EFFECT OF CALCINATION TEMPERATURE VARIATION ON GREEN SYNTHESIS OF CADMIUM SULFIDE FOR CIPROFLOXACIN PHOTODEGRADATION

Aminatul Haq Faizah 1, Gunawan 1 ![]()

![]() ,

Khabibi 1, Roni Adi Wijaya 1

,

Khabibi 1, Roni Adi Wijaya 1

1 Department

of Chemistry, Diponegoro University, Semarang, 50275, Indonesia

|

|

ABSTRACT |

||

|

The green

synthesis method has been successfully carried out to CdS with tea leaf

extract and calcination temperature variation for the application of

photocatalytic degradation of ciprofloxacin antibiotic. Variations in

calcination at temperatures of 500, 600, and 700 ℃ were carried out to

determine the effect of temperature on morphology and elemental composition,

crystal structure and size, functional groups, and band gap energy by

SEM-EDX, XRD, FTIR, and UV-DRS Spectrophotometer. The SEM-EDX image of the

synthesized CdS is smooth and spherical and there is agglomeration with an

even distribution of elements. The results of XRD and FTIR characterization

showed the CdS peaks. The size of the CdS crystal increased with increasing

temperature, namely CdS-600 at 64 nm and CdS-700 at 81.58 nm. The band gap

energy value is influenced by the calcination temperature during synthesis

with the band gap energy values of CdS-600 2.3 eV and CdS-700 2.38 eV. The

percentage of CdS effectiveness with variations in calcination temperature in

ciprofloxacin photodegradation is CdS-500 at 32.18%, CdS-600 at 48.72%, and

CdS-700 at 8.73%. The optimum condition of CdS synthesis in degrading

ciprofloxacin by photocatalytic process occurs at a temperature of 600℃

with a photocatalytic irradiation time under visible light for 120 minutes, a

CdS mass of 10 mg, and an initial concentration of ciprofloxacin of 25 ppm.

This result demonstrates the potential of an environmentally friendly method

that can be applied in wastewater treatment. |

|||

|

Received 22 April

2024 Accepted 27 May 2024 Published 30 June 2024 Corresponding Author Gunawan, gunawan@live.undip.ac.id DOI 10.29121/granthaalayah.v12.i6.2024.5681 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2024 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Cadmium Sulfide, Green Synthesis,

Calcination, Photocatalytic, Ciprofloxacin |

|||

1. INTRODUCTION

Ciprofloxacin (CIP) is a third-generation fluoroquinolone antibiotic, which is widely used to treat bacterial infections due to its broad spectrum of antibacterial activity (i.e., it can inhibit both gram-negative and gram-positive bacteria). On the other hand, excessive use of CIP can pose a serious threat to the ecosystem such as antibiotic resistance Kelly & Brooks (2018), Mathur et al. (2021). Consumption of water contaminated by ciprofloxacin in the environment can cause health problems such as vomiting, headaches, diarrhoea, skin disorders, and the immune system Gunawan et al. (2023), Shehu Imam et al. (2018). Organic contamination in waters originating from the pharmaceutical industry often contains toxic pollutants with low biodegradability Barra Caracciolo et al. (2015), Chopra & Kumar (2017), Dsikowitzky & Schwarzbauer (2014), so an efficient method is needed to overcome this problem.

Various methods are carried out to overcome organic pollutants in waters such as bioremediation and coagulation-flocculation followed by the activated sludge biological process Kumar et al. (2023), Majumder et al. (2014). This method still has shortcomings compared to photocatalytic. The semiconductor photocatalytic method is considered one of the promising methods for CIP degradation in water because it is environmentally friendly, has low energy consumption, low cost, and has no secondary pollutants Zhao et al. (2021), Zhao et al. (2021). Another advantage is that the photocatalytic reaction is a non-specific reaction, meaning it can destroy organic compounds widely ranging from alkanes, alkenes, alcohols, phenols, carboxylic acids, aromatic compounds, dyes, pesticides, to surfactants. In addition, photocatalysis can degrade organic compounds because it has a very strong oxidation power Akerdi & Bahrami (2019).

The photocatalytic activity comes from a hydroxyl radical resulting from an electron-hole pair (e-/h+), an electron-hole pair e-/h+ is produced when the photon energy exceeds the band gap value, electrons (e-) then settle in the conduction band (CB) after leaving their place in the valence band (VB) producing holes (h+) in the valence band Gunawan et al. (2023), Verma & Singh (2023). Photocatalytic activity depends on semiconductor characteristics, where the photocatalytic properties can be modified through the techniques and methods used for synthesis to control particle size and shape.

Cadmium sulfide (CdS) is a semiconductor compound with a band gap of 2.4 eV which is suitable and excellent in photocatalytic activity due to its visible light absorption feature. The photocatalytic activity of CdS is influenced by the synthesis conditions, structure, morphology, particle size, surface area, and crystallinity Lang et al. (2014). CdS displays efficient visible light absorption at wavelengths up to 530 nm Shen et al. (2013). CdS is easy to synthesize, one of which is by the green synthesis method.

The synthesis of cadmium sulfide by the green synthesis method is now starting to be developed because it is cost-effective, harmless, and environmentally friendly. Several biological entities that can play a role in the green synthesis method to produce nanoparticles include algae, fungi, microbes, actinomycetes, and plant extracts. Each of these agents has its advantages. Compared to other agents, tea extract used as a component in green synthesis acts as a complexing agent that regulates the size of cadmium sulfide in the form of more stable nanoparticles Shivaji et al. (2018).

Efforts to increase the photocatalytic effectiveness of semiconductors can be calcined to increase light absorption and charge separation processes during the reaction. Increasing the calcination temperature will affect the increase in crystal size. In addition, heating with high temperature can also affect the band gap energy so that it can increase photocatalytic activity Asadah et al. (2022). Therefore, in this study, the synthesis of green semiconductor CdS with tea leaf extract with calcination temperature variation was carried out for the application of photocatalytic degradation of ciprofloxacin antibiotic. Calcination variations at 500, 600, and 700 °C were carried out to determine the effect of temperature on crystal size, crystallinity, and band gap energy. Morphology and elemental composition, crystal structure and size, functional groups, and band gap energy of the synthesized CdS were characterized by SEM-EDX, XRD, FTIR, and UV-DRS spectrophotometer. The results of this study are expected to provide new insights into developing more efficient and environmentally friendly photocatalysts for wastewater treatment applications.

2. EXPERIMENTS

2.1. MATERIALS AND INSTRUMENTS

Trade tea powder, Cadmium sulfate octahydrate (3CdSO4.8H2O) (Merck), sodium sulfide (Na2S) (Loba Chemie), methanol (Merck), deionized water (Waterone), acetone, distilled water, ciprofloxacin (Sigma Aldrich). The instruments used are glassware (Herma), filter paper (Whatman no.42 ), 1 mL volume pipette (Iwaki), analytical balance (Ohaus, Model PA323), oven, furnace (Nabertherm), hotplate (Thermo Scientific Cimarec), centrifuge (Hettich Zentrifugen), photocatalytic reactor with visible light (Vaco IP 66, 200 W), UV-Vis spectrophotometer (Shimadzu UV-1280), UV-DRS spectrophotometer (Shimadzu UV-2450), Scanning Electron Microscope (JSM-6510LA), Energy Dispersion X-Ray Spectroscopy (JED-2300 Analysis Station Plus), X-Ray Diffraction (Shimadzu 7000), and FTIR Spectrophotometer (PerkinElmer Frontier).

2.2. Green synthesis of Cadmium sulfide

The synthesis was carried out by dissolving 3.848 grams of 3CdSO4.8H2O and 0.39 grams of Na2S each in a 10 mL volumetric flask using distilled water to obtain a solution of 0.5 M CdSO4 and 0.5 M Na2S. The solution was stored in vials for further use. 0.5 grams of tea powder was mixed in 30 mL of methanol and left in the dark for 1 day, after 1 day filtering was done to separate the tea precipitate from the solution. The extract was added to 2 mL of 0.5 M CdSO4 solution and left in the dark for 3 days, followed by the addition of 0.5 mL of 0.5 M Na2S solution and left in the dark for 4 days. The precipitate was washed with deionized water and centrifuged at 6000 rpm for 10 minutes then dried on a hotplate at 70℃.

2.3. Determination of temperature Calcination variation

The calcination process was carried out at temperature variations of 500, 600, and 700 °C for 2 hours each, which were then named CdS-500; CdS-600; and CdS-700. The process started by putting the samples into a vacuum furnace instrument at a constant time for 60 minutes.

2.4. Characterization

The synthesized CdS samples were characterized using a Scanning Electron Microscope-Energy Dispersive X-ray (SEM-EDX) instrument to determine the morphology and elemental composition. Meanwhile, X-ray diffraction (XRD) to determine the crystal structure and a UV-DRS Spectrophotometer to determine the band gap. In addition, the difference in functional groups of CdS was observed by Fourier Transform Infrared (FTIR).

2.5. Photocatalytic test

Photodegradation applications were carried out with 100 mL of 25 ppm ciprofloxacin solution added with 10 mg of CdS semiconductor catalyst and mixed in dark conditions for 1 hour to achieve adsorption-desorption equilibrium. It was illuminated with visible light and stirred with a magnetic stirrer at time intervals of 15; 30; 45; 60; 75; 90; 105; and 120 minutes. The solution was centrifuged at 5000 rpm for 5 minutes before measuring the absorbance of ciprofloxacin solution after photocatalytic with UV-Vis spectrophotometer at 319 nm wavelength.

3. RESULT AND DISCUSSION

3.1. Green synthesis of CdS

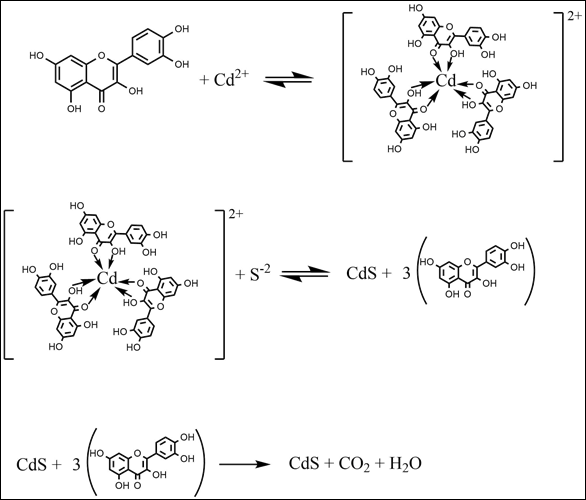

The synthesis of green CdS was carried out using tea leaves that had previously been tested for flavonoids with the results in 0.01 g of tea containing 0.41% flavonoid quercetin. Predicted reactions that occur in the mechanism of green cadmium sulfide synthesis are described in Figure 1. Phytochemical screening is carried out first to determine the presence or absence of alkaloids, flavonoids, phenols, tannins, quinones, saponins, etc. Quercetin can chelate metal ions (Cd2+) to form metal complexes Dolatabadi (2011). The cadmium complex with quercetin is formed by the way quercetin acts as a capping agent which then can also protect Cd from bulk and against aggregation so that when the addition of S-2 ions from Na2S can form nano-sized CdS crystals Zhou et al. (2014).

Figure 1

|

Figure 1 CdS Formation Reaction by Green Synthesis Method |

3.2. CHARACTERIZATION

3.2.1. MORPHOLOGY AND ELEMENTAL COMPOSITION

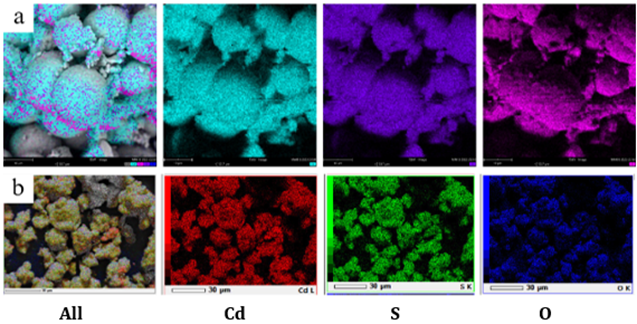

The semiconductor catalysts that were characterized

were CdS powder calcined at 600 ℃ and 700 ℃ while SEM images at

1000x, 5000x, 7500x, and 10000x magnifications are given in Figure 2. Based on the SEM

characterization results of the CdS-600 sample at 5000x magnification, it can be seen that the morphology of the particles is

smooth and round and there is agglomeration. The CdS-700 sample SEM

characterization results at 1000x magnification showed a less smooth spherical

change with non-uniform size and agglomeration. The spherical morphology and

small particle size are expected that the synthesized cadmium sulfide has good

photocatalytic activity. In the case of biogenic synthesis based on plant

extracts, nanoparticles are generally formed that are very stable and

homogeneous in shape Shivaji et al. (2018). In addition, Figure 3 is the result of mapping or

elemental distribution of samples tested with the different colouring of each

element. Both CdS-600 and CdS-700 samples have an even distribution of

elements.

Figure 2

|

Figure 2 SEM Morphology of a) CdS-600 b) CdS-700 |

Figure 3

|

Figure 3 Surface Metal Mapping of a) CdS-600 b) CdS-700 |

The

EDX analyzer results of both samples prove that there are elements of the

constituent elements of cadmium sulfide, namely Cd and S, so it can be

concluded that cadmium sulfide has been synthesized properly as shown in Table 1. The CdS-600 sample contained

the element C which was thought to come from the carbon tab used to attach the

sample during EDX testing. The O element that appears with a large enough

percentage is caused by air during the calcination process. The presence of

additional oxygen peaks in the EDX spectra may come from the organic capping

material i.e. tea extract bound to the surface. Another possibility for the

presence of elemental oxygen is due to calcination occurring in atmosphere

conditions. Shivaji et al. (2018).

Table 1

|

Table 1 Shows the Atomic Element Content on the Surface of Each CdS Sample |

||

|

Sample |

Element |

Weight Concentration (%) |

|

CdS 600 |

Cd |

48,18 |

|

O |

38,23 |

|

|

S |

9,47 |

|

|

C |

4,13 |

|

|

|

Cd |

44,41 |

|

CdS 700 |

S |

11,53 |

|

|

O |

44,06 |

3.2.2. CRYSTALLINITY ANALYSIS

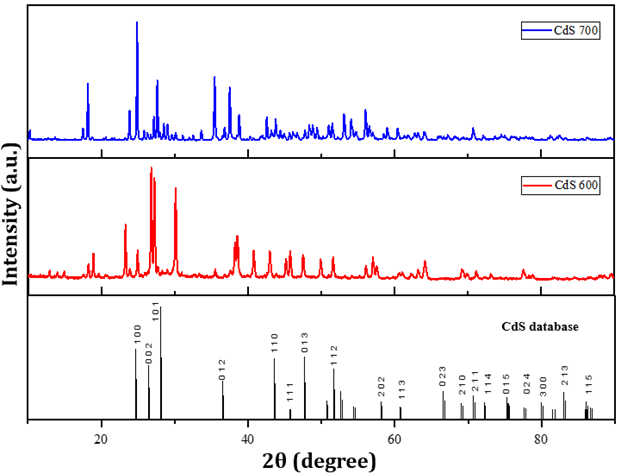

To examine the crystal size

and phase structure, XRD testing of CdS nanoparticle structures prepared by

green synthesis at different temperatures was carried out. The test was

conducted using Kα radiation from a copper anode (Cu- Kα) with a wavelength

of 0.154 nm and recorded at a diffraction angle of 2θ between 10-90°. The

diffractogram of the measurement results in the form of diffraction peaks with

a certain intensity was then compared with the standard data obtained from

Crystallography Open Database (COD) No. 1011054 shown in Figure 4.

Figure 4

|

Figure 4 XRD Spectrum CdS-600 dan CdS-700 |

The XRD pattern results of

the measured samples show that cadmium sulphide (CdS) has been formed which is

characterised by the formation of diffraction peaks with high intensity, this

proves that the crystallinity of the synthesised CdS sample is quite good Asadah et al. (2022). Diffractogram peaks with the highest

intensity of CdS-600 and CdS-700 samples are shown in Table 2. The peak intensity of the diffractogram

increases with increasing synthesis temperature, The increase in the intensity

of various peaks indicates better crystallinity which leads to a decrease in

the strain value and dislocation density Chauhan (2020). The synthesised CdS has a crystal phase with

a p-63mc space group, which is hexagonal. To maintain excellent optoelectronic

properties, CdS must remain in the hexagonal wurtzite structure Xiao et al. (2014). The crystal size was calculated based on the Full Width at

Half Maximum (FWHM) values at various peaks with the Debye-Scherrer equation

(1) Gunawan et al. (2022).

![]() (1)

(1)

Where

G is the crystal size, k = 0.9 is the formation factor, λ is the

wavelength of the CuKα line, D is the FWHM in radians, and θ is the

Bragg angle.

The

crystal size increases with increasing synthesis temperature, the crystal size

of CdS-600 is 64 nm to CdS-700 of 81.58 nm and it can be concluded that the

synthesized CdS includes nanoparticles. Crystal grains undergo a growth process

when CdS is calcined. If the temperature used is a temperature that exceeds the

optimum temperature, the crystals will be larger. If the temperature used is

below the optimum temperature, it is possible that the expected crystals have

not formed or even formed but are not pure Aprilianingrum (2016). The higher calcination

temperature causes the crystal size and per cent crystallinity to be greater.

This is because high temperatures make particles move more reactive and faster

than low temperatures and result in agglomeration Asadah

et al. (2022).

Table 2

|

Table 2 XRD Result Analysis of CdS-600 and CdS-700 |

|||

|

Sample |

2 |

h k l |

d

(nm) |

|

24,95 |

(1 0 0) |

43,74 |

|

|

26,44 |

(0 0 2) |

40,23 |

|

|

CdS-600 |

28,28 |

(1 0 1) |

64,00 |

|

45,79 |

(1 1 1) |

39,02 |

|

|

47,53 |

(0 1 3) |

38,58 |

|

|

51,62 |

(1 1 2) |

37,87 |

|

|

24,88 |

(1 0 0) |

81,35 |

|

|

26,29 |

(0 0 2) |

81,58 |

|

|

CdS-700 |

27,99 |

(1 0 1) |

48,16 |

|

43,47 |

(1 1 0) |

37,84 |

|

|

47,79 |

(0 1 3) |

77,66 |

|

|

51,51 |

(1 1 2) |

66,31 |

|

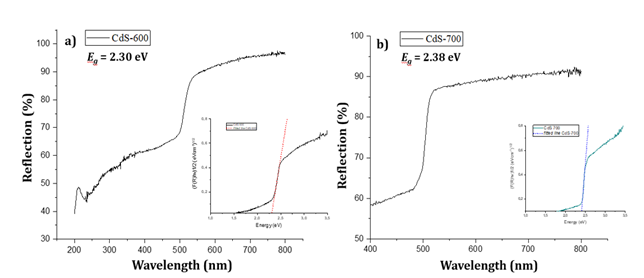

3.2.3. BAND GAP DETERMINATION

Determination

of the band gap of each CdS sample that has been synthesized is done by UV-DRS

characterization, where data will be obtained in the form of absorbance,

reflectance, and wavelength. Band gap calculation can use the tauc plot method

and the absorbance edge method. Cadmium sulfide is a semiconductor so the

calculation of the tauc plot method is done by extrapolating from the graph of

the relationship between transmittance (αhv2) to band gap

energy (eV) then forming a straight line to the x-axis (hv) Asadah et al. (2022). The band gap energy graph is

shown in Figure 5.

Figure 5

|

Figure 5 UV-DRS Result Graph of Tauc Plot Method a) CdS-600 and b) CdS-700 |

Figure 5 shows that the calcination

temperature during synthesis affects the band gap energy. The band gap value of

CdS-600 is 2.30 eV while the CdS-700 band gap energy is 2.38 eV. Crystal

formation is accelerated by the calcination temperature, which allows agglomeration

to occur. The shift in absorption can be affected by agglomeration which causes

a change in the Eg (band gap energy) value Asadah et al. (2022). The smaller the band gap, the

lower the energy required to excite electrons. As a result, the light

adsorption of the sample is greater. Increased light adsorption offers better

opportunities for photocatalytic applications Asadah et al. (2022).

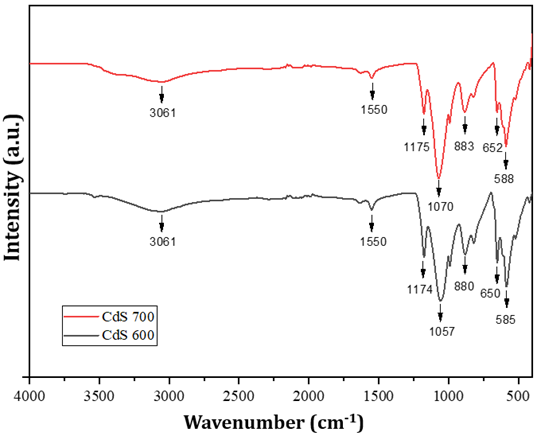

3.2.4. FUNCTIONAL GROUP ANALYSIS

The

peak spectra for the two cadmium sulfide samples, CdS-600 and CdS-700, did not

show significant peak shifts, proving that the change in calcination

temperature did not affect the functional groups. The absorption peak at 3061

cm-1 corresponds to the stretching vibration of hydroxyl group (O-H)

adsorbed on the catalyst surface. The absorption peak at 1550 cm-1

indicates the presence of C=O asymmetry stretching vibration. Peaks at 1174 cm-1;

1175 cm-1; 1070 cm-1; and 1057 cm-1 are

related to C=S stretching vibrations derived from sulfide compounds and C-O Kumar & Sharma (2016). Other absorption peaks at 880

cm-1 and 883 cm-1 are out-of-plane bending vibrations of

O-H from H2O molecules Kumar & Sharma (2016). Typical absorption peaks of

Cd-S bond stretching vibrations were observed at peaks below 700 cm-1

namely 585, 588, 650, and 652 cm-1 Munyai et al. (2021), Bakhsh & Khan (2022). These results indicate that

tea leaf extract has a good effect in stabilizing CdS nanoparticles.

Figure 6

|

Figure 6 FTIR Spectrum CdS-600 (Black Line) and CdS-700 (Red Line) |

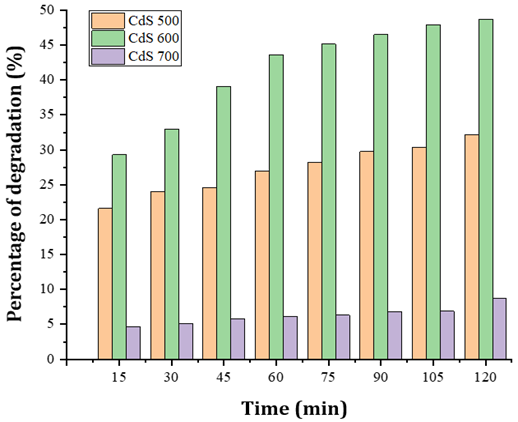

3.3. Application of CdS for ciprofloxacin photodegradation

The

photocatalytic degradation in Figure 7 shows that the variation of

calcination temperature in the synthesis of cadmium sulfide affects the

photocatalytic quality. The three variations of CdS show that the longer the

irradiation time of the photocatalyst, the higher the percentage of degradation.

This is due to the more energy the electrons get to excite to produce hydroxy

radicals. The increasing number of hydroxy radicals will increase the

bond-breaking process in organic pollutants, namely ciprofloxacin and is

characterized by a decrease in the absorbance of ciprofloxacin Kumar & Sharma (2016).

The

degradation of ciprofloxacin by CdS-500 to CdS-600 increased and decreased at

CdS-700. The decreased photocatalytic activity can be caused by precipitation

on the catalyst during photocatalysis so that there are parts of the catalyst

surface that do not absorb photons or ciprofloxacin compounds optimally.

Another possibility is that CdS-700 is affected by a decreased surface area. A

large surface area will provide more active sites that not only react with

absorbed water and hydroxyl to form oxidative hydroxyl radicals but also

organic molecules for photodegradation. Generally, the specific surface area

increases with decreasing crystal size Cheng et al. (2014) (this is supported by CdS

crystal size data by XRD).

The

best degradation percentages of each sample namely CdS-500; CdS-600; and

CdS-700 were 32.18%; 48.72%; and 8.73%, respectively. The optimum condition of

CdS synthesis in photocatalytic degradation of ciprofloxacin in this study

occurred at a temperature of 600 ℃ with a CdS mass of 10 mg, irradiation

time for 120 minutes and ciprofloxacin concentration of 25 ppm. The

photocatalytic degradation test was carried out to see how effective the

photocatalyst activity of the synthesized CdS was in degrading ciprofloxacin at

various photocatalytic times.

Figure 7

|

Figure 7 Graph of Degradation Percentage of Ciprofloxacin 25 ppm 100 mL Using CdS 10 mg for Variations of CdS-500; CdS-600; and CdS-700 Against Time. |

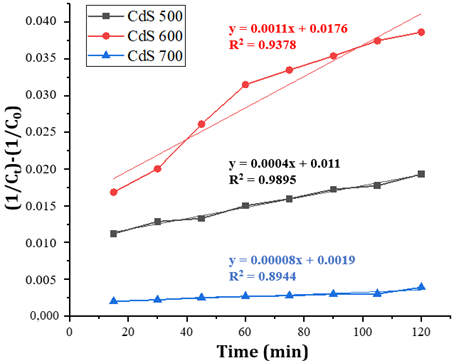

3.4. Reaction kinetics of the photocatalytic process

Pseudo reaction order is

determined by making a graph between the concentration of ciprofloxacin at time

t (Ct) against time. A pseudo-first-order reaction is a graph

between ln initial ciprofloxacin concentration (C0) divided by

ciprofloxacin concentration at time t against time. While pseudo-second order

is a graph between (1/Ct) - (1/C0) against time. From the

calculation of the reaction order, R2 data were obtained for each

CdS calcination temperature variation which followed the second-order pseudo

kinetics. The kinetics curve of ciprofloxacin degradation by cadmium sulfide at

various calcination temperatures is shown in Figure 8. Based on the figure, explains

that the rate of photocatalytic degradation of ciprofloxacin is the highest on

CdS-600. It was found that the reaction rate constants for CdS-500; CdS-600;

and CdS-700 were 4 x 10-4; 11x10-4; and 8x10-5

mg-1Lmin-1, respectively. The value of the reaction rate

constant depends on several factors, in this study is the initial concentration

of ciprofloxacin Usman et al. (2021).

Figure 8

|

Figure 8 Kinetic Curve of Ciprofloxacin Degradation |

4. CONCLUSION

Cadmium sulfide has been successfully synthesized via the green synthesis method with various calcination temperature variations for ciprofloxacin photocatalytic degradation applications. XRD and FTIR characterization results display CdS peaks. SEM-EDX image of the synthesized CdS is smooth round and there are agglomerations with an even distribution of elements. The band gap energy value is influenced by the calcination temperature obtained by CdS-600 of 2.3 eV and CdS-700 of 2.38 eV. Calcination temperature variations affect the size of CdS crystals formed and their band gap energy. Increasing the calcination temperature gives a larger crystal size but the energy of the pit gap increases due to agglomeration which results in a shift in the energy of the band gap. The effectiveness of cadmium sulfide in degrading ciprofloxacin was shown in CdS-600 with a result of 48.72%, CdS-500 at 32.18%, and CdS-700 at 8.73%. Photocatalytic optimal conditions under visible light for 120 minutes with 10 mg of CdS catalyst and an initial ciprofloxacin concentration of 25 ppm. This shows the potential of developing an environmentally friendly antibiotic waste treatment method.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

Akerdi, A. G., & Bahrami, S. H. (2019). Application of Heterogeneous Nano-Semiconductors for Photocatalytic Advanced Oxidation of Organic Compounds: A Review. Journal of Environmental Chemical Engineering, 7(5). https://doi.org/10.1016/J.JECE.2019.103283

Aprilianingrum, F. A. (2016). Optimasi Dan Regenerasi Fotokatalis Ca. Universitas Negeri Yogyakarta.

Asadah, E., Hadisantoso, E. P., Soni Setiadji, D., Kimia, J., Sains, F., Teknologi, D., Gunung, S., Bandung, D., Nasution, J. A. H., 105 A, N., Cibiru, C., & Jawa Barat, B. (2022). Pengaruh Suhu Kalsinasi Terhadap Sintesis Kadmium Sulfida (Cds) Menggunakan Metode Presipitasi untuk Penanganan Metilen Biru Secara Fotokatalisis. Gunung Djati Conference Series, 7, 60–69.

Bakhsh, E. M., & Khan, M. I. (2022). Clove Oil-Mediated Green Synthesis of Silver-Doped Cadmium Sulfide and Their Photocatalytic Degradation Activity. Inorganic Chemistry Communications, 138(November 2021). https://doi.org/10.1016/j.inoche.2022.109256

Barra Caracciolo, A., Topp, E., & Grenni, P. (2015). Pharmaceuticals in the Environment: Biodegradation and Effects on Natural Microbial Communities. A review. Journal of Pharmaceutical and Biomedical Analysis, 106, 25–36. https://doi.org/10.1016/J.JPBA.2014.11.040

Chauhan, J. K. R. P. (2020). Effect of Temperature on Properties of Cadmium Sulfide Nanostructures Synthesized by Solvothermal method. Journal of Materials Science: Materials in Electronics. https://doi.org/10.1007/s10854-019-02807-7

Cheng, H., Wang, J., Zhao, Y., & Han, X. (2014). Effect of Phase Composition, Morphology, and Specific Surface Area on the Photocatalytic Activity of TiO2 Nanomaterials. RSC Advances, 4(87), 47031–47038. https://doi.org/10.1039/C4RA05509H

Chopra, S., & Kumar, D. (2017). Ibuprofen as an Emerging Organic Contaminant in Environment, Distribution and Remediation. https://doi.org/10.1016/j.heliyon.2020.e04087

Dolatabadi, J. E. N. (2011). Molecular Aspects on the Interaction of Quercetin and its Metal Complexes with DNA. International Journal of Biological Macromolecules, 48(2), 227–233. https://doi.org/10.1016/J.IJBIOMAC.2010.11.012

Dsikowitzky, L., & Schwarzbauer, J. (2014). Industrial Organic Contaminants: Identification, Toxicity and Fate in the Environment. Environmental Chemistry Letters, 12(3), 371–386. https://doi.org/10.1007/S10311-014-0467-1/METRICS

Gunawan, Adi Wijaya, R., Suseno, A., Lusiana, R. A., Septina, W., & Harada, T. (2023). Synthesis of CuInS2 thin Film Photocathode with Variation of Sulfurization Sources and Pt-In2S3 Modification for Photoelectrochemical Water Splitting. Journal of Electroanalytical Chemistry, 945. https://doi.org/10.1016/J.JELECHEM.2023.117683

Gunawan, G., Megawati, S. G. L., Prasetya, N. B. A., & Wijaya, R. A. (2022). Synthesis, Characterization of Ag2s from AgCl Waste of Argentometry Titration with Heating Temperature Variations and Its Application as a Temperature Sensor Based on Negative Temperature Coefficient (NTC). Jurnal Kimia Sains Dan Aplikasi, 25(8), 292–299. https://doi.org/10.14710/JKSA.25.8.292-299

Gunawan, G., Prasetya, N. B. A., & Wijaya, R. A. (2023). Degradation of Ciprofloxacin (CIP) Antibiotic Waste using The Advanced Oxidation Process (AOP) Method with Ferrate (VI) from Extreme Base Electrosynthesis. Trends in Sciences, 20(7). https://doi.org/10.48048/TIS.2023.6639

Kelly, K. R., & Brooks, B. W. (2018). Global Aquatic Hazard Assessment of Ciprofloxacin: Exceedances of Antibiotic Resistance Development and Ecotoxicological Thresholds. Progress in Molecular Biology and Translational Science, 159, 59–77. https://doi.org/10.1016/BS.PMBTS.2018.07.004

Kumar, R. N., Sadaf, S., Verma, M., Chakraborty, S., Kumari, S., Polisetti, V., Kallem, P., Iqbal, J., & Banat, F. (2023). Old Landfill Leachate and Municipal Wastewater Co-Treatment by Sequencing Batch Reactor Combined with Coagulation–Flocculation Using Novel Flocculant. Sustainability (Switzerland), 15(10), 8205. https://doi.org/10.3390/SU15108205/S1

Kumar, S., & Sharma, J. K. (2016). Stable Phase CdS Nanoparticles for Optoelectronics: A Study On Surface Morphology, Structural and Optical Characterization. Materials Science- Poland, 34(2), 368–373. https://doi.org/10.1515/MSP-2016-0033

Lang, D., Xiang, Q., Qiu, G., Feng, X., & Liu, F. (2014). Effects of Crystalline Phase and Morphology on the Visible Light Photocatalytic H2-Production Activity of CdS Nanocrystals. Dalton Transactions, 43(19), 7245–7253. https://doi.org/10.1039/C3DT53601G

Majumder, S., Gupta, S., & Raghuvanshi, S. (2014). Removal of Dissolved Metals by Bioremediation. Heavy Metals in Water, 44–56. https://doi.org/10.1039/9781782620174-00044

Mathur, P., Sanyal, D., Callahan, D. L., Conlan, X. A., & Pfeffer, F. M. (2021). Treatment Technologies to Mitigate the Harmful Effects of Recalcitrant Fluoroquinolone Antibiotics on the Environment and Human Health. Environmental Pollution, 291. https://doi.org/10.1016/J.ENVPOL.2021.118233

Munyai, S., Tetana, Z. N., Mathipa, M. M., Ntsendwana, B., & Hintsho-Mbita, N. C. (2021). Green Synthesis of Cadmium Sulphide Nanoparticles for the Photodegradation of Malachite Green Dye, Sulfisoxazole and Removal of Bacteria. Optik, 247. https://doi.org/10.1016/J.IJLEO.2021.167851

Shehu Imam, S., Adnan, R., & Mohd Kaus, N. H. (2018). Photocatalytic Degradation of Ciprofloxacin in Aqueous Media: A Short Review. Toxicological & Environmental Chemistry, 100(5–7), 518–539. https://doi.org/10.1080/02772248.2018.1545128

Shen, L., Liang, S., Wu, W., Liang, R., & Wu, L. (2013). CdS-Decorated UiO–66(NH2) Nanocomposites Fabricated by a Facile Photodeposition Process: An Efficient and Stable Visible-Light-Driven Photocatalyst for Selective Oxidation of Alcohols. Journal of Materials Chemistry A, 1(37), 11473–11482. https://doi.org/10.1039/C3TA12645E

Shivaji, K., Mani, S., Ponmurugan, P., De Castro, C. S., Lloyd Davies, M., Balasubramanian, M. G., & Pitchaimuthu, S. (2018). Green-Synthesis-Derived CdS Quantum Dots Using Tea Leaf Extract: Antimicrobial, Bioimaging, and Therapeutic Applications in Lung Cancer Cells. ACS Applied Nano Materials, 1(4), 1683–1693. https://doi.org/10.1021/acsanm.8b00147

Usman, M. R., Prasasti, A., Fajriyah, S., Marita, A. W., Islamiah, S., Firdaus, A. N., Noviyanti, A. R., & Eddy, D. R. (2021). Degradation of Ciprofloxacin by Titanium Dioxide (TiO2) Nanoparticles: Optimization of Conditions, Toxicity, and Degradation Pathway. Bulletin of Chemical Reaction Engineering & Catalysis, 16(4), 752–762. https://doi.org/10.9767/bcrec.16.4.11355.752-762

Verma, V., & Singh, S. V. (2023). Augmentation of Photocatalytic Degradation of Methylene Blue Dye Using Lanthanum and Iodine Co-Doped TiO2 Nanoparticles, Their Regeneration and Reuse; and Preliminary Phytotoxicity Studies for Potential use of Treated Water. Journal of Environmental Chemical Engineering, 11(6). https://doi.org/10.1016/J.JECE.2023.111339

Xiao, J., Wen, B., Melnik, R., Kawazoe, Y., & Zhang, X. (2014). Phase Transformation of Cadmium Sulfide Under High Temperature and High Pressure Conditions. Physical Chemistry Chemical Physics, 16(28), 14899–14904. https://doi.org/10.1039/C4CP01003E

Zhao, W., Li, Y., Zhao, P., Zhang, L., Dai, B., Xu, J., Huang, H., He, Y., & Leung, D. Y. C. (2021). Novel Z-Scheme Ag-C3N4/SnS2 Plasmonic Heterojunction Photocatalyst for Degradation of Tetracycline and H2 Production. Chemical Engineering Journal, 405, 126555. https://doi.org/10.1016/J.CEJ.2020.126555

Zhao, Y., Li, Y., & Sun, L. (2021). Recent Advances in Photocatalytic Decomposition of Water and Pollutants for Sustainable Application. Chemosphere, 276. https://doi.org/10.1016/J.CHEMOSPHERE.2021.130201

Zhou, G. J., Li, S. H., Zhang, Y. C., & Fu, Y. Z. (2014). Biosynthesis of CdS Nanoparticles in Banana Peel Extract. Journal of Nanoscience and Nanotechnology, 14(6), 4437–4442. https://doi.org/10.1166/JNN.2014.8259

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© Granthaalayah 2014-2024. All Rights Reserved.