INTEGRATION OF SIX SIGMA AND DIGITIZATION FOR QUALITY ENHANCEMENT IN CONSTRUCTION

Amisha Bansal 1![]() , Kranti Kumar Myneni 2

, Kranti Kumar Myneni 2![]()

![]()

1 Student, Master of Building Engineering

and Management, School of Planning and Architecture, Vijayawada, India

2 Assistant Professor, Master of Building Engineering and Management, School of Planning and Architecture, Vijayawada, India

|

|

ABSTRACT |

||

|

The construction industry is characterized by its complex processes, high variability, and demand for consistent quality, particularly in high-rise projects. Despite advancements, recurring issues such as defects, delays, and inefficiencies persist. This paper explores the integration of Six Sigma methodologies with digital tools to develop a robust framework for improving the quality of the concrete pouring process in high-rise construction. Focusing on

the DMAIC (Define-Measure-Analyze-Improve-Control) methodology, the research

identifies construction activities suitable for Six Sigma application,

evaluates digital tools for compatibility, and proposes an optimized

framework. It investigates tools like SIPOC, Pareto charts, Fishbone

diagrams, Kaizen, and Control Plans, emphasizing their digitized application

to enhance process efficiency and decision-making. |

|||

|

Received 15 January 2025 Accepted 17 February 2025 Published 18 March 2025 Corresponding Author Kranti

Kumar Myneni, kranti.myneni@spav.ac.in

DOI 10.29121/IJOEST.v9.i2.2025.672 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2025 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Digital Tools,

DMAIC, Six Sigma, Quality Management |

|||

1. INTRODUCTION

The construction industry is facing increasing pressure to deliver projects on time, within budget, and to the highest standards of quality. With projects becoming more complex and client expectations rising, ensuring consistent quality control is critical. Yet, construction projects frequently suffer from rework, delays, and cost overruns due to defects and inefficiencies in processes. Traditional quality management approaches in construction often fall short of addressing these issues systematically. The construction industry has faced considerable criticism for its deficiencies in quality during both the design and execution phases Vijayabanu et al. (2022). Deviations in quality often result in rework, which can lead to cost overruns of approximately 4.4% and schedule delays of about 7.1%, as indicated by a case study conducted in Sweden Muwafaq et al. (2020). The Indian construction industry plays a pivotal role in the country's economic growth, serving as the second-largest employer after agriculture. The Indian construction industry is projected to grow by 11.2% in 2024, reaching INR 25,316 billion, with a CAGR of 9.4% through 2028. This growth is further driven by robust government spending, economic expansion, and rising demand for housing, positioning high-rise residential buildings at the forefront of the industry's future.

Quality is a critical aspect of construction and product development, according to the study, by Mustapha et al. (2023) defined as the extent to which a product is executed and produced by design and material specifications while also satisfying user requirements with minimal or no rework. The challenges associated with quality management can significantly impact productivity, contributing to both time and cost overruns as well as disputes among stakeholders Shibani et al. (2021).

Quality management refers to a comprehensive system established to ensure that an organization consistently meets customer expectations while enhancing its processes and products over time. It is essential to distinguish between quality management and quality control; the former focuses on preventing defects by performing tasks correctly, while the latter involves inspecting and verifying the quality of finished products Vijayabanu et al. (2022).

Six Sigma, a data-driven methodology, focuses on minimizing defects by identifying and eliminating variations in processes. Though it has been widely adopted in industries like manufacturing, its application in the construction sector is still relatively new. Construction projects, with their unique activities and phases, present numerous opportunities to apply Six Sigma principles. The methodology’s potential to enhance efficiency and ensure higher quality by reducing rework can significantly improve project delivery outcomes, especially in residential and commercial building projects. It can enhance operational efficiency by reducing errors and accelerating project delivery, with a strong emphasis on improving quality. Conversely, digitization has the potential to streamline processes, improve data management, and enable real-time monitoring of construction activities. Thus, this paper aims to develop a Six Sigma and digital tool-based framework to improve construction quality.

2. LITERATURE REVIEW

2.1. Quality Management in the Construction Industry

While the Indian construction industry has witnessed remarkable growth and the demand for high-rise residential buildings is at an all-time high, the sector faces significant execution challenges. It has been noticed that quality has been a critical issue in the construction industry as it involves a systematic process and procedural activities for determining that construction projects meet quality requirements, including the client’s requirements, regulatory requirements, and fit for the purpose. Ghansah & Edwards (2024). Quality is accordingly considered a prime target in any project, as well as a critical indicator of the success or failure of that project. Moreover, the need to control the level of quality from the very beginning is utterly significant whenever construction projects are concerned. Sahlih et al. (2020).

Quality management in construction is a systematic process essential for ensuring that projects meet a variety of requirements, including client specifications, regulatory standards, and functional objectives. As stated Sahlih et al. (2020), quality in construction involves procedural activities to ensure the final product fits its intended purpose. The importance of quality management becomes even more apparent when considering its impact on a project's overall success. As Alia et al. (2022) emphasised, without a structured approach to quality control, projects may suffer from issues such as extended timelines and increased costs. Quality planning, control, and assurance are essential to achieving the desired outcomes within the defined scope. Quality management is not only vital for delivering a successful construction project but also for ensuring that it is completed on time, within budget, and to the client’s satisfaction. This underscores the importance of adopting rigorous quality management systems in construction projects, particularly in high-rise residential developments where complexity and stakes are higher. Poor quality management may cause the project late, over cost and endure from poor materials and workmanship. According to a study on Kuala Lumpur International Airport project application of quality management, had some problems like lack of experience in execution of QMS, exceeding dependence on construction traditional management method, passive behaviour towards on new way and misunderstanding of the QMS application. At the same time, it was discovered that the problems of organization implementing QMS in the Malaysian construction Industry are lack of benefits’ consciousness of QMS and lack of exposure in application of QMS among labours.

2.2. Quality Management Techniques

Quality management in construction has evolved over the years, driven by the need to enhance project performance, reduce waste, and improve client satisfaction. Various methodologies have been developed to ensure that construction projects meet the required quality standards while maximizing efficiency. This section introduces three prominent approaches: Total Quality Management (TQM), Lean Construction, Six Sigma and ISO Standards, highlighting how they contribute to continuous improvement and the reduction of waste in construction processes.

Total Quality Management (TQM)- According to R. S. V. et al. (2017) TQM, it focuses on building a culture of continuous improvement and customer satisfaction across the entire organization R. S. V. et al. (2017). It emphasizes employee involvement, leadership commitment, and long-term quality goals but can be time-consuming and less structured in solving specific process defects.

According to Jaegar & Adair (2015) TQM, it improves efficiency, client satisfaction, and reduces errors but faces challenges such as cultural resistance, lack of management commitment, and insufficient employee involvement in Kuwait's construction industry. Successful adoption requires overcoming these organizational and communication barriers.

Six Sigma - According to R. S. V. et al. (2017)Six Sigma, it is a data-driven methodology aimed at reducing process variability and defects using tools like DMAIC. It delivers measurable results and precision in quality improvement, but its focus on data can make it rigid and resource-intensive due to training and specialized personnel requirements.

According to Solis et al. (2018) Six Sigma, it improves construction quality by minimizing defects and reducing process variability through a data-driven approach. It enhances precision and leads to more consistent project outcomes. However, Six Sigma requires significant training and specialized resources, which can be costly and time-intensive. Despite these challenges, Six Sigma offers valuable opportunities for improving construction quality and operational performance.

Lean- According to R. S. V. et al. (2017) Lean, it prioritizes waste reduction and efficiency by eliminating non-value-adding activities and streamlining workflows. It enhances speed and reduces costs, but its strong focus on efficiency can sometimes overlook deeper quality variability or defect issues.

According to Solis et al. (2018) Lean, it improves construction efficiency by reducing waste, streamlining workflows, and enhancing productivity. It results in faster project delivery and cost savings. However, challenges include resistance to cultural change, as Lean requires a shift in mindset and ongoing commitment to continuous improvement. Despite these obstacles, Lean presents significant opportunities for optimizing construction processes and delivering value to clients.

ISO 9001- According to Khalfan et al. (2020) ISO 9001, certification in construction enhances operational performance by standardizing processes, improving quality control, and increasing client confidence. It emphasizes systematic documentation and audits, resulting in more consistent project outcomes. However, challenges include high implementation costs, bureaucratic requirements, and the ongoing need for monitoring and auditing, which can strain resources.

For improving quality control in construction, Six Sigma is the most effective technique due to its structured, data-driven approach. Using tools like DMAIC, Six Sigma focuses on identifying defects, minimizing variability, and ensuring consistent, high-quality outcomes. Unlike TQM, which fosters an overall culture of improvement but lacks targeted problem-solving, Six Sigma directly addresses specific quality issues. Lean prioritizes efficiency and waste reduction, but it doesn't concentrate on quality control, and ISO 9001, while standardizing processes, can become bureaucratic without delivering the same level of detailed analysis. Therefore, Six Sigma is the superior method for achieving precise, measurable improvements in construction quality.

2.3. Six Sigma Application in Construction

Six Sigma is a statistical problem-solving methodology aimed at reducing defects and improving quality in various industries, including construction. It employs the DMAIC framework to enhance processes and minimize variability, which is crucial in construction projects where quality issues can lead to delays and increased costs Singh, R. R. D. K. G. P. M. (2020). The implementation of Six Sigma in the construction industry is essential due to its emphasis on reducing defects and enhancing quality control—key factors in minimizing errors that could lead to substantial financial losses. In a field where precision is paramount, Six Sigma’s focus on reducing process variation contributes significantly to maintaining high-quality outcomes. Research has demonstrated that applying Six Sigma within construction processes, such as competitive tendering, can notably improve time efficiency and reduce delays Ottou et al. (2020). Moreover, adopting Six Sigma practices allows construction companies to identify and reduce waste, which in turn enhances customer satisfaction. Prior studies have shown that implementing Six Sigma in construction projects can lead to increased customer satisfaction while meeting expected costs, thus promoting business excellence. Handayani et al. (2020). Research has shown that Six Sigma is a high investment management initiative, full-time effort is required, and it is very resource intensive.

In order for Six Sigma to be efficiently and successfully implemented in construction, some prerequisites must be satisfied. These included knowledgeable and supportive management, trained specialists in the field of Six Sigma, the organisational culture to be driven towards quality and customer satisfaction and appropriate employee training by the Six Sigma principles to be implemented

DMAIC is a structured problem-solving methodology used within Six Sigma, a quality management approach aimed at improving processes by identifying and eliminating defects, reducing variation, and ensuring consistency. DMAIC is an acronym for the words Define-Measure-Analyze-Improve-Control. This method is based on process improvement according to the Deming cycle. This methodology offers a structure for the analysis and diagnosis of problems, driven by powerful tools and techniques.

The use of the DMAIC method is getting more and more popular in processes that are related not only to production and manufacturing but also to IT, healthcare, and many others as well as to construction. Nowotarski & Rzepecka (2018)

2.4. Digital Tools Used in Construction

Digital tools play a crucial role in enhancing quality collaboration in the construction industry, particularly through the integration of Building Information Modelling (BIM) and other digital technologies.

· BIM facilitates effective communication and information sharing among stakeholders, ensuring that all parties are aligned with project specifications and quality requirements.

· Augmented Reality (AR) enhances real-time training, safety, and communication in projects.

· Internet of Things (IoT) simplifies communication between devices for real-time monitoring.

· Computer Vision (CV) analyzes images for construction activity identification and quality assessment.

Categories of Digital Tools

· Data Collection Technologies: Tools that gather real-time data on construction processes, facilitating immediate quality assessments Ghansah & Edwards (2024). Sensors, Drones, Mobile Applications, and Wearable technology

· Decision-Oriented Technologies: Systems that support decision-making through data-driven insights, enhancing quality assurance processes Ghansah & Edwards (2024). Artificial Intelligence (AI), Machine Learning,

· Collaborative Technologies: Platforms that promote teamwork and communication among stakeholders, crucial for maintaining quality standards Ghansah & Edwards (2024). BIM, Cloud-Based Collaborative Platforms

3. METHODOLOGY

A comprehensive evaluation of quality management methods and digital tools used in construction was conducted through a systematic literature review and thematic analysis. The study began by identifying key search terms such as "quality," "quality management," "digital tools," and related topics. These keywords were employed to retrieve relevant material from various electronic databases, including Google Scholar, Scopus, and Science Direct, focusing on journal articles, conference papers, and other scholarly publications.

The inclusion criteria prioritized studies that specifically addressed quality in construction and the techniques employed for its management. Extracted data were meticulously analyzed to identify recurring methods and techniques across various stages of the DMAIC framework. This analysis emphasized recognizing patterns, interactions, and interdependencies among the listed aspects to uncover commonly used practices in construction quality management.

Additionally, interviews were conducted with industry professionals that are project managers, site supervisors, Six Sigma consultants to gain insights into current trends and applications of quality management techniques and digital tools. The combination of insights from the literature review and survey responses facilitated the identification of common parameters. These parameters formed the basis for developing a comprehensive framework integrating quality management techniques with digital tools tailored to the construction industry.

4. RESULTS AND ANALYSIS

Current Quality Management Techniques in the Construction Industry - The construction industry utilizes a range of quality management techniques to ensure adherence to required standards and specifications. Key practices include: Quality Control (QC) Checklists, Material Testing, Site Inspections, Documentation and Traceability

The Need for Quality Management in Construction - The implementation of effective quality management systems is integral to achieving project success and mitigating risks. Specific benefits include: Reduction of Defects and Delays, Regulatory Compliance, Customer Satisfaction

Familiarity with Advanced Quality Management Methods - Construction professionals exhibit varying levels of familiarity with advanced quality management frameworks such as Total Quality Management (TQM), ISO 9001, Lean Construction, and Six Sigma. Many companies have adopted principles from these methodologies to improve efficiency and reduce costs. For example, Lean Construction is increasingly employed to streamline workflows and minimize waste. ISO 9001 certification is prevalent among organizations seeking to standardize processes and improve quality outcomes.

Challenges in Adopting Six Sigma in Construction - Although Six Sigma offers potential benefits, its adoption within the construction industry is limited due to several challenges: The cost of training and the need for specialized expertise pose External consultants, often required for effective deployment, further increase costs. The entrenched reliance on traditional construction practices. Practical Limitations

Current Use of Digital Tools in Construction - The adoption of digital tools has significantly enhanced quality management practices in construction. Some widely used tools include Building Information Modelling (BIM), Procore, Microsoft Project, and Copro

Familiarity with Digital Tools - Industry professionals, particularly in high-rise residential projects, have shown growing familiarity with digital tools. These technologies are increasingly recognized for their potential to enhance project efficiency, reduce errors, and improve overall quality.

Barriers to the Adoption of Advanced Digital Tools - Despite their potential, the widespread adoption of advanced digital technologies such as virtual reality (VR), augmented reality (AR), and robotic automation remains limited. Key challenges include High Costs and training Requirements, Technical Support Limitations, and Workforce Adaptability

Multiple academic papers were reviewed to analyze the application of Six Sigma in construction quality management. The focus was on identifying the quality tools used at each stage of the DMAIC framework.

Techniques were selected based on the frequency of their mention across the studies. Tools consistently highlighted were prioritized, ensuring their relevance and practicality. This data-driven approach provided a robust foundation for integrating the most commonly used quality techniques into the DMAIC framework, tailored for construction industry applications.

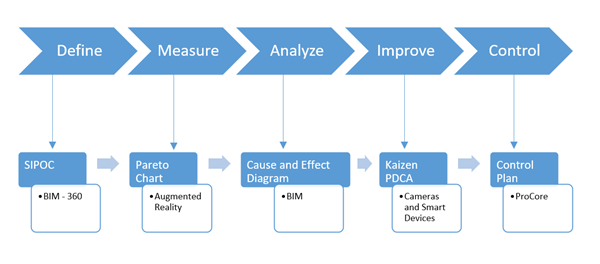

In the DMAIC approach, a specific quality tool was selected for each stage to optimize its application in construction quality management: Define: SIPOC Analysis, Measure: Pareto Chart, Analyze: Cause and Effect Analysis, Improve: Kaizen, Control: Control Plan

4.1. Define Stage: SIPOC Analysis with BIM 360

In the Define stage, SIPOC (Suppliers, Inputs, Process, Outputs, and Customers) analysis is employed to map out the key elements of a construction process. However, one limitation of SIPOC is its static nature, often leading to time-consuming updates and communication delays among stakeholders. To overcome this, BIM 360 is integrated into SIPOC analysis. BIM 360 provides a dynamic, real-time platform that allows stakeholders to collaborate, update, and modify the SIPOC map instantly as the project progresses. This real-time integration enhances the efficiency of SIPOC by ensuring that all team members are informed of any changes, thereby reducing delays and improving communication. BIM 360 helps address the issue of time inefficiencies, making the SIPOC process a more agile and adaptable tool.

4.2. Measure Stage: Pareto Chart with Augmented Reality (AR)

In the Measure stage, the Pareto Chart is used to identify and prioritize key issues in the construction process. This traditional tool helps to highlight the most frequent problems that impact project quality. However, its effectiveness can be limited by the accuracy and speed of data collection. To enhance this, Augmented Reality (AR) technology is employed. AR tools help in visual inspections by overlaying defect hotspots onto construction models. By doing so, AR not only speeds up the identification of defects but also integrates the findings into the Pareto chart, enabling real-time prioritization of recurring issues. This integration improves the accuracy of data collection and streamlines the process of identifying and addressing the most critical problems.

4.3. Analyze Stage: Cause and Effect Diagram with BIM

In the Analyze stage, the Cause and Effect (Ishikawa) Diagram is used to identify the root causes of defects or inefficiencies. The traditional method involves brainstorming and organizing potential causes, which can be subjective and time-consuming. To augment this process, BIM is incorporated. BIM provides visual models of the construction site, which can be used to pinpoint exact areas where issues are arising. By linking BIM data with the Cause and Effect diagram, the analysis becomes more objective and data-driven, offering a clearer understanding of the underlying causes. BIM's integration enhances the effectiveness of the diagram by providing a visual and data-supported method for root cause analysis.

4.4. Improve Stage: Kaizen with Cameras and Smart Devices

In the Improve stage, Kaizen is applied to foster continuous improvement through incremental changes. While Kaizen encourages small, consistent improvements, its effectiveness can be hindered by the lack of real-time monitoring and feedback. To overcome this, cameras and smart devices are used for continuous monitoring. High-resolution cameras capture live footage of construction processes, enabling real-time feedback on performance. Automated image analysis identifies deviations, which can be quickly addressed using Kaizen principles. This integration allows for faster identification of areas requiring improvement, ensuring that the Kaizen process is dynamic and responsive to real-time data.

4.5. Control Stage: Control Plan with Procore

In the Control stage, a Control Plan is developed to maintain improvements and ensure that the desired quality standards are sustained over time. A common challenge in the control phase is managing and organizing large volumes of documentation and updates. Procore is used to overcome this limitation by centralizing all project documentation and providing real-time updates. Procore enables easy access to control plan documents, ensuring that all stakeholders are aligned and that changes are communicated effectively. The tool also tracks compliance and performance, helping to maintain control over quality standards and ensuring that any deviations from the plan are promptly addressed.

5. CONCLUSION

This study presents a comprehensive framework for integrating traditional quality management techniques with digital tools across the approach to enhance the quality management processes in construction. By incorporating cutting-edge technologies, such as BIM 360, Augmented Reality (AR), Procore, and real-time monitoring devices, this framework addresses the limitations of conventional methods and offers significant improvements in communication, data accuracy, and process efficiency.

In the Define stage, the integration of SIPOC analysis with BIM 360 provides a dynamic platform for real-time collaboration, ensuring up-to-date information is shared across all stakeholders. The Measure phase benefits from the combination of the Pareto Chart and AR, enabling faster defect identification and more accurate data collection. The Analyze stage is enhanced by BIM-integrated Cause and Effect Diagrams, offering data-driven insights into root cause analysis. In the Improve phase, Kaizen principles are supported by real-time feedback from cameras and smart devices, ensuring continuous monitoring and immediate corrective actions. Lastly, the Control phase is optimized through the use of Procore, which centralizes documentation and tracks compliance, ensuring long-term sustainability of improvements.

The findings of this research underscore the importance of digital tools in transforming traditional quality management methods, making them more responsive, efficient, and data-driven. These tools facilitate a more integrated and transparent approach to construction management, ultimately contributing to higher project quality and better overall outcomes. However, the successful implementation of this framework requires overcoming challenges such as the initial investment in technology, training, and system integration.

Future research could examine the impact of this framework on project timelines, costs, and stakeholder satisfaction to better understand its full potential in improving construction project outcomes.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

Alia, K., Mubina, S., & Ekatrina, G. (2022). Evaluating Quality Management System of Construction Projects. International Journal of Project Engineering. https://doi.org/10.23940/ijpe.22.07.p4.492501

Ghansah, F. A., & Edwards, D. J. (2024). Digital Technologies for Quality Assurance in the Construction Industry: Current Trend and Future Research Directions Towards Industry 4.0. Buildings. https://doi.org/10.3390/buildings14030844

Handayani, N. U., Wibowo, M. A., Mustikasari, A., Nurwidanto, I. W., & Dilaga, D. A. (2020). The Implementation of Lean Construction and Six Sigma Concepts in Light Brick Installation: A Case Study in Cordova Apartment Project.

Jaegar, M., & Adair, D. (2015). Perception of TQM Benefits, Practices, and Obstacles: The Case of Project Managers and Quality Management Representatives in Kuwait. The TQM Journal. https://doi.org/10.1108/TQM-10-2014-0091

Khalfan, I., Said, S., Jamaluddin, Z., & Widyarto, S. (2020). Conceptual Framework on Quality Management Practices and Operational Performance for ISO 9001 Certified Construction Industries. International Journal of Academic Research in Accounting, Finance and Management Sciences. https://doi.org/10.6007/ijarafms/v10-i2/7437

Mustapha, Z., Akomah, B. B., & Ansah, S. K. (2023). Construction Project Success: Time, Cost, Quality and Safety. International Journal of Research and Innovation in Social Science. https://doi.org/10.47772/ijriss.2023.70958

Muwafaq, A., Monem, M. A., & El-Dash, K. M. (2020). Review Study for Rework Causes in Construction Industry. Frontiers in Built Environment, 26(7), 666-689. https://doi.org/10.3389/fbuil.2023.1143829

Nowotarski, P. S., & Rzepecka, P. (2018). DMAIC method of Quality Improvement of Ground Works Processes: Case Study. IOP Conference Series: Earth and Environmental Science. https://doi.org/10.1088/1755-1315/221/1/012002

Ottou, J. A., Nani, B. K. B., & Tuuli, M. M. (2020). Benefits of Implementing Six Sigma in Competitive Tendering Process. Built Environment Project and Asset Management. https://doi.org/10.1108/bepam-07-2020-0117

R. S. V., V. S. M., & R. R. (2017). Critical Success Factors of TQM, Six Sigma, Lean, and Lean Six Sigma: A literature review and key findings. Benchmarking: An International Journal. https://doi.org/10.1108/BIJ-08-2017-0223

Sahlih, M. A. M., Mahmoud, A. H., & Khalaf, B. A. (2020). The Application of Six Sigma-Supported Expert System in Construction Projects. Materials Science and Engineering. https://doi.org/10.1088/1757-899X/881/1/012168

Shibani, A., Chahine, H., Saidani, M., Hassan, D., & Agha, A. (2021). Benefits and Challenges of Implementing Six Sigma as a Process Improvement Management Strategy. Annals of Operations Research. https://doi.org/10.46254/an11.20210514

Singh, R. R. D. K. G. P. M. (2020). Six Sigma Methodology and Implementation in INdian Context: A Review-Based Study. In Advances in Manufacturing Technology. https://doi.org/10.1007/978-981-15-4565-8_1

Solis, J. L. F., Gadhok, N., & Nipun. (2018). Comparative Analysis of Lean and Six Sigma in building construction: Benefits, Obstacles, and Opportunities. Semantic Scholar. https://www.semanticscholar.org/

Vijayabanu, C., Karthikeyan, S., & Surya, P. V. (2022). Total Quality Management Practices and its Impact on Indian Construction Projects. Organization, Technology and Management in Construction. https://doi.org/10.2478/otmcj-2022-0013

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© Granthaalayah 2014-2025. All Rights Reserved.