Comparative CFD Analysis of Conventional and Modified Solar Stills

Priyanka Sharma 1, Shyam Kumar Birla 1

1 Department of Mechanical Engineering, Oriental University, Indore, M.P. 453555, India

|

|

ABSTRACT |

||

|

This research

presents a comparative analysis between a conventional solar still and a

modified version to determine the most efficient design for freshwater

production. Computational Fluid Dynamics (CFD) simulations were carried out

using ANSYS FLUENT to analyse the heat and mass

transfer processes occurring within the solar stills. A single-slope solar

still configuration was modelled for both setups, and key performance

parameters were evaluated. The results aim to provide a deeper understanding

of the thermal behaviour and effectiveness of

design modifications, offering practical guidance for the development of

high-efficiency solar desalination systems. |

|||

|

Received 11 June 2022 Accepted 20 July 2022 Published 05 August 2022 DOI 10.29121/granthaalayah.v10.i8.2022.6292 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2022 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Solar Still, CFD, ANSYS FLUENT, Heat Transfer |

|||

1. INTRODUCTION

Access to clean drinking water is a growing global concern, especially in regions with limited freshwater resources. Among the available methods for water purification, distillation remains a reliable technique for converting saline, brackish, or contaminated water into potable water. Solar distillation, in particular, offers the advantage of utilizing sunlight as a free and renewable energy source, though it typically requires a relatively large surface area for effective operation. Contrary to popular belief, water does not need to reach its boiling point to undergo distillation; elevating the temperature to a moderate level is sufficient to enhance the evaporation process. In fact, operating below the boiling point can reduce the risk of impurities being carried into the distilled water, thereby improving purity. Additionally, systems that rely on moderate temperatures tend to be more cost-effective and simpler in design than those requiring intense heat, making them a practical option for individuals seeking affordable and efficient alternatives to conventional water purification systems. Numerous experimental and theoretical investigations have been conducted on various solar still configurations to enhance their efficiency and water output Tiwari et al. (1986). Al-Hayek and Badran reported that using mirrors in asymmetrical solar greenhouse-type stills enhanced productivity by approximately 20% compared to symmetrical designs presented a comprehensive review of multiple active solar distillation systems Al-Hayeka and Badran (2004). In active systems, basin water is heated either directly or through external sources such as solar collectors or industrial waste heat. Environmental parameters like solar radiation, wind velocity, and ambient temperature were found to significantly influence the system’s performance Mishra and Tiwari (2013). While the starting temperature of the basin water and insulation thickness play a positive role, the cover angle impacts performance differently across seasons—negatively in summer and positively in winter. A mathematical model was also developed to predict the effects of climatic and design parameters, suggesting that greater efficiency is achieved with a higher temperature difference between the basin water and the glass cover Raval (2016). Conducted a comparative analysis of three single-basin solar still designs Tiwari and Tiwari (2007). Their results showed that during winter, a single-slope still made from fiber-reinforced plastic (FRP) delivered a higher yield compared to double-slope designs, while the reverse was observed in summer. Similarly, further investigated the impact of absorber materials such as blackened metal chips and coal dust, concluding that metal chips produced better yields under consistent bed heights of 2.5 cm Tiwari and Tiwari (2007).

The solar distillation process essentially replicates the natural hydrological cycle on a smaller scale. Water evaporates when exposed to solar heat, condenses on a sloped transparent surface, and is collected as purified distillate. With increasing global population and environmental degradation, ensuring access to clean drinking water has become a critical challenge. Solar distillation offers a low-cost, sustainable solution, particularly suited for rural and underdeveloped regions Gnanadason et al. (2015). It works by evaporating saline or impure water using solar heat, allowing only clean water vapor to condense and be collected.

Researchers have also examined the influence of water depth on heat and mass transfer rates under various climatic conditions, especially in summer Adenauer and Nafila (2007). To boost efficiency, alternative designs such as double-basin stills, multi-basin setups, wick-based systems, and single-slope stills with multiple wicks have been explored Musher et al. (2010). Integrated solar distillers designed for multipurpose and multi-source applications have shown promising results. Additionally, studies on the use of internal and external reflectors—angled to enhance solar absorption—report significant productivity improvements, ranging from 70% to 100% Abolfazli et al. (2011). The agreement between theoretical predictions and experimental data has been particularly strong on clear days Raval and Patel (2013)- Sampathkumar et al. (2010).

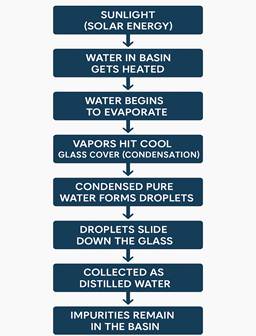

2. Basic principle of a solar still

The distillation process mimics

the natural water cycle, particularly how rain is formed. In a solar still,

sunlight heats the basin water, increasing its temperature and causing it to

evaporate. These water vapors then rise and come into

contact with the cooler inner surface of the glass cover, where they condense

into liquid droplets. This condensed water is collected as fresh, clean water.

During this process, impurities such as salts, heavy metals, and harmful

microorganisms are left behind, resulting in highly purified water, similar to

rainwater. Figure 1 shows the basic principle of solar still.

Figure 1

|

Figure 1 Shows the Basic Principle of Solar Still |

3. Material and method

Two solar stills, identical in geometry and structure,

were carefully designed and fabricated in Shahdol, Madhya Pradesh, India

(Latitude: 23.3002° N, Longitude: 81.3569° E). To evaluate their performance, a

comparative experimental investigation was carried out. One of the systems

functioned as a Conventional Solar Still (CSS), while the other was developed

as a Modified Solar Still (MSS) with certain passive enhancements aimed at

improving efficiency. Both setups were subjected to the same climatic conditions

to ensure consistency and reliability in the results. The experiments were

conducted over two separate cycles, allowing for accurate performance

comparison in terms of water productivity, temperature variations, and thermal

behaviour.

4. Conventional Solar Still (CSS)

The conventional solar still was constructed with a square basin measuring 1 m × 1 m. The vertical height of the rear wall was maintained at 527 mm, while the front wall stood at 100 mm to create a sloped cover. The basin was fabricated from a 1 mm thick galvanized iron (GI) sheet. To minimize thermal losses, 20 mm thick glass wool insulation was applied to the bottom and side walls. An outer casing of 15 mm thick plywood was used to enhance structural integrity and additional thermal resistance. A transparent glass cover of 4 mm thickness was installed on the top to allow solar radiation to enter while facilitating condensation on its inner surface.

4.1. Modified Solar Still (MSS)

Two configurations of modified solar stills were developed, both based on the same geometric dimensions as the conventional unit (basin area of 1 m × 1 m, rear wall height of 527 mm, and front wall height of 100 mm) but incorporating material and structural modifications to improve thermal performance.

4.2. GI-Based Modified Solar Still

This configuration retained the 1 mm thick galvanized iron basin but featured enhanced thermal insulation. A 10 mm thick layer of glass wool was used along the base and side walls to reduce conductive heat losses. The outer casing was constructed from 30 mm thick plywood, offering better insulation compared to the conventional setup. A 3 mm thick glass cover was installed on the top, which allowed solar radiation to pass through and supported condensation of water vapours.

4.3. GI with Aluminium Lining Modified Solar Still

In this variant, the basin was similarly made from a 1 mm thick GI sheet but was further lined with a 1 mm thick aluminium sheet to enhance thermal conductivity and heat absorption. As with the previous design, 10 mm thick glass wool insulation was applied to the base and sidewalls. The outer structure used 30 mm thick plywood for improved thermal resistance. A 3 mm thick transparent glass sheet was mounted on the top to enable effective solar transmission and vapor condensation.

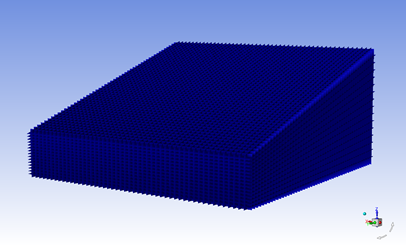

5. Modelling

In computational fluid dynamics (CFD), the physical domain is segmented into smaller computational regions known as subdomains, which are typically made up of geometric shapes—such as hexahedrons and tetrahedrons in three-dimensional models, or quadrilaterals and triangles in two-dimensional cases. Within each of these subdomains, the governing equations for fluid flow are discretized and numerically solved.

To obtain approximate solutions, one of several numerical techniques is employed, most commonly the finite volume method (FVM), finite element method (FEM), or finite difference method (FDM). These subdomains are often referred to as elements or cells, and the full set of these components constitutes what is known as a mesh or computational grid. The generation of this mesh, known as meshing or grid generation, is a critical step in the simulation process. However, due to the complexity involved in creating an optimal and accurate mesh, especially for irregular geometries, it is often regarded as one of the most challenging and time-consuming phases of CFD modelling.

5.1. Conventional solar still

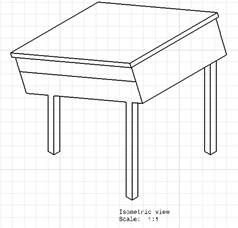

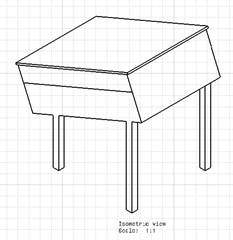

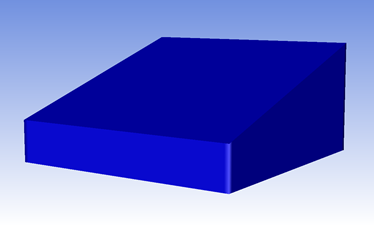

Figure 2

|

Figure 2 Isometric View of Conventional Solar Still. |

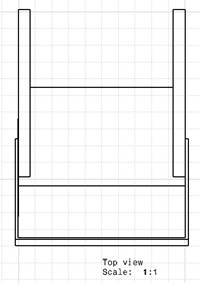

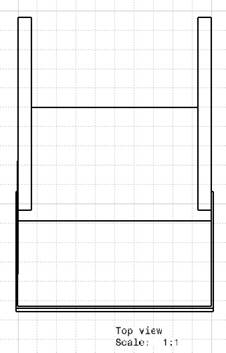

Figure 3

|

Figure 3 Top view of Conventional Solar Still |

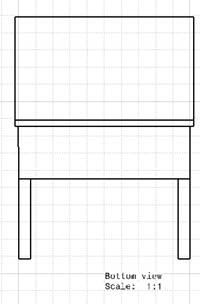

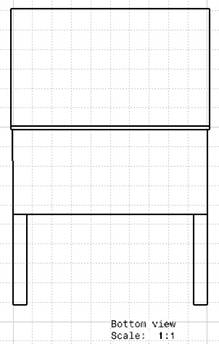

Figure 4

|

Figure 4 Bottom View of Conventional Solar Still |

6.2. Modified solar still

Figure 5

|

Figure 5 Isometric View of Modified Solar Still |

Figure 6

|

Figure 6 Top View of Modified Solar Still |

Figure 7

|

Figure 7 Bottom View of Modified Solar Still |

6. Result and Discussion

6.1. Conventional solar still

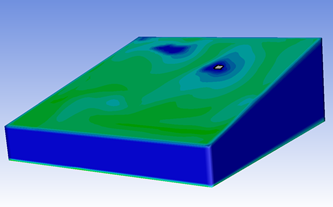

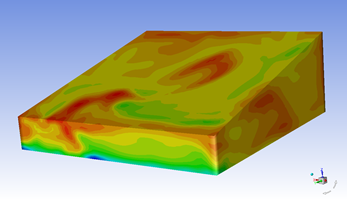

Figure 8 presents the static temperature distribution on the full-body surface of the conventional solar still. The temperature is observed to be relatively uniform on the upper surface, with slightly higher values near the central basin area where solar radiation is most concentrated. The side walls and base region exhibit lower temperature values due to thermal losses to the surroundings.

Figure 8

|

Figure 8 Static Temperature of Full-body Surface of Conventional Solar Still |

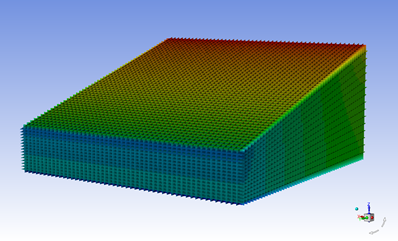

In Figure 9, the corresponding density distribution of the full-body surface is shown. The density variation is inversely proportional to the temperature distribution—areas with higher temperatures display lower fluid density, indicating enhanced vapor formation potential in the central basin region.

Figure 9

|

Figure 9 Density of Full-body Surface of Conventional Solar Still |

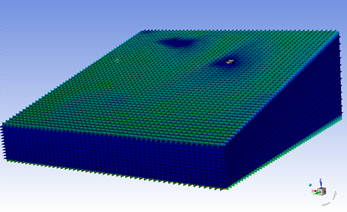

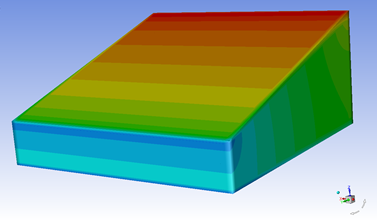

Figure 10 shows the internal static temperature distribution. A noticeable temperature gradient is observed from the basin water surface to the inner side of the glass cover, confirming the occurrence of effective heat transfer. This gradient supports the evaporation-condensation cycle inside the still.

Figure 10

|

Figure 10 Static Temperature of Interior of Conventional Solar Still |

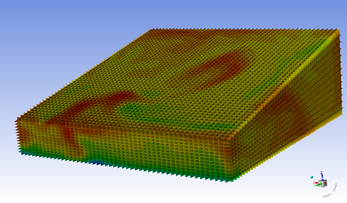

Figure 11 illustrates the internal density distribution. The denser regions near the bottom suggest cooler fluid zones, while the upper vapor region has lower density, confirming active evaporation and moisture rise due to thermal convection.

Figure 11

|

Figure 11 Density of Interior of Conventional Solar Still |

6.2. Modified solar still (Galvanized iron sheet based the solar still)

Figure 12 displays the surface temperature distribution of the GI-based modified solar still. Compared to the conventional design, a more uniform and slightly higher temperature profile is observed across the basin surface. This can be attributed to improved insulation and structural modifications that reduce heat losses.

Figure 12

|

Figure 12 Static temperature of Full-Body Surface of Modified Solar

Still |

Figure 13 shows the density profile on the full-body surface. The distribution is more uniform than in the conventional case, indicating steady thermal behavior and improved thermal retention, which promotes consistent vapor generation.

Figure 13

|

Figure 13 Density of Full-Body Surface of Modified Solar Still |

The internal temperature profile (Figure 14) shows increased thermal stratification within the basin. The higher temperature near the basin water surface indicates improved solar energy absorption, leading to an enhanced evaporation process.

Figure 14

|

Figure 14 Static Temperature

of Interior of Modified Solar Still |

Figure 15 presents the internal density distribution, which supports the thermal behaviour seen in the temperature plot. The reduction in density near the top of the water surface suggests efficient thermal transfer and vapor buildup.

Figure 15

|

Figure 15 Density of Interior of Modified Solar Still |

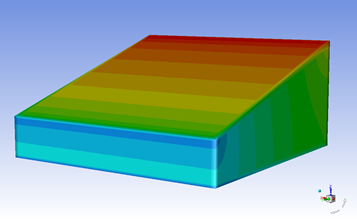

6.3. Modified solar still (Galvanized iron with addition of aluminum sheet based the solar still)

The static temperature distribution for the GI-aluminium hybrid design is shown in Figure 16. This configuration demonstrates the highest surface temperature among all three stills, primarily due to the enhanced thermal conductivity of the aluminium sheet, which improves heat spread across the basin surface.

Figure 16

|

Figure 16 Static Temperature of Modified Solar Still |

Figure 17 shows the density distribution of this advanced design. The lowest density regions are concentrated near the evaporative zone, indicating intense thermal activity and suggesting that the aluminum sheet significantly boosts evaporation by accelerating heat transfer to the water layer.

Figure 17

|

Figure 17 Density of Modified Solar Still |

7. Conclusions

· CFD simulation results closely matched expected physical behavior, validating the simulation approach for both conventional and modified solar stills.

· The maximum water temperature of 397.823 K was observed in the modified solar still using galvanized iron with an aluminum sheet, indicating superior thermal performance.

· At 1:00 PM, the largest temperature difference of 69.182 K between water and glass was also recorded in the same modified setup, with a percentage difference of 17.39%.

· The conventional solar still had the lowest temperature difference (22.093 K) and water temperature (350.734 K), demonstrating reduced efficiency compared to modified designs.

· The density variation between designs (44.1 kg/m³ for conventional, 1.23 kg/m³ and 1.08 kg/m³ for the modified types) indicates different fluid dynamic behaviors, which affect evaporation rates and heat transfer.

· The use of advanced materials like galvanized iron and aluminium significantly enhances the thermal performance and evaporation rate of the solar still.

· Advanced optimization of material combinations, including nanomaterials or coated surfaces, can further improve heat absorption and efficiency.

· Hybrid designs integrating thermal storage materials (PCM) with modified structures may ensure better night-time productivity.

Conflicts of Interests

The authors declare no conflict of interest.

ACKNOWLEDGMENTS

None.

REFERENCES

Tiwari, G. N., Mukherjee, K., Ashok, K. R., & Yadav, Y. P. (1986). Comparison of Various designs of Solar Stills. Desalination, 60*, 191–202. https://doi.org/10.1016/0011-9164(86)90008-1

Abolfazli, J., Rahbar, N., & Lavvaf, M. (2011). Utilization of Thermoelectric Cooling in a Portable Active Solar Still: An Experimental Study on Winter Days. Desalination, 269, 198–205. https://doi.org/10.1016/j.desal.2010.10.062

Adenauer, P. K., & Nafila, S. (2007). Impact of Temperature Difference (Water–Solar Collector) on Solar-Still Global Efficiency. Desalination, 209, 298–305. https://doi.org/10.1016/j.desal.2007.04.043

Al-Hayeka, I., & Badran, O. O. (2004). The Effect of Using Different Designs of Solar Stills on Water Distillation. Desalination, 169, 121–127. https://doi.org/10.1016/j.desal.2004.08.013

Gnanadason, M. K., Kumar, P. S., Wilson, V. H., & Kumaravel, A. (2015). Productivity Enhancement of a Single Basin Solar Still. Desalination and Water Treatment, 55(8). https://doi.org/10.1080/19443994.2014.930701

Mishra, D. R., & Tiwari, A. K. (2013). Effect of Coal and Metal Chip on the Solar Still. Journal of Scientific and Technical Research, 3(1), 1–6.

Musher, S. A., Mir-Nasiri, N., Wong, S. Y., Ngoo, K. C., & Wong, L. Y. (2010). Improving a Conventional Greenhouse Solar Still Using Sun Tracking System to Increase Clean Water Yield. Desalination and Water Treatment, 24, 140–149. https://doi.org/10.5004/dwt.2010.1473

Raval, T. N. (2016). Performance Enhancement of Combined Cycle Power Plant. ICPMAE, 3(2), 68–71.

Raval, T. N., & Patel, R. N. (2013). Optimization of Auxiliary Power Consumption of Combined Cycle Power Plant. Procedia Engineering, 51, 751–757. https://doi.org/10.1016/j.proeng.2013.01.107

Sampathkumar, K., Arjunan, T. V., Pitchandi, P., & Senthil Kumar, P. (2010). Active Solar Distillation: A Detailed Review. Renewable and Sustainable Energy Reviews, 14, 1503–1526. https://doi.org/10.1016/j.rser.2010.01.023

Shankar, P., & Kumar, S. (2012). Solar Distillation: A Parametric Review. VSRD-MAP, 2, 17–33.Tiwari GN, Mukherjee K, Ashok KR, Yadav YP. Comparison of various designs of solar stills. Desalination 1986; 60:191–202. doi:10.1016/0011-9164(86)90008-1.

Tiwari, A. K., & Tiwari, G. N. (2007). Thermal Modelling Based on Solar Fraction and Experimental Study of the Annual and Seasonal Performance of a Single Slope Passive Solar Still: The Effect of Water Depths. Desalination, 207(1–3), 184–204. https://doi.org/10.1016/j.desal.2006.07.011

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© Granthaalayah 2014-2022. All Rights Reserved.