Review

on advances in biodegradation of phenols: kinetics, modelling and mass transfer

Ladi Reshma 1![]()

![]() ,

V. Sridevi 2

,

V. Sridevi 2![]()

![]() ,

M. N. N. Sai Rachana 1

,

M. N. N. Sai Rachana 1![]()

![]() ,

J. Akhila 1

,

J. Akhila 1![]()

![]() ,

M. Yamini 1

,

M. Yamini 1![]()

![]() ,

Katru Ramya Sugandhi 1

,

Katru Ramya Sugandhi 1![]()

![]() ,

Husam Talib Hamzah 3

,

Husam Talib Hamzah 3![]()

![]() ,

R. Sri Harsha 1

,

R. Sri Harsha 1![]()

![]()

1 M. Tech Biotechnology, Department of Chemical Engineering, AU College of Engineering (A), Andhra University, Visakhapatnam, India

2 Professor, Department of Chemical Engineering, Andhra University, Vishakhapatnam-530003, India

3 Ph.D. Scholar, Department of Chemical

Engineering, Andhra University, Vishakhapatnam-530003, India

|

|

ABSTRACT |

||

|

Harmful

pollutants like phenol and its derivatives are found in wastewater from a

wide range of industries, including oil refining, medicines, coal conversion,

chemistry, and petrochemistry. The high concentration, high toxicity, and

difficult-to-degrade characteristics of phenols in wastewater pose a serious

threat to the environment and to human health. By employing different strains

of microorganisms and biocatalysts to create biodegradation procedures of

diverse pollutants and a wide spectrum of hazardous compounds, biotechnology

has successfully addressed significant environmental challenges. Among

various phenols removal techniques, biodegradation is both economical and

environmentally friendly. During the study of microbial degradation

processes, there is a great deal of interest in the potential for

mathematical modelling to forecast microbial growth and degrade harmful or

inhibiting environmental pollutants at variable quantities. Such mathematical

models are frequently created using aromatic compounds like phenol. The

review discusses the following topics: kinetics, modelling, and mass

transfer; future scope and directions; diverse microorganisms, bioreactors,

the metabolic pathway of phenol, influencing factors, and recent advancements

in biological therapy. |

|||

|

Received 11 December 2022 Accepted 12 January 2023 Published 31 January 2023 Corresponding Author Ladi Reshma, ladi.reshma123@gmail.com DOI 10.29121/granthaalayah.v11.i1.2023.4968 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2023 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Biodegradation, Phenol, Mechanism,

Immobilization, Modelling, Kinetics, Mass Transfer HIGHLIGHTS · The manufacturing of paper, coking, insecticides, plastics, and pharmaceuticals are only a few of the industrial processes that produce phenol, which has a very broad range of sources. · An intricate process involving the creation of several enzymes is required to biodegrade the aromatic molecule phenol. · When organic matter, in this case phenolic compounds, is transformed into carbon dioxide, this process is known as carbon mineralization. · To explore the kinetics of phenol biodegradation in the SBR mode and to compare the findings with the available data, the Haldane equation (Eq. This formula is used to calculate the rate at which an inhibiting substrate degrades. |

|||

1. INTRODUCTION

As industrial production increased and the demand for chemicals increased, massive amounts of phenol-tainted effluent were discharged into waterways. Phenol and its derivatives were chosen due to their extensive industrial use and threat to aquatic life Duan et al. (2018). The removal of various dangerous organic compounds from wastewater can be accomplished using three main techniques: non-destructive, oxidative destructive, and biologically destructive. Since non-destructive methods rely on the physical adsorption and removal of contaminants, they produce a lot of waste. Oxidative destructive methods include incineration, moist oxidation, and complex oxidation processes (AOPs). Although oxidative destruction may be able to eliminate contaminants, the cost of the necessary equipment, operations, and maintenance make it difficult to use. Biological activities consume a lot less energy and chemicals than other types of processes.

One of the biggest challenges to microbial pollutant degradation is the inability to retain enough biomass for the biodegradation of a target molecule. Antimicrobials can be used to treat both inhibiting compounds like phenols and microbiological illnesses in living things. If either is present, it may cause a die-off of microorganisms in the bioreactor and ineffective wastewater treatment. Although maintaining the bioaugmented culture in a bioreactor can be difficult, adding certain bacterial cultures to a system (bioaugmentation) may expedite the breakdown of antimicrobial contaminants and resistant chemicals Kuc et al. (2022). The washout and dilution of the suspended bacterial culture in a bioreactor are frequently brought on by the continuous injection of wastewater to the reactor. To get around these difficulties in biological degradation, researchers have created a variety of methods for immobilising microbial cultures as well as methods for accelerating phenol degradation through the use of kinetics, modelling, and mass transfer.

2. ORGANIC POLLUTION OF PHENOL

Today's

population must regularly deal with a frustrating issue that includes land

pollution, water contamination, other environmental problems, and air pollution

Sun et al. (2022). One of the most pressing

environmental problems on a global scale is organic pollution, which has risen

quickly in importance due to the rapid development in urbanisation and

industrialization Touliabah et al. (2022). Water that has been tainted

with phenolic pollutants is challenging to clean up since they arrive in a

variety of concentrations from various industrial processes. Phenolic compounds

are present in wastewater and are dangerous to both people and the environment

because of their high solubility in water and sluggish rate of biodegradation.

for a variety of reasons. Even at modest doses, phenols and phenolic compounds

are toxic to human health, and many of them are considered dangerous pollutants

as a result, Aminophenols, butylhydroxytoluene,

nonylphenols, and bisphenols are only a few examples of the phenolic substances

Aisami et al. (2020).

1) SOURCE

OF PHENOLS

Typically, the primary environmental sources of phenol are man-made or natural materials. It results from its processing and use in many contexts, such as, for example, wood burning and automotive exhaust Khleifat et al. (2007). Endogenous and exogenous phenolic compounds are the two types of phenolic compounds that are frequently found in nature Sun et al. (2022). Endogenous phenols are phenolic chemicals that are present in nature and have biological effects. They frequently include the leaves, stems, fruits, roots, and other plant or crop elements. The by products are exogenous phenols. Exogenous phenols and substituted phenols, mostly from vehicle exhaust and smoke from burning biomass, were present in the air. Related phenolic compounds are also created during the production and processing of industrial items. During the coking and refining processes, phenol was one of the principal ingredients obtained from coal and oil mines Wang et al. (2011), Viraj et al. (2017). The creation of oil and its by products, fibreglass, steel, furnace coke, cork, explosives, paint, the manufacture and recycling of rubber products, the textile industry, and several segments of the food and beverage industry are just a few industrial processes that produce phenols Bhatia et al. (2018).

2) LIMITS

OF PHENOL

The

EPA has established a threshold for phenol in surface water of fewer than 1 ppb

Kazemi et al. (2014). The toxicity thresholds are

typically between 9 and 25 mg/L for both aquatic life and humans. Phenol may

have immediate or long-term negative consequences on one's health. Humans who

are exposed to toxic compounds over an extended period of time may have deadly

dosages of respiratory risks, tremor, weakness, and erratic breathing. The

National Institute for Occupational Safety and Health (NIOSH REL), which stands

for "NIOSH Recommended Exposure Limit," specifies the upper limit or

exposure limit for an 8- or 10-hour timeweighted average. The acceptable

exposure limit, or OSHA PEL, is the maximum concentration of a material to

which most employees can be exposed without suffering adverse consequences. It

is a time-weighted average across a normal 8-hour workday or 40-hour workweek.

The United States Environmental Protection Agency (USEPA) recommends that lead

levels in drinking water not go over 0.05 mg/l Kazemi et al. (2014).

3) HARMFUL

EFFECTS OF PHENOL

In

addition to cancer and genetofibre striation, severe

phenol exposure produces disorders of the central nervous system, hepatic

damage, anorexia, cutaneous rash, dysphasia, gastrointestinal disturbance,

vomiting, weakness, and weightlessness González et al. (2001). According to an animal study,

oral phenol exposure results in decreased foetus weights, delayed growth, and

aberrant development in the offspring of the animals. Increased maternal

mortality and decreased maternal weight gain were also discovered González et al. (2001).

2.1. ANALYSIS OF PHENOL

Numerous techniques, including

spectrophotometry, HPLC, GC, and their combinations, have been employed to

measure phenolic chemicals from plant materials as analytical science has

advanced.

2.1.1. SPECTROPHOTOMETRY

Spectrophotometry,

which largely relies on many measurement techniques for the different

structural changes of the phenolic compounds, is a rapid and simple methodology

for figuring out how much phenolic compounds are present in plant materials.

Typically, the content of flavonoids is determined using spectrophotometry.

(2016) Pouraboli et al. Additionally, condensed

tannin concentration and total phenolic amount can both be determined using

spectrophotometry Sankhalkar and Vernekar

(2016). Spectroscopy is a frequently

utilised technique for quantifying many different types of phenolic compounds

due to its simplicity of use and inexpensive cost.

2.1.2. GAS CHROMATOGRAPHY (GC)

GC is a useful method for separating, identifying,

and measuring the numerous phenolic chemicals present in plants, including

anthocyanins, flavonoids, and tannins. Samples are heated in a heated column

that uses the evaporation temperature specific to each compound to separate it

from the solution. The column is lined with a thin layer of non-volatile liquid

that is coated with an inert substrate Vaičiulyte et al. (2016).

2.1.3. High-Pressure Liquid Chromatography (HPLC)

The

most popular method for separating and detecting phenolic chemicals is HPLC. It

is a flexible and adaptable tool with a number of benefits, including good

selectivity, sensitivity, resolution, and sample behaviour Naczk and Shahidi (2006). The basic idea behind the

method is to separate chemicals from complex mixtures based on how soluble they

are and/or how they interact with a less polar stationary phase and a more

polar mobile phase Coskun (2016). Thus, some variables,

including column types, used detectors, mobile phase, and the characteristics

of the tested substances, have an impact on HPLC analysis of phenolic

compounds.

2.1.4. HPLC–Mass Spectrometry

HPLC

and tandem MS can be used to examine phenolic substances. An innovative

analytical method with great sensitivity and selectivity is HPLC supplemented

by MS detection. With this method, unidentified chemicals in samples of natural

sources that have been partially or crudely purified can have their structural

information measured. Mocan et al. (2014). Numerous studies on the

analysis of phenolic compounds have recently concentrated on the evaluation of

techniques including various couplings between HPLC and MS.

2.1.5. HPLC–Diode Array Detector

Another

popular technique for determining the presence of phenolic compounds in plants

is HPLC combined with a diode array detector (HPLC-DAD). Da Silva Siqueira et al. (2016), Alqahtani et al. (2015).The most expensive and uncommon

of the detectors used in conjunction with HPLC to the

identification of phenolic chemicals

is MS, whereas the most practical and widespread is DAD Rejczak and Tuzimski

(2017).The entire UV/visible spectrum

of the analytes can be simultaneously scanned by the DAD detector, which can

also provide details on unique spectral characteristics for compound

identification.

3. METABOLIC PATHWAYS FOR PHENOL

An

aromatic hydrocarbon called phenol is broken down by a variety of bacteria, which

obtain all of their carbon needs from phenol. Both

aerobic and anaerobic environments can lead to the degradation of phenol.

3.1. AEROBIC BIODEGRADATION OF PHENOL

Oxygenation

starts the biodegradation of phenol under aerobic conditions. A monooxygenase

phenol hydroxylase first monohydroxylates the

aromatic ring in this process at an ortho location to the pre-existing hydroxyl

group to produce catechol. This is the primary intermediate produced when

various microbial strains break down phenol. Depending on the strain, catechol

is either oxidised by catechol 1,2-dioxygenase via the ortho-cleavage pathway,

which results in the creation of succinyl Co-A and acetyl Co-A, or by catechol

2,3-dioxygenase via the meta-pathway, which results in the formation of

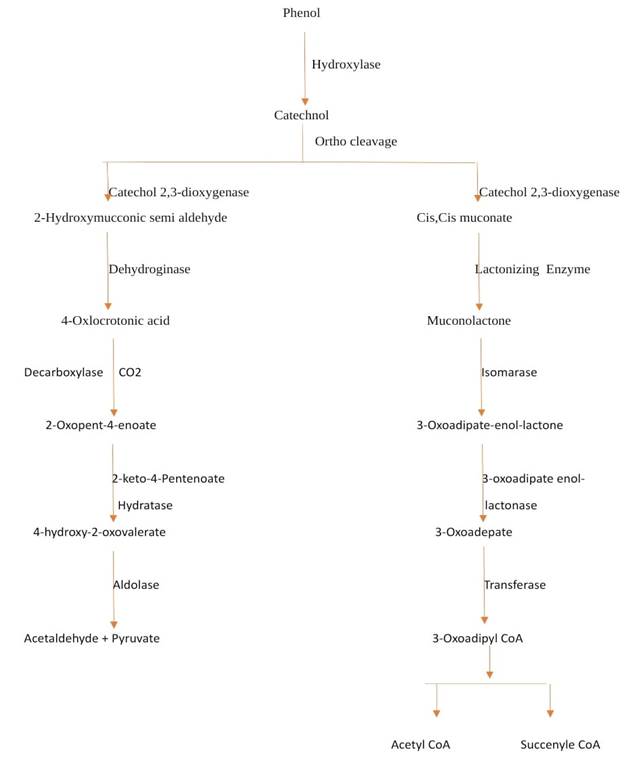

pyruvate and acetaldehyde Patil et al. (2014).

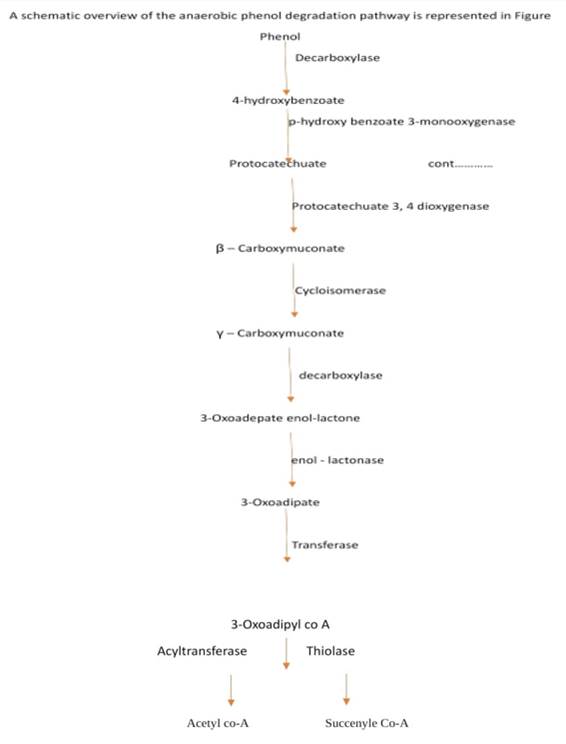

3.2. Anaerobic biodegradation of phenol

The aerobic

phase of phenol decomposition is more advanced than the anaerobic process. The

aerobic phase of phenol decomposition is more advanced than the anaerobic

process. The first step in the anaerobic process is the 4-hydroxy benzoate

carboxylase-mediated carboxylation of phenol at the para position to

4-hydroxybenzoate. Carboxylation and subsequent dihydroxylation are the

mechanisms through which phenolic chemicals, such as o-cresol, catechol, and

ortho-halogenated phenol, are degraded by anaerobic bacteria González et al. (2001). Figure 1 and Figure 2 shows aerobic and anaerobic

degradation pathway for phenol.

Figure

1

|

Figure 1 Aerobic Degradation Pathway for Phenol |

Figure 2

|

Figure 2 Anerobic Degradation Pathway for Phenol |

4. MECHANISM, VARIOUS MICROORGANISMS, AND REACTORS FOR PHENOL BIODEGRADATION

Phenol, an aromatic

hydrocarbon is degraded by various microorganisms, Table 1 which utilizes phenol as the sole carbon

source for the growth of the organisms. Among the various microorganisms Pseudomonas

putida is the most popular organism for the degradation of phenol as this

species uses phenol as the carbon source . Numerous

microorganisms—including both aerobic and anaerobic ones—use phenol as their

only source of carbon and energy as a result of the

substance's extensive prevalence in the environment. The presence of phenolic compounds in water

and soil has become significant problems. Common commercial wastewater

treatment methods utilize the combination of physico-chemical

and biological treatment. Both chemical and biological processes were used for

many years to treat phenolic wastewater. Activated sludge, fluidized, packed

bed and moving bed biofilm reactors were studied as biological treatment

processes. Table 2 shows various reactors used in phenol

degradation and their effect. The degradation rate depends on the state of

biomass development, feed concentration, liquid flow rate, and air flow rate.

4.1. DEGRADATION OF PHENOL THROUGH AEROBIC AND ANAEROBIC PATHWAYS

4.1.1. AEROBIC BIODEGRADATION OF PHENOL

At

the beginning of the 19th century, research on aerobic biodegradation began.

The enzyme phenol hydroxylase uses molecular oxygen to add a second hydroxyl

group in ortho-position to the one that already exists in the initial phase of

the aerobic route for the biodegradation of phenol. Pyridine nucleotide

reduction is necessary for the process (NADH2). Depending on the causative

bacterium, one of two procedures can then be used to get rid of the resultant

catechol (1, 2- dihydroxy benzene) molecule. A catechol 1, 2-dioxygenase splits

the aromatic ring between the catechol hydroxyls via the ortho- or ketoadipate

pathway (intraradiol fission) Harwood and Parales (1996). The first to provide

circumstantial evidence that strain "Vibrio 01" generated

-ketoadipate while metabolising phenol was Evans and Kilby Evans (1947).

The

resultant cis, cis muconate undergoes further

metabolism to create -ketoadipate, which is a Krebs cycle intermediate. Ring

fission takes place in the meta-pathway close to the two hydroxyl groups of

catechol (extra diol fission). Catechol 2, 3-dioxygenase is an enzyme that

changes catechol into 2-hydroxymuconic semialdehyde. This chemical is converted

into Krebs cycle intermediates by further metabolism. Acinetobacter calcoceticus, Pseudomonas species, and Candida tropicalis

use the aerobic pathway to consume phenol, whereas other eukaryotes frequently

use the ortho pathway. Numerous studies have focused on the aerobic Pseudomonas

species, and their capacity to grow on a range of aromatic substrates makes

them an appealing organism for use in wastewater treatment applications Kilby (1948).

4.1.2. Anaerobic biodegradation of phenol

The

first stage of the anaerobic phase of this process is the carboxylation of

phenol at the para position to 4 hydroxybenzoate. The 4-hydroxybenezoate

carboxylase is the enzyme in question here. It has been demonstrated that a

carboxylation reaction is a key component of the anaerobic decomposition of

many more aromatic compounds. It has been proposed that o-cresol can be denitrified

to produce 3-methyl 4-hydroxybenzoate by carboxylating

the aromatic ring in para position to the hydroxy group. Studies demonstrated

that Para coccus-like organisms and the methogenic

consortia moved through a variety of phenolic chemicals, including catechol,

ortho halogenated phenols, and o-cresol, after para Dehydroxylation,

followed by carboxylation.

Table 1

|

Table 1 Phenol Degrading Microorganisms Fan et al. (2008) |

||

|

Source |

Genus |

Species |

|

Bacteria |

Alcaligenes Anthrobacter Pseudomonas Cyanobacterium

Bacillus |

Alcaligenes

faecalis Alcaligenes

xylosoxidans Y234 Arthobacter species Arthobactercitreus Arthobacterchlrophenolicus A6 Pseudomonas

putida Pseudomonas

cepacian Pseudomonas

pictorum Pseudomonas

aeruginosa MTCC 4996 Pseudomonas

aeruginosa Pseudomonas

aeruginosa CC7CCAB919095 Cyanobacterium

synechococcus Bacillus

species strain PHN1 Bacillus

brevis Bacillus

badius |

|

Fungi |

Candida Fusarium Graphium Ochromonas Aspergillus |

Candida

Tropicalis Candida

Tropicalis NICM 3556 Fusarium

species Graphiumsp FIB4 Ochromonasdanica Aspergillus

awamori NRRL3112 |

|

Yeast |

Phanerochaete Rhodococus Rhodotorula Sphigmonas Trichosporon |

Phanerochaetechrysosporium Rhodococuserythropolis UPV-1 Rhodotorulacreatinivora Sphigmonaschlorophenica R4 2 Trichosporon species LE3 TrichosporonCutaneum R57 |

Table 2

|

Table 2 Reactors Used in the Phenol Degradation Khazi Et Al. (2010) |

|||

|

S.No |

Reactor |

Organisms Used |

Effect On Phenol

Degradation |

|

1 |

Packed bed Reactor |

Rhodococcus erythropolis |

Able to degrade completely phenol in defined mineral medium at a maximum

rate of 18kg of phenol m-3 per day |

|

2 |

Air stirred Reactor. |

Rhodococcus erythropolis UPV-1 |

Completely degrade phenol in synthetic wastewater at a volumetric productivity of 11.5 kg of phenol/m3 /day |

|

3 |

Packed bed Reactor |

Alcaligenes xylosoxidans

Y234 |

Able to degrade phenol of 1000 ppm completely in 60 h |

|

4 |

Hallow Fiber Membrane bioreactor |

Pseudomonas putida |

Able to degrade phenol of 1000 – 2000 mg/L |

|

5 |

Rotating biological contactors (RBC) |

Mixed culture |

Input loading 1754 – 3508 mg phenol/m2h |

|

6 |

Air lift bioreactor |

Alcaligenes xylosoxidans and Xanthomonas

maltophilia |

The fractional conversion of phenol over 99% was achieved |

|

7 |

Loop airlift bioreactor with a packed bed. |

Pseudomonas putida ATCC 17484 |

100% phenol removal was achieved at phenol loading rates up to 33120 mg /h m |

|

8 |

Pulsed plate bioreactor |

Immobilized Nocardia hydrocarbonoxydans |

100% degradation could be achieved with 300 and 500ppm influent phenol concentrations and at very low dilution. rate of 0.4094 1/h |

|

9 |

Self-cycling Fermentation in a stirred tank reactor |

Pseudomonas putida |

Substrate utilization rates as high as 14.5 kg of phenol per cubic meter

of fermentor volume per day of Fermentation, |

|

10 |

Granular activated carbon was incorporated into hollow fiber membrane bioreactor. |

Pseudomonas putida |

1000 ppm phenol was removed within 25 h. |

5. EFFECTS OF PARAMETERS FOR BIODEGRADATION OF PHENOL

5.1. Effect of pH

It is

believed that the internal environments of all living cells are fairly neutral. A pH of 4.0 or above is inhospitable to the majority of life. At pH 4.0 or 9.0, acids and bases

typically don't dissociate from one another and are resistant to electrostatic

fields, making them easier to enter cells. The optimal pH for phenol breakdown

in Pseudomonas putida NICM 2174 is 7.0. Annadurai et al. (2002).

5.2. Effect of temperature

The

key factor in the breakdown of organic contaminants is temperature, not the

presence of nutrients. Numerous investigations revealed that the rate of phenol

biodegradation considerably decreased around 30 °C Pakuła et al. (1999). The majority of studies on

phenol degradation have been done in the laboratory at the ideal temperature of

30°C, and they also found that as the temperature increased from 30 to 34°C, no

phenol degradation happened due to cell death, demonstrating that phenol

decomposition is a temperature-dependent process Annadurai et al. (1999). Growth rates typically double

for every 10°C increase in temperature in the typical mesophilic working range

of 10 to 30°C.The denaturation of proteins at higher temperatures lowers

mesophile growth rates, but growth rates in general do not vary between 35°C

and 40°C Ratkowsky et al. (1982).

5.3. EFFECT OF ADDITIONAL CARBON SOURCES ON PHENOL DEGRADATION

Diverse

strategies have been put out to handle highly concentrated phenolic wastewater

by discovering ways to get around substrate inhibition. These include the use

of genetically engineered microorganisms, cell immobilisation, and phenol

concentration adaption. One may be able to boost the cells' tolerance to

substrate inhibition by supplementing the growth medium with additional

conventional carbon sources, like yeast extract or glucose. Yeast extract has

also been seen to boost Pseudomonas putida's affinity

for phenol Armenante et al. (1995).

5.4. Effect of dissolved oxygen concentration

Most

frequently, oxygen serves as the ultimate electron acceptor in aerobic respiration

in aerobic microorganisms. Additionally, the microbial breakdown of a variety

of organic molecules, including hydrocarbons and compounds with aromatic rings,

requires a co-substratum known as molecular oxygen. The rate of organic load

breakdown under aerobic growth conditions is mostly determined by the dissolved

oxygen (DO) level. In studies on this subject, much attention has been paid to

how dissolved oxygen content affects microbial growth and respiration rate.

6. ADVANCES IN BIODEGRADATION OF PHENOL: KINETICS, MODELING, AND MASS TRANSFER

6.1. Kinetics and Modelling

Studies

on the kinetics of biodegradation reactions give an indication of how

effectively the microbial system is working. Gaining an understanding of these

dynamics will improve phenol removal efficiency and process control. By tying a

certain biomass growth rate to a specific substrate consumption rate, any

biodegradation process may be predicted (contaminant). A variety of kinetic

models have been used to describe the kinetics of microbial growth on phenol Table 3.

Two

of the most popular models for the biodegradation of phenol are the Monod model

Table 3, Equation 1 and the Haldane (Andrew's) model

Table 3, Equation 2.

Table 3

|

Table 3 Biodegradation Models (Kinetics and Mass Transfer) Taghreedalkhalid et al. (2012) |

|

|

Name

of model |

Equation |

|

Monad Haldane Linearized haldane Han- Levenspiel Yano Edwards Wang-Loh2 |

μ =

K is a constant

|

|

Monod: Sum Kinetics Binary mixture, no interaction Monod: sum kinetics Binary mixture, purely competitive interaction (inhibition) Binary mixture, Non-competitive inhibition Binary mixture, uncompetitive enzyme inhibition SKIPb Binary mixture unspecified type of interaction SKIP Three compound mixture, unspecified type of interaction Proposed by jiang et al. Michaelis-MentenC JD -factor Fick’s Lawd Thiele Moduluse |

|

Kp is a proportionality constant,

and aR is the specific substrate consumption rate

(mg/mg.hr) and ks is the saturation constant for

substrate consumption (mg/l), respectively. F(i)

depicts the functional relationship of the effect of metabolic intermediates on

phenol degradation. The interaction parameter, bIij,

shows how much substrate I influences substrate j's deterioration. v is the

reaction's initial speed (in mg/s), Km is the Michaelis constant, and V m is

the reaction's maximal speed in the case of catechol dioxygenase activity. ρp and De are the density of dried microbe (g/cm3) and

effective diffusion coefficient of phenol within the bead, respectively. dC is the phenol concentration within the immobilised

particles (mg/l), r is the radial position within the

bead. The real rate of deterioration is v (mg/g/hr). The rate constant, k', is

equal to kρp, where k is the fist-order

degradation rate constant (cm3/g.hr), and er0 is the particle's radius.

6.2. TEMPERATURE MODELS FOR KINETIC PARAMETERS

There

are fundamentally two types of treatment models for Monad maximum specific

growth rate (1/h). The dependent variable is written as rate0.5 in square-root models and as ln rate in Arrhenius type models. The

Arrhenius (1889) model's equation is

m = Ae - RT H* Equation 3

Where

m is the monad maximum specific growth rate (1/h) and H * is the Arrhenius

temperature characteristic (kJ/mol). It contains the generally assumed constant

temperature characteristic H*, however for microbial cultures, H* can vary by

up to three or four times, depending on the temperature range utilised.

6.3. Response Surface Methodology (RSM)

RSM,

is the most popular statistical method for optimising bioprocesses. It is a

graphical statistical method and empirical modelling methodology that is used

to assess the correlation between a number of

experimental variables that can be controlled and the observed findings.

Basically, this optimization approach entails three key steps: carrying out

statistically planned trials, determining the coefficies

in a mathematical model, and predicting the response and evaluating the model's

suitability. Prior understanding of the procedure to produce a statistical

model is necessary for response surface methodology, and takes the following

form:

Y = f (x1, x2, x3, x4,..., xk) Equation 4

The

variable xi is coded for statistical calculations as Xi = (xi -x0)/x.

The

following quadratic (second-degree) polynomial equation can be used to

approximate how these variables respond mathematically:

Y = b0 + bi Xi + bii Xi2 + bi j Xi Xj Equation 5

where

Y represents the anticipated response, b0 the offset term, bi the linear

effect, bii the square effect, and bij the interaction effect. The low, middle, and high

values of each variable (equally spaced) are denoted by the numbers -1, 0, and

+1, respectively. RSM was used by Annadurai et al. to optimise the medium

composition for P.putida's

phenol degradation (ATCC 31800).A mathematical model was then created to

illustrate the impact of each medium composition and their interactions on the

biodegradation of phenol. The mathematical expression of the relationship

between phenol degradation and variables like glucose, yeast extract, ammonium

sulphate, and sodium chloride was discovered. The

response for the aforementioned variables may always

be predicted by this model Taghreed al-khalid et al. (2012).

6.4. Mass Transfer

But the

inherent development It is inferred that models for the dynamics of cells in

suspension will also work well for biofilm cultures since kinetic models for

phenol degradation in biofilms are complex and difficult to create. Kinetics

degrade when the internal diffusion resistances are ignored. Despite its many

advantages, the fundamental drawback of biomass immobilisation by entrapment is

the limiting of product or nutrient diffusion caused by the resistance of the

protective framework. The effectiveness of deterioration is usually decreased

by a prevalent problem called diffusion limitation. The biomass is not easily

accessible to contaminants because the majority of

locations will be inside the bead. A support material should be strong,

chemically inert, and inexpensive to efficiently immobilise biomass. It should

have a strong connection to the cells, a large capacity for loading, and a

flexible structure to allow for minimal restriction on diffusion.

For

any phenol biodegradation process in a moving bed reactor using immobilised

biomass, there are three basic steps that occur in the bioreactor:

1) the movement of oxygen into the

liquid phase from the gas phase.

2) moving phenol, oxygen, and other

nutrients from the bulk liquid phase to the biofilm's surface; and

3) the biofilm's phenol, oxygen,

and other nutrients diffuse and react at the same time.

The

final step (3), which is a molecular phenomenon, is independent of the

reactor's flow parameters or turbulence.100 When it comes to the first process

(1), dissolved oxygen is a key factor. Oxygen transfer restrictions can cause

insufficient oxygen to have an impact on phenol biodegradation.

If

oxygen were utilised instead of air, there would be five times

increase in the oxygen mass transfer rate. Alternately, increasing stirring speed correspondingly

improved phenol decomposition and increased the mass transfer coefficient of

oxygen.

In

step (2), the substrate is thought to be transferred into the biofilm in two

steps:

·

the

substrate's transition from bulk liquid to a bioparticle's surface; and

·

Diffusion

through the layer of microorganisms (biofilm).

Numerous

research have concentrated on this process since the

speed at which phenol is transported from the bulk phase to the biofilm's

surface would directly affect the biochemical reaction taking place there. The

design and modelling of bioreactors must therefore take into account external

mass transfer coefficients for the transport of phenol from the bulk phase to

the surface of the biofilm.

7. Conclusion

Phenolic compounds must be eliminated as priority pollutants in order to maintain environmental quality. Since biological treatment is the most successful, cost-effective, and ecologically friendly technology now available, it is receiving more and more attention in the field of pollution control. The basic function of microbial metabolism is energy conversion, and it is controlled by enzymatic systems in which reaction intermediates are important. In addition, numerous models have been put forth in order to better understand the kinetics of phenols' biodegradation. The Haldane and Monod models are most frequently employed. The effectiveness of the biodegradation process is significantly influenced by the mass transport mechanisms and regimes.

8. Future scope and directions

Development

efforts should focus on novel types of bioreactors targeting practical

utilization and efficient long-term performance. It is essential to develop and design efficient reactors that

would reduce mass transfer limitations and enhance the degradation rate. Novel

processes are required as well.

Credit author statement

M.N.V.

Sai Rachana: Organic pollution of phenol, sources of phenol, Limits of phenol; J.

Akhila : harmful effects of phenol ; L. Reshma: analysis of phenol, degradation of

phenol through aerobic and anaerobic pathways M. Yamini : Mechanism of phenol, Effects of Parameters

for biodegradation of phenol, metabolic pathways for phenol : Supervision.

V.

Sridevi: Advances in biodegradation of

phenol: kinetics, modelling and Mass Transfer, Various microorganisms, and

reactors for phenol biodegradation , visulisation : Husam Talib Hamzah

, Grammar and spellcheck – R.Sri Harsha and Katru Ramya sugandhi.

CONFLICT OF INTERESTS

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

ACKNOWLEDGMENTS

The authors are sincerely thankful to the Department of Chemical Engineering, Andhra University, Visakhapatnam, Andhra Pradesh, India.

REFERENCES

Agarry,

S. E., Durojaiye, A. O., and Solomon, B. O. (2008). Microbial

Degradation of Phenols : A Review. International Journal of Environment and

Pollution, 32(1), 12–28. Https://Doi.Org/10.1504/Ijep.2008.016895.

Aisami, A., Yasid, N. A., and Shukor, M. Y. A. (2020). Optimization of Cultural and Physical Parameters for Phenol Biodegradation by Newly Identified Pseudomonas Sp. Aq5-04. Journal of Tropical Life Science, 10(3), 223–233. Https://Doi.Org/10.11594/Jtls.10.03.06

Al-Khalid, T., and El-Naas, M. H. (2012). Aerobic

Biodegradation of Phenols : A Comprehensive Review. Critical Reviews In

Environmental Science and Technology, 42(16), 1631–1690.

Https://Doi.Org/10.1080/10643389.2011.569872.

Alqahtani,

A., Tongkao-On, W., Li, K. M., Razmovski-Naumovski, V., Chan, K., and Li, G. Q.

(2015). Seasonal Variation of Triterpenes and Phenolic Compounds In

Australian Centella Asiatica (L.) Urb. Phytochemical Analysis, 26(6), 436–443.

Https://Doi.Org/10.1002/Pca.2578.

Annadurai, G., Juang, R. S., and Lee, D. J. (2002).

Microbiological Degradation of Phenol Using Mixed Liquors of Pseudomonas Putida

and Activated Sludge. Waste Management, 22(7), 703–710.

Https://Doi.Org/10.1016/S0956-053x(02)00050-8.

Annadurai,

G., Mathalai Balan, S., and Murugesan, T. (1999). Box-Behnken Design In

The Development of Optimized Complex Medium For Phenol Degradation Using

Pseudomonas Putida (Nicm 2174). Bioprocess Engineering, 21(5), 415–421.

Https://Doi.Org/10.1007/Pl00009082.

Armenante,

P. M., Fava, F., and Kafkewitz, D. (1995). Effect Of Yeast Extract on

Growth Kinetics During Aerobic Biodegradation of Chlorobenzoic Acids.

Biotechnology and Bioengineering, 47(2), 227–233.

Https://Doi.Org/10.1002/Bit.260470214.

Bhatia, S. K., Joo, H. S., and Yang, Y. H. (2018). Biowaste-To-Bioenergy Using Biological Methods – A Mini-Review. Energy Conversion And Management, 177, 640–660. Https://Doi.Org/10.1016/J.Enconman.2018.09.090.

Coskun,

O. (2016). Separation Techniques : Chromatography. Northern Clinics of

Istanbul, 3(2), 156–160. Https://Doi.Org/10.14744/Nci.2016.32757.

Da

Silva Siqueira, E. M., Félix-Silva, J., De Araújo, L. M., Fernandes, J. M.,

Cabral, B., Gomes, J. A., De Araújo Roque, A., Tomaz, J. C., Lopes, N. P., De

Freitas Fernandes-Pedrosa, M., Giordani, R. B., and Zucolotto, S. M. (2016).

Spondias Tuberosa (Anacardiaceae) Leaves : Profiling Phenolic Compounds By

Hplc-Dad and Lc-Ms/Ms and In Vivo Anti-Inflammatory Activity. Biomedical

Chromatography, 30(10), 1656–1665. Https://Doi.Org/10.1002/Bmc.3738.

Duan, W., Meng, F., Cui, H., Lin, Y., Wang, G., and Wu, J. (2018).

Ecotoxicity of Phenol and Cresols to Aquatic Organisms : A Review.

Ecotoxicology and Environmental Safety, 157, 441–456. Https://Doi.Org/10.1016/J.Ecoenv.2018.03.089.

Evans,

W. C. (1947). Oxidation of Phenol and Benzoic Acid by Some Soil

Bacteria. Biochemical Journal, 41(3), 373–382. Https://Doi.Org/10.1042/Bj0410373.

Fan, J., Fan, Y., Pei, Y., Wu, K., Wang, J., and Fan, M. (2008). Solvent Extraction of Selected Endocrine-Disrupting Phenols Using Ionic Liquids. Separation and Purification Technology, 61(3), 324–331. Https://Doi.Org/10.1016/J.Seppur.2007.11.005.

González, G., Herrera, G., García, M. T., and Peña, M. (2001). Biodegradation of Phenolic Industrial Wastewater in a Fluidized Bed Bioreactor With Immobilized Cells of Pseudomonas Putida. Bioresource Technology, 80(2), 137–142. Https://Doi.Org/10.1016/S0960-8524(01)00076-1.

Harwood, C. S., and Parales, R. E. (1996). The

Beta-Ketoadipate Pathway and the Biology of Self-Identity. Annual Review of

Microbiology, 50, 553–590. Https://Doi.Org/10.1146/Annurev.Micro.50.1.553.

Kazemi, P., Peydayesh, M., Bandegi, A., Mohammadi, T., and

Bakhtiari, O. (2014). Stability and Extraction Study of Phenolic

Wastewater Treatment by Supported Liquid Membrane Using Tributyl Phosphate and

Sesame Oil as Liquid Membrane. Chemical Engineering Research and Design, 92(2),

375–383. Https://Doi.Org/10.1016/J.Cherd.2013.07.023.

Kilby, B. A. (1948). The Bacterial Oxidation of Phenol to Beta-Ketoadipic Acid. Biochemical Journal, 43(1), V–V.

Kuc, M. E., Azerrad, S., Menashe, O., and Kurzbaum, E. (2022).

Efficient Biodegradation of Phenol At High Concentrations By Acinetobacter

Biofilm At Extremely Short Hydraulic Retention Times. Journal Of Water Process

Engineering, 47, 102781. Https://Doi.Org/10.1016/J.Jwpe.2022.102781.

Letelier, M. E., Rodríguez-Rojas, C., Sánchez-Jofré, S., and Aracena-Parks, P. (2011). Surfactant and Antioxidant Properties of an Extract From Chenopodium Quinoa Willd Seed Coats. Journal of Cereal Science, 53(2), 239–243. Https://Doi.Org/10.1016/J.Jcs.2010.12.006.

Mocan, A., Crișan, G., Vlase, L., Crișan, O., Vodnar, D.

C., Raita, O., Gheldiu, A. M., Toiu, A., Oprean, R., and Tilea, I. (2014).

Comparative Studies on Polyphenolic Composition, Antioxidant and Antimicrobial

Activities of Schisandra Chinensis Leaves and Fruits. Molecules, 19(9),

15162–15179. Https://Doi.Org/10.3390/Molecules190915162.

Naczk, M., and Shahidi, F. (2006). Phenolics In Cereals,

Fruits and Vegetables: Occurrence, Extraction and Analysis. Journal of

Pharmaceutical and Biomedical Analysis, 41(5), 1523–1542.

Https://Doi.Org/10.1016/J.Jpba.2006.04.002.

Pakuła, A., Bieszkiewicz. E., Boszczyk-Maleszak, H., and Mycielski, R. (1999). Biodegradation of Phenol by Bacterial Strains from Petroleum-Refining Wastewater Purification Plant. Europepmc.Org.

Patil, S. S. (2014). Biodegradation Study of Phenol By Burkholderia Sp. Ps3 And Bacillus Pumilus Os1 Isolated From Contaminated Soil.

Pouraboli, I., Nazari, S., Sabet, N., Sharififar, F., and

Jafari, M. (2016). Antidiabetic, Antioxidant, and Antilipid Peroxidative

Activities Of Dracocephalum Polychaetum Shoot Extract In Streptozotocin-Induced

Diabetic Rats: In Vivo and in Vitro Studies. Pharmaceutical Biology, 54(2),

272–278. Https://Doi.Org/10.3109/13880209.2015.1033561.

Ratkowsky, D. A., Olley, J., Mcmeekin, T. A., and Ball, A.

(1982). Relationship Between Temperature and Growth Rate of Bacterial

Cultures. Journal of Bacteriology, 149(1), 1–5.

Https://Doi.Org/10.1128/Jb.149.1.1-5.1982.

Rejczak, T., and Tuzimski, T. (2017). Application of

High-Performance Liquid Chromatography With Diode Array Detector for

Simultaneous Determination of 11 Synthetic Dyes In Selected Beverages and

Foodstuffs. Food Analytical Methods, 10(11), 3572–3588.

Https://Doi.Org/10.1007/S12161-017-0905-3.

Rozich,

A. F., and Colvin, R. J. (1986). Effects of Glucose on Phenol

Biodegradation by Heterogeneous Populations. Biotechnology and Bioengineering,

28(7), 965–971. Https://Doi.Org/10.1002/Bit.260280706.

Sankhalkar,

S., and Vernekar, V. (2016). Quantitative and Qualitative Analysis of

Phenolic and Flavonoid Content In Moringa Oleifera Lam and Ocimum Tenuiflorum

L. Pharmacognosy Research, 8(1), 16–21.

Https://Doi.Org/10.4103/0974-8490.171095.

Satish,

K., Neeraj, Viraj, K. M., and Santosh, K. K. (2018). Biodegradation of

Phenol By Free and Immobilized Candida Tropicalis Npd1401. African Journal of

Biotechnology, 17(3), 57–64. Https://Doi.Org/10.5897/Ajb2017.15906.

Sun, J., Mu, Q., Kimura, H., Murugadoss, V., He, M., Du, W., and Hou,

C. (2022). Oxidative Degradation of Phenols and Substituted Phenols In

The Water And Atmosphere : A Review. Advanced Composites and Hybrid Materials,

5(2), 627–640. Https://Doi.Org/10.1007/S42114-022-00435-0.

Touliabah, H. E. S., El-Sheekh, M. M., Ismail, M. M., and

El-Kassas, H. (2022). A Review of Microalgae- and Cyanobacteria-Based

Biodegradation of Organic Pollutants. Molecules, 27(3).

Https://Doi.Org/10.3390/Molecules27031141.

Vaičiulyte, V., Butkienė, R., and Ložiene, K. (2016). Effects of Meteorological Conditions and Plant Growth Stage On the Accumulation of Carvacrol and its Precursors in Thymus Pulegioides. Phytochemistry, 128, 20–26. Https://Doi.Org/10.1016/J.Phytochem.2016.03.018.

Williams,

R. J., and Evans, W. C. (1975). The Metabolism of Benzoate By Moraxella

Species Through Anaerobic Nitrate Respiration. Evidence For a Reductive

Pathway. Biochemical Journal, 148(1), 1–10. Https://Doi.Org/10.1042/Bj1480001a.

Xiang, Y., Xing, Z., Liu, J., Qin, W., and Huang, X. (2020). Recent Advances In The Biodegradation of Polychlorinated Biphenyls. World Journal of Microbiology and Biotechnology, 36(10), 145. Https://Doi.Org/10.1007/S11274-020-02922-2.

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© Granthaalayah 2014-2023. All Rights Reserved.