AJRAKH - THE ANCIENT BLOCK PRINTING TEXTILE CRAFT OF INDIA

Dr. Anjali Pandey 1

1 HOD, Drawing and Painting Department,

Government M.L.B. Girls PG. Auto. College, Bhopal, Madhya Pradesh, India

|

|

ABSTRACT |

||

|

The cotton fabrics of India ornamented by dyeing, painting and block printing were a major part of international trade for many centuries, spreading through the maritime routes of the Indian Ocean to the Arab world and Southeast and East Asia in medieval times. Ajrak is the oldest form of block Printing. It is recognized as a tradition of Sindhi culture. These prints are mostly found in Sindh in Pakistan and Ajrakhpur and Barmer in India. All

ingredients in Ajrakh are derived from nature, be

it botanical essences or common minerals. It is one of the madar other block printing methods. It has undergone some

changes in the production of traditionally two-sided durable block printed

cotton fabrics.Indigo blue

and red are the predominant colors used in the Ajrakh

print. 1 Muthu

and Gardetti (2020), 7.

|

|||

|

Received 12 January 2025 Accepted 18 March 2025 Published 15 April 2025 DOI 10.29121/granthaalayah.v13.i3.2025.6004 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2025 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Textile Craft, Patterns, Block Printing,

Natural Dyes, Designs |

|||

1. INTRODUCTION

"Decoration in Indian Textiles is never employed just for its own sake. It is always used with regard to the specific purpose of which the garment fulfills customs and determines the community of tradition in this respect."2 Mookerjee (1986), 37-47

The art of block printing on cotton fabric has been practiced in India for over 4,500 years. It is an ancient block printing method on cloth that originated in present-day Sindh of Pakistan, Kutch provinces of Gujarat and Barmer in Rajasthan. 3 Shah (2021), Gupta (2016)

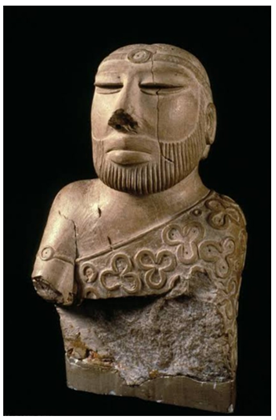

In the antiquity of hand printing culture, Statue of a priest wearing a shawl in a trefoil pattern excavated from Mohenjo Daro, Indus Valley Civilization period is evidence of block printing in geometric patterns on cotton cloth. Egyptian graves have yielded similar patterns which are also worthy of note. The murals on the walls of the Ajanta Caves also feature printed clothing. The history of dyeing has a close relationship with the production of textiles. While the tools needed for painting, dying, and block printing differ, they are all based on the same method: mordant. That is how mordant is used.

Archaeological evidence indicates that the use of mordant began in the late Harappan culture 1700 B.C. These skill and knowledge were passed down from generation to generation. 4 Chattopadhyay (2000), 61-65, 63-87

Indian textile producers began exporting their products to other parts of the world in the sixteenth century. They lost their hegemonic status in the late 1800s. In the 18th century Producers played a significant role by experimenting with new techniques. An expansion of knowledge of materials and the dyeing process could be seen.Globalization has become a permanent trademark of the textile business. It was not only the vogue of colors but also the art of dyeing that global networking process. In contact with designers and individual retailers around the world, contemporary Indian block printers are once again combining traditional craftsmanship with global marketing and communicating about fashion, using the technology by which they used to create their goods. 5 Mishra (2007), 20-34 & 62

2. Ajrakh - Unique Block printing craft

The word "Ajrak" is derived from "Ajraq", which means blue in Arabic, as blue is one of the major dyes in Ajrak printing. Local healers have a common belief that the word "Ajrakh" is related to the Hindi word "Aaj Rakh," which means "keep it today." 6 Gupta (2016).

Natural dyeing is an ancestral skill in the block printing segment of traditional Textiles. Rajasthan, Gujarat, and Andhra Pradesh are the primary locations for the production of textile crafts. These craftspeople continue to employ the antiquated techniques of block printing and natural dyeing, which is a combination process. 7 Mishra (2007), 20-34 & 62.

Figure 1

|

Figure 1 Source http://threads-unpicked.com/craft-series-the-ajrakh-block-printing-of-kachchh-india/ |

3. Natural Dyeing Patterns

"Vegetable and stone dyes have been widely used from ancient times. The fragments of cotton discovered at Mohenjo Daro reveal traces of purple dye, thought to be maddar. The major vegetable dyes used were Indigo, chay-root, lac, turmeric and safflower."8 Mookerjee (1986), 37-47

Natural colors that are readily available locally are harmonious with the environment. Its two main colors are crimson red and indigo blue. Colors derived from minerals, plants, and other organic materials are utilized. Harde, pomegranate seeds and bark, and wild indigo are a few typical ingredients. In addition to using natural pigments to print on fabrics, the artisans wash fabrics with natural ingredients.

Camel dung, which is found in abundance, is used as an ingredient to remove starch from cloth. It is amazing to think that the artists create dye with the leftover iron. To make a black dye for Ajrakh, scrap iron jaggery and tamarind seeds are soaked in water for two weeks and then burned over high heat. Kat is the name of this paste.

The fabric is dyed after being printed with resist paste in the Ajrakh printing process. 9 Gupta (2016)

The striking results are achieved when they dye it with natural dye extracts.

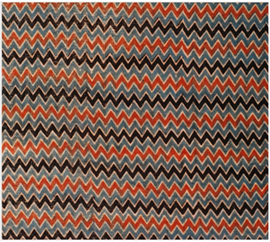

Figure 2

|

Figure 2 Source www.dsource.in |

4. Block Printing

Handcrafted wooden blocks are used by Ajrakh printing artisans to apply elaborate designs to fabric. The blocks are dipped in natural dye and gently pressed into the fabric to produce a repeating pattern.This printing is unique in that it can be printed in two different ways. Ek-Puri is the term for fabric printed on one side, and Bi-Puri is the term for fabric printed on both sides.

The preparation of the overall design and the ultimate execution of a project was in the hands of elders. 10 Chattopadhyay (2000), 14-15.

The wooden blocks which are used in Ajrakh printing, have been traditionally hand-picked by experts.

There are numerous printing specialties designed for particular kinds of blocks. Acacia wood is typically used to make ajrakh blocks.

When printing something else, teak or rosewood blocks are used. The artists now demonstrate how to carve elaborate geometric and floral patterns into teak wood blocks.

With wooden blocks, printing is done by hand. Mishra (2007) 20-34 & 62

5. Technique

"A greater grasp over the use of colors came with the development of dyes from Minerals and the discovery of mordants. This too was quite an early development in India".12 Mookerjee (1986), 37-47

Ajrakh printing in Sindh Kutch and Barmer are almost similar in terms of production technique, motifs and use of colors.

The process of Azrak printing is long and laborious. Since the traditional method of making Ajrakh involves repeatedly printing and washing the fabric with various natural dyes and mordants, the craft demands a high level of skill and patience. The resist printing technique is used. This allows dyes to absorb in the areas that are needed and prevents dyes from absorbing in the areas that aren't supposed to be colored.

The cloth is processed into 16 different steps, each involving washing, drying, printing, and dyeing. After each step is finished, the cloth is left to rest for a day. Water is necessary for the dyeing process and the quality of the water is as important as the quantity. It impacts everything. If the water is high in minerals the color and concentration of the dyes are affected.) 13 Gupta (2016)

Another feature of this printing is that the designs are printed in it exclusively in geometric shapes, which is another characteristic of this printing. Up to 14 blocks are used in this design printing of Ajrakh. It takes about 40 days to print 1 cloth by the specific method. To facilitate printing on both sides, the printing blocks for double sided printing are attached with nails at their corners creating a miniscule hole.

6. Saaj

Saaj- washing of clothes- the raw fabric is cleared of any wax or coating that might prevent the dyes from binding by washing, beating, and rinsing. Castor oil, water, natural caustic soda, and camel or goat dung are mixed together to treat the fabric. This removes coating and cleans the cloth. This process is repeated over several days.

7. Kasanu

In the second Step Kasanu, the fabric is dyed with Myrobalan in a cold solution, which gives a yellow tinge and acts as a mordant helping to fix the dyes and gives a shiny effect after, it is laid to flat to dry in hot sun.

8. Rekh

Outline of block printing is known as Rekh. The design motif is drawn on the fabric using a mixture of natural gum (Babool tree resin) and lime, which serves as a resist. Sometimes it is done on the double side of the cloth. The printed lines are resistant to alizarin as well as indigo which appears white in the finished product. 14 map academy

Artists design wooden blocks for the process of block printing. Few blocks are authentic and few are designed as per today's trendy style.

The black design is printed using a black dye made of rusted iron that has been ground into powdered chickpea and jaggery. The powder is then placed in a pot and left for seven or eight days, depending on the season, before being extracted into water and mixed with tamarind seed powder. The paste is then boiled for an hour and printed onto the cloth.

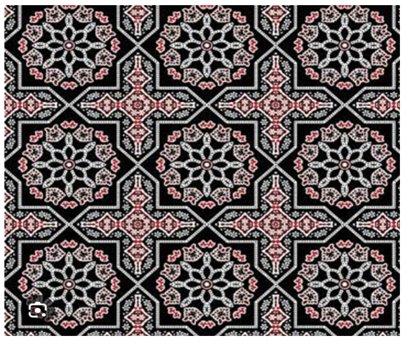

Figure 3

|

Figure 3 Source Tailoringindia |

9. Gach

resist block printing design from dyeing colors. The block print is intended to shield all the areas in which one does not want dyed.

The ingredients of the Gach print paste are millet flour, mud, and alum. Sawdust is added to prevent the mud from cracking. After the Gach printing, the cloth is allowed to air dry for a few days.

The paste applied for gach printing is created using local clay that has been filtered through millet floor and Muslin.

10. Dying in Indigo

The fabric is dyed in Indigo. In order to establish an Indigo vat, natural Indigo.

Figure 4

|

Figure 4 Source Design duality. Studio |

11. Vichharnu

Washing of cloth- The cloth is washed thoroughly in running water to remove all of the resist print and unfixed dye and then spread out to dry in the Sun.

12. Rang

The cloth is boiled in a solution of tamarix + Madder root (Sanskrit. Manjistha root) gives an orange color, Al Zarine for a red color. Alum acts as a mordant to help fix the red color. Rhubarb root gives a pale brownish color.

For the green color, pomegranate skins are boiled and liquid is sprayed on the cloth. Henna gives a light yellowish-green color. The gray areas from the black printing stages get a deep shade.For other colors the cloth is boiled with a different dye.

The color is then washed in water and hung in the sun to dry. At this stage the red and black areas of design develop and resists areas are revealed as White.

Block printing on flat surfaces is done manually. Even

today, many fabrics are still produced manually in India. I5 Muthu and Gardetti (2020)

13. Symmetrical Design

Ajrakh designs are characterized by symmetrical geometric patterns incorporating intricate interlocking motifs and floral elements, carefully aligned to create a harmonious and balanced look to the design. Barmeri has geometric pattern printing all over and has deep colors of blue and red. The symbols in Ek- Puri and Bi- Puri are almost the same. The names of the typical symbols are- khakham, Badam, moru (peacock) Jileb, daboli, kekki, chhap, Ishq pech, chalo Sarak, government seat rug Garden, Serpent, Morthi, Aan.

In the printing of Bi-Puri where the dot appears on one side the dot should appear on the other side as well; this can be checked by crossing the needle through that dot. 16 Mishra (2007) 20-34 & 62

Figure 5

|

Figure 5 Source wwwbandhej.com |

14. Uniqueness Specification

14.1. Reversibility

One of the best things about Ajrakh is that it can be worn either way around because the block printing process is applied to both sides of the cloth, making the design visible on both.Ajrakh has traditionally been printed on both sides because cattle headers are customarily used to wear Asrar as a form.They used to leave their houses before the sun rose because there was no electricity, making it impossible to tell which side was right in the dark. Printing on both sides, allowing them to wear it however they please.

In the White Desert, It wasn't just cattle that could get lost in the never-ending desert sands, Many of the time, herders also lost their sense of direction. Ajrakh is colorful and shiny for this reason. The colors made it easy for others to recognize them even and at a distance.

14.2. Season friendly

In the summer, it causes clothing's pores to open up, allowing more air to flow through. The clogged pores in winter clothing can induce vomiting. It makes sense why they claimed that Ajrakh wears it all year round.

Royal/ Imperial - This has been the dress of Hindi nawabs and nobles.

Hindi nawabs and nobles have traditionally worn this attire. It is said that at the time of independence a lungi 2.25 M was found in Sindh for a Tola of gold. Today the sheet printed by this method is sold out at Rs 10 to 12 thousand. It takes four months to print this sheet. Including printing and dying.

14.3. Challenging Task-

Due to being very expensive, there was a problem in its sale. To remove this here another printing is done from the blocks of Ajrakh, it is called M Indigo is not used for dying this fabric after printing.

In this sequence there is another printing halari. This printing dye is done with a line but it is dyed by making a green color from Indigo and pomegranate peel. The world's most beautiful block printing Ajrakh is in Barmer.

The major problem in the printing here is the scarcity of water. The major part of the cost was to be incurred by these printers. Barmer is the last important center of traditional printing in Rajasthan where there is a lack of colors in nature. On the other hand, these tools make the whole thing colorful. Lack of water is motivating them to use chemical dyeing and printing.

The block print fabric which goes in on caste faces is still in work, due to which some small traditional printing is able to survive, otherwise most of them are doing job work some for local businessmen and some in Ahmedabad and Delhi. Mishra (2007) Some small-scale traditional printing businesses are able to survive because the block print fabric that depicts caste faces is still in use, otherwise, the majority of them work for local business owners in Ahmedabad and Delhi.

Figure 6

|

Figure 6 Source https://designduality.studio/products/ajrakh-print-chaniya-choli |

14.4. Changing pattern

Ajrakh is primarily a craft using natural dyes which makes it inherently expensive. The artisans are not only preserving their age-old art of Ajrakh printing and giving it a modern twist like bags and boots as well as creating new patterns and designs in different ways for a contemporary feel apart from the sarees, dupattas and dress materials for which it has been used for almost four centuries. Their dedication to keeping the tradition alive is truly inspiring.

Traditionally Ajrakh was only worn by men from the pastoral region of Kutch. As the time passed, many changes can be seen in textile craft. Now this fabrics are used in a variety of garments, including sarees, dupattas, stoles and shawls bed sheets, scarves, turbans. Craftsmen are also making accessories such as bags, stars and home decor items. The articles of daily use are has now become increasingly popular among block print lovers. The demand for Ajrakh has increased after the earthquake, which has moved from the status of a local aboriginal caste to a catwalk verde craft. Today it has become a fashion statement for affluent shoppers of both men and women looking for organic ethical fashion.

The art of Ajrak is not just a

craft but a way of life for the people, it is also a craze among youth of urban

areas. Through their efforts, the artisans are not only preserving their

cultural heritage but also creating economic opportunities for their community.

This has led to an enormous amount of funding and dedication from a range of

brands focusing on innovation in block print. Along with new blocks, new colors, techniques have also been developed.

Figure 7

|

Figure 7 Source https://mapacademy.io/article/ajrakh |

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

Chattopadhyay, K. D. (2000). India's Craft Tradition. Publication Division, Ministry of Information and Broadcasting, Government of India, New Delhi. 37/61–65, 14–15.

Edward, E. (2019). Indian Block Printing, Entrepreneurship, and Innovation Across Time and Place. Pages 63–87.

Gupta, R. (2016). The Ageless

Art of Ajrakh Printing. Fibre2Fashion.com.

Mishra, C. (2007). Ankan. Pages 20–34 & 62, 9.

Mookerjee, A. (1986). Folk Art of India. Clarion Books. New Delhi. 37–47.

Muthu, S. S., & Gardetti, M. A. (2020). Sustainability in Textiles and Apparel Industry. 7, 9.

Shah, A. (2021). Ajrakh: The Ancient Craft of Block Printing.

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© Granthaalayah 2014-2025. All Rights Reserved.