.i3.2022.327 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2022 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Aerobic Waste,

Energy Demand, Waste Disposal & Management, Advanced Generation, Ship

Waste |

|||

1. INTRODUCTION

Waste disposal is a major issue that the world is dealing with today. Around the world, researchers are working to develop new and more efficient methods of handling and recycling waste. In addition, new methods for converting organic and inorganic waste into useful alternatives are being developed. Adopting waste-to-energy (WTE) initiatives is one of the most effective ways to address this waste management issue. This, in turn, addresses another serious challenge: the search for alternative energy sources. Although research has discovered a number of methods for transforming waste - to - energy, field applications, especially in India, are quite limited. The waste-to-energy sector has enormous untapped potential, and the shipping industry can play a significant role in this.

According to the World Bank, 1.3 billion tonnes of waste are produced globally each and every year, with this figure expected to rise to 2.2 billion tonnes by 2025. As a result, the urge for municipal solid waste treatment and disposal are becoming extremely relevant around the world. Solid Waste Management is a prevailing philosophy shared by evolved and emerging nations Moya et al. (2017). Municipal Solid Waste is a useful natural resource with the ability to produce biogas for combined heat and power (CHP) production when suitable waste-to-energy techniques are used. This paper discusses the current potentials for WTE in India, as well as the various technologies used for WTE. It also stresses the importance of integrating these energy and resources onboard vessels.

This section should put the focus of the manuscript into a broader context. As you compose the Introduction, think of readers who are not experts in this field. Include a brief review of the key literature. If there are relevant controversies or disagreements in the field, they should be mentioned so that a non-expert reader can delve into these issues further. It should conclude with a brief statement of the overall aim of the research or experiments and a comment about whether that aim was achieved.

2. CURRENT WASTE-TO-ENERGY SCENARIO IN INDIA

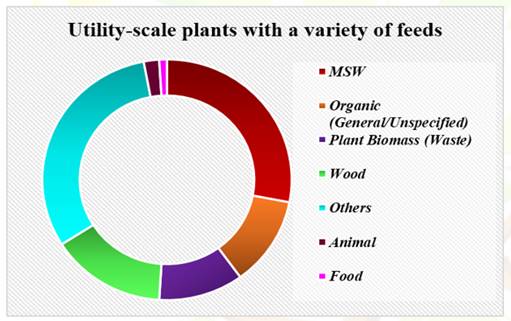

India is a big subcontinent with a populace of roughly 1.38 billion people World Population Prospects (2019) as of 2020. The nation produces 450 gm of municipal solid waste (MSW) per capita each day Tripathy (2018). In 2017, the gross production of MSW had been almost 1,33,760 tonnes a day Kumar et al. (2017), of which approximately 91,152 tonnes were collected but only 25, 884 tonnes were treated. As per the Central Pollution Control Board's Yearly Report on the Deployment of Solid Waste Management Regulations for 2018-19, MSW collection rate is 98.4 percent of waste produced Central Pollution Control Board (2020). Nevertheless, the report also indicated that the large percentage of waste processing infrastructure in most of of states are not in working order. A significant chunk of this collected waste is lying around in open dumping sites and landfills, desegregated, making ecological and health risks. Not to mention that they would have rendered vast swaths of land desolate and unusable. The various wastes produced and filling the landmasses are depicted in Figure 1.

In 1987, the first massive MSW incinerator was established in Timarpur, New Delhi, as part of India's WTE initiatives Kumar et al. (2017), which had a daily potency of 300 tonnes of waste and cost Rs. 250 million. However, this strategy failed for a range of factors, including poor waste separation, climatic variables in waste composition, an absence of suitable technology, and operation & maintenance challenges. Following the Timarpur plant, 14 additional WTE plants with an overall capacity of 130 MW were implanted in the country, but 7 of these have already become inoperable, leading to a loss of roughly 66 MW. As of now, only 7 plants with a cumulative capacity of nearly 69.2 MW Solid Waste in India (2019) are operational. Inhabitants and greenies had also criticised and opposed many of the above projects for triggering pollution and posing health hazards.

As of 2018, India had installed 9.54 GW of grid-connected bio-power capacity, including 8.73 GW from bagasse cogeneration, 0.68 GW from non-bagasse cogeneration, and 0.13 GW from waste to energy MNRE (2018). Another 84.3 MW of WTE is reportedly being built Solid Waste in India (2019). Even though volume of energy generated from waste in India is presently insignificant, the nation's future in waste-to-energy sounds exciting. The Ministry of New and Renewable Energy has exhibited a strong fascination in waste-to-energy and bioenergy and has amended the regulations of its waste-to-energy programme to establish a much more suitable atmosphere for the long-term viability of WTE plants. The government plans to offer funds in the form of investment subsidies and Grants-in-Aid under this revised framework for the setup of a number of waste-to-energy and bio-energy plants, and also for widening the potency of existing plants Government of India (2021).

Figure 1

|

Figure 1 Utility-scale Plants with a Variety of Feeds Antony (2017) |

However, some of India's biggest challenges in the production of energy from waste continue to stay. The volume of waste is just the first major concern in this respect. The quality of waste produced in countries such as Sweden and Norway, where WTE is a significant source of power generation now, differs greatly from that found in India. Whilst calorific value of waste produced in such countries varies from 1,900 to 3800 kcal/kg, waste produced in India has a calorie content of just around 1,411–2,150 kcal/kg Solid Waste in India (2019). This renders it inappropriate for burning, and even when burned, the energy gained is extremely low. This is primarily due to the fact that the large percentage of waste derived in India is organic waste with an increased water content.

3. THE PROSPECTS OF INDIA IN THE WASTE-TO-ENERGY MARKET

Ports are facing unique challenges of environmental, energy efficiency enhancement, renewable energy integration, regulatory and legislative policies, power and grid stability, infrastructure complexity, and increased energy demand Indo-UK Seminar Report (2015), The MSW accumulated in India's urban zones does have the capacity to generate roughly 500 MW of power, which is estimated to reach to 1,075 MW by 2031 and just about 2,780 MW by 2050 Tripathy (2018). Meanwhile, in order to realize the full potential, the authorities must enforce harsher actions to guarantee that ongoing and future projects can be sustained. Only segregated, non-recyclable, high calorific waste should be sent to WTE plants, as per the Solid Waste Management Regulations 2016 Government of India (2021) This implies that only 30,000 tonnes per day of the overall MSW produced in urban localities can be sent to WTE plants, that have a gross potency of 37,000 tonnes each day Solid Waste in India (2019).

4. TECHNIQUES FOR WASTE-TO-ENERGY

There are numerous methods for converting waste to energy. This section discusses the most commonly used methods.

4.1. INCINERATION

Incineration is perhaps the most widely used thermal treatment based WTE technology today. The waste is supplied into the incinerator furnace during the incineration process, where it is burnt down at extreme temps (>850°C) with an adequate airflow Nidoni (2017). To avoid the formation of dioxins or carbon monoxide, the waste is permitted to thoroughly burn. The warm air of burning, in the form of flue gases, is being used for energy recovery in boilers to generate steam. This high-temperature steam can then be exploited for space heating, power production, and a variety of other purposes. Incineration is better adapted for wastes with a high energy density Kalyani and Pandey (2014). Incineration, on the other hand, does not function properly with waste that contains a high moisture level. Particulate emissions and toxic metal content in bottom ash, which may be disposed of in landfills, are also major issues with this approach.

4.2. GASIFICATION

Gasification is just another standard practice for heat treatment of solid waste. It is the conversion of carbonaceous substances into carbon dioxide, carbon monoxide, and a low percentage of hydrogen. This is a high-temperature mechanism as well, however the waste is not permitted to burn in this technique. The heating rate in gasification is typically 760°C to 1300°C Rogoff and Meng (2019). The gas formed by this process is known as syngas, and it can be burned as fuel. This fuel is being used in producing electricity and the generation of steam, among many things. Gasification is superior to incineration in terms of pollution control because particulate emissions are much lower. Even so, the quantity of energy retrieved is primarily determined by the type of waste used.

4.3. PYROLYSIS

Pyrolysis is yet another high-temperature strategy that causes carbon-based waste to decompose thermally in an oxygen-deficient, inert atmosphere. Pyrolysis of biomass produces pyrolysis fumes, which can be condensed into biofuel and biochar.

4.4. LANDFILL GAS RECOVERY

Landfill gas recovery is a waste treatment thermo-chemical methodology. Landfill gas is produced as a result of thermal, chemical, and microbial processes occurring on waste matter. This gas is generated as a by-product of landfill anaerobic degradation of organic waste. The gas is primarily constituted of methane and carbon dioxide, with trace amounts of many other organic compounds. Aerobic decomposition occurs in the early phases of waste dumped in a landfill, producing small quantities of methane. Anaerobic conditions develop gradually, and methane-producing bacteria start to decompose organic matter, releasing sizeable volumes of methane and Carbon dioxide. This gas can be collected and treated for use in a variety of applications, including cooking gas, vehicle fuel, and also for producing power.

4.5. ANAEROBIC DIGESTION

Anaerobic digestion is an analogous practise to landfill gas generation. In this process, the organic content of waste is permitted to degrade by microorganisms in the absence of air, resulting in biogas that can be used in a variety of applications. The main benefit of this technique is that it can be used on both a large- and small - scale.

The Figure 2. displays the different methods used for WTE. It shows that combustion/incineration has always been the most common type of technology, whereas the gasification as well as AD are less explored.

Figure 2

|

Figure 2 Techniques for Waste-To-Energy [17] |

5. POSSIBILITIES FOR RENEWABLES AND WTE ON BOARD SHIPS

Shipping, as an energy-intensive industry, is in desperate need of more renewable energy alternatives. Renewable energy applications on ships can deliver long-term remedies for hybrid, auxiliary, and perhaps main propulsion, as well as on energy demands.

Nationally and internationally, the maritime industry is already implementing fresh and innovative steps to integrate renewable power into existing fleets as well as latest shipbuilding and layouts.

The primary emphasis on renewable energy initiatives in shipping is on a few regions, such as wind and solar energy-based design optimizations. Wind energy is being harnessed through the use of specially built soft sails, fixed sails, and kite sails IRENA (2015). Wind turbines have also been examined, but still no effective prototypes have yet been produced. On smaller vessels, solar photovoltaic cells are often used in conjunction with numerous different sources of electricity. Biofuels are also making an appearance in shipping, with the Meri cargo ship confirming to be the first of its size to operate exclusively on biofuel.

However, waste-to-energy is still a relatively unexplored technology in the shipping industry. Large cruise ships generate massive quantities of waste. This in and of itself represents a large avenue for WTE as a source of renewable energy on board ships. There are very few manufacturers venturing into the WTE segment to create power from ship waste. Scan ship, a Norwegian ship waste management system manufacturer, has established a system that uses microwave-assisted pyrolysis to transform carbon-based waste generated on ships into biofuels. Waste materials such as food, paper, plastic, and oils can be converted into combustible gases, bio-oil, and charcoal by the system The Explorer (2020). TECO TECH, another Norwegian manufacturer, has created a waste management process that involves waste gasification to recoup heat via a proprietary sodium heat pipe economizer Waste to power (2020).

These are among the forerunners in the use of WTE systems in shipping. However, with the use of WTE, waste management on ships can enhance by great strides. Presently, the majority of food waste from ships is expelled at sea, as allowed by MARPOL Annex V, plastics are not incinerated, and sewage is discharged to the sea as permitted by MARPOL Annex V EMSA (2016). On board ships, techniques such as gasification, pyrolysis, and incineration have by now been put in place. With additional breakthroughs in these systems through research and innovation, the maritime industry may be able to become self-sufficient in terms of energy generation and consumption. Figure 3. illustrates the plastic waste generated at sea and the waste management process.

Figure 3

|

Figure 3 Waste Management Process in a Cruise Ship Kotrikla et al. (2021) |

6. CONCLUSION

WTE is still a developing business in India, and the country has not had much popularity in this ground so far. But even so, with new initiatives in place and the government's and MNRE's growing interest in waste management and WTE, significant improvements can be anticipated in the near future. WTE is also a relatively new concept in the shipping industry. Countries such as Norway, which is successfully operating WTE plants on land, are progressively migrating the technology and paving the way for others. More initiatives like these can radically decrease the amount of waste that ships discharge into the sea, resulting in a more comprehensive ecosystem for all life forms.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

Antony, A. (2017). What are some of the latest waste-to-energy technologies available ? - PreScouter - Custom Intelligence from a Global Network of Experts.

Central Pollution Control Board (2020). Management Rules (As per provision 24(4) of SWM Rules,16).

EMSA (2016). The Management of Ship-Generated Waste On-board Ships.

Government of India (2021). Revised Guidelines of Waste-to-energy Programme, Programme on Energy from Urban, Industrial, Agricultural Wastes/ Residues and Municipal Solid Waste. Government of India, Ministry of New And Renewable Energy.

IRENA (2015). Renewable Energy Options For Shipping, Technology Brief, International Renewable Energy Agency (IRENA).

Indo-UK Seminar Report (2015). Sustainable solid waste management for cities: opportunities in SAARC countries.

Kotrikla, A.M. Zavantias, A. Kaloupi, M. (2021). Waste generation and management onboard a cruise ship: A case study, Ocean & Coastal Management, 212. https://doi.org/10.1016/j.ocecoaman.2021.105850

Kumar, S. Smith, S. R. Fowler, G. Velis, C. Kumar, S. J. Rena, A. S. Kumar, R. Cheeseman, C. (2017). Challenges and opportunities associated with waste management in India. Royal Society Open Science, 4(3). https://doi.org/10.1098/rsos.160764

Kalyani K. A. Pandey K. K. (2014). Waste to energy status in India: A short review, Renewable and Sustainable Energy Reviews 113-120. https://doi.org/10.1016/j.rser.2013.11.020

Moya, D. Aldás, C. Jaramillo, D. Játiva, E. Kaparaju, P. (2017). Waste-To-Energy Technologies : an opportunity of energy recovery from Municipal Solid Waste, using Quito - Ecuador as case study, 134, 327-336. https://doi.org/10.1016/j.egypro.2017.09.537

MNRE (2018). Year End Review 2018 - MNRE, Press Information Bureau Government of India Ministry of New and Renewable Energy

Nidoni G. P. (2017). Incineration Process For Solid Waste Management And Effective Utilization Of By Products, International Research Journal of Engineering and Technology (IRJET), 4(12), 78-382.

Rogoff M. J. Meng F. S. (2019). Chapter 3 - Energy From Waste Technology, Technologies and Project Implementation. 29-56. https://doi.org/10.1016/B978-0-12-816079-4.00003-7

Solid Waste in India (2019). Feasibility of Waste to Energy plants in India, Centre for Science and Environmenthttps.

Tripathy, U. (2018). A 21st Century Vision on Waste to Energy in India: A Win-Win Strategy for Energy Security and Swachh Bharat Mission (Clean India Mission). Eighth Regional 3R Forum In Asia And The Pacific, Indore, Madhya Pradesh, India.

The Explorer (2020). Powering cruise ships with waste.

World Population Prospects (2019). United Nations, Department of Economic and Social Affairs, Population Division World Population Prospects 2019, Online Edition.

Waste to power (2020). Large cruise ships generate substantial amounts of waste per day – Norwegian manufacturer TECO TECH has developed a solution that could enable shipowners to turn this waste into energy at sea.

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© Granthaalayah 2014-2022. All Rights Reserved.