Manufacture of Paver Blocks Using a Prototype Waste Plastic Melting Machine

Sandeep B 1![]()

![]() ,

Dr. Suma 2

,

Dr. Suma 2![]()

![]() ,

Arjun Dev K 3, Darshan S 3, Ganesh B S 3,

Mayoora M 3

,

Arjun Dev K 3, Darshan S 3, Ganesh B S 3,

Mayoora M 3

1 Assistant

Professor, Department of Mechanical Engineering, VVIET - VTU, Mysuru, Karnataka,

India

2 Associate

Professor, Electronics and Communication Engineering, VVIET - VTU, Mysuru, Karnataka,

India

3 UG

Students, Department of Mechanical Engineering, VVIET - VTU, Mysuru, India

|

|

ABSTRACT |

||

|

The present

world is witnessing the challenges of managing the waste or life span ended

components or parts or structures made out of

plastics of different grades. Researchers have always found some

technological breakthrough in managing those plastics which are affecting or

polluting the environment by coming up with innovative techniques of

recycling those plastics making them less toxic, biodegradable, and easy

handling or disposing suitably. To manage waste plastics always many materials

developer have found better path in this regard. Considering such potential

situations, an attempt has been made to develop a prototype machine which

uses waste plastics to produce paver blocks. |

|||

|

Received 05 February 2023 Accepted 04 March 2023 Published 15 March 2023 Corresponding Author Sandeep B,

sandeep06.402@gmail.com

DOI 10.29121/granthaalayah.v11.i2.2023.5055 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2023 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Bricks, Plastics, Paver Blocks, Prototype,

Machine |

|||

1. INTRODUCTION

From our modern-day kitchen utensils to the packaging materials, we use to transport our food, plastics have become a ubiquitous part of our lives. We can almost find plastic wherever we look - from the devices and gadgets that surround us to the clothes we wear. Yet, not many of us are aware of the incredible journey that this versatile material has gone through in order to become one of the most widely used materials in the world. Plastics are man-made compounds, created from polymers derived from petroleum and natural gas. The process of creating plastics dates back to the 19th century, when scientists discovered that manipulating the molecular structure of petroleum and natural gas could produce a wide range of 0materials with unique characteristics. Over the years, these materials have been improved and refined, leading to the development of the durable, lightweight, and versatile plastics that we use today. Thanks to its flexibility, the use of plastics has become so widespread that it has become almost impossible to imagine our lives without them. From durable containers to replaceable parts, plastics have revolutionized the way we manufacture, package, and transport goods Richardson (1989).

Industrial

plastics are a broad category of materials used in a variety of applications in

the manufacturing and industrial sectors. The most common industrial plastics

are polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC),

polystyrene (PS), polyurethane (PU), acrylonitrile butadiene styrene (ABS),

nylon, and acetal. These materials are used for a variety of purposes, such as

for pipes, fittings, insulation, and packaging. Industrial plastics can also be

used to make components for heavy machinery, medical equipment, and motor

vehicles. Additionally, they can be used to make items such as furniture, toys,

and automotive parts. Industrial plastics are typically classified according to

their physical properties, such as their strength, heat resistance, and

flexibility. Brief classification of industrial plastics Lokensgard (2009).

·

Thermoplastics: Polypropylene

(PP), Polyethylene (PE), Polystyrene (PS), Polyvinyl Chloride (PVC),

Acrylonitrile Butadiene Styrene (ABS), Polycarbonate (PC), Nylon (PA), Acetal

(POM), Polyurethane (PU), etc.

·

Thermosets: Epoxy,

Polyester, Phenolic, Melamine, Urea, Polyimide, Polysulfone,

Polyphthalamide (PPA), etc.

·

Elastomers: Natural

Rubber, Synthetic Rubber, Silicone, Fluoropolymers, etc.

·

Reinforced

Plastics:

Fiberglass-Reinforced Plastic (FRP), Carbon Fiber-Reinforced

Plastic (CFRP), Aramid-Reinforced Plastic (ARP), etc.

·

Bioplastics: Polylactic

Acid (PLA), Polyhydroxyalkanoates (PHA), Starch-Based

Plastics, etc.

Industrial plastics can be extremely harmful to the environment. They are non-biodegradable and can take hundreds of years to decompose. The manufacturing process also releases harmful toxins into the air and water, which can have long-term consequences for the environment and human health. Additionally, plastics can be an eyesore and can take up valuable space in landfills. Industrial plastics are widely used in many industries due to their durability, low cost, and ease of manipulation. However, they can be harmful to the environment if not disposed of properly. Plastics can leach toxins into the environment when they are burned or degraded and can create large amounts of pollution when they are manufactured. Additionally, the production of plastics often uses chemicals that can be toxic to humans and animals, and these chemicals can end up in the environment. In order to reduce the harm of industrial plastics, it is important to ensure proper disposal and recycling of these materials Letcher (2020).

Recycling industrial plastics is an important environmental issue because it helps reduce the amount of plastic waste that is sent to landfills and incinerators, which can have a negative impact on the environment. Industrial plastic recycling also helps conserve resources by reducing the need to manufacture new plastics and by using less energy to process recycled plastics. Additionally, recycling industrial plastics can reduce air and water pollution, as well as greenhouse gas emissions. Finally, recycling industrial plastics can generate economic benefits, as recycled plastics are often used to produce new products, creating jobs, and stimulating economic growth Rudolph (2017).

Nivetha et al. (2016) The Production of Plastic Paver Block from Solid Waste is a great way to reduce the amount of solid waste in the environment. It involves a process that recycles plastic waste and turns it into a useful product that can be used in a variety of applications. The process is cost-effective, energy-efficient, and can be used to make a variety of products. It is also eco-friendly, as the process recycles plastic and keeps it out of landfills. The Production of Plastic Paver Block from Solid Waste is a great way to reduce waste and create a useful product.

Tapkire et al. (2014) Recycled plastic used in Concrete Paver Block is an excellent way to reduce waste and create an eco-friendly product. The plastic is melted down and mixed with sand and cement to create a product that is strong and durable, yet lightweight. The recycled plastic creates a more sustainable product and also helps reduce the energy used in the production process. The paver blocks are easy to install and require minimal maintenance. In addition, they are resistant to weather and fading, making them a great choice for outdoor applications. Overall, recycled plastic used in Concrete Paver blocks is a great choice for creating a green, energy efficient product.

Sharma and Batra (2016) Cement Concrete Paver Blocks for Rural Roads are highly durable and cost-effective solutions for rural roads. They are specially designed to withstand the heavy load of the rural traffic and provide a smooth riding surface. The blocks are made from a combination of cement, sand, and aggregate and possess high compressive strength. The blocks are also resistant to weathering and provide a long-lasting surface. They provide an excellent base for rural roads and can be used to construct roads of various sizes.

Santhosh and Talluri (2015) Interlocking Concrete Paving Blocks with Fly Ash and Glass Powder is an innovative, eco-friendly product that provides superior durability and strength. It is easy to install and can be used for both residential and commercial projects. The use of fly ash and glass powder significantly reduces the cost of production, making the product more affordable for consumers. The product also has excellent compressive strength and resistance to extreme weather conditions. Overall, the product is a great choice for construction projects and offers a cost-effective solution to paving.

Reddy and Ajitha (2012) Melt-Densified Post-Consumer Recycled Plastic Bags used as Light Weight Aggregate in Concrete is a great way to reduce environmental impacts and reuse a common waste material. The process of densifying plastic bags and using them as aggregate in concrete has been studied and results show that the concrete has a higher compressive strength than traditional concrete. Additionally, it is also lighter in weight and cheaper to produce, making it a great sustainable solution. Overall, this is a great way to move towards more sustainable construction materials.

Ghernouti et al. (2014) Recycled plastic bag waste has been proven to be a valuable material for the concrete industry. It has been proven to increase the strength and durability of concrete, reduce its weight, and reduce the amount of energy required for production. The use of recycled plastic bag waste in concrete also reduces the amount of waste that goes to landfills, helping to reduce pollution and preserve natural resources. The use of this recycled material provides a sustainable and cost-effective solution for concrete production.

Mathew et al. (2013) Recycled plastic is an effective and viable alternative coarse aggregate for structural concrete. It has several advantages over conventional materials, such as being lightweight, impermeable, and non-corrosive. This makes it ideal for use in construction projects, as it reduces the weight of the concrete while maintaining its structural integrity. Additionally, the use of recycled plastic in concrete can also provide environmental benefits, such as reducing the total amount of plastic waste in landfills. Overall, recycled plastic is a viable option for use as a coarse aggregate for structural concrete.

Sarwe (2014) This study is

a comprehensive look at the strength properties of concrete, when reinforced

with waste plastics and steel fibers. The study used

different mixes, and tested them for compressive, flexural, split tensile and

bond strength. The results showed that all of the mixes had improved strength

properties, compared to the control mix. The study is a valuable resource for

engineers and researchers looking to utilize waste plastics and steel fibers as reinforcement. The findings provide valuable

insight into the strength properties of reinforced concrete and can be used to

inform new designs.

Bhogayata et al. (2012) the performance of concrete made with non-recyclable plastic wastes as a concrete constituent has been found to be satisfactory. The compressive strength of concrete made with plastic wastes was found to be higher than that of conventional concrete. The addition of plastic wastes also improved the workability and durability of concrete. The results of the study have shown that non-recyclable plastic wastes can be successfully used as a concrete constituent without any negative effect on the performance of concrete.

Elzafraney et al. (2005) Integrated the use of recycled plastic aggregates into the cementitious material, allowing the building to define its thermal properties and effective energy performance compared to regular aggregated concrete. Plastic Concrete has been made from refined and highly processed plastics to meet the various needs of structures such as strength, workability, and surface finish etc. Both buildings were subjected to long-term and short-term monitoring to determine their energy efficiency and comfort. A well-insulated building made from recycled plastic has been observed to use 8% less energy than regular concrete; However, the energy savings were greatest in cold climates in a building with weaker insulation. They suggested that energy efficiency could be further improved by using recycled plastics with high heat capacity. They suggested that the recycled plastic concrete is cheap, lightweight, and highly heat resistant.

2. PROJECT OBJECTIVES

Framing

project objectives for any fabrication-based project is essential for its

successful completion. It helps in proper planning and execution of the

project, thus ensuring that the project is completed within the stipulated time

and budget. It also helps in identifying the resources needed for the project

and enables better management of the project. Objectives provide clear guidance

to the team members on what needs to be done and how it should be done. It also

helps in ensuring that the project meets the customer’s expectations and is in

line with the overall organizational goals. A well-defined objective will also

help in efficient utilization of resources, thus leading to cost savings.

Following are the objectives that are framed.

To

identify the waste plastics available in common surrounding or from common

waste management centers.

Separate

those plastics that are less harmful in terms of toxic levels as per the knowledge

of plastics and its harmful effects to environment.

An

attempt to melt the waste plastics in the prototype machine and make an

appropriate paver blocks for some constructive usage for decorative display or

pathway less exposed to heat.

To

reduce the cost involved in producing the paver blocks.

3. PROJECT METHODOLOGY

Project Methodology is a set of techniques and an activity used to ensure that a project is completed on time, within budget and meets the customer's requirements. It is a systematic approach to planning and managing a project from start to finish. It is important for project managers to understand the project methodology in order to successfully plan and execute a project. It helps provide a framework for making decisions about how the project should be organized and executed, which tasks should be done first, and how to measure success. Project Methodology also helps to identify potential risks and develop strategies to mitigate them. Ultimately, it is a tool to ensure the success of a project Kothari (2014). Following are the stages of research methodology set in the present project.

1) Problem Definition: Plastic have become a huge problem considering its non-degradable nature, thereby recycling it is a major concern.

2) Problem Analysis: Study about those plastics that can be easily recycled with less toxic in nature.

3) Literature Survey: Information to be collected from various sources regarding the problem identified and its review which includes journals, magazines, data handbooks, reports etc…

4) Feasible Idea Selection: Selecting few plastics under study that are commonly found from waste management centers for melting and producing paver blocks.

5) Machine Design: A trial method to develop a prototype design machine which melt the identified plastics.

6) Materials and Fabrication: Appropriate selection of materials meant for fabrication.

7) Testing: Testing of prototype machine built.

8) Performance Monitoring: Monitor the results obtained while melting the plastics out of prototype machine that was built to enhance the features.

4. MACHINE DESIGN

Machine

design is an important part of engineering and is the process of creating and

developing machines that are efficient, safe, and cost-effective. Good machine

design not only improves the overall performance of the machine, but also reduces

costs associated with its operation and maintenance. Machine design also pays

attention to the safety of the operator, minimizing the risk of injury or

accidents. Additionally, it is important to consider the environment when

designing a machine, as many machines can produce emissions that can be

detrimental to the environment if not properly designed. By considering all of these factors, machine design can be an important

tool in creating efficient, safe, and cost-effective machines Khurmi (2020).

4.1. COMPONENT DESIGN

1)

The design mainly consists of:

2)

Outer Frame

3)

Container and Burner

4)

Exhaust Fan

5)

DC Motor

6)

Metal Stirrer and Exhaust Valve

7)

Electronics Unit

Solid

modeling helps to create precise 3D models of

components and assemblies that are used in the manufacturing process. It also

helps to reduce costs, improve accuracy, and accelerate the design process.

Solid modeling also allows for better visualization

of a product, enabling engineers to create better designs while reducing

development time Stroud (2011) Figure 1 shows the 3-D

model of the machine designed and its components.

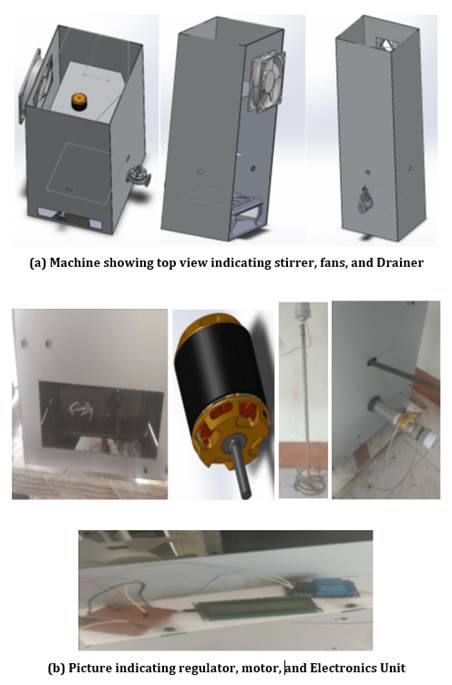

Figure 1

|

Figure 1 3-D Model and Machine Components |

4.2. CODING

Coding is necessary for electronic devices in

order to provide them with instructions and enable their functioning. It allows

us to create programs and apps that provide us with a variety of functions and

features. Without coding, electronic devices would not be able to perform their

intended functions. Coding is necessary for creating efficient and effective

electronic devices. Coding is essential for electronic device as it

allows us to create instructions for a device to follow. It is used to create

software, websites, apps, and more. Coding is the language of computers, and it

allows us to communicate with them in order to make them do what we want.

Coding is used to create user interfaces, algorithms, and databases which make

electronic devices work properly. Without coding, electronic devices would be

unable to function. Coding is important for troubleshooting and debugging as

well, as it allows us to identify and fix any problems with the device.

Finally, coding is important for making sure that electronic devices function

securely and properly Dhurat, C. (n.d.).

4.2.1. CODE FOR THE ELECTRONICS UNIT

#define

BLYNK_PRINT Serial

#include

<ESP8266WiFi.h>

#include

<BlynkSimpleEsp8266.h>

const int rel = 2;

char

auth[] ="MImt0Lx7AAtH2GPp7A7NawmjIyZkBqaE";

char

ssid[]

= "funking7";

char

pass[] = "123456789";

int

ThermistorPin = 0;

intV;

float

R1 = 10000;

float

logR2, R2, T, Tc, Tf;

float

c1 = 1.009249522e-03, c2 = 2.378405444e-04, c3 = 2.019202697e-07;

void

setup() { Serial.begin(9600);

Blynk.begin(auth, ssid, pass);

pinMode(rel,OUTPUT);

}

void

loop() {

Blynk.run(

);

V =

analogRead(ThermistorPin);

R2

= R1 * (1023.0 / (float)V - 1.0);

logR2

= log(R2);

T =

(1.0 / (c1 + c2*logR2 + c3*logR2*logR2*logR2)); Tc = T

- 314.15;

Tf = (Tc * 9.0)/ 5.0 + 32.0;

Serial.print("Temperature:");

Serial.print(Tf); Serial.print(" F;");

Serial.print(Tc);

Serial.println("C");

Blynk.virtualWrite(V0,Tf);

Blynk.virtualWrite(V1,Tc);

delay(500);

}

BLYNK_WRITE(V2)

{

{

digitalWrite(rel,LOW);

Serial.println("HIGH");

/*speed1

= analogRead(A0);

speed1

= speed1 * 0.2492668622;

analogWrite(ConA, speed1);

speed2

= analogRead(A0);

speed2

= speed2 * 0.2492668622;

analogWrite(ConB, speed2);*/

}

else

{

digitalWrite(rel,HIGH);

Serial.println("LOW");

}

Internet

source (web resources 19 & 20)

4.2.2. EXPLANATION FOR THE ELECTRONIC UNIT

Nodemcu is a WiFi module

and a microcontroller.

First

temperature sensor measures the temperature of the controller and is sent to

blank on the user phone and is displayed as a bar meter (both Celsius and

Fahrenheit).

Relay

is used to turn on the stirrer using the blank button virtually on and off.

5. WORKING OF THE MACHINE

5.1. COMPOSITION OF RAW MATERIALS

The

materials used for the machine are shredded plastic, cooking oil and shredded styro. The composition of the materials is given in Table 1.

Table 1

|

Table 1 Composition of Materials |

||||

|

Trial |

Raw

Materials Composition (%) |

Results |

||

|

|

Shredded Plastic |

Cooking Oil |

Shredded styro |

|

|

1 |

40 |

50 |

10 |

BAD |

|

2 |

45 |

45 |

10 |

BAD |

|

3 |

50 |

35 |

15 |

GOOD |

5.2. WORKING PROCEDURE OF THE PLASTIC DENSIFIER

·

Firstly, recycled plastic mixture is mixed and put it into the

metal container.

·

Then the mixture is heated through induction stove to 300 degrees

·

There is a metal stirrer which is stirred uniformly by DC motor.

·

After thoroughly mixed, the mixture is discharged from stop valve

to mold box.

·

After cooling in mold box, the hardened

plastic is removed and can be used again.

5.3. ADVANTAGES OF PLASTIC DENSIFIER

·

It can be molded into different shapes.

·

Better appearance.

·

Strength to Weight ratio is more.

·

Volume to Weight ratio is more.

·

Finishing cost is less as the appearance is good.

5.4. DISADVANTAGES OF PLASTIC DENSIFIER

·

Cost is comparatively more than red brick.

·

Plastic fumes are produced and therefore careful treatment is

essential.

·

Suitable locations must be chosen for the process.

·

Management of waste is difficult in India.

5.5. CHALLENGES FACED

·

Overheating of the vessel was an issue, therefore we chose

stainless for the vessel.

·

At first, gas was used for heating, but the replacement of gas was

a problem, hence we selected induction heating.

·

Even during the assembly, we faced difficulties.

·

At first, the fumes formation during the process was more; hence

we used high quality exhaust fans.

·

Lastly, during the welding of motor shaft, short circuit occurred

in the welding, therefore we welded coupler instead of motor shaft.

6. PROJECT MANAGEMENT and COST ESTIMATION

It involves a series of activities aimed at defining,

planning, and controlling the scope, cost, schedule, and quality of the

project. It is a critical process for successful project completion and ensures

that all stakeholders are involved in the decision-making process Singh (2019). Cost

estimation is an important part of any fabrication-based project is shown in

the Table 2. It helps to

determine the cost of materials, labor, and other

associated costs that go into the fabrication process. Without accurate cost

estimation, a fabrication project can easily become too expensive to complete

and could potentially lead to a loss of money. Cost estimation also helps to

identify potential areas of cost savings. By accurately estimating the cost of

materials, labor, and other associated costs, a

project manager can make informed decisions about which materials to use, and

which areas of the fabrication process can be improved to help reduce costs.

This can help to ensure that the project remains within a reasonable budget.

Cost estimation also allows project managers to set realistic timelines and

expectations. Cost estimation also helps to identify potential problems before

they become too costly to address. By accurately estimating the cost of

materials, labor, and other associated costs, project

managers can identify potential problems and proactively address them before

they become too expensive to fix Panneerselvam and Sivasankaran

(2015).

Table 2

|

Table 2 Project Cost Estimation |

|||

|

S. No. |

Component |

Quantity |

Cost

in Rs. |

|

1. |

ACP Sheets |

4 |

15000 |

|

2. |

Exhaust Fan |

1 |

2000 |

|

3. |

Industrial Induction Stove |

1 |

5000 |

|

4. |

Metal Container |

1 |

1500 |

|

5. |

Metal Clamps |

1 |

1000 |

|

6. |

Dc Motor |

1 |

500 |

|

7 |

Allen Bolts and Nuts (M4) |

100 |

300 |

|

8. |

Metal Stirrer |

1 |

500 |

|

9. |

Rods and Welding Parts |

5 |

1000 |

|

10. |

Miscellaneous |

|

3200 |

|

|

|

Total |

30000 |

7. CONCLUSION

A

small prototype melting machine that can melt and produce paver blocks from

waste plastics that are less harmful for the environment which can be used for

some general-purpose applications. The prototype has been developed in terms of

easy to handle keeping in mind the safety aspects.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

We would like to express our sincere gratitude to our teachers for their constant guidance and support throughout this project work.

REFERENCES

Bhogayata, A., Shah, K. D., Vyas, B. A., and Dr Arora, N. K. (2012). Performance of Concrete by Using Nonrecyclable Plastic Wastes as Concrete Constituent. International Journal of Engineering Research and Technology (IJERT), 1(4).

Dhurat, C. (n.d.). Programming Basics : Learn. C No. Coding For Beginners, Kindle Edition.

Elzafraney, M., Soroushian, P., and Deru, M. (2005). Development of Energy Efficient Concrete Buildings Using Recycled Plastic Aggregate. Journal of Architectural Engineering © American Society of Civil Engineers, 11(4), 122-130. https://doi.org/10.1061/(ASCE)1076-0431(2005)11:4(122)

Ghernouti, Y., Rabehi, B., Safi, B., and Chaid, R. (2014). Use of Recycled Plastic Bag Waste in the Concrete Journal of International Scientific Publications : Materials. Methods and Technologies, 8, ISSN 1314-7269 [Online].

Khurmi, R. S. (2020). A Textbook of Machine Design, S Chand (25th Ed).

Kothari, C. R. (2014). Research Methodology: Methods and Techniques, New Age Publication.

Letcher, T. M. (2020). Plastic Waste and Recycling Environmental Impact, Societal Issues, Prevention, and Solutions. Academic Press.

Lokensgard, E. (2009). Industrial Plastics : Theory and Applications Misc. (International Student Ed). Cengage Learning.

Mathew, P., Varghese, Shibi, Paul, T., and Varghese, E (2013). Recycled Plastic as Coarse Aggregate for Structural Concrete. International Journal of Innovative Research in Science, Engineering and Technology, 2(3).

Nivetha, C., Rubiya, M., Shobana, S., and Vaijayanathi, G. (2016). Production of Plastic Paver Block from the Solid Waste. ARPN Journal of Engineering and Applied Sciences, 11(2).

Panneerselvam, R. and Sivasankaran P. (2015). Process Planning and Cost Estimation, PHI Learning Pvt Ltd.

Reddy, M. M., and Ajitha.B. (2012). "Melt-Densified Post- Consumer Recycled Plastic Bags Used as Light Weight Aggregate in Concrete". B and Bhavani.R. International Journal Of Engineering Research and Applications (IJERA) ISSN : 2248-9622, 2(40), 1097-1101.

Richardson, T. L. (1989). Industrial Plastics : Theory and Application (2nd Ed). Cengage Learning.

Rudolph, N. (2017). Raphael Kiesel, Chuanchom Aumnate, Understanding Plastics Recycling: Economic, Ecological, and Technical Aspects of Plastic Waste, Hanser Publications; Pap/Psc Edition. https://doi.org/10.3139/9781569906774.fm

Santhosh, J., and Talluri, R. (2015). Manufacture of Interlocking Concrete Paving Blocks With Fly Ash and Glass Powder. International Journal of Civil Engineering and Technology, 6(4), 55-64.

Sarwe, K. (2014). Study of Strength Property of Concrete Using Waste Plastics and Steel Fibers. International Journal of Engineering Science (IJES. Department of Civil Engineering, Jabalpur Engineering College. 3(5), 09-11.

Sharma, P., and Batra, R. K. (2016). Cement Concrete Paver Blocks for Rural Roads. International Journal of Current Engineering and Scientific Research, 3(1), 114-121.

Singh, K. (2019). Project Management - Evolution To Solution, White Falcon Publishing (1st Ed).

Stroud, I. (2011). Hildegarde Nagy, Solid Modelling and CAD Systems: How to Survive a CAD System, Springer. https://doi.org/10.1007/978-0-85729-259-9

Tapkire, G., Parihar, S., Patil, P., and Hemra, R. (2014). Recycled Plastic Used in Concrete Paver Block. Kumavat. International Journal of Research in Engineering and Technology, 3(09).

Blynk Community. Internet Source.

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© Granthaalayah 2014-2023. All Rights Reserved.