Traditional cheese produced in Fogo Island - Cape Verde: Physico-chemical, Sensory, Hygienic and Safety Characteristics

Wilson Paulo Semedo Tavares 1![]()

![]() ,

Simone Da Cruz Andrade 2

,

Simone Da Cruz Andrade 2![]()

![]() ,

Beatriz Monteiro da Silveira 3

,

Beatriz Monteiro da Silveira 3![]()

![]()

1 College

of Science and Technology, University of Cabo Verde, Campus of Palmarejo Grande, Praia, Santiago Island, Cabo Verde

2 Faculty

of Pharmacy, University of Lisbon, Av. Prof. Gama Pinto, 1649-003 Lisbon,

Portugal

3 School of Agriculture, University of Lisbon, Tapada

da Ajuda, 1349-017 Lisbon, Portugal

|

|

ABSTRACT |

||

|

Cheese is a nutritionally

rich product, distinguished by its unique sensorial qualities. Processing

technology for cheeses in different countries is still handmade, thus, the

microbial community structure is complex and the

cheese flavour fluctuates wildly. Therefore, this

study aimed to investigate the sensory acceptance, microbiological and

physical-chemical properties of traditional cheese produced in Fogo Island –

Cape Verde. Coalho cheese is the most produced and

consumed cheese in Cape Verde and is frequently made according to traditional

or artisanal procedures. Regarding to

physical-chemical analyses, parameters such as fat, moisture, pH, titratable

acidity, protein, and ash were studied. Microbiological parameters such as Escherichia

coli, Listeria monocytogenes, salmonella and coliforms were

studied. A Sensory acceptance test was carried out by 23 panellists,

where all evaluated attributes obtained an acceptability index greater than

70%. According to the Cape Verdean standard for cheese, the cheeses were

classified as fresh and low-fat cheese. Regarding moisture content, the

obtained results allow to classify cheese A as

semi-soft cheese and B and C as soft cheese. Concerning pH and titratable

acidity, the values ranged from 5.68 to 6.19 and 6.4 to 11.1 mLNaOH1N/100g,

respectively. Salmonella and L.

monocytogenes were not detected, E. Coli was lower than the

maximum accepted value established by Commission Regulation (EC) No

2073/2005 and Commission Regulation (EC) No 1441/2007. In

contrast, faecal coliforms in cheeses B and C were

higher than those established by the Commission Regulation (EC). Overall, the

results from this study may contribute to improving the production process

and quality control of coalho cheese. |

|||

|

Received 28 January 2024 Accepted 29 February 2024 Published 14 March 2024 Corresponding Author Wilson

Paulo Semedo Tavares, wilson.tavares@docente.unicv.edu.cv DOI 10.29121/granthaalayah.v12.i2.2024.5497 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2024 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Coalho Cheese,

Quality, Centesimal Composition, E. Coli, Salmonella |

|||

1. INTRODUCTION

The archipelago of Cabo Verde is located on the west coast of Africa, which it consists of ten islands clustered in two groups: the Barlavento group (comprising the islands of Santo Antão, São Vicente, Santa Luzia, São Nicolau, Sal, and Boavista) and the Sotavento group (comprising the islands of Maio, Santiago, Fogo, and Brava).

In Cape Verde, there is a great tradition related to the production and consumption of fresh cheese, mainly goat's milk cheese, and this activity is possibly inherited from colonial ancestors Santos (2015). Cheese production in Cape Verde is an essential dairy production sector, especially on the islands with the highest livestock expression, such as Santo Antão, Fogo, Boavista, Santiago and Maio. The specific flavour and pleasant aroma of fresh goat cheeses have made it a well-known and highly sought-after product in the national and tourist market Jurisic & David (2020).

Cheese is an ancient traditional fresh or fermented dairy product with a very long history of production and high nutritional value Zheng et al. (2021). Fresh goat cheese is an artisanal cheese produced in Fogo Island (Cape Verde), and it´s made according to traditional manufacturing practices. Cheese is defined by Norma Cabo Verdiana (NCV). (2015) as a fresh or cured product of varying consistency, by draining after coagulation of the whole or partially skimmed milk, and also of the buttermilk cream, as well as the mixture of some or all of these products, including whey, without or with the addition of optional ingredients other. According to Tunick & Van Hekken (2010), fresh cheese usually has the following characteristics: moisture content from 46% to 57%, fat content from 20% to 29%, protein content from 15% to 21%, salt content from 1 to 3% and pH from 5.3 to 6.5.

In general, cheese is a fermented milk product resulting from the fermentation of milk by yeasts, with the primary purpose of preserving the milk constituents by reducing the water activity, low pH, NaCl, and low temperature. Cheese is an enriched source of milk proteins, fat, minerals, and vitamins Bansal & Mishra (2020). The hydrolysis of milk proteins during cheese production makes proteins in the cheese 100% digestible. The protein breakdown is exhibited by producing bioactive peptides that have therapeutic value and can exert a hormone-like regulatory effect in the human body O'Brien & O'Connor (2004), Santiago-López et al. (2018). Due to food-borne illnesses, especially illnesses associated with drinking raw milk contaminated with pathogenic microorganisms, many countries require the pasteurization of milk. Pasteurization is essential for preventing microbial growth and improving cheese quality Johnson (2017) . Nowadays, food quality and safety are consumer's first concerns Severová et al. (2021). The specific hygiene rules applied to the production of raw milk can be accessed at Regulation (EC) N° 853/2004 of the European Parliament and of the Council, of April 29, 2004.

In Cape Verde, cheese making is a vital dairy farming, especially on the islands with the highest livestock activity, namely Santo Antão, Boavista, Maio, Santiago, and Fogo. The Cape Verdean coalho cheeses are produced under modest manufacturing conditions, as simple technology allows. The specific flavour and pleasant aroma of fresh goat's cheese have made it a well-known and highly sought-after product on the national and tourist markets. In some regions, we also found cheese produced from cow's milk or a mixture of goat and cow's milk.

The purpose of this study was to characterize goat cheese produced in Fogo Island (Cape Verde), regarding microbiological, sensory, and physicochemical properties and evaluate their acceptability. The results from the present study would be helpful for cheese-making industries in Cape Verde, the protection and preservation of cheese-making traditions, and provide a better understanding of cheese production on this island.

2. Material and methods

2.1. Sampling

The goat cheeses analysed in this study were produced at Fogo Island in February 2022. For the chemical, sensory, and microbiological analyses, 30 cheeses were used, and identified as Cheese A, B, and C. The cheeses A and B (10 each) were obtained from two different semi-artisanal cheese factories, and the sample C (10 cheeses) was obtained by local producers (homemade production). All samples were obtained directly from the producers, just before being sent to retail markets. After being sampled, the cheeses were transported to the laboratory using an icebox and then stored at 5°C, similar to the conditions used in retail stores. Half of the cheeses were prepared for sensory analysis, and the other half for physical, physicochemical, and microbiological analysis. Microbiological and physico-chemical experiments were carried out in the InLab laboratory – Cabo Verde. Sensory and physical analysis were conducted in the Chemistry laboratory at the University of Cape Verde. The photograph and main points of the making process of the studied cheeses are shown in Table 1.

Table 1

|

Table 1 Photography and Key Points in the Cheese Making Processes |

||

|

Samples |

Key

points of processing |

Photography |

|

Cheese

A |

Produced

using pasteurized milk; Rennet

coagulation; Curd

time in vat before draining: 35-40 min; Curd

grain at cutting: 1 - 2 cm3; Salting

in vat by adding dry salt; Moulding. Vacuum

packaging; Storage:

< 5 °C |

|

|

Cheese

B |

Produced

using pasteurized milk; Rennet

coagulation; Curd

time in vat before draining: 40 min; Curd

grain at cutting: 1 - 2 cm3; Moulding; Dry

Salting on the cheese surface; Washing. Vacuum packaging; Storage: 0-4 °C |

|

|

Cheese

C |

Produced

using non-pasteurized milk (homemade production); Traditional rennet; Cut

using a knife (horizontal and vertical lines); Salting; Moulding; Washing. |

|

2.2. Physical Parameters

A digital Vernier calliper (POWERFIX Profi, Z22855) was used to determine the height and diameter and a digital balance (KERN, 440-55) was used to weigh the samples. The height and diameter were expressed in cm and the weight in grams.

2.3. Sensory Analysis

The descriptive quantitative sensory analysis was carried out by a group of twenty-three panellists (frequent consumers of fresh cheese), including teachers and students from the Biology and Chemistry Laboratory of the University of Cape Verde. The attributes evaluated were colour, flavour, aroma, texture, salt, and general acceptability, using the effective method on the verbally structured hedonic scale of 9 points (9 – I liked it extremely, 5 – I neither liked nor disliked it and 1 – I disliked it extremely). Three 1.5 cm cubes of each cheese were presented to a panel of non-professional tasters at a cooling temperature. The samples were presented in white plastic dishes, coded with randomly chosen 3-digit numbers. A small cup of mineral water and salt-free bread crackers were given to the panellist to cleanse their palate between samples. According to Pinto and Atzingen (2010), samples were considered acceptable when the majority of the tasters (≥ 70%) presented results as, at least, “like slightly” (value 6) in the mentioned scale. Purchase intention was performed using the verbally structured 5-point hedonic scale (5 – definitely would buy it, 3 – Might or might not buy it, and 1 – definitely would not buy it) as described by Srebernich et al. (2015). The tasters were allowed to swallow the samples if so desired.

2.4. Physico-Chemical Analysis

The pH values of the studied cheeses were obtained by homogenizing the cheese samples with distilled water (1:5, w/v) and measured directly on a digital pH meter (CRISON, basic 20). The equipment was previously calibrated with pH 4.0 and 7.0 calibration solution. The determination of titratable acidity was carried out using the official method AOAC 942.15 AOAC. Association of Official Analytical Chemists (2000), where five grams of homogenized samples were diluted in 25 mL in distilled water and titrated with sodium hydroxide (NaOH, 0.1N). The results were expressed as mLNaOH1N/100g of sample.

Moisture, lipid, protein and ashes were analysed by the AOAC - association of official analytical chemists AOAC. Association of Official Analytical Chemists (2005): Moisture by the method 950.46, by drying the samples under vacuum at 105 °C until constant weight; lipids was extracted by the method 991.36, by solvent extraction in a soxhlet apparatus; protein content, was determined by the method 928.08 where nitrogen was performed using micro-Kjeldahl method, using a conversion factor (nitrogen-protein) of 6.38. Ashes were quantified using a direct method (carbonization) at 550 °C for 12 hours (method 920.153). All the chemicals and reagents used in this study were of analytical grade or better.

2.5. Microbiological Analysis

The determination of the number of colony-forming units (CFU) of E. Coli, per gram of cheese were carried out at 44°C (5-bromo-4chloro-3-indolyl B-D-glucoronate) in accordance with the ISO 16649-2:2001. Faecal coliforms were quantified by counting colonies in a solid medium after incubation at 44°C according to French standard (NF V08-060:2009). Salmonella was quantified using a rapid salmonella method (AFNOR BRD 07/11-12/05) according to ISO 6579-1:2017. Modified Oxford Agar (MOX) was used for selective isolation and detection of L. monocytogenes, according to the ISO 11290 (2017).

2.6. Statistical analysis

The results were expressed in means ± standard deviation (SD). The statistical analysis was performed using SPSS 21.0 software, at a level of p < 0.05 by one-way ANOVA and Duncan test. The analysis of the correlation between physico-chemical and sensory parameters analysed was evaluated by Pearson's correlation test, and p < 0.05 or p < 0.01 represented different statistically significant levels.

3. Results and discussion

3.1. Physical parameters of coalho cheese

Table 2 presents the results for the physical parameters, such as diameter, weight, and height. Weight ranged from 186 -195g, height ranged from 2.45-4.16cm and diameter ranged from 6.7-8.2cm. In the present study, almost no difference was verified on physical parameters of samples A and B, since the molds used during cheese production were uniform. However, sample C presented differences due to homemade production and the use of non-uniform molds.

Table 2

|

Table 2 Physical Characteristics of Fresh Cheese |

|||

|

Samples |

Diameter

(cm) |

Height

(cm) |

Weight

(g) |

|

Cheese

A |

6.8±

0.27 |

2.45±

0.19 |

191±

2.5 |

|

Cheese

B |

6.7±

0.20 |

2.73±

0.15 |

195±

3.86 |

|

Cheese

C |

8.2±

0.51 |

4.16±

0.23 |

186±

6.57 |

In general, coalho cheese produced in Fogo Island-Cape Verde, presents cylindrical form with weight ranged of 180-200g. In this study, the cheeses from semi-artisanal factories (A and B) presented 191 and 195g, respectively, and the cheese from homemade production (Cheese C) presented the lowest weight, 186g. The main difference identified in the height and weight could be related to the fact that the cheeses are made manually, and the cheese is less compact. Consequently, this variation of physical parameters will have a negative impact on the sales revenue, due to the fact that in Cape Verde fresh cheese is sold by piece and not by weight Tavares (2021).

3.2. pH and titratable acidity analysis

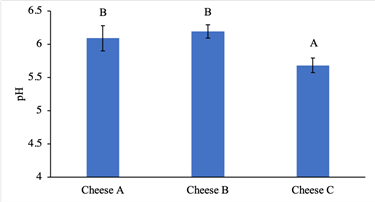

The changes in the mean values of pH and titratable acidity are presented in Figure 1 and Figure 2, respectively. Tritratable acidity and pH both measure acidity, but pH directly affects microbial growth and survival, so pH, rather than titratable acidity, is the best indicator of the preservation and safety effects of acidity. According to USDA (United States Department of Agriculture), the pH of fresh cheese should be close to the fresh milk, with a range between 6.5 and 6.9. As described by Fox et al. (2017) the pH of milk presents a mean value of 6.6 and increases with advancing lactation and may exceed 7.0 in very late lactation. On the other hand, colostrum may have lower pH, as low as 6.0.

However, due to the coagulation in cheese production, pH values are expected to be lower than milk since the pH values decrease because of the presence of acid lactic bacteria that resist pasteurization or contamination after pasteurization González et al. (2017).

Figure 1

|

Figure 1 pH of Goat Cheese. Different Letters on Top of Bars Denote Significant Differences (P<0.05) Using the Duncan’s Average Comparison Test |

In this study, the values of pH (5.68-6.19) were lower compared to raw milk. The lower value of pH was found in sample C, traditional producer, since the hygiene conditions are lower than semi artisanal factories. Cooke et al. (2013). reported that in low-fat cheeses, the moisture-lactose ratio is higher than other samples, and as lactose easily ignites lactic acid bacteria, there is an increase in lactic acid production and a consequent decrease in pH. Similar to this study, Caro et al. (2014) reported pH values of 5.30 ± 0.21 and 6.12 ± 0.41 in Manchego and Panela Mexicana cheese samples, respectively. In the study of fresh cheese from Santiago Island, Tavares (2021) mentioned values of pH oscillated from 5.37 to 6.33. Santos (2015) evaluated the pH of different cheeses produced in Cape Verde and obtained values ranged from 5.32 to 6.28, where the samples from the Fogo Island presented lower pH values compared to the other islands. The author also mentioned that the pH of the samples from Boavista and Santo Antão islands were closer to the pH value of goat's milk. Van Hekken et al. (2012) described a pH value of 6.36 ± 0.03 in fresh cheese, values similar to the fresh cheeses produced in Cape Verde. pH is the main factor available to the cheese maker to control spoilage and pathogenic organisms Hill & Ferrer (2021).

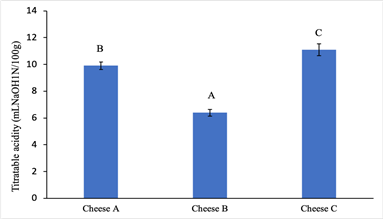

In general, the titratable acidity ranged in levels usually observed in fresh cheeses. Significant difference (p < 0.05) was verified in titratable acidity values (Figure 2), and there was verified higher titratable acidity in the samples with lower pH.

Figure 2

|

Figure 2 Titratable Acidity of Goat Cheese. Different Letters on Top of Bars Denote Significant Differences (P<0.05) Using the Duncan’s Average Comparison Test |

In the study of Feta-Type Cheese Production, Terpou et al. (2019) also mentioned that titratable acidity increased in parallel with the decrease of pH. The acidity of coalho cheese had a variation of 6.4 to 11.1 mLNaOH1N/100g. As described by González et al. (2017), this range of acidity is normal in fresh cheeses with a short ripening time. In general, increasing storage time leads to increased acidity in cheeses, due to the presence of microorganisms Pinho et al. (2004). Milk conservation, cheese production and conservation are the main factors that influence the differences in the acidity of the cheese.

3.3. Physico-chemical properties

The content of moisture, protein, fat, and ashes of the studied cheese are presented in Table 3. Moisture content ranged from 51.45 to 62.40%, fat from 19.07 to 24.60%, protein from 12.62 to 18.03% and ashes from 2.66 to 3.21%.

Table 3

|

Table 3 Proximate Composition of Fresh Cheese |

||||

|

Samples |

Moisture

(%) |

Fat

(%) |

Protein

(%) |

Ashes

(%) |

|

Cheese

A |

60.52±

4.07B |

21.30±

1.39AB |

13.67±

1.19A |

2.85±0.15A |

|

Cheese

B |

51.78±

2.80A |

24.60±

2.08B |

18.03±

1.71B |

2.66±0.23A |

|

Cheese

C |

62.40±

3.56B |

19.07±

2.87A |

12.62±

1.13A |

3.21±0.26A |

|

Different

uppercase letters in the same column indicate significant differences (p <

0.05). |

||||

From Table 3, it is possible to verify that there were significant differences (p < 0.05) in the moisture content of the cheeses. According to Norma Cabo Verdiana (NCV). (2015) cheeses A and C are classified as soft cheeses since their moisture content is higher than 55%, but cheese B is classified as semi-soft cheese (moisture lower than 55%). The relatively low pH, due to the presence of organic acids (mainly lactic, acetic, butyric, or sorbic acid), and the low moisture content of some types of cheeses reduce the growth and survival capacity of pathogenic bacteria during shelf-life Possas et al. (2021). Moisture content is also linked to the shelf life of food and the manufacturing process. Cheeses with high moisture content are vulnerable to several changes caused by the development of microorganisms Delamare et al. (2012).

Regarding fat content, significant difference (p < 0.05) was observed. The highest content was verified in sample C (24.60±2.08 %) and lowest content in sample C (19.07±2.87 %). According to Norma Cabo Verdiana (NCV). (2015), all the studied cheeses are classified as low-fat cheese since fat content was higher than 10% and lower than 25%. The results of this study research were similar to that found by Tavares (2021) in the study of fresh cheese from Santiago Island (Cape Verde). In general, fat content has direct correlation with sensory acceptance. The fat contained in cheese substantially affects its texture and taste and also gives appropriate structure (consistency) to the cheeses Kaczyński et al. (2023). Cheeses with a reduced fat content are less accepted by consumers because they have a harder texture, uncharacteristic aroma, and taste problems De Rensis et al. (2009).

Sample B presented the highest protein content (18.03±1.71) and sample C the lowest (12.62±1.13), and no significant difference (p < 0.05) were observed in the studied cheeses. Protein content in this study was higher than those mentioned by Tavares (2021) in the study of fresh cheese from Santiago Island, which reported values of protein ranged from 10.79 to 12.52%. This parameter could be affected directly by the quality of milk, and several factors such as animal diet supplementation, type of feeding, hygiene condition in milking, breed of cattle and cattle’s health Erickson & Kalscheur (2020). In general, the studied cheese was classified as fresh, semi-soft or soft cheese due its high moisture content, semi-skimmed since fat content was greater than 24% and less than 45% Norma Cabo Verdiana (NCV). (2015).

No significant difference (p < 0.05) was found in ashes content, and it ranged from 2.66 to 3.21%. Sample C (homemade production) presented higher content of ashes compared to samples A and B (semi-artisanal cheese factories), this could be due to the type of rennet used or also the enzyme dosage. Based on the result of this study, it can be concluded that the different production techniques (homemade vs factories) have effect on the ash content.

3.4. Sensory evaluation

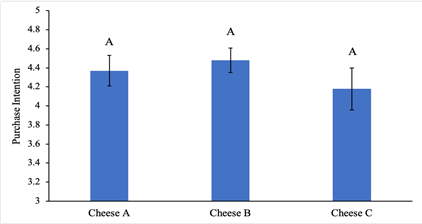

Table 4 shows the average and acceptance percentage of the studied cheese obtained based on the values attributed by tasters following the 9-point hedonic scale. Figure 3 shows the purchase intention of coalho cheeses. Under a structured 5-point hedonic scale, samples A, B, and C presented an average of 4.37, 4.48, and 4.18, respectively, corresponding to “definitely would buy it”.

Table 4

|

Table 4 Sensory Acceptance of Fresh Cheese |

||||||

|

Parameters |

Cheese

A |

Cheese

B |

Cheese

C |

|||

|

Mean

± SD |

Acceptance

(%) |

Mean

± SD |

Acceptance

(%) |

Mean

± SD |

Acceptance

(%) |

|

|

Colour |

7.59±1.74A |

84.34 |

7.31±1.67A |

81.31 |

7.14±1.45A |

79.29 |

|

Taste |

7.14±1.78A |

77.38 |

6.81±1.62A |

75.76 |

7.41±1.62A |

82.32 |

|

Aroma |

7.22±1.87A |

80.30 |

7.14±1.25A |

79.29 |

7.05±1.43A |

78.28 |

|

Texture |

7.73±1.24A |

85.86 |

7.10±1.19A |

78.79 |

7.36±1.40A |

81.82 |

|

Salt |

7.36±2.36A |

81.81 |

7.23±1.77A |

80.81 |

7.86±1.21A |

87.37 |

|

Overall

Acceptability |

7.50±1.77A |

83.33 |

7.50±1.14A |

83.33 |

7.55±1.37A |

83.84 |

As mentioned by Chiciudean et al. (2016), factors such as intrinsic and extrinsic attributes of the cheese are those that most affect the purchasing decision process. In their study of cheese`s intrinsic and extrinsic attributes during the buying decision process, results showed that some customers adopt their buying decision based only on extrinsic attributes such as brand, package, label, etc. Other costumers are more interested in the intrinsic attributes such as taste (made from natural ingredients) and aspects than the extrinsic factors.

Figure 3

|

Figure 3 Purchase Intention of Tasters with regard to Fresh Cheese. Different Letters on Top of Bars Denote Significant Differences (p<0.05) using the Duncan’s Average Comparison Test |

3.5. Microbiological analysis

Microbiological flora is one of the most important factors which affect the quality of cheese. The microflora of cheeses is results from the microorganisms in the raw milk used in production and the contaminations during and after the production Possas et al. (2021). The microbiological parameters are presented in Table 5.

Table 5

|

Table 5 Microbiological Parameters of Fresh Cheese |

||||

|

Samples |

E.

Coli (cfu/g) |

Fecal coliforms (cfu/g) |

Salmonella (cfu/g) |

L.

monocytogenes (cfu/g) |

|

Cheese

A |

<1.0x101 |

<1.0x101 |

ND |

ND |

|

Cheese

B |

<1.0x101 |

3.5x102 |

ND |

ND |

|

Cheese

C |

5.0x101 |

9.7x102 |

ND |

ND |

|

Maximum

Value * |

1.0x102 |

1.0x104 |

Absence

in 25 g |

1.0x102 |

|

Maximum

Value ** |

1.0x102 |

1.0x102 |

Absence

in 25 g |

1.0x102 |

|

* Maximum acceptable by NCV No12/2015 **Maximum

acceptable by Commission Regulation (EC) No 2073/2005 and Commission

Regulation (EC) No 1441/2007. ND - Not detected. |

||||

Salmonella and L. monocytogenes were not detected, E. Coli and Fecal coliforms were lower than the stablished by the NCV No 12/2015, 1.0x102 and 1.0x104 CFU/g respectively. All the samples were in accordance with the legally acceptable standard established by Commission Regulation (EC) No 1441/2007, with the exception of samples B and C, which showed Fecal coliforms higher than the stablished (1.0x102 CFU/g). The highest contamination by fecal coliforms was observed in sample C, from homemade production, probably due to deficiencies in hygienic-sanitary conditions. The high content of fecal coliforms in samples B and C demonstrate possible failures in its fabrication process, which can be related mainly to the poor quality of the raw material used and the different technologies used in artisanal fabrication. In general, many countries use E. coli and coliforms as indicators of sanitary quality of cheeses, thus according to NCV No 12/2015, the studied cheeses presented excellent sanitary quality since E. Coli and Fecal coliforms were lower than the stablished.

Santos (2015) in the study of microbiological and physico-chemical quality of fresh goat's milk cheese goat's milk cheese produced in Cape Verde also reported that Salmonella and L. monocytogenes were not detected, whereas 63% of the samples presented E. coli higher than stablished by NCV No 12/2015. According to Alessandria et al. (2010), in the study of the survival of fecal coliforms and coliforms in fresh cheese from the Cape Verde, the cheese from the producer A contained fecal coliform and coliform levels of 0.65 and 0.53 log10 CFU/g, respectively and the cheese from producer B contained 4.25 log10 CFU/g of fecal coliform and 4.29 log10 CFU/g of coliform.

3.6. Relationship evaluation

A Pearson correlation study was completed to establish links between sensory attributes and physico-chemical parameters of coalho cheese (Table 6). The linear correlation between the variables should be interpreted according to the size (strength) of a correlation coefficient ®: (i) 0.90 to 1.00 (-0.90 to -1.00) very high positive (negative) correlation; (ii) 0.70 to 0.89 (-0.70 to -0.89) high positive (negative) correlation; (iii) 0.40 to 0.69 (-0.40 to -0.69) moderate positive (negative) correlation; (iv) 0.10 to 0.39 (-0.10 to -0.39) weak positive (negative) correlation; (v) 0.00 to 0.10 (0.00 to -0.10) negligible correlation Schober et al. (2018).

In general, the sensory attribute of food is extremely correlated with Physico-chemical and microbiological parameters. As expected, cheese texture correlated well with moisture content (r = 0.703). Fat content presented a very high positive correlation with protein (r = 0.974), very high negative correlation with ashes (r = -0.959), acidity (r = -0.982), taste (r = -0.999) and salt (r = -0.906), and high negative correlation with overall acceptability (r = -0.805). The high correlation between fat and acceptability can be explained by the fact that fat content significantly improves the colour and texture of the cheese, having a favourable impact on the sensorial acceptance of the cheese.

Unique organoleptic characteristics such as flavour and texture contribute to cheese`s higher acceptability and popularity. Moisture presented a very high negative correlation with fat (r = -0.970), protein (r = -1.00) and very high positive correlation with acidity (r = 0.998) and taste (r = 956). pH showed a very high negative correlation with salt (r = -0.936) and overall acceptability (r = -0.9878), a very high positive correlation with aroma (r = 0.947), a high positive correlation with colour (r = 0.877) and a high negative correlation with taste (r = -0.736). Acidity is an important parameter in determining a food's conservation status. In this study, acidity presented a very high positive correlation with taste (r = 0.971) and a moderate positive correlation with overall acceptability (r = 0.679). The attribute salt presented a very high negative correlation with overall acceptability (r = -0.836) and the attribute aroma demonstrated a very high negative correlation with overall acceptability (r = -0.882).

Table 6

|

Table 6 Correlation Matrix of Sensory and Physical-Chemical Parameters |

||||||||||||

|

Variables |

Moisture |

Fat |

Protein |

Ashes |

pH |

Acidity |

Colour |

Taste |

Aroma |

Texture |

Salt |

Overall Acceptability |

|

Moisture |

1 |

|||||||||||

|

Fat |

-0.97 |

1 |

||||||||||

|

Protein |

-1 |

0.974 |

1 |

|||||||||

|

Ashes |

0.861 |

-0.959 |

-0.87 |

1 |

||||||||

|

pH |

-0.503 |

0.699 |

0.518 |

-0.874 |

1 |

|||||||

|

Acidity |

0.998 |

-0.982 |

-0.999 |

0.888 |

-0.552 |

1 |

||||||

|

Colour |

-0.026 |

0.269 |

0.044 |

-0.531 |

0.877 |

-0.083 |

1 |

|||||

|

Taste |

0.956 |

-0.999 |

-0.961 |

0.973 |

-0.736 |

0.971 |

-0.32 |

1 |

||||

|

Aroma |

-0.199 |

0.432 |

0.216 |

-0.67 |

0.947 |

-0.255 |

0.985 |

-0.479 |

1 |

|||

|

Texture |

0.703 |

-0.509 |

-0.691 |

0.244 |

0.26 |

0.662 |

0.692 |

0.462 |

0.556 |

1 |

||

|

Salt |

0.775 |

-0.906 |

-0.786 |

0.989 |

-0.936 |

0.81 |

-0.652 |

0.927 |

-0.774 |

0.096 |

1 |

|

|

Overall Acceptability |

0.637 |

-0.805 |

-0.65 |

0.94 |

-0.987 |

0.679 |

-0.788 |

0.836 |

-0.882 |

-0.1 |

-0.981 |

1 |

|

Significant correlation at P < 0.05. |

||||||||||||

4. Conclusion

Fogo fresh cheese is one of the most consumed cheeses in Cape Verde, it presents high humidity, is not subjected to curing, with low percentage of salt, and has great manipulation during manufacture. The results of this study enabled us to classify the cheeses produced in Fogo Island using goat milk as fresh, semi-soft or soft cheese and semi-skimmed. All the studied samples were well accepted for the parameters such as texture, aroma, salt, colour, taste, and overall acceptability, showing a minimum acceptance percentage of 75.76% for the attribute taste of cheese B. The physico-chemical parameters analyzed, such as protein, moisture, fat, ashes, pH, titratable acidity were common for the fresh cheese and were similar to different other varieties of this type of cheese. Mostly, the quality of cheeses depends on the quality of milk and the sanitary conditions during production, thus the result from the present study indicates that rigorous control during production is essential to improve the quality of fresh cheese. This study also showed that cheeses made under sanitary conditions and using good manufacturing practices should not contain high levels of indicator bacteria such as E. Coli and coliforms.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

REFERENCES

AOAC. Association of Official Analytical Chemists (2000). Official Method 942.15 Acidity (Titrable) of Fruit Products Read with A.O.A.C Official Method 920.149, 17th ed. Preparation of Test Sample. Gaithersburg MD.

AOAC. Association of Official Analytical Chemists (2005). AOAC Official Methods of Analysis, 18th ed. Gaithersburg MD.

Alessandria, V., Dolci, P., Rantsiou, K., Pattono, D., Dalmasso, A., Civera, T., & Cocolin, L. (2010). Microbiota of the Planalto de Bolona: An Artisanal Cheese Produced in Uncommon Environmental Conditions in the Cape Verde Islands. World J. Microbiol. Biotechnol. 26, 2211-2221. https://doi.org/10.1007/s11274-010-0406-7

Bansal, V., & Mishra, S. K. (2020). Reduced-Sodium Cheeses: Implications of Reducing Sodium Chloride on Cheese Quality and Safety. Comprehensive Reviews in Food Science and Food Safety, 19(2), 733-758. https://doi.org/10.1111/1541-4337.12524

Caro, I., Soto, S., Fuentes, L., Gutiérrez-Méndez, N., García-Islas, B., Monroy-Gayosso, K. E., & Mateo, J. (2014). Compositional, Functional and Sensory Characteristics of Selected Mexican Cheeses. Food and Nutrition Sciences, 5, 366-375. https://doi.org/10.4236/fns.2014.54044

Cooke, D., Khosrowshahi, A., & Mcsweeney, P. (2013). Effect of Gum Tragacanth on the Rheological and Functional Properties of Full-Fat and Half-Fat Cheddar Cheese. Dairy Science & Technology, 93(1), 45-62. https://doi.org/10.1007/s13594-012-0088-z

De Rensis, C. M. V. B., Petenate, A. J., & Viotto, W. H. (2009). Caracterização Físico-Química, Reológica E Sensorial De Queijos Tipo Prato com teor Reduzido de Gordura. Food Science and Technology, 29, 488-494. https://doi.org/10.1590/S0101-20612009000300005

Delamare, A. P. L., de Andrade, C. C. P., Mandelli, F., de Almeida, R. C., & Echeverrigaray, S. (2012). Microbiological, Physico-Chemical and Sensorial Characteristics of Serrano, An Artisanal Brazilian Cheese. Food and Nutrition Sciences, 3(8), 1068. https://doi.org/10.4236/fns.2012.38142

EU Commission. (2004). Commission Regulation(EC) No. 853/2004 of the European Parliament and of the Council of 29 April 2004 Laying Down Specific Hygiene Rules for Food of Animal Origin. Official Journal of the EU, 139, 55-205.

EU Commission. (2007). Commission regulation (EC) No 1441/2007 of 5 December 2007 Amending Regulation (EC) No 2073/2005 on Microbiological Criteria for Foodstuffs. J. Eur. Union, 322, 2-29.

Erickson, P. S., & Kalscheur, K. F. (2020). Nutrition and Feeding of Dairy Cattle. In Animal Agriculture, 157-180. https://doi.org/10.1016/B978-0-12-817052-6.00009-4

Fox, P. F., Guinee, T. P., Cogan, T. M., & McSweeney, P. L. (2017). Fundamentals of Cheese Science (Vol. 1, p. 271). Boston, MA, USA:: Springer. https://doi.org/10.1007/978-1-4899-7681-9

González, M. L., Sánchez, H. C., Franco, F. M. J., Güemes, V. N., & Soto, S. S. (2017). Physical, Chemical and Texture Characteristics of Aro Cheese. Food Research, 2(1), 61-67. https://doi.org/10.26656/fr.2017.2(1).211

Hill, A., & Ferrer, M. (2021). Cheese Making Technology e-Book. University of Guelph.

ISO 11290 (2017). Microbiology of the Food Chain - Horizontal Method for the Detection and Enumeration of Listeria Monocytogenes and of Listeria spp. - Part 1: Detection Method and Part 2: Enumeration Method.

ISO 16649-2 (2001). Microbiology of Food and Animal Feeding Stuffs - Horizontal Method for the Enumeration of Beta-Glucuronidase-Positive Escherichia Coli - Part 2: Colony-Count Technique at 44 Degrees C using 5-bromo-4-chloro-3-indolyl beta-D-glucuronide.

ISO 4832, N. F. (2009). Microbiologie Des Aliments, Dénombrement Des Coliformes Thermotolérants Par Comptage Des Colonies Obtenues à 44 °C. Biokar Diagnostics Violet Red Bile Agar (VRBA). 4p.

Johnson, M. E. (2017). A 100-Year Review: Cheese Production and Quality. Journal of Dairy Science, 100(12), 9952-9965. https://doi.org/10.3168/jds.2017-12979

Jurisic, D. J., & David, A. (2020). Manual Do Queijo: Rotas do Fogo. (1st Ed).

Kaczyński, Ł. K., Cais-Sokolińska, D., Bielska, P., Teichert, J., Biegalski, J., Yiğit, A., & Chudy, S. (2023). The Influence of the Texture and Color of Goat's Salad Cheese on the Emotional Reactions of Consumers Compared to Cow's Milk Cheese and Feta Cheese. European Food Research and Technology, 249(5), 1257-1272. https://doi.org/10.1007/s00217-023-04211-2

Norma Cabo Verdiana (NCV). (2015). Queijo fresco e curado. Definição, Classificação, Características E Apresentação. (NCV- 012/2015).

O'Brien, N. M., & O'Connor, T. P. (2004). Nutritional Aspects of Cheese. In P. L. H. McSweeney, P. F. Fox, T. M. Cogan, & T. P. Guinee (Eds.), Cheese: Chemistry, Physics and Microbiology (3rd ed., Vol. 1, 573-581). London, UK: Elsevier Ltd.

Pinho, O., Mendes, E., Alves, M. M., & Ferreira, I. M. P. L. V. O. (2004). Chemical, Physical, and Sensorial Characteristics of "Terrincho" ewe Cheese: Changes During Ripening and Intravarietal Comparison. Journal of Dairy science, 87(2), 249-257. https://doi.org/10.3168/jds.S0022-0302(04)73163-X

Pinto, S. M. E. M., and Atzingen, M. C. V. (2010). Sensory Analysis of Hydrolysed Meat Preparations. Ciência e Tecnologia de Alimentos, 30, 349-353. https://doi.org/10.1590/S0101-20612010000200010

Possas, A., Bonilla-Luque, O. M., & Valero, A. (2021). From Cheese-Making to Consumption: Exploring the Microbial Safety of Cheeses Through Predictive Microbiology Models. Foods, 10(2), 355. https://doi.org/10.3390/foods10020355

Santiago-López, L., Aguilar-Toalá, J. E., Hernández-Mendoza, A., Vallejo-Cordoba, B., Liceaga, A. M., & González-Córdova, A. F. (2018). Invited Review: Bioactive Compounds Produced During Cheese Ripening and Health Effects Associated with Aged Cheese Consumption. Journal of Dairy Science, 101(5), 3742-3757. https://doi.org/10.3168/jds.2017-13465

Santos, E. V. (2015). Qualidade Microbiológica e Físico - Química de Queijo Fresco de Leite de Cabra produzido em Cabo Verde (Master thesis, Universidade de Coimbra).

Schober, P., Boer, C., & Schwarte, L. A. (2018). Correlation Coefficients: Appropriate use and Interpretation. Anesthesia & analgesia, 126(5), 1763-1768. https://doi.org/10.1213/ANE.0000000000002864

Severová, L., Svoboda, R., Šrédl, K., Prášilová, M., Soukup, A., Kopecká, L., & Dvořák, M. (2021). Food Safety and Quality in Connection with the Change of Consumer Choice in Czechia (A Case Study). Sustainability, 13(11), 6505. https://doi.org/10.3390/su13116505

Srebernich, S. M., Silveira, E. T. F., Gonçalves, G. M. S., Ormenese, R. C. S. C., and Morgano, M. A. (2015). Development and Evaluation of Iron-Rich Meatloaves Containing Pork Liver for Schoolchildren. Food Science & Technology, 35(3), 460-467. https://doi.org/10.1590/1678-457X.6703

Tavares, W. P. S. (2021). Physico-Chemical and Sensory Characteristics of Cow's Milk Cheese Produced in São Jorge-Cape Verde. Kwanissa: Revista de Estudos Africanos e Afro-Brasileiros, 4(8).

Terpou, A., Mantzourani, I., Galanis, A., Kanellaki, M., Bezirtzoglou, E., Bekatorou, A., ... & Plessas, S. (2019). Employment of L. Paracasei K5 as a Novel Potentially Probiotic Freeze-Dried Starter for Feta-Type Cheese Production. Microorganisms, 7(1), 3. https://doi.org/10.3390/microorganisms7010003

Tunick, M. H., & Van Hekken, D. L. (2010). Rheology and Texture of Commercial Queso Fresco Cheeses made from Raw and Pasteurized Milk. Journal of Food Quality, 33, 204-215. https://doi.org/10.1111/j.1745-4557.2010.00331.x

Van Hekken, D. L., Tunick, M. H., Leggett, L. N., & Tomasula, P. M. (2012). Impact of Curd Milling on the Chemical, Functional, and Rheological Properties of Starter-Free Queso Fresco. Journal of Dairy Science, 95(10), 5527-5535. https://doi.org/10.3168/jds.2011-4933

Zheng, X., Shi, X., & Wang, B. (2021). A Review on the General Cheese Processing Technology, Flavor Biochemical Pathways and the Influence of Yeasts in Cheese. Frontiers in Microbiology, 2186. https://doi.org/10.3389/fmicb.2021.703284

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© Granthaalayah 2014-2024. All Rights Reserved.