A Study of Inventory And Logistical Operations in Warehousing

Aditya Saran 1![]() ,

Dr. Priya Satsangi 2

,

Dr. Priya Satsangi 2

1 BBA,

Amity Business School, Amity University Maharashtra, Mumbai, India

2 Associate

Professor, Amity Business School, Amity University Maharashtra, Mumbai, India

|

|

ABSTRACT |

||

|

Warehousing is essential to logistics and supply chain management, it acts as a bridge between two everyday important things, those being production and consumption. This absolutely makes sure of the fact that the materials and products are stored, processed, and delivered to customers in an effective, safe and a timely manner. This work looks at the principal inventory and logistical operations of warehousing, considering its structure, relevance, procedures, and technological integration. Consequently, this research, based on industrial practice, secondary literature, and conceptual frameworks in inventory management and logistics, will explore methods such as Just-in-Time, ABC analysis, and Warehouse Management Systems which facilitate the activities within the warehouse and minimize costs. The study, therefore, concludes that contemporary warehousing efficiency thrives on digital transformation, automation, and real-time data management to achieve high levels of accuracy and productivity and satisfy the customer |

|||

|

Received 07 April 2025 Accepted 08 May 2025 Published 30 September 2025 DOI 10.29121/granthaalayah.v13.i9.2025.6461 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2025 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Warehousing, Logistics, Inventory

Management, Warehouse Management System (WMS), Supply Chain Optimization,

Inventory Control |

|||

1. INTRODUCTION

The field of warehousing has advanced significantly. It is now a crucial supply chain hub rather than merely a location to store excess inventory. In addition to storing goods, warehouses also move, sort, pack, add value, and ship goods on time. Businesses can satisfy customer demand and control expenses when warehouse operations are efficient.

E-commerce and globalization have altered the rules. Inventory management and logistics are now essential to staying ahead of the competition. Businesses compete on more than just price and quality. How quickly and effectively they can deliver goods is the true challenge. It balances incoming and outgoing inventory while guaranteeing that goods arrive at the appropriate location at the appropriate time.

Inventory management determines what, how much, and how long to store product in a warehouse. Effective inventory management ensures that products are received and shipped out without causing congestion or too much cash to be tied up. It helps free up capital, cut costs and reduces waste. On the other side of the coin however, poor management of warehouses may result in products that won't sell, dozens of empty shelves, and high inventory costs and can negatively impact sales and customer service and reputation. Logistics includes receiving, handling, storing, and shipping a product in and out of a warehouse. When logistics are well executed, the products flow smoothly and accurately to the letter, thereby offering the ability for the organization to act quickly and in haste regarding possible changes within the market and customers.

Global sourcing, e-commerce, and just-in-time production have contributed to the complexity of supply chains. Automation, IoT, AI, and warehouse management systems are some of the key ingredients to adapting to these more complex warehouse management processes. Such technologies can definitely help enhance the overall performance while providing managers visibility over each and every item, maximizing their use of space, and help with data driven decision making. Customers, transporters, and suppliers must work closely together to complete these steps. Goods move swiftly and precisely when logistics are done correctly, enabling the business to react quickly to changes in the market and customers. Global sourcing, e-commerce, and just-in-time production have made supply chains considerably more complicated. New technologies like automation, IoT, AI, and warehouse management systems are helping warehouses adapt. These tools increase overall performance by giving managers visibility over every item, optimizing space utilization, and facilitating data-driven decision-making.

This research paper, "A Study of Inventory and Logistical Operations in Warehousing," focuses on the motivations for today's warehouses. We will explore the basic operations the sector carries out, the challenges it faces, and the technology that is transforming the sector.

In particular, we are exploring how effective coordination of inventory and logistical operation increases value in supply chains, lowers costs, and facilitates better warehouse performance. The advancement of warehousing parameters has been noteworthy.

Warehouses serve as a critical node of the supply chain rather than simply a storage location for excess inventory. Warehouses do more than store goods; warehouses are also involved in movement, sorting, packing, value added and shipping of goods in a timely manner. When warehouse operations are efficient, businesses can respond to changing customer demand and control costs. E-commerce and globalization have changed the rules.

1.1. Significance of the Study

This research matters both for academics and people in the industry. For the researchers, it goes into detail about how logistics and inventory work together to drive warehouse results.

Now, for the managers and companies, for their point of view, it offers practical and logical ideas on using the technology at their disposal, standardizing processes, and integrating management to make operations smoother.

As warehouses continue to be the connective tissue between production, storage, and delivery, what we find here in this research paper can help logistics managers, policymakers, and industry leaders build supply chains that are bigger, better, stronger, more flexible, and powered by superior technology.

1.2. Research Problem

Many warehouses all over the world are still face difficulties despite all the new technology that has come into play, and standard operating procedures that are ironed out. Logistics feel dispersed, manual labour takes up time, and inventory remains hazy. Some managers tend to overstock, pack shelves in an attempt to be safe. Poor coordination between what all comes in and what goes out of the warehouses, you also have some who have antiquated material handling styles, and insufficient data driven decision making are just some of the issues and problems that come with logistics. Warehouses experience bottlenecks, delays, and lost potential when inventory control and logistics are not coordinated.

2. Objectives of the Study

1) Figure out what inventory management does for warehouses and why it matters.

2) Break down which logistics operations keep warehouse activities running smoothly.

3) Pinpoint the main challenges facing today’s warehouses.

4) Look into new tech that’s making warehouse logistics and inventory control smarter.

5) Suggest practical ways to improve warehouse performance and cut out inefficiencies.

3. Literature Review

Understanding Warehousing

Warehousing sits right at the heart of the journey from production to consumer. It’s not just simply about stacking boxes in a big room anymore. These days, in the era of the modern man, warehouses handle everything from distribution, sorting, packing, even some assembly. What started as simple storage has morphed into a complex logistics operation that keeps goods available exactly when and where people need them. Its importance cannot be understated. It has massive contribution to the operations of the world.

Storage Inventory Management

Managing inventory well is what keeps shelves stocked without wasting space or money. The goal is to have just enough to meet demand, but not so much that you’re drowning in extra products. Chopra and Meindl (2019) point to a few tried-and-true methods, such as Just-in-Time (JIT), Economic Order Quantity (EOQ), and ABC Analysis. Now that is something that helps businesses find that all important and desired sweet spot between saving money and delivering a good and satisfactory service. When companies get inventory management right, they boost accuracy, cut down on storage costs, and avoid having products sit around until they are out of date.

Logistical Operations According to Christopher (2016), logistics is all about managing how materials and information move from start to finish. In a warehouse, this covers everything from receiving goods to putting them away, storing them, picking orders, packing, and finally shipping them out. When these steps line up smoothly, orders go out on time and operations stay on track.

Technology in Warehouse Logistics Modern warehouses lean into tech like Warehouse Management Systems (WMS), Automated Storage and Retrieval Systems (AS/RS), and Internet of Things (IoT) tools. These upgrades make it easier to see what’s going on, track inventory accurately, and make quick decisions Rushton et al. (2017). AI and data analytics are also changing the game—now warehouses can predict demand better and optimize delivery routes.

The Role of Warehousing in Supply Chain Warehousing holds everything together in the supply chain. It keeps production steady, manages demand, and makes distribution possible. KPMG (2020) points out that India’s warehousing sector is booming, thanks to organized retail, e-commerce growth, and government programs like Make in India and GST that push for more regional distribution hubs.

4. Research Methodology

4.1. Research Design

This study uses a descriptive approach, mixing qualitative insights with secondary quantitative data. Most of the work comes from reading through the latest research, digging into industry reports, and mapping out how warehouse logistics and inventory systems actually work.

4.2. Data Collection

· Primary Data: Direct observations from site visits and hands-on analysis inside logistics companies.

· Secondary Data: Pulls from journals, books, industry articles, government documents, and real-life company case studies.

4.3. Scope

The research looks at warehousing operations in a broad sense—what applies across manufacturing, retail, and e-commerce. The main focus sits on how logistics and inventory management work together.

4.4. Limitations

· The study skips over detailed financial data for individual companies.

· Operational differences can pop up depending on the industry or where in the world the warehouse sits.

5. Inventory Operations in Warehousing

5.1. Inventory Control Systems

Effective inventory control in a warehouse means monitoring everything and preventing merchandise from building up in incorrect locations. A few key methods provide the structure for this control:

· ABC Analysis: Categorizes inventory items based on their value and how often they change.

· FIFO (First-In-First-Out): Ensures that the oldest stock is utilized first.

· FEFO (First-Expire-First-Out): Critical for perishable inventory, ensuring that items with expiration dates are utilized before nonperishable items.

· Cycle Counts: Actively counting inventory regularly ensures awareness of the variances between on-hand stock balances and physical counts.

5.2. Key Inventory Metrics

Metric Description Ideal Value

Inventory Turnover Ratio How often the warehouse sells inventory per year 6–8 times/year

Stock Accuracy How closely actual stock matches recorded stock 98-100%

Order Accuracy On-time, correct orders 97-99%

Space Utilization How much of your available space is actually used 85-90%

5.3. Inventory Optimization Strategies

· Just-in-Time (JIT): Limits inventory levels by coordinating supply with production.

· Safety Stock Calculations: Avoids stockouts, even with spikes in demand.

· Reorder Point Systems: Automatically triggers restocking when inventory levels go below a preferred minimum.

6. Logistical Operations in Warehousing

6.1. Inbound Logistics

Inbound logistics covers everything from getting raw materials and goods from suppliers into the warehouse. This means:

· Receiving shipments

· Inspecting quality

· Barcoding and labelling

· Putting items in the right storage spots

Getting this part right keeps the warehouse running smoothly and prevents bottlenecks at the docks.

6.2. Internal Logistics

No inside any warehouse in the world, it’s all about moving products. To put them away, storing, picking orders, and restocking shelves. That is most of what happens in a warehouse. Tools like scanners, conveyor belts, and automated forklifts speed things up and reduce mistakes that may be caused by any human error.

6.3. Outbound Logistics

Outbound logistics takes over when goods leave the warehouse for customers or stores. This includes:

• Picking and consolidating orders

• Packing and labelling

• Loading trucks and scheduling shipments

• Handling paperwork and keeping customers updated

Using route optimization and real-time tracking helps cut costs and makes sure deliveries show up on time.

7. Technology and Automation in Warehousing

Automation and digital tools have completely changed how warehouses operate. Some key technologies include:

1) Warehouse Management Systems (WMS): Centralizes order handling, inventory, and reporting of all products inside any given warehouse.

2) Barcode and RFID Scanning: Tracks products instantly, much faster than doing it by pen and paper and it also cuts down on manual errors.

3) Automated Guided Vehicles (AGVs): Move materials with little help from people.

4) IoT and Cloud Systems: Gives you live updates on the stock, temp, and equipment health of everything in said warehouses.

5) Predictive Analytics: Uses AI to predict demand, shorten lead times, and plan purchases better.

Warehouses using these tools see faster operations, fewer mistakes, and can grow more easily. Out of all of them, the WMS stands out as the backbone of modern warehouse management.

|

Figure 1 |

8. Challenges in Inventory and Logistical Operations in Warehousing

Even with all the new tech and automation, warehouses still deal with a ton of issues that drag down efficiency, accuracy, and profits.

Despite new technologies and automation, warehouses still have a multitude of issues that contribute to inefficiency, inaccuracy and lost revenue. The problems fall into three big buckets: day-to-day operations, long-term strategy, and outside factors.

Inventory Inaccuracy There is always inventory inaccuracies. People make mistakes, data is not entered correctly, or the systems simply do not refresh quickly enough. Inventory variance results in late orders, mismatched quantity on hand, and unnecessary work to resolve everything. While an orderly cycle count and updates to the warehouse management system (WMS) may help, as long as humans are in the process some mistakes will occur.

Space Utilization Constraints Many warehouses waste a lot of space or have aisles that are hard to navigate simply because of layout or lack of planning. When the most frequently sold item is placed in the back or side of the warehouse, it creates extra labour in navigating the warehouse. There are software options that will analyse the space and help mitigate wasted space, but it's expensive and many employees are not trained to use it.

Operating Costs As a warehouse operator, you are not running your business for free. Fuel, labour, and repair costs continue to escalate. The more you rely on manual warehousing operations, the more you increase your inefficiencies. While automation and lean warehousing will reduce costs, small businesses typically do not have the financial resources to upgrade their operations.

Supply Chain Disruptions

Whether it is a pandemic, a strike among the employees, transport holdups, you name it, something always seems to upset the supply chain apple chart. This sets up extreme oscillations and high variance in demand and inventory levels. Too much or too little of a stock result in wasted money, resources and dissatisfied customers. Predictive analytics with flexible inventory systems help keep things under control.

Technological Gaps

Many warehouses still use old software systems, and those systems don't integrate. When warehouse management systems (WMS), enterprise resource planning (ERP) systems and transportation management systems (TMS) aren't connected, it creates data silos and slow processes. Cloud-based options provide visibility, but require people isn't present due to skills gap and budget constraints in creating, maintaining and enhancing cloud-based options.

Workforce and Skill Gaps

Warehousing is still very labour intensive. High turnover of employees, limited training, and insufficient safety practices all diminish productivity. There is a measurable return when investments are made for training and enhancing digital skills for all employees, and taking action results in satisfied employees and even better operational efficiency.

Inefficient Material Handling

Outdated, ineffective or clunky material handling leads to delays and increased damaged goods. Automation equipment such as automated guided vehicles (AGVs) and robotic picker devices minimizes delays and increase accuracies. However, the costs of equipment itself as well as upkeep of the equipment has to be factored into any acquisition.

Lack of Real-Time Visibility

When information becomes unstable in the production chain between suppliers, shippers, and warehouses, there is no visibility in real time. For example, imagine and instance of new technologies like the use of Internet of Things (IoT) sensors, GPS and digital dashboards help to track inventory and orders and provide visibility for timely decision making.

Sustainability Issues

Warehouses consume a lot of energy and generate waste, which is not good for the planet. Changing to solar, using recyclable materials, and running electric forklifts can help lower the carbon footprint, but those changes can be fairly expensive up front.

Regulatory and Compliance Barriers

Meeting safety, labour, and tax regulations adds a lot of documentation and can slow down processes due to constantly changing regulations. Auditing on a consistent basis and properly documenting processes protect you from compliance problems, but it is additional work.

Poor Strategic Coordination

When the procurement of goods, warehousing and storing of them, and then the distribution teams do not communicate well with each other at all, also strategies do not go as planned, and the organizational and operational inefficiencies plummet down the supply chain. Sharing data and working together as a team with good comms will help with coordination and effectiveness.

Slow Digital Transformation

The world went online as a result of the pandemic, and warehouses must keep pace with those changes. Too many warehouses still rely on outdated legacy systems. If they do not move to a new system, they can fall behind and competitors with better systems, will render them obsolete.

|

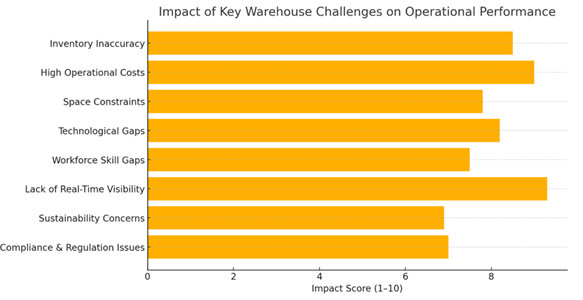

Figure 2 The Impact of Key Warehouse Challenges on Operation Performance |

Observations from the chart:

Warehouse headaches usually start with old systems, not enough skilled people, and sloppy data integration.

Look at the chart above, real-time visibility tops the list of warehouse challenges, right alongside high costs and inventory mistakes. These issues scream for better tech and smarter processes. Gaps in technology, cramped spaces, and not having enough skilled staff keep dragging performance down. Clearly, both the physical setup and the team need upgrades. Even though sustainability and regulations aren’t the biggest headaches, they still matter if you want your operation to last. Bottom line: sharpen your digital tools, automate what you can, and train your people. That’s how you drive efficiency, cut expenses, and lift warehouse performance across the board.

9. Findings and Discussion

Efficient warehousing depends on three things: accurate inventory, strong logistics, and smart technology.

9.1. Integration of Inventory and Logistics Systems

When inventory and logistics systems actually communicate, everything starts to click. Real-time links between WMS, TMS, and ERP systems cut delays, stop stockouts, and catch errors before they turn costly. You get smoother workflows, fewer hassles, and real savings.

9.2. Role of Technology

Technology fuels and drives the whole show more or less nowadays. RFID, barcode scanners, automation—they’re not just shiny add-ons only there for show. They slash costs by up to 40% and boost speed. Inventory tracking goes from slow and clunky to instant. Manual work drops, accuracy soars.

9.3. Cost, Speed, and Accuracy

Smarter systems do not just help save you and your company some money, but instead they help save time and keep mistakes in check. With real-time, accurate data, warehouses avoid stock errors, deliver faster, and make customers happy. Less wasted effort, less wasted space, more savings where it counts.

9.4. Inventory Accuracy and Customer Satisfaction

Get inventory right, and you will for sure build trust. Orders show up as promised, and customers will remember that and keep it in mind. Mess up your data, and you are left with delays, wrong shipments, and lost confidence.

9.5. Human Resources and Process Integration

Even the best technology still needs skilled people behind it. Well-trained teams who are disciplined that keep operations running and catch whatever the machines might miss. You require a perfect and harmonious blend of tech and people.

10. Recommendations

This study aims to makes one thing very clear, and that is to boost warehouse efficiency and performance, you need a mix of smart tech, better processes, greener practices, and people who know what they’re doing. The recommendations below focus on making warehousing not just more accurate and effective, but also more sustainable.

10.1. Recommendations, Ideas and Suggestions

1) Digital

Transformation:

· Carry out the use of advanced Warehouse Management System (WMS), Transportation Management System (TMS), & also Enterprise Resource Planning (ERP) integration for real-time visibility and input to adjust on the fly.

· Make sure to utilize the Internet of Things (IoT) and cloud platforms to oversee and organize multi-location operations efficiently.

2) Automation:

· Bring in RPA, AGVs, conveyors, and barcode systems to cut errors and drive down costs.

· Make sure that the staff are trained to be able to handle and maintain automated systems effectively and with a high degree of skill.

3) Lean

Warehousing:

· Apply 5S and Kaizen to clear out waste and to keep workflows smooth and flawless.

· Keep pushing for continuous improvement and stay organized. Remember that productivity climbs when you do.

4) Green

Logistics:

· Consider switching to solar energy, try installing LED lighting, and roll out eco-friendly vehicles to be more environmentally conscious.

· Tighten up your transport routes to slash emissions and save on operating costs.

5) Employee

Training and Development:

· Try and run regular training on digital tools, safety, and quality control.

· Get employees involved in finding new ways to innovate and boost efficiency.

6) Data

Analytics and Predictive Intelligence:

· Leverage analytics for demand forecasting, route planning, and performance tracking

· Fuse and blend ML/AI for more informed, data driven decision-making.

7) Collaborative

Planning and Communication:

· Build real coordination between suppliers, warehouse teams, and transport partners.

· For the benefits of real time collaborations, implement the use of shared data platforms and dashboards.

8) Constant

observation and assessment of performance:

· Pay close attention to KPIs including order accuracy, inventory turnover, and space utilization.

· Perform audits and contrast your results with those of the leading companies in the sector.

11. Conclusion

The warehouse has evolved. They serve as more than just storage facilities these days. They are a crucial aspect and part of the whole supply chain. Making it essential for them to be optimized.

Being ahead of the competition is important for staying in business; and another thing to keep in mind is your customers’ happiness and if their needs are being catered to, you will need to stay sharp with inventory and logistics. Doing things by hand are getting more and more archaic and outdated. You cannot rely on just that anymore. Things such as automation, smart data, and up-to-date technology aren’t optional anymore but a must if you want to stay relevant. They are what help keep everything running smoothly and accurately in the modern day.

Logistics is not just trying to catch up; it is leading the way. Data influences every decision now.

Bringing together automation and humans together and working together in harmony is the ideal way to keep moving forward without being left behind.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

Ballou, R. H. (2007). The Evolution and Future of Logistics and Supply Chain Management. European Business Review, 19(4), 332–348. https://doi.org/10.1108/09555340710760152

Chopra, S., and Meindl, P. (2019). Supply Chain Management : Strategy,

Planning, and Operation. Pearson Education.

Christopher, M. (2016). Logistics and Supply

Chain Management. Pearson UK.

KPMG India.

(2020). Indian Logistics Industry Report. KPMG

Publications.

PwC. (2023). The Future of Warehousing: Automation and Data Integration.

PwC Research Insights.

Rushton, A., Croucher, P., and Baker, P. (2017). The Handbook of Logistics and Distribution Management. Kogan Page.

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© Granthaalayah 2014-2025. All Rights Reserved.