INFLUENCE OF COMMONLY USED HEAT TREATMENTS OF ROW MILK ON PRESENCE AND NUMBER OF COAGULASE-POSITIVE STAPHYLOCOCCI

Abstract

Motivation/Background: Coagulase positive staphylococci (CPS) are common contaminants of raw milk. Before it is used, various heat treatments are applied to destroy microorganisms, inactivate enzymes and improve technological properties and concentration of dry matter of milk. This work aimed to determine the influence of commonly used heat treatments in diary industy on presence and number CPS in raw milk from Bosnia and Herzegovina area and to affirm whether there is a difference in efficacy between different treatments.

Method: Using the standard method, 40 samples of raw milk from farms were inoculated for counting the initial number of CPS in raw milk. Samples were then exposed to heat treatments in vapor sterilizer and CPS number was counted using the same standard method.

Results: Applied treatments included heat treatments at: 68 °C/40 s, 70 °C/15 s, 72 °C/without holding, 63 °C/30 min and 72 °C/15 s. CPS presence was detected in all tested samples of raw milk in numbers ranging from 2,82 to 5,32, with an average of 4,30, calculated as log10 cfu/ml.

Conclusions: Raw milk samples collected in the field initially registered a high CPS number. The applied heat treatments were effective to a large extent. The initial CPS count of milk seems to be the most important factor determining the number of CPS after heat treatments as well as traits of the strains.

Keywords

Raw Milk, Coagulase Positive Staphylococci, Heat Treatment, Foodborne Diseases, Diary Industy

INTRODUCTION

Foodborne bacterial diseases have become a worldwide concern which highlighted the importance of prevention, prediction as well as the role of control and management of foodborne bacterial diseases. The ongoing discussion is related to food matrices because of its complex and highly variable nature affecting the expression of virulence in different and unpredictable ways. Staphylococcus aureus (S. aureus) is opportunistic pathogen, gram-positive and coccus-shaped bacterium (1). Most of the diseases that originate from food are related to thermostable toxins that are produced from such kind of pathogen microorganisms (2). From a public health policy framework perspective, among many others foodborne pathogens, S. aureus is recognized as the most common worldwide cause of diseases. Hence, prevention measures which include detection of bacteria became a very important factor in food safety policy (3). There are many reports regarding health problems related to staphylococcal food poisoning which are caused by staphylococcal enterotoxin (SEs) but there are also heterogeneous results regarding dose levels of such enterotoxins that contaminate food (4). S aureus and many other microorganisms are easy to cultivate in milk, as an ideal medium (5). Typical diseases caused by S. aureus vary from skin lesions to septicaemia or meningitis. Besides inframammary infection sources, namely mammary secretions as the most common source of prevalence of Staphylococcus pathogen, there are many others such as teat canal, skin and other environmental sources. This qualifies S. aureus as the key pathogen responsible for dairy cow mastitis (7). S. aureus is usually divided into coagulase-negative staphylococci (CNS) and coagulase-positive staphylococci (CPS) (8). The presence of S. aureus in raw milk, in general, originates from cows with mastitis, from handlers or deficient hygiene. It presents a real problem in diary industry since it can occur in any phase of the diary production process. This means that levels of contamination with this pathogen grows rapidly in raw milk in particular, not only because of handlers and environment contamination but as a consequence of subclinical or clinical bovine mastitis as well. S. aureus can be shed into the milk (9) and produce SEs which represents the most common source of raw milk poisoning (10). Cheese can be detected as a source of S. aureus if it is produced from staphylococcal contaminated milk without pasteurization, and with inadequate starter culture activity, or contaminated due to unappropriated conditions for processing and storage of the product (11).

The quality of cheese depends on the microbiological quality of milk, especially in the production of cheese from raw milk. It is considered that unpasteurized raw milk cheese products are more preferred because of their stronger and richer flavour or preserved natural properties of microflora and because of reduced levels of harmful microorganisms due to ripening process (12). However, when both pasteurized milk and milk products are produced, the microbiological quality of milk must be high, because high-temperature milk processing is not applied in the area of cheese production.

High temperatures, in dairy production, are used to eliminate microorganisms, inactivate enzymes, improve the technological properties and concentration of dry matter of milk. They are very important and play the most important role in milk processing. The milk can be heat treated with the methods of thermalization and pasteurization. The thermalization and pasteurization of raw milk are carried out during cheese production to improve biological quality of milk and final product. Pathogen microorganisms as well as other microorganisms are present in raw milk cheese and pasteurized milk products during production (13).

Pasteurization can be carried out at temperatures from 63 °C to 74 °C. Unlike pasteurization, sterilization is carried out at higher temperatures of 120 °C to 140 °C (14). Recently it became common practice to use higher temperatures with shorter duration which has also resulted with improved or at least same levels of microorganisms, termination and inactivation of ferments without organoleptic changes in milk.

Thermalization process differs and includes different or separate procedures: heating at 72 °C without retention; heating at 70 °C for 15 seconds; heating at 68 °C for 40 seconds. There are also different types of pasteurization process common for cheese production: low pasteurization at 63 °C for 30 minutes (used if the lipase is to be preserved in milk), medium pasteurization on at least 72 °C for at least 5 seconds (plate pasteurization), high pasteurization at 85 °C for 1 minute (used only in production fermented dairy products because it reduces the coagulation properties of milk) (15).

This work aimed to determine the influence of commonly used heat treatments in diary industy on presence and number CPS in raw milk from Bosnia and Herzegovina area and to affirm whether there is a difference in efficacy between different treatments.

MATERIALS AND METHODS

Milk samples

40 samples of raw milk were collected from farms in Bosnia and Herzegovina and transported to the microbiological laboratory. The samples were collected and processed in the period from 1 May - 15 May 2019.

Heat treatment

After inoculation for counting the initial number of CPS in raw milk, samples were exposed to heat treatments in vapor sterilizer. During treatments, temperatures of milk samples were monitored using calibrated thermocouples. Applied treatments included temperature points at 68 °C/40 s, 70 °C/15 s and 72 °C/without holding, 63 °C/30 min and 72 °C/15 s.

Enumeration of CPS

The number of CPS in raw and heat-treated milk was determined based on valid standard method BAS EN ISO 6888-1:2005 (16). After making initial suspensions and further decimal dilutions up to 10-6, 1 ml initial suspension and all consecutive dilutions of milk samples were pipetted on Baird-Parker agar, per surface of 3 (90 mm diameter) agar plates, in duplicate (6 plates), spread with a sterile smear and incubated for 24 ± 2 h in an incubator set at temperature at 37 °C. The same procedure was applied to raw milk samples and milk samples after heat treatments. CPS was recognized as black or grey, shiny and convex colonies 1 to 1.5 mm in diameter, surrounded by an opaque halo. Typical and atypical colonies of CPS were further confirmed by transferring from the surface of each selected colony an inoculum with a sterile inoculating loop to a Brain-heart infusion (BHI) broth. Incubation was at 35 °C or 37 °C for 24 h ± 2 h. Under aseptic conditions, 0.1 ml of the resulting culture was added to 0.3 ml of rabbit plasma in a sterile tube and incubated at 35 °C or 37 °C. After 4 to 6 h of incubation, the presence of coagulation (plasma patch) was monitored. The coagulase test was positive if the amount of clot occupied more than ½ of the original fluid volume.

Statistical analysis

Statistical analysis of the data was performed in IBM SPSS Statistics 24 (IBM Corp. Released 2016. IBM SPSS Statistics for Windows, Version 24.0. Armonk, NY: IBM Corp.) using the Jonckheere - Terpstra test, bearing in mind that data distribution is not normal (p<0.000) as determined by the Shapiro-Wilk test. A statistically significant difference is determined based on the p<0.05 value.

RESULTS AND DISCUSSIONS

Relevant data on the presence and number of CPS in milk samples after treatments are shown in Table 1 .

|

CPS number after treatment |

Treatments |

|||||||||

|

63 °C/30 min |

68 °C/40 s |

70 °C/15 s |

72 °C/ without holding |

|

72 °C/ 15 s |

|||||

|

CFU/ml |

log10 CFU/ml |

CFU/ ml |

log10 CFU/ml |

CFU/ml |

log10 CFU/ml |

CFU/ml |

log10 CFU/ml |

CFU/ml |

log10 CFU/ml |

|

|

Mean |

121.67 |

1.10 |

189.65 |

1.16 |

51.47 |

0.98 |

41.42 |

0.75 |

10.87 |

1.04 |

|

SD |

318.10 |

0.98 |

410.85 |

1.08 |

101.16 |

0.83 |

105 |

0.88 |

18.72 |

1,27 |

|

MIN |

2 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

|

MAX |

1600 |

3.20 |

1800 |

3.26 |

470 |

2.67 |

580 |

2.76 |

85.00 |

1,93 |

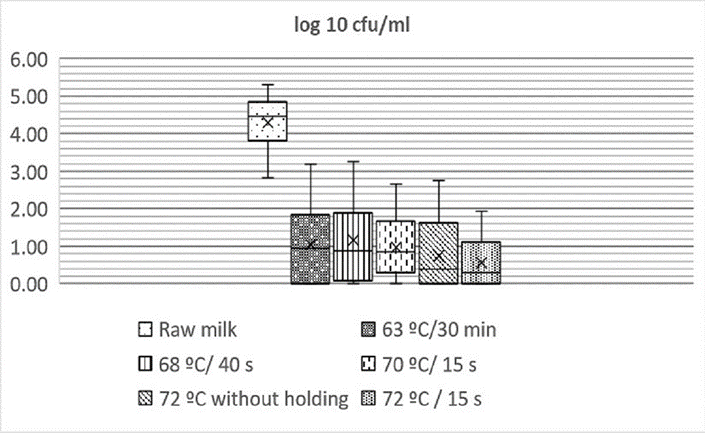

CPS presence was detected in all tested samples of raw milk in numbers ranging from 6.6 x 102 – 2.1 x 105 cfu/ml, with an average value of 4.4 x 104. Calculated as log10 cfu/ml, the number of CPS in raw milk samples ranged between 2.82 and 5.32, with an average of 4.30 (Figure 1 ).

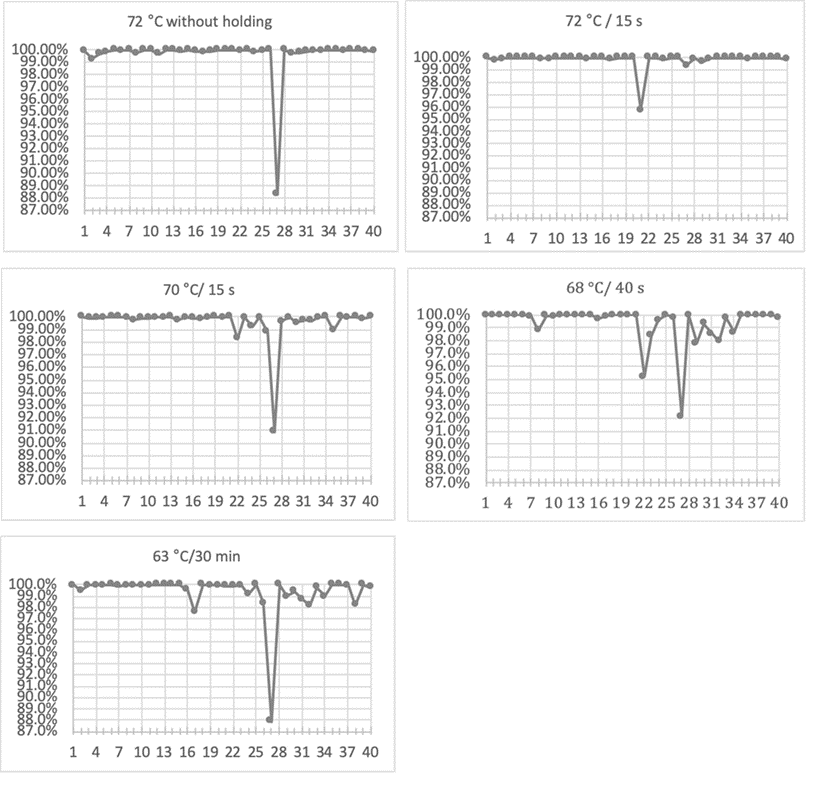

After heat treatments have been applied, reduction in presence and number of CPS is visible. CPS was not detected in 11 samples after heat treatmen at 63 °C/30 min and in 7 samples CPS viability reduction was 99.99 % or higher (Figure 2 .). The average reduction in viability after this treatment was 99.34 %, with a minimum of 87.88 %. Treatment at 68 °C/40 s resulted in total viability reduction of CPS in 9 samples and in 6 samples this reduction was 99.99 % or higher. Minimal reduction in CPS number was 92.12 % and an average 99.37 %. CPS was not detected in 9 samples after treatment at 70 °C/15 s, with reduction of 99.99 % or higher in 4 samples. Minimal viability reduction was 90.91 % and an average 99.59 %. Total viability reduction after heat treatment at 72°C without holding was detected in 18 samples and 2 samples was 99.99 % or higher. Minimal viability reduction after this heat treatment was 88.33 % and average 99.63 %. CPS was not detected in 17 samples after heat treatment at 72 °C/15 s and in 4 samples CPS viability reduction was 99.99 % or higher. This treatment demonstrated the highest minimal viability reduction (95.78 %) and the highest average reduction in CPS number (99.84 %), while the lowest values of viability reduction were detected after heat tretment at 63 °C/30 min (Figure 2 ).

Each of two treatments at 72 °C resulted in viability reduction lower than 99.9 % in only one sample, while in the rest of treated samples, the reduction in CPS number was higher than 99.9 %. Lowest viability reductions and the number of samples with total viability reduction are seen in treatments at 63 °C/30 min and 68 °C/40 s.

After statistical analysis, it can be concluded that the results indicate that there was a statistically significant difference before and after treatment of the sample with 68 °C/40 sec (p = 0.003) and before and after treatment with 72 °C/without holding (p = 0.020). Although the results after treatment at 70°C/15 sec have a rather low p - value (p = 0.067), it cannot be considered statistically relevant (Table 2 ).

|

Analysis |

p-value |

|

Raw milk – 63 °C/30 min |

0.424 |

|

Raw milk – 68 °C/40 sec |

0.003 |

|

Raw milk – 70 °C/15 sec |

0.067 |

|

Raw milk – 72 °C/without holding |

0.020 |

|

Raw milk – 72 °C/15 sec |

0.284 |

The data obtained on the reduction of a number of CPS in row milk after different heat treatments at 68 °C/40 s, 70 °C/15 s and 72 °C/without holding, 63 °C/30 min and 72 °C/15 s are comparable, with some exceptions to the results obtained by other investigators. This bacterium produces a heat-stable enterotoxin which survives pasteurization although organism of the bacterium does not. When ingested, heat-stable enterotoxin can cause nausea, vomiting and diarrhoea. The most significant problem with CPS contamination occurs during cheesemaking, as most of the organisms are trapped in the curd (17). Applied heat treatments are used in cheese production and CPS can be present in cheese made of poor hygienic quality raw but even heat-treated milk. According to Commission Regulation (EC), cheeses made from milk that has undergone a lower heat treatment than pasteurisation and ripened cheeses made from milk or whey that has undergone pasteurisation or a stronger heat treatment, if values of CPS >105cfu/g are detected, the cheese batch has to be tested for staphylococcal enterotoxins. Action in case of unsatisfactory results is improvements in production hygiene and selection of raw materials (18). Current United States Standards of Identity (19) permit treatment of the cheese milk with hydrogen peroxide and catalase specifically to reduce CPS numbers during the production of cheeses such as Cheddar and Colby.

Microbiological analysis of pasteurized milk indicated presence of pathogens like Staphylococcus sp., Salmonella sp. (20), coliform (21) from India, Salmonella (22) from Nigeria, Enterobacter spp., Escherichia coli from Jamaica (23), S. aureus from Brazil (24), coliform, Bacillus cereus from Kuwait (25) and Escherichia coli and S. aureus from Iran (26).

In our research, CPS has not been detected in 17 samples after heat treatment at 72 °C/15 s and in 4 samples CPS viability reduction was 99.99 % or higher (Figure 2 ). According to Holsinger et al. (27), pasteurized milk is usually considered pathogen-free except for the spores of Bacillus cereus if present in large numbers. Pearce et al. (28), reported kinetic data on the survival of a range of significant, the most heat-resistant strain of milk-borne pathogens, such as S. aureus, under commercial-type pasteurization conditions. UHT (ultra-high temperature processing) milk was inoculated with the most heat-resistant pathogens at ∼107/mL and heat-treated in a pilot-plant-scale pasteurizer under commercial-type conditions of the turbulent flow for 15 s over a temperature range from 56 to 66 °C and at 72 °C. Survivors were enumerated on nonselective media chosen for the highest efficiency of plating of heat-damaged bacteria of each of the chosen strains. The mean log10 reductions and temperatures of inactivation of CPS during a 15-s treatment was >6.7 at 66.5 °C. In our research, after heat treatments at 63 °C/30 min in 7 samples CPS viability reduction was 99.99 % or higher, in 6 samples this reduction was 99.99 % or higher after heat treatment at 68 °C/40 s, after treatment at 70 °C/15 s the reduction was 99.99 % or higher in 4 samples and two treatments at 72 °C resulted in viability reduction lower than 99.9 % in only one sample. When calculating the magnitude of the change in cell number, microbiologists often use a logarithmic scale (log scale), so according to the translation of log reductions to percent reductions, 6 log reduction = 99.9999% reduction.

Out of 40 samples tested, 27 samples of raw milk had over 104 CPS, 11 samples of raw milk over 103 CPS, and 2 analysed samples of raw milk over 500 cfu/ml.

S. aureus is a ubiquitous organism. It is frequently manually isolated from raw milk from individual animals, bulk raw milk and from the milk of dairy cattle suffering from mastitis. The typical counts of S. aureus are 100-200 cfu/ml in properly drawn milk. In the case of a contaminated udder, the counts may increase up to 104 cfu/ml (29).

It can be concluded that the best treatment results under conditions of 68 °C/40 sec, followed by conditions 72 °C if p values and parameters from descriptive statistics are compared. The heat treatment of CPS bacteria at 80 °C for 20 minutes allowed the protein to envelop the denatured S. aureus resulting in cell death. Protein will lose shape which will lead to decreased ability to protect the bacterial cell. The moment temperature reaches 80 °C, the cell will experience plasmolysis resulting in peeling of the cytoplasm membrane of the cell wall because of cytoplasm penetration. This will allow breakthrough of the liquid from outside into the cell and it will damage it, hence, heating can lead to the death of bacterial cells. The number of dead bacterial cells depends on the heating intensity and heating time (30). Research shows that the higher the temperature used, the shorter the time to kill bacteria, especially S. aureus. The usual time and temperatures pasteurization, 60 – 65 °C for 30 minutes, cannot kill CPS producing enterotoxins. The optimal temperature and time to reduce the level of contamination in food products, especially milk products, is 80 °C for 20 minutes (31).

CONCLUSIONS AND RECOMMENDATIONS

It could be stated that traditional heat treatments are the exemplar methods for milk treatment. Raw milk samples collected in the field initially registered a high CPS number. The initial CPS count of milk seems to be the most important factor determining the number of CPS after heat treatments. The applied heat treatments were effective to a large extent. The ability of CPS colonies to survive even after heat treatments were applied may be due to traits of the strains, which needs to be explored in further studies.

ACKNOWLEDGEMENTS

The authors would like to thank the Institute of Public Health SBK / KSB for providing and collecting samples for conducting this research, as well as funding the necessary nutrient media and reagents. I would like to acknowledge my gratitude to Prof. Sead Karakaš, Director of the Institute of Public Health SBK / KSB, for his endless patience, useful advice and selfless leadership.