THE EFFECT OF POLYPROPYLENE FIBERS ON COMPRESSIVE AND SPLIT TENSILE STRENGTH OF LIGHTWEIGHT CONCRETE

Mufti Amir Sultan 1![]()

![]() ,

Abdul Gaus 1

,

Abdul Gaus 1![]() , Muhammad Taufiq Yudasaputra 1

, Muhammad Taufiq Yudasaputra 1![]() , Zulham

Lambado 2

, Zulham

Lambado 2![]() ,

,

Ilman Nofiyanto Hi Bayan 3![]()

1 Department

of Civil Engineering, University of Khairun, Ternate,

Indonesia

2 Student

of the Civil Engineering Master’s Program, University of Khairun,

Ternate, Indonesia

3 Student

of the Civil Engineering Department, University of Khairun,

Ternate, Indonesia

|

|

ABSTRACT |

||

|

This study was

carried out to design lightweight concrete, which is enriched with

polypropylene fibers using coarse pumice and sand fine aggregates.

Lightweight concrete specimens were classified into distinct groups based on

fibers content employed, namely a control group with 0 kg/m³ and the

experimental incorporating 0.1 kg/m³, 0.3 kg/m³, 0.5 kg/m³, and 0.7 kg/m³

varying quantities of polypropylene fibers. Subsequently, after a curing

period of 28 days, the hardened concrete test was conducted on cylinder

specimens measuring 150 mm x 300 mm. The consistency of the fresh concrete

mixture was tested using the Abrams cone test, which revealed a decrease in

the workability of fibers-reinforced concrete with

an increase in fibers volume in the mixture. The test aimed to determine the

effect of polypropylene fibers on compressive and tensile strength of

lightweight concrete. The optimal compressive and split tensile strength was

observed at fibers volume fraction of 0.5, to obtain 7.84 MPa, or 56.68%

increase in compressive strength, and 2.12 MPa or 42.86% rise in tensile

strength. Based on compressive and split tensile strength obtained from this

study, concrete was classified as highly lightweight structural concrete,

which served as an insulator. |

|||

|

Received 10 July

2024 Accepted 12 June 2024 Published 05 August 2024 Corresponding Author Mufti

Amir Sultan, muftiasltn@unkhair.ac.id DOI 10.29121/granthaalayah.v12.i7.2024.5725 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2024 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Lightweight Concrete, Fibers-Reinforced

Concrete, Pumice, Compressive Strength, Spilt Tensile Strength |

|||

1. INTRODUCTION

Based on seismic zoning, a significant portion of

Indonesia is located

within earthquake-prone regions making the

meticulous selection of

building materials a crucial endeavor. This importance arises from the fact that these structures bear

the primary permanent load of a building. The considerable weight of this permanent

load exacerbates the vulnerability of the structure to seismic

forces, increasing the risk of potential collapse. In order to address this issue, opting for

lightweight concrete emerges as a strategic choice. By reducing the overall

weight of the building, the cumulative impact of earthquake-induced loads can

be mitigated, ultimately leading to enhanced safety measures. Moreover,

the benefits of this method extend to the foundation of these structures. The reduced

weight of the building places less stress on the capacity of the foundation to

support vertical loads. Strength of lightweight concrete is generally 25

to 35% lower than that of the conventional

type Bindu et al. (2022) .

Lightweight concrete is commonly described

as having a volume

weight that does not exceed 2000 kg/m3 Kabay & Aköz (2012). However,

this definition

varies across different

regions worldwide. For instance, in the United States, lightweight concrete is

defined by a volume weight range of 1440 to

1840 kg/m3 ACI 318-02. (2014).

In

Japan, the specific volume weight value is not specified, rather, it depends on the use of lightweight aggregates for both

coarse and fine aggregates. Concrete

regulations in Norway states that lightweight type has a maximum compressive strength of 85 MPa, and it is permissible to use any type

of aggregate. This includes a combination of lightweight and natural

aggregates, but the volume weight should not exceed 1200 kg/m3. In Australia,

lightweight concrete is classified based on a volume weight of less than 1800

kg/m3 for its constituent aggregates Clarke (2005). According to ACI 213R guidelines, structural lightweight concrete is

defined as a 28-day concrete with strength of 17 MPa and a density range of

1120 to 1920 kg/m3ACI 213R. (2014). In

Indonesia, lightweight concrete is

characterized by a volume weight of less than 1850 kg/m3.

Pumice, lightweight

and porous volcanic rock, presents an intriguing option for producing

lightweight concrete. This natural

material can potentially reduce the overall weight of concrete while

maintaining satisfactory strength, making it suitable for various construction

applications. The concept involves using pumice as both coarse and fine aggregates in concrete. It

is found in various countries, such as

Japan and New Zealand Liu et al. (2015). In Indonesia, this stone is distributed in

Jambi, Lampung, West Java, Banten, Yogyakarta, West, and East Nusa Tenggara, as well as North

Maluku, specifically on Tidore Island Sultan

et al. (2021).

This distinctive rock is characterized by its light color and high porosity. It is a type of igneous rock

formed from explosive volcanic eruptions. This rock is often referred to as

volcanic glass silicate due to the presence of foam originating from

glass-walled gas bubbles during its formation. Pumice is widely used as lightweight

concrete aggregate and an abrasive material in various industrial products. Its

high porosity allows it to float on water. The rock exhibits high vesicular

properties, containing numerous cells formed from the expansion of the gas foam

trapped within. The abundant pore spaces enclosed by thin,

delicate walls contribute to

its exceptionally low density. Generally, pumice has a density of less than 1,

enabling it to remain afloat on water effortlessly. It is found as fragments or debris within volcanic breccias.

Common minerals found in pumice include feldspar, quartz, tridymite, and

cristobalite Rashad (2019).

Pumice possesses the essential physical characteristics required for functioning as concrete aggregate, offering a compelling option as lightweight alternative. It fulfills the requirements of lightweight concrete and

significantly reduces the structural load, leading to smaller foundation

designs Suseno et al. (2021). Pumice-aggregate concrete is usually used in earthquake-resistant buildings, particularly where thermal resistance is a primary

criterion, as well as in areas prone to acid rain Muralitharan & Ramasamy

(2015). When used as a coarse aggregate, pumice substantially contributes to the

overall reduction in

concrete weight, thereby categorizing

it as lightweight Mushtaq Khan & Sachar (2022). In cases where pumice substitutes for coarse

aggregate, compressive strength is slightly reduced compared to standard concrete. This

necessitates the incorporation of additives to maintain adequate strength

levels. However,

this type of concrete typically exhibits lower volume weight than regular

concrete mixes Idi et al. (2020). The integration

of pumice into concrete formulations involves partial substitution for coarse

aggregate. The

replacement of pumice up to a

threshold of 50% maintains

tensile, compressive, and

flexural strength levels

comparable to conventional concrete. Once the replacement surpasses 50%, its strength experiences

a gradual decline. As a result, replacing 50% of aggregate with pumice

proves effective for structural purposes, while the 60% to 100% replacement

range is only suitable for non-structural applications. It was concluded that due to its concrete-like

properties, pumice can effectively serve as lightweight aggregate. The outcome also meets the specified criteria for lightweight

concrete production Numan et al. (2021). Lightweight concrete with

varying strength grades and unit weights can be produced by combining pumice aggregate with an air-entraining agent admixture. This type of concrete

falls short of meeting strength requirements for load-bearing structural elements Manzoor et al. (2018). The use of 100% pumice coarse aggregate

tends to decrease compressive and flexural strength of reinforced concrete

beams Sultan

et al. (2021).

In order to address this issue, it is imperative to explore innovative solutions, such as the incorporation of fibers into concrete mixture. Numerous studies have been

conducted to enhance concrete properties, particularly its toughness. The use

of fibers has been proven to enhance the

mechanical properties and durability of concrete. Many studies have been conducted to investigate the performance and advantages of fibers-reinforced

concrete in recent decades Annamaneni & Pedarla

(2023), Biradar et al. (2020), Geremew et al. (2021), Gupt & Dulawat

(2020), Khan & Ali (2019), Nkomo et al. (2022), Wang et al. (2023), Zhang & Li (2013). Furthermore, steel, glass, polyethylene, polypropylene, polyvinyl alcohol,

polyester, basalt, and natural fibers, are commonly used in concrete materials. These fibers serve three main benefits in concrete

compositions, namely reducing cracking, providing reinforcement, and enhancing toughness.

2. MATERIAL AND METHOD

This

study was based on an experimental method and involved the use of several

materials. Portland Type 1 cement and water were used as the binding and mixing

materials. The composition also included pumice sand fine and coarse aggregates.

In addition, polypropylene fibers were introduced as

an additional component in the mixture.

2.1. AGGREGATES

Pumice

sand fine and coarse aggregates were sourced from the Goto quarry in North

Maluku. The gradation of the fine aggregate in Zone I. Meanwhile, pumice coarse

aggregate in Zone I (max 40 mm). The visual representation of the texture of

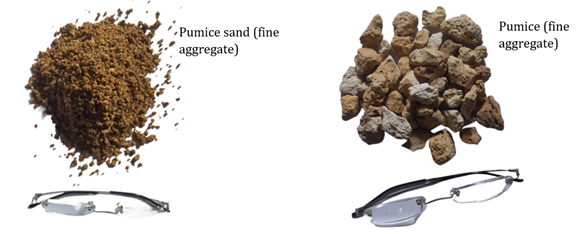

both aggregates is shown in Figure 1.

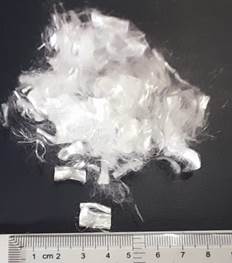

2.2. Polypropylene fibers

Polypropylene

fibers possess water-repellent properties and are

resistant to alkali, chemicals, and chlorides. In this study, polypropylene fibers were cut to a length of 12 mm. The amount of fibers used was based on

volume fraction for concrete mixture, namely 0.1 kg/m3, 0.3 kg/ m3,

0.5 kg/ m3, and 0.7 kg/ m3. In contrast, the control

specimens were prepared without the use of polypropylene fibers

(0%). Figure 2 shows the visual

representation of polypropylene fibers used in this

study.

Figure 1

|

Figure 1 The Texture of Fine Aggregate and Coarse Aggregate |

Figure 2

|

Figure 2 Polypropylene Fibers Used in this Study |

2.3. SPECIMENS

Cylinderical-shaped concrete specimens

were used for the assessment of compressive and split tensile strength. These

cylinders were characterized by a diameter and height of 150 mm and 300

cm. The testing took place once the specimens

reached 28 days of curing, with a total of 90 samples involved in the analysis.

3. RESULTS AND ANALYSIS

3.1. Slump test

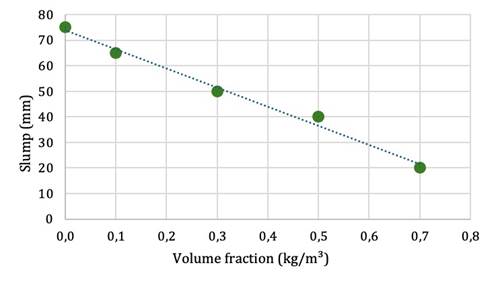

The

slump value of fresh concrete was examined to ensure the required workability.

In this study, the planned slump value falls within the range of 60 to 80 mm.

The slump value of concrete without fibers was

approximately 75 mm, whereas that of the first fibers-reinforced

concrete mixture decreased from 65 mm at a volume fraction of 0.1 to 20 mm at a

volume fraction of 0.7, as shown in Figure 3.

Figure 3

|

Figure 3 Concrete Slump to Polypropylene Fibers Volume Fraction |

Figure 3 shows that an increase in fibers

volume fraction within fibers-reinforced concrete

mixture requires more water. The decrease in fibers-reinforced

concrete workability with an increased volume fraction of polypropylene fibers in the mixture is due to the significant frictional

resistance generated between polypropylene fibers and

concrete particles Hasan et al. (2019).

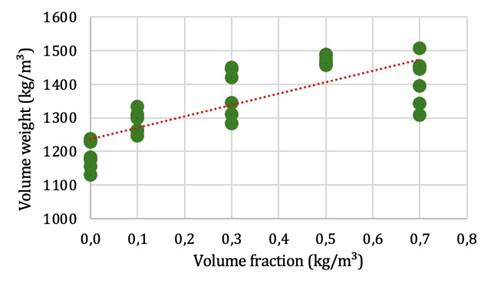

3.2. Volume weight of fibers-reinforced concrete

The volume weight of polypropylene fibers-reinforced

concrete after 28 days of curing is shown in Figure 4. Lightweight concrete

without polypropylene fibers exhibits the highest

density value of 1505

kg/m3. Meanwhile, concrete with polypropylene fibers

has the lowest value, recorded

at 1129 kg/m3, thereby classifying it as lightweight concrete.

Figure 4

|

Figure 4 The Volume Weight of Polypropylene Fibers-Reinforced Concrete |

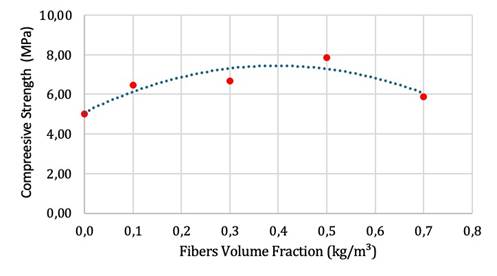

3.3. The effect of polypropylene fibers on compressive strength

Figure 5 shows that

polypropylene fibers tend to affect concrete mixture by enhancing the 28-day

compressive strength. The maximum compressive strength of 7.84 MPa was achieved at a volume

fraction of 0.5, accounting for 56.68% of strength observed in concrete

without fibers. Strength starts

to decrease as fibers concentration increases further

because higher fibers volume disrupts the compactness

of concrete matrix. Based on the test results, the produced concrete falls into

the highly lightweight structural concrete category, serving as an insulator Gaus et al. (2022).

Figure 5

|

Figure 5 Compressive Strength of Polypropylene Fibers-Reinforced Concrete |

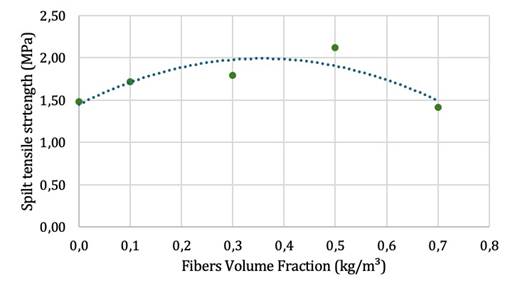

3.4. The effect of polypropylene fibers on split tensile strength

According

to Figure 6, tensile strength starts to increase as fibers volume

fraction rises. It reaches a maximum value of 2.12 MPa at fibers volume

fraction of 0.5, which is 42.86% higher than tensile strength of fibers-less

concrete. The increase in split tensile strength occurred due to two factors, namely the even distribution of fibers within the mixture and the careful selection of fibers proportions. Tensile strength improves primarily

because of the bonding mechanism of polypropylene fibers.

However, the addition of fibers volume fraction greater than 0.5 leads to a reduction in the bond

strength between concrete components, resulting in earlier failure compared to

concrete with a lower fibers volume Ahmed et al. (2006).

Figure 6

|

Figure 6 Split Tensile Strength of Polypropylene Fibers-Reinforced Concrete |

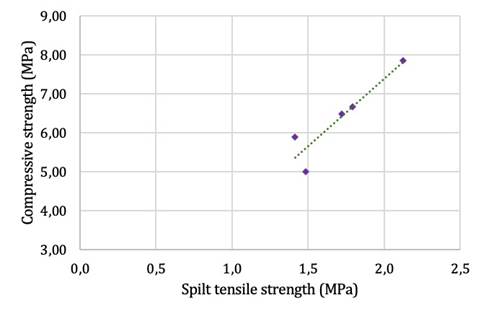

3.5. Relationship between compressive and split tensile strength

A suitable method for calculating tensile strength of normal concrete, fct, is 0.10f’c < f’ct < 0.2f’c Nawy (2005). Based on Table 1 and Figure 7, the obtained split tensile strength values from the calculations do not align with the theoretical ranges. For instance, tensile strength of normal concrete without fibers is 1.49 MPa, surpassing the projected range of 0.50 to 1.00 MPa. Split tensile strength of concrete with the addition of polypropylene fibers at a volume fraction of 0.1 is 1.72 MPa, exceeding the range of 0.65 to 1.29 MPa. Furthermore, split tensile strength of concrete with the addition of polypropylene fibers at a volume fraction of 0.3 is 1.79 MPa, surpassing the expected range of 0.67 to 1.33 MPa. This trend persists as concrete containing polypropylene fibers at a volume fraction of 0.5 showed split tensile strength of 2.12 MPa, which is above the projected range of 0.78 to 1.57 MPa. Meanwhile, split tensile strength of concrete with the addition of polypropylene fibers at a volume fraction of 0.7 is 1.41 MPa, exceeding the range of 0.59 to 1.18 MPa. The addition of polypropylene fibers to lightweight concrete results in a decrease in compressive strength, albeit not significantly. Split tensile strength of lightweight concrete increases due to the addition of polypropylene fibers. The measured values for each variant surpass the theoretical tensile strength of normal concrete.

Table 1

|

Table 1 Relationship Between Compressive and Tensile Strength in Concrete |

||||

|

Fibers Fraction (kg/m3) |

Compressive Strength (MPa) |

Spilt Tensile Strength (MPa) |

Tensile Strength (MPa) |

|

|

|

|

|

0.1fct |

0.2fct |

|

0.0 |

5.00 |

1.49 |

0.50 |

1.00 |

|

0.1 |

6.47 |

1.72 |

0.65 |

1.29 |

|

0.3 |

6.67 |

1.79 |

0.67 |

1.33 |

|

0.5 |

7.84 |

2.12 |

0.78 |

1.57 |

|

0.7 |

5.88 |

1.41 |

0.59 |

1.18 |

Figure 7

|

Figure 7 Graph of the Relationship Between Compressive and Split Tensile Strength |

4. RESULTS AND ANALYSIS

In conclusion, the analysis of the experimental results and data showed that the volume weight of the obtained concrete ranged between 1129 kg/m3 and 1505 kg/m3. Therefore, it was classified as lightweight concrete. The workability of lightweight concrete decreased as the volume fraction of polypropylene fibers in the mixture increased. The optimal compressive and split tensile strength of lightweight concrete occurred at a volume fraction of 0.5 kg/m3, with values of 7.84 MPa and 2.12 MPa, respectively. These values represented an increase of 56.68% and 42.86% compared to compressive and split tensile strength of fibers-less concrete. The relationship between compressive and split tensile strength of polypropylene fibers-reinforced lightweight concrete exceeded that of the normal type.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

The authors are grateful to the Research and Community Service Institute of Khairun University for funding this study through the Higher Education Superior Competitive Research (PKUPT) Grant for the Graduate Program level in 2023.

REFERENCES

ACI 213R. (2014). Guide for Structural Lightweight Agregate Concrete. In ACI Committee Report. https://doi.org/10.14359/7576

ACI 318-02. (2014). Building Code Requirements For Structural Concrete.

Ahmed, S., Bukhari, I. A., Siddiqui, J. I., & Qureshi, S. A. (2006). A Study on Properties of Polypropylene Fiber Reinforced Concrete. 31st Conference on Our World in Concrete and Structures, 1–10.

Annamaneni, K. K., & Pedarla, K. (2023). Compressive and Flexural Behavior of Glass Fiber-Reinforced Concrete. Journal of Physics: Conference Series, 2423(1), 1–9. https://doi.org/10.1088/1742-6596/2423/1/012025

Bindu, H. M., Geethika, P., Kumari, P. B., & Kumar, M. A. (2022). A Review on Lightweight Aggregate Concrete. Journal of Architecture and Civil Engineering, 7(11), 34–41.

Biradar, S. V, Dileep, M. S., & Gowri, V. T. (2020). Studies of Concrete Mechanical Properties with Basalt Fibers. IOP Conference Series: Materials Science and Engineering, 1006(1), 1–8. https://doi.org/10.1088/1757-899X/1006/1/012031

Clarke, J. L. (2005). Structural Lightweight Aggregate Concrete (J. L. Clarke, Ed., First). Blackie Academic & Prefessional.

Gaus, A., Sultan, M. A., Hakim, R., & Rauf, I. (2022). Effects of Using Pumice Sand as A Partial Replacement of Fine Aggregate in Lightweight Concrete Mixtures. International Journal of Entrepreneurship and Business Development, 5(4), 660–666. https://doi.org/10.29138/ijebd.v5i4.1882

Geremew, A., Winne, P. De, Demissie, T. A., & Backer, H. De. (2021). Treatment of Natural Fiber for Application in Concrete Pavement. Advances in Civil Engineering, 2021, 1–13. https://doi.org/10.1155/2021/6667965

Gupt, R., & Dulawat, S. (2020). Effect of Polypropylene Fiber for Cement Concrete Based on Rigid Pavement. Journal of Xidian University, 14(4), 2339–2346. https://doi.org/10.37896/jxu14.4/259

Hasan, A. H., Maroof, N. R., & Ibrahim, Y. A. (2019). Effects of Polypropylene Fiber Content on Strength and Workability Properties of Concrete. Polytechnic Journal, 9(1), 7–12. https://doi.org/10.25156/ptj.v9n1y2019.pp7-12

Idi, M. A., Abdulazeez, A. S., Usman, S. A., & Justin, T. (2020). Strength Properties of Concrete Using Pumice Aggregate As Partial Replacement of Coarse Aggregate. International Journal of Engineering Applied Sciences and Technology, 04(11), 519–525. https://doi.org/10.33564/ijeast.2020.v04i11.092

Kabay, N., & Aköz, F. (2012). Effect of Prewetting Methods on Some Fresh and Hardened Properties of Concrete with Pumice Aggregate. Cement and Concrete Composites, 34(4), 503–507. https://doi.org/10.1016/j.cemconcomp.2011.11.022

Khan, M., & Ali, M. (2019). Improvement in Concrete Behavior with Fly Ash, Silica-Fume and Coconut Fibres. Construction and Building Materials, 203, 174–187. https://doi.org/10.1016/j.conbuildmat.2019.01.103

Liu, L., Orense, R. P., & Pender, M. J. (2015). Crushing-Induced Liquefaction Characteristics of Pumice Sand. 2015 NZSEE Conference, 522–528.

Manzoor, M. M., Gupta, A., Gani, R., & Tanta, A. (2018). Floating Concrete by Using Light Weight Aggregates (Pumice Stones) and Air Entraining Agent. International Journal of Scientific Development and Research, 3(6), 99–104.

Muralitharan, R. S., & Ramasamy, V. (2015). Basic Properties of Pumice Aggregate. International Journal of Earth Sciences and Engineering, 8(4), 1845–1852.

Mushtaq Khan, M., & Sachar, A. (2022). Experimental Study on Light Weight Concrete by Partial Replacement of Cement by Flyash, Coarse Aggregate Pumice Stone and Thermocol Beads. International Journal of Innovative Research in Computer Science & Technology, 10(3), 114–119. https://doi.org/10.55524/ijircst.2022.10.3.19

Nawy, E. G. (2005). Reinforced Concrete: A Fundamental Approach (W. J. Hall, Ed.; 5th Ed., Vol. 5).

Nkomo, N. Z., Masu, L. M., & Nziu, P. K. (2022). Effects of Polyethylene Terephthalate Fibre Reinforcement on Mechanical Properties of Concrete. Advances in Materials Science and Engineering, 2022, 1–9. https://doi.org/10.1155/2022/4899298

Numan, N., Gaus, A., & Sultan, M. A. (2021). Comparison of Compressive Strength Value of Concrete Using Pumice Sand with Ordinary Sand as Fine Aggregate. E3S Web of Conferences, 328, 1–4. https://doi.org/10.1051/e3sconf/202132810017

Rashad, A. M. (2019). A Short Manual on Natural Pumice as a Lightweight Aggregate. Journal of Building Engineering, 25, 1–10. https://doi.org/10.1016/j.jobe.2019.100802

Sultan, M. A., Gaus, A., Hakim, R., & Imran, I. (2021). Review of the Flexural Strength of Lightweight Concrete Beam Using Pumice Stone as of Substitution. International Journal of GEOMATE, 21(85), 154–159.

Sultan, M. A., Kusnadi, K., & Adingku, J. (2022). Determination of Geopolymer Mortar Characterization Using Fly Ash and Pumice Sand. International Journal of GEOMATE, 23(100). https://doi.org/10.21660/2022.100.3630

Suseno, H., Wijaya, M. N., & Firdausy, A. I. (2021). Correlation Between Destructive and Non-destructive Characteristics of Pumice and Scoria Lightweight Concretes. Engineering Journal, 25(8), 113–126. https://doi.org/10.4186/ej.2021.25.8.113

Wang, J., Li, M., Chen, J., Zhao, Z., Zhao, H., Zhang, L., & Ren, J. (2023). Investigation on Shrinkage Characteristics of Polyester-Fiber-Reinforced Cement-Stabilized Concrete Considering Fiber Length and Content. Buildings, 13(4), 1–15. https://doi.org/10.3390/buildings13041027

Zhang, P., & Li, Q. F. (2013). Effect Of Polypropylene Fiber On Durability Of Concrete Composite Containing Fly Ash And Silica Fume. Composites Part B: Engineering, 45(1), 1587–1594. https://doi.org/10.1016/j.compositesb.2012.10.006

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© Granthaalayah 2014-2024. All Rights Reserved.