|

|

|

|

Article Type: Research Article

Article Citation: Francisco de A. Ribeiro Filho, Fernando B. Mainier, and Luciane P. Costa

Monteiro. (2020). EVALUATION OF THE USE OF GLYCERIN AND SODIUM SILICATE IN

WATER-BASED DRILLING FLUID. International Journal of Research -GRANTHAALAYAH, 8(5),

187-193. https://doi.org/10.29121/granthaalayah.v8.i5.2020.156

Received Date: 16 May 2020

Accepted Date: 31 May 2020

Keywords:

Drilling Fluid

Bi-Distilled Glycerin

Corrosion Inhibitor

Sodium Silicate

ABSTRACT

Glycerin is a by-product of the transesterification reaction of vegetable oil to produce biodiesel. Glycerin production has increased as the number of biodiesel industries has grown. With features such as water solubility, low cost, and non-toxicity, it is a good substance for water-based drilling fluid formulations with less environmental contamination. The experiments were conducted using a drilling fluid commonly used in Brazil and were compared with glycerin additions at concentrations of 5, 10, 15, and 20% by volume. Considering that as a result of the raw materials used, the biodiesel production routes produce a contaminated glycerin, it was decided to use a bi-distilled glycerin. In addition, sodium silicate, which uses industrial water or seawater, was added as a corrosion inhibitor due to its good performance and environmental non-toxicity. The sodium silicate was effective in combating corrosion without interfering with the fluid properties. The values of plastic viscosity, yield point, L3 (reading 3 rpm), and gel strength, mostly presented results equal to or better than the original formulation of the fluid used as a comparison.

1. INTRODUCTION

Drilling

fluid, or mud as it also called, is a mixture of natural and synthetic chemical

compounds used to cool and lubricate the drill bit, clean the hole bottom,

carry cuttings to the surface, control subsurface pressure, provide wellbore

stability, and minimise formation damage, etc. Drill muds are generally

classified into water-based mud (WBM) and oil-based mud (OBM). The WBM have

greater environmental acceptance but must meet certain standards in order to be

in contact with oil well drilling operations. OBM are extremely harmful to

marine life therefore it is necessary to use risers to avoid the direct contact

of the OBM with the seabed. Risers are tubular structures that connect the BOP

(Blowout Preventer) to the turntable of the platform [1], [2], [3], [4].

The muds

are usually composed of two phases: a dispersant (aqueous or organic), and a

scattered phase, the complexity of which depends on the nature of the scattered

products and its required functions.

Each

drilling fluid has a specification for the operation to be completed safely and

quickly. Therefore, it is necessary to present characteristics compatible with

the lithology and types of rocks present in the drilling area.

The main

requirements are [1], [2], [3], [4]

·

Chemical

stability;

·

Acceptance

of any chemical and physical treatment;

·

Be

easily separated from gravel on the surface;

·

Do

not cause damage to formations;

·

Be

easy to pump;

·

Have

low degree of corrosion and abrasion;

·

Facilitate

geological interpretation of cuttings and well logging;

·

Respect

environmental laws;

·

Low

cost.

Most of the

equipment used in drilling operations consisting of tanks, pumps, and pipes, is

made of carbon steel. Special steels target mainly the contamination from rocks

and water forming salinity, CO2 and H2S [1], [5], [6].

The

objective of this work is centred on the evaluation of formulated drilling

fluids containing glycerin and sodium silicate. Glycerin is a by-product of biodiesel production and its

raw material is oils from soybean, peanuts, corn, sunflower, etc.

Considering

that in Brazil the biodiesel program aims to incorporate vegetable raw material

(oilseeds) through the transesterification synthesis into conventional diesel

oil (2 to 5%), it is valid to state that there is a large availability of glycerin byproducts at a low cost

[7], [8], [9] while sodium silicate is a corrosion inhibitor

that has shown excellent performance for saline solutions.

2. MATERIALS AND METHODS

As

previously mentioned, glycerin is a by-product of

biodiesel production. The process consists essentially of oil extraction from

oilseeds (soybean, sunflower, peanut, cotton, etc.) by pressing and solvent

extraction. In order to identify the best industrial options for biodiesel

production, the composition of the triglyceride-rich produced oil, which

largely depends on the etymology of the plant species, as well as the seed oil

content and oil productivity per planted area, have to be taken into

consideration.

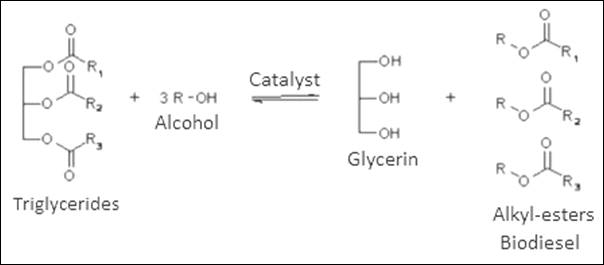

The

transesterification process consists of the stoichiometric reaction of three

moles of low molecular weight alcohol (methanol or ethanol) for each mole of

triglyceride in the oil, in the presence of a catalyst and at a temperature of

50 to 60°C, as shown in Figure 1. Some variables influence the

transesterification reaction, namely: reagent purity, alcohol/oil molar ratio,

reaction temperature, catalyst, and agitation [7], [8], [9].

Figure 1: Transesterification

reaction

Given this

production process it can be assumed that glycerin

marketed as a by-product has a series of contaminants from the seeds used (raw

material), as well as the operating conditions of the processing (extraction

and purification).

The mud

used for this experiment is polymeric with a good performance considering the

shale lithological standard. The aim is, at least, to maintain the rheological

parameters of the original fluid, but reduce the xanthan gum concentration by

the addition of bi-distilled glycerin. The option of

using the bi-distilled glycerin rather than a

commercial product was that the commercial glycerins

that were analysed had several constituents that might hinder the process of

evaluating the mud properties.

Glycerol or

glycerin is a colourless, odourless, viscous liquid

that is sweet-tasting and non-toxic. The main physicochemical properties of the

glycerin used in the assays are presented in Table 1 [10].

Table 1: Physicochemical properties of glycerin [10].

|

Molecular formula |

C3H8O3;

CH2OH-CHOH-CH2OH |

|

Molecular Weight |

92.09 g/mol |

|

Boiling point |

290 °C |

|

Flash Point |

160 °C |

|

Melting point |

18 °C |

|

Viscosity |

1410 mPa.s at 20 ° C |

|

Density |

1.26 g/cm3

at 20 ° C |

High purity

sodium silicate hydrate (Na2SiO3.9H2O) was

used as a corrosion inhibitor. This corrosion inhibitor was chosen because it is

inorganic, non-toxic, and has had good results in the protection of carbon

steel in saline solutions [11].

Table 2, below, shows the standard drilling fluid formulation (base

fluid) used as a reference and the glycerin and

sodium silicate additions made to this standard formulation.

Table 2: Drilling Fluids Composition

|

Substances |

Function |

Base fluid |

Adding glycerin to base fluid |

|||

|

5 % |

10% |

15% |

20 % |

|||

|

Water,

v/v% |

Continuous

phase |

49 |

44 |

39 |

34 |

29 |

|

Bi-distilled

glycerin, v/v% |

Continuous

phase |

0 |

5 |

10 |

15 |

20 |

|

Saturated

sodium chloride brine, v/v% |

Continuous

phase |

40 |

40 |

40 |

40 |

40 |

|

Sodium bicarbonate,

g/L |

Hardness

removal |

0.57 |

0.57 |

0.57 |

0.57 |

0.57 |

|

Polydimethylsiloxane,

g/L |

Defoamer |

0.57 |

0.57 |

0.57 |

0.57 |

0.57 |

|

Xanthan gum,

g/L |

Viscosifier |

2.28 |

1.43 |

1.43 |

1.43 |

1.43; 1.71 |

|

Polyanionic

cellulose – low Viscosity, g/L |

Filtration

control agent |

5.70 |

5.70 |

5.70 |

5.70 |

5.70 |

|

Hydroxypropyl

starch, g/L |

Filtration

control agent |

11.41 |

11.41 |

11.41 |

11.41 |

11.41 |

|

Magnesium

oxide, g/L |

Alkaline agent |

1.42 |

1.42 |

1.42 |

1.42 |

1.42 |

|

Potassium

chloride, g/L |

Shale inhibitor |

42.80 |

42.80 |

42.80 |

42.80 |

42.80 |

|

Polyamine, g/L |

Swelling agent |

17.12 |

17.12 |

17.12 |

17.12 |

17.12 |

|

Glutaraldehyde,

g/L |

Biocide |

0.85 |

0.85 |

0.85 |

0.85 |

0.85 |

|

Calcium

carbonate, g/L |

Weighting /

bridging agent |

114.12 |

114.12 |

99.86 |

85.59 |

71.32 |

|

Polyol ester

oil, g/L |

Bit balling

preventer |

0.85 |

0.85 |

0.85 |

0.85 |

0.85 |

|

Polyethylene

glycol oleate, g/L |

Lubricant |

14.26 |

14.26 |

14.26 |

14.26 |

14.26 |

|

Sodium silicate,

g/L |

Corrosion

inhibitor |

2.28 |

2.28 |

2.28 |

2.28 |

2.28 |

A

rotational viscometer with a mud cup was used to measure the rheological

properties. The mud cup heats the fluid to the desired temperature, which is

120°F (48.88°C) according to the American Petroleum Institute (API) [12]. Measurements were taken at the following

speeds in revolutions per minute: 600, 300, 200, 100, 6 and 3. With these

measurements, it is possible to determine the plastic viscosity and the yield

point using the formulae below:

Plastic

Viscosity (PV) = L 600 – L 300.

Yield Point

(YP) = PV – L 300.

For the

base fluid, the xanthan gum concentration was 2.28

g/L. After manufacture, the fluids were placed in scroll caps and

inserted in an oven for 16 hours to simulate their ageing.

The

referral values for the main properties are summarised in Table 3.

Table 3: Properties and their target values

|

Properties |

Referral values* |

|

Plastic Viscosity |

15 – 40 cP |

|

Yield Point |

15 – 40 lb/100ft² |

|

Gel Strength (10 seconds) |

7 – 15 lb/100ft² |

|

Gel Strength (10 minutes) |

8 – 25 lb/100ft² |

|

L3, rpm |

7 – 10 |

|

Fluid Density |

9.8 – 10.2 lb/gal |

*Considering the fluid under operation

AISI 1020 carbon coupon (0.21 % of carbon) mass loss assays

were performed by immersion in the base fluids and base fluids with the

addition of 20% v/v% glycerin for 10 days.

3. RESULTS AND DISCUSSIONS

The

objective of using glycerin, besides giving value to

the product, is to keep the rheological parameters constant, and to decrease

the concentration of xanthan gum in the fluid formulation, with the aim to have

a good rheology for the drilling of an oil well.

The results of laboratory tests that can determine the conditions of the use of drilling fluid in oil well drilling operations are presented below in Figures 1, 2 and 3.

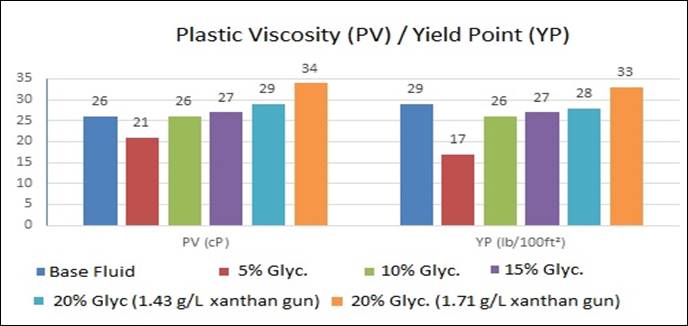

Plastic

viscosity is directly linked to the internal resistance exerted by a fluid to

flow. The solids content in a drilling fluid influences the particle friction,

a higher solid content results in a higher particle friction, which results in

a higher plastic viscosity [13].

The Yield

point (YP) indicates the ability of the fluid to carry the cuttings generated

by the drilling up to the surface. It is the minimum effort required to

initiate the fluid movement [14].

Figure 1: Plastic viscosity and Yield point

All values

obtained regarding the plastic viscosity (PV) of the fluid and the Yield Point

(YP) were within the range considered ideal for the formulation of the base

fluid. Fluids with a 10% bi-distilled glycerin

content had values similar to the base fluid. Compared to the 20% content of

bi-distilled glycerin, the influence of the xanthan

gum concentration on the properties is more evident with an increase, as seen

when comparing the concentrations of 1.43 g/L and 1.71 g/L.

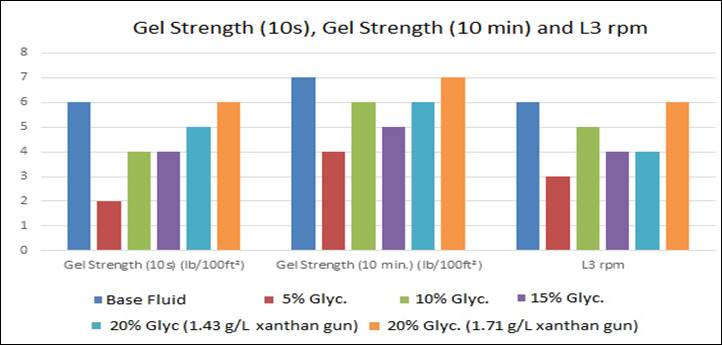

Figure 2: Gel strength and L3 rpm results

Gel

strength is a rheological parameter that indicates the degree of gelification due to the electrical interaction between the

dispersed particles. The gel strength 10s measures the resistance to flow of

the fluid, while the gel strength 10 min. measures the resistance of the fluid

to restart the flow after it has been at rest for a while. The difference

between them indicates the degree of fluid thixotropic [2], [15], [16].

The L3 rpm

reading is used to determine the 10 seconds and 10 minutes gel strengths,

however, the conditions under which they are measured are different. The

10-second gel has a lower gel level than that for 10 minutes because the

particle aggregation is lower so resulting in different values.

Only the

values obtained in the fluid with 20% bi-distilled glycerin

and 1.71 g/L xanthan gum reached the referral value.

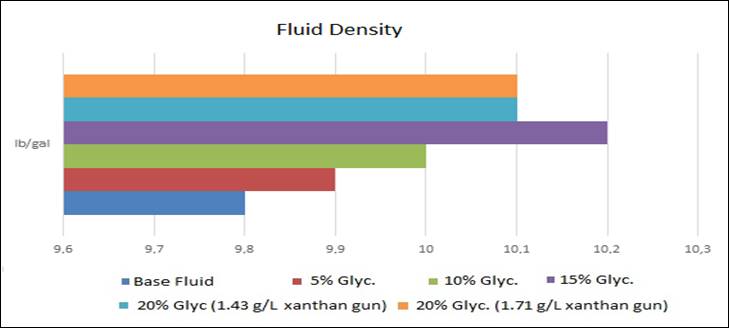

Figure 3: Fluid density results

The fluid

density values fluctuated according to the bi-distilled glycerin

content, however this is because the calcium carbonate concentrations in the

fluids were different, as can be seen in Table 1.

The desired

density value for the project can be achieved by increasing or decreasing the

amount of calcium carbonate accordingly.

The mass

losses in carbon steel coupons were negligible, evidencing that the sodium

silicate addition, at the concentration of 2.28 g/L, offers excellent

anti-corrosion protection to the carbon steel, validated by mass loss assays

performed using sodium chloride solution at 3.5 % in mass [11].

4. CONCLUSIONS

The fluid

parameters were generally within, or very close to the, stipulated ranges,

which is satisfactory for laboratory testing. In a field simulation, the

rheology would probably be slightly higher due to the solids that aggregate

during drilling.

From the

tests performed with bi-distilled glycerin on a

specific fluid formulation, it can be concluded that the presence of

bi-distilled glycerin contributes to the fluid

density, besides increasing the plastic viscosity and yield point parameters.

The fluid with a concentration of 1.71 g/L xanthan gum and 20% bi-distilled glycerin resulted in a rheology similar to that of the base

fluid (2.28 g/L of xanthan gum), but there are

possible scenarios for the results obtained with the concentration of 1.43 g/L

xanthan gum.

The

laboratory performance of the fluid can be equated with an OBM. However, the

bi-distilled glycerin fluid is far less harmful to

the environment, although the stability of the OBM is greater for drilling in

saline formations and also in the pre-salt formations.

Bi-distilled

glycerin has an advantage over crude glycerin because its properties have a standard which is

not presented by crude glycerin. In addition, the

purity percentage is close to 99%, which is higher than that of crude glycerin which has an average 30% of impurities.

SOURCES OF FUNDING

None.

CONFLICT OF INTEREST

None.

ACKNOWLEDGMENT

None.

REFERENCES

[1] Fink, J.

K. Oil field chemicals. New York: Gulf Professional Publishing, 2003.

[2]

Caenn, R. & Chillingar, G. V. Drilling fluids: State of the art. Journal

of Petroleum Science and Engineering, 14(3-4), 1996, 221-230. https://doi.org/10.1016/0920-4105(95)00051-8.

[4]

Khodja, M., Khodja-Saber, M., Canselier, J. P., Cohaut, N., &

Bergaya, F. Drilling fluid technology: performances and environmental

considerations. In: Products and services; from R&D to final

solutions, 2010, IntechOpen.

[5] Al Juhaiman, L. A.;

Mustafa, A. A.; Mekhamer, W. K. Polyvinyl pyrrolidone

as a green corrosion inhibitor for carbon steel in alkaline solutions

containing NaCl. Anti-Corrosion Methods and Materials, n. 1, v. 60, 2013,

28-36, https://doi.org/10.1108/00035591311287429

[7] Sinha, S., Agarwal, A. K., & Garg, S. Biodiesel

development from rice bran oil: Transesterification process optimization and

fuel characterization. Energy conversion and management, 49(5), 2008,

1248-1257. https://doi.org/10.1016/j.enconman.2007.08.010

[8] Meher, L. C.,

Sagar, D. V., & Naik, S. N. Technical aspects of biodiesel production by

transesterification -a review. Renewable and sustainable energy reviews, 10(3),

2006, 248-268. https://doi.org/10.1016/j.rser.2004.09.002

[9] Garcia,

E., Laca, M., Pérez, E., Garrido, A., & Peinado, J. New class of acetal

derived from glycerin as a biodiesel fuel component.

Energy & fuels, 22(6), 2008, 4274-4280. https://doi.org/10.1021/ef800477m

[10] U.S. National Library of

Medicine, National Center for Biotechnology

Information, https://pubchem.ncbi.nlm.nih.gov/compound/glycerol.

[11] Mainier, F.

B., Figueiredo, A. A., de Freitas, A. E. R., & de

Alencar Junior, A. A. M. The Use of

Sodium Silicate as a Corrosion Inhibitor in a Saline Drilling Fluid: A

Nonaggressive Option to the Environment. Journal of Environmental Protection,

7(13), 2016, 2025. http://dx.doi.org/10.4236/jep.2016.713157

[15] Jachnik, R. Drilling Fluid

Thixotropy & Relevance. Stress, 2000, 1500.

[16] Maxey, J.

Thixotropy and yield stress behavior in drilling

fluids. In AADE 2007 Drilling Fluids Conference, april

(AADE-07-NTCE-37, 2007.

|

|

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© Granthaalayah 2014-2020. All Rights Reserved.