High shear rheology of PBT/Coir fibre composites revealing the impact of surface treatment of coir fibre

Manish 1

1 Department of Chemistry

Lajpat Rai College, Sahibabad, India

|

|

ABSTRACT |

||

|

Poly(butylene terephthalate), (PBT)

was melt blended with coir fibre

using twin extruder in the ratios 0%, 5%, 10%, 15% and 25% (wt. percent) to

prepare composites . In order to

understand the role of surface functionalities and properties, the coir fibre was treated with alkali (NaOH) to remove impurities

from the surface and again the alkali treated coir fibre

was treated with silanizing agent, 3-aminopropyl triethoxy silane, to silanize

the surface. Thus, way three classes of composites

were more prepared with untreated, alkali treated

and silane treated coir fibre in abovesaid fibre contents. Their rheological properties were studied

using capillary rheometer. It was found that the fibre

content as well as surface interactions enhanced and modified the rheological

properties of the composites revealing the role of entalglement,

steric hindrance and surface interactions. |

|||

|

Received 07 January 2025 Accepted 08 February 2025 Published 31 March 2025 DOI 10.29121/granthaalayah.v13.i3.2025.6279 Copyright: © 2025 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: PBT, Coir Fibre,

Surface Treatment, Rheology, Composites, Power Law Index, Consistency Index |

|||

1. INTRODUCTION

Poly (butylene terephthalate) (PBT) is a semicrystalline engineering polymer with a high rate of crystallization, good chemical resistance, thermal stability, and excellent flow properties Paul & Newman (1978), Chirawithayaboon & Kiatkamjornwong (2004). PBT is used in various automotive, electrical and other engineering applications owing to a combination of good tensile strength, flexural modulus, and dimensional stability especially in water, and high resistance to hydrocarbons. It provides innovative solutions that save weight and decrease costs and offers fast crystallization. The chemical structure of PBT is shown in Figure 1

2. Materials and methods

2.1. Materials

PBT was purchased from Sparsh PolyChem Pvt. Ltd., Haryana. It was injection moldable grade with density 1.31 and it’s MFI at 250 °C and 2.16 kg load was 35.

Coir fiber (untreated, CN) was procured from Coco Florings, Kerala, India in short fibrous form. It was treated with alkali (NaOH) to remove impurities on the surface to give alkali treated coir fibre (CN) and a part of alkali treated fibre was silanized using (3-aminopropyl) triethoxysilane to introduce silane groups on the surface, thus giving silane treated fibre (CS).

Figure 1

|

Figure 1 Chemical Structure of Poly (Butylenes Terephthalate), (PBT) |

2.2. Melt Blending

The melt mixing was done in a PRISM EUROLAB 16 co-rotating twin screw extruder having a high shear screw configuration for better mixing. The screws are made up with the kneading blocks which are staggered at 30° angle from each other. Each of kneading block had seven discs with L/D = 25, where L is the length and D is the diameter of the disc. The Processing was done at 240 °C.

The compositions were made with 0%, 5%, 10%, 15% and 25% with each untreated (PBT/CU), Na-treated (PBT/CN) and silane treated fibre (PBT/CS). Composites CU00, CU05, CU10, CU15, CU25 were prepared using untreated fibres, CN00, CN05, CN10, CN15 and CN25 with alkali treated fibre while CS00, CS05, CS10, CS15 and CS25 were prepared with silane treated fibre in the said compositions.

2.3. Capillary Rheometry

The rheological (capillary rheometry) was carried out and the effects of coir fiber contents and surface treatment on it were analyzed. The rheological properties were measured at 245 °C in the shear rate range 100 s-1 to 5000 s-1 on a Rosand Advanced Rheometer system dual bore capillary rheometer. The capillary rheometer mimics on the model flow behaviour in the common important polymer processing instruments, e.g., extrusion and injection moulding. The L/D ratio of the capillary in one bore was 16/1 whereas for the comparison the orifice die had zero length capillary. The application of two capillary system permits standard Bagley and Rabinowitsch corrections automatically during the measurements.

3. Results and discussion

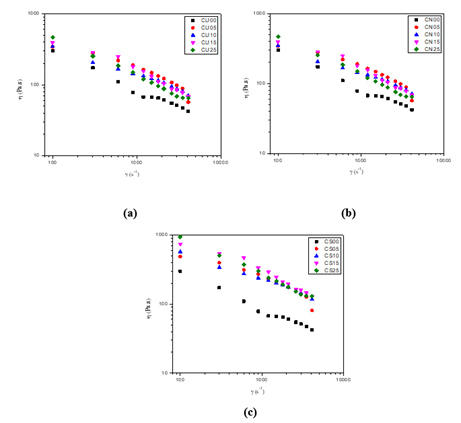

The apparent shear viscosity vs. shear rate curves of the PBT/coir fiber composites at the temperature 245 °C are shown in Figure 2 (a)-(c). The melt viscosity-shear rate variation followed the power law in the entire range of the shear rate studied, and the viscosity decreased linearly with the increase in the shear rate. At any constant shear rate with increase in the coir fiber content, the shear viscosity of the green composites increases. This might be because of the restriction created by the coir fibers in the flow of PBT chains. The melt viscosity of the polymer system depends upon the molecular chain arrangements. The flow starts when the polymeric chains slide upon each other under the influence of the external forces. When filler is added in the polymeric system, it creates the hindrance in the sliding of the polymeric chains and thus enhances the viscosity of the system. At higher shear rate, the flow curves tend to merge with each other. This may be because variation in the coir fiber content has lower effect on the flow of the polymer at high shear rates. All the green composites showed higher shear viscosity than that of PBT. The viscosity increased with increase in the coir fiber content. Similar behavior was reported elsewhere Martuscelli et al. (1982). The rheological behavior of the PBT/CN and PBT/CS composites are similar to that of the PBT/CU composites, however their values are higher. This might be because of the improved matrix/fiber phase adhesion in case of PBT/CN and PBT/CS composites. Enhanced phase adhesion restricted the sliding of the polymeric chains upon each other and thus enhanced the shear viscosity of the composites Couch & Binding (2000), Bigg (1983).

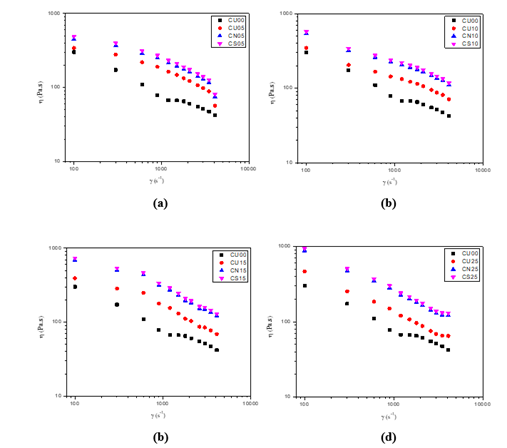

Figure 3(a)-(d) depicts the comparison of the shear viscosities of the same fibre content but different surface properties. In Figue 3 (a) the 5 % composites (PBT/CU) are plotted with the neat PBT (CU00) showing the increase in the viscosities as the fibre properties changed from untreated to alkali treated and then to silane treated. The difference in the shear viscosities accordingly enhanced as the fibre content was raised to 10 % in Figure 3 (b), 15 % in Figure 3 (c) and to 25% inFigure 3 (d) and therefore establishing the combinatorial effects of fibre content and the surface properties.

Figure 2

|

Figure 2 Variation of the Shear Stress with Shear rate at 245 °C: (a) Composites with Untreated fibre; (b) Composites with Na-treated fibre; (c) Composites with Si-treated Fibre |

The power law coefficient (n) values of the composites at three different temperatures are shown in Table 1 The values of n are less than unity which clearly indicates pseudoplastic behavior of the composites. The values of n decreased with increase in the coir fiber content (wt%). This indicates that shear thinning behavior of the composites increased with an increase in the coir fiber content.

Figure 3

|

Figure 3 Variation of the Shear viscosity with Shear rate at 245 °C: (a) Composites with 5% fibre content ; (b) Composites with 10% fibre content; (c) Composites with 15% fibre Content; (d) Composites with 25% Fibre ontent |

This may be due to the hindrance of the PBT chain entanglement in the presence of the coir fibers so that the PBT chains are easily oriented in the flow direction. In case of PBT/CN and PBT/CS composites, similar to the PBT/CU composites, n values decreased with increase in the coir fiber content. However the n values are to an extent lower which may be due to improved phase adhesion in case of PBT/CN and PBT/CS composites Han et al. (1981).

Table 1

|

Table 1 Values of the Power law Coefficient (n) at three Different Temperatures |

|||

|

Fibre Content% |

n values |

||

|

Composites with untreated fibre (PBT/CU) |

Composites with Na-treated fibre (PBT/CN) |

Composites with Si-treated fibre (PBT/CS) |

|

|

0 |

0.74 |

0.74 |

0.74 |

|

5 |

0.65 |

0.6 |

0.61 |

|

10 |

0.61 |

0.57 |

0.54 |

|

15 |

0.54 |

0.49 |

0.46 |

|

25 |

0.47 |

0.43 |

0.42 |

Consistency coefficient (K) values of the composites are shown in Table 2 With increase in the Coir fiber content in the composites the values of K increased. This may be due to the increase in the resistance to flow of the composites melts with increase in the coir fiber content.

The PBT/CN and PBT/CS composites show similar behavior to the PBT/CU composites, however their K values were higher than those of the PBT/CU composites which is due to the improved phase adhesion in case of PBT/CN and PBT/CS composites.

Table 2

|

Table 2 Values of the Consistency coefficient (K) at Three Different Temperatures |

|||

|

Fibre Content% |

K- values (Pa-s) |

||

|

Composites with untreated fibre |

Composites with Na-treated fibre |

Composites with Si-treated fibre |

|

|

0 |

1254 |

1475 |

1738 |

|

5 |

1438 |

1847 |

2756 |

|

10 |

1546 |

2258 |

4576 |

|

15 |

1893 |

3968 |

6281 |

|

25 |

2567 |

6583 |

7893 |

4. Conclusions

The green composites were successfully prepared by melt compounding PBT with coir fibers. PBT/Coir fiber composites show higher values of shear viscosity, than that of the neat PBT and as the coir fiber content increased these properties increased. PBT/CN and PBT/CS composites present higher values of shear viscosity than those of PBT/CU composites. Phase interactions enhanced the melt viscosity as reported in some other systems too Gupta et al. (1991).

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

Bigg, D. (1983). Rheological Behavior of Highly Filled Polymer Melts. Polymer Engineering and Science, 23(4), 206-210. https://doi.org/10.1002/pen.760230408

Chirawithayaboon, A., & Kiatkamjornwong, S. (2004). Journal of Applied Polymer Science, 91, 742. https://doi.org/10.1002/app.13215

Couch, M., & Binding, D. (2000). High Pressure Capillary Rheometry of Polymeric Fluids. Polymer, 41(16), 6323-6334. https://doi.org/10.1016/S0032-3861(99)00865-4

Gupta, A. K., Kumar, P. K., & Ratnam, B. K. (1991). Journal of Applied Polymer Science, 42, 2595. https://doi.org/10.1002/app.1991.070420925

Han, C., Van Den Weghe, T., Shete, P., & Haw, J. (1981). Effects of Coupling Agents on the Rheological Properties, Processability, and Mechanical Properties of Filled Polypropylene. Polymer Engineering and Science, 21(4), 196-204. https://doi.org/10.1002/pen.760210404

Martuscelli, E., Silvestre, C., & Abate, G. (1982). Morphology, Crystallization and Melting Behaviour of Films of Isotactic Polypropylene Blended with Ethylene-Propylene Copolymers and Polyisobutylene. Polymer, 23(2), 229-237. https://doi.org/10.1016/0032-3861(82)90306-8

Paul, D. R., & Newman, S. (1978). Polymer blends Vol. 2 (35-36). Academic Press. https://doi.org/10.1016/B978-0-12-546802-2.50008-7

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© Granthaalayah 2014-2025. All Rights Reserved.