COMPATIBILIZATION STUDY OF BLENDING POLYMERS PLA-PCL WITH FILLERS CATECHIN-CHITOSAN AS NEW MATERIALS FOR BIOPLASTIC MANUFACTURE

Suryani Salim 1![]() , Teuku Rihayat 1, Fitria 2, Aida safitri 3

, Teuku Rihayat 1, Fitria 2, Aida safitri 3

1 Department of Chemical Engineering, Politeknik Negeri Lhokseumawe, Lhokseumawe, Aceh 24301, Indonesia

2 Department of Dermato

Venereology, Medical Faculty, Syiah Kuala University,

Aceh 23111, Indonesia

3 Department of Chemical Engineering,

Faculty of Engineering, Universitas Sumatera Utara, Kota Medan 20222, Indonesia

|

|

ABSTRACT |

||

|

The use of agents in the form of nanochitosan to develop active bioplastics offers a new way to modify the transport properties and release of active compounds while increasing the mechanical resistance and compatibility between polymers. This study aims to study the effect of mixing two polymers in the form of polylactic acid (PLA) and polycaprolactone (PCL) as a matrix and 10% (w/v) filler. The matrix for bioplastic film-forming was prepared by mixing 8 g PLA and 2 g PCL. The internal film and surface microstructures were characterized by scanning electron microscopy (SEM) and interactions between the particles using FT-IR. Mechanical physical properties were reviewed using ASTM D638. The results show that amount of filler composition promotes a significant change in the microstructure of the film and is associated with to improve properties. The amount of nanochitosan (0.9 g) and catechin (0.1) was homogeneously distributed. As a consequence. However, when the filler composition is varied in other quantities, the tensile strength will fluctuate. |

|||

|

Received 24 September 2022 Accepted 25 October 2022 Published 14 November 2022 Corresponding Author Suryani Salim, suryani.salimpnl@gmail.com

DOI10.29121/granthaalayah.v10.i10.2022.4834 Funding: The author

expresses his gratitude and highest appreciation to Sincere appreciation to

the Ministry of Research, Technology and Higher Education of the Republic of

Indonesia and Lhokseumawe State Polytechnic which

has funded through grants number: 737/SPK/D4/PPK.01.APTV/VI/PNL/2022. Copyright: © 2022 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: PLA, PCL, Bioplastic, Mechanical Properties |

|||

1. INTRODUCTION

Concerns about non-biodegradable plastic waste and limited petroleum resources have increased global interest in using bio-based, biodegradable materials, particularly in packaging. Siracusa and Blanco (2020), Sid et al. (2021), Patti and Acierno (2022). Biodegradable packaging materials are a viable alternative to synthetic packaging materials based on petrochemical product. Mohamed and Yusoh (2016), Temesgen et al. (2021) Because biodegradable polymers are becoming more affordable, they have the potential to be used as an environmentally friendly alternative to plastic packaging. Polymers such as polylactic acid (PLA) and polycaprolactone (PCL) can be used as biodegradable packaging materials to replace traditional plastics. PLA and PCL are biopolymers with a high potential to replace traditional plastics. Luckachan and Pillai (2011), Ganewatta et al. (2021), Martinez Villadiego et al. (2021).

Previous research has shown that PLA, PCL, and other polymers are all biodegradable. However, it is still not widely used due to a number of drawbacks. Incorporating polymers rather than chemical modification or customized macromolecular synthesis is one method for improving the thermal resistance and mechanical strength of biodegradable polymers, resulting in balanced properties. Ashothaman et al. (2021), Termizi et al. (2022), PLA (polylactide) is a biodegradable polymer made from renewable sources. PLA is made from lactic acid polymers, whereas lactic acid can be made through enzymatic processes using starch as a raw material. PLA has a wide range of applications (biomedical, packaging, textile fiber and technical goods). Under the influence of heat, bacteria, and light, PLA degradation can occur naturally. Nabgui et al. (2021), El Assimi et al. (2022), Lin et al. (2021) Furthermore, PLA can be degraded in the body without causing harm. Plants like corn and potatoes can be used as feedstock for PLA production. PLA's properties are comparable to those of fossil-based polymers Joseph et al. (2021).

Ring-opening polymerization (ROP) of e-caprolactone and polycondensation of 6-hydroxyhexanoic acid are two methods for producing polycaprolactone. Vieira et al. (2022), Firouz et al. (2021), Barone et al. (2021), Da Costa Monção et al. (2021) The ROP method is preferred because it produces polymers with lower polydispersity index (PDI) values and higher molecular weight, as well as better mechanical properties. PCL is typically synthesized without a catalyst using ring-opening polymerization, but its low melting point results in high production costs and commercial limitations. Rihayat et al. (2021), Ju et al. (2019). Because PCL is used primarily in biomedical and pharmaceutical fields, it should be produced with caution to avoid the presence of toxic compounds that may cause side effects in users or organisms. As a result, combining PLA - PCL with other biofillers can cause deformation and affect its end-of-life characteristics under a variety of environmental conditions. Chitosan is a polysaccharide derived from the deacetylation of chitin found in marine waste, specifically crustacean shells like shrimp, oyster, crab, and lobster. Sucinda et al. (2021), Liu et al. (2021), Salim et al. (2021), Shen et al. (2021), Tezara et al. (2021).

Because it is non-toxic and biodegradable, chitosan has been widely used in the production of edible films. It has high film-forming ability, broad antimicrobial activity, selective permeability to gases (CO2 and O2), and is compatible with vitamins, minerals, and antimicrobial agents. With the addition of chitosan, PLA-mechanical PCL's ability to crystallize and antibacterial properties can be improved. Research in Catechins were used as natural plastic antioxidants to protect the polymer matrix from thermal treatment. Liu et al. (2020) Because catechins have a high hydroxyl group, they can interact with polymer groups, including PLA and PCL, via hydrogen bond interactions.

Based on the advantages of the PLA polymer and several studies, the addition of filler to the PLA matrix and PCL matrix has not produced strong characteristics, so an innovation will be carried out in this study by adding a combination of both catechin and chitosan fillers into the PLA-PCL matrix, which is expected to produce a new biocomposite that has strong characteristics and overcomes the shortcomings of Biodegradable composite.

2. MATERIALS AND METHODS

2.1. MATERIALS

The materials used for the extraction of catechins are jamblang seeds and methanol. The materials used for the manufacture of plastic wrap are PLA, PCL, Nanochitosan, jamblang seed (Lokal agriculture plant), PEG and chloroform all those materials were purchased from sigma aldrich, Jakarta.

2.2. METHODS

2.2.1. EXTRACTION OF CATECHINS USING SOXHLET EXTRACTION

Extraction was carried out using a conventional Soxhlet apparatus referring to the research conducted by previous research. Rihayat (2010) The distillation flask is placed in a bath, thimble holder and condenser. Jamblang seeds are cleaned of flesh, washed and then dried in the sun for 3 hours. The dried seeds are blended until they become powder. Jamblang seed powder is packed in filter paper and placed in a thimble holder. The solvent in the form of methanol was put into a distillation flask. When the boiling point is reached, the liquid moves through the siphon and is lowered back into the distillation flask, bringing the extracted solute into the liquid. The extraction process was carried out for 6 hours. In a solvent flask, the solute is separated from the solvent by the distillation method.

2.2.2. SAMPLE PREPARATION

PLA, PCL, Nanochitosan, Catechins, Aluminum foil, Analytical Balance, Beaker glass, Hotpress, Petri dish and Rod mold. PLA 8 g and PCL 2 g were mixed using a DSM Xplore co-rotating extruder at a melting temperature of 180oC and a screw speed of 100 rpm. Furthermore, it is inserted into the ASTM 638 D Type I Standard specimen mold which is coated with aluminum foil, then compressed using a hot press at a temperature of 180oC for 20 minutes under atmospheric pressure. The formed biocomposite was allowed to stand at room temperature until it solidified completely for further FTIR, and SEM testing.

Table 1

|

Table 1 Sample Preparation |

|||

|

Sample |

Fillers |

||

|

|

|

Nanochitosan |

Catechin |

|

1 |

Xa1 |

0.9 |

0.1 |

|

2 |

Xa2 |

0.8 |

0.2 |

|

3 |

Xa3 |

0.7 |

0.3 |

|

4 |

Xa4 |

0.6 |

0.4 |

|

5 |

Xa5 |

0.5 |

0.5 |

|

6 |

Xa6 |

0.4 |

0.6 |

|

7 |

Xa7 |

0.3 |

0.7 |

|

8 |

Xa8 |

0.2 |

0.8 |

|

9 |

Xa9 |

0.1 |

0.9 |

|

10 |

Xa10 |

1 |

1 |

2.3. CHARACTERIZATION TECHNIQUE

2.3.1. TENSILE STRENGTH

Engineering

tensile tests are mostly carried out to complement the basic design

in-formation for the strength of a material and as supporting data for material

specifications. In the tensile test, the test object is given an axial tensile

force load which increases continuously, at the same time observing the

elongation experienced by the test object.

2.3.2. FT-IR (FOURIER TRANSFORM INFRARED)

Fourier Transform Infrared (FT-IR) is used to identify the type of functional group bonding possessed

by materials including plastics. The purpose of FT-IR analysis on plastic film

samples is to see the wavelength and characteristic peaks in the sample. This

wavelength indicates the presence of certain functional groups in the sample,

because each functional group sample has a characteristic peak that is specific

to that functional group.

2.3.3. Scanning Electron Microscopy (SEM)

Scanning Electron Microscope (SEM) is an electron microscope that is used to view the image surface of a material, besides that it can also provide information regarding the chemical composition of a material, both conductive and non-conductive materials. This microscope uses electro magnetic and electro static to control the incoming light and the appearance of the resulting image. Salim et al. (2021)

3. RESULTS AND DISCUSSIONS

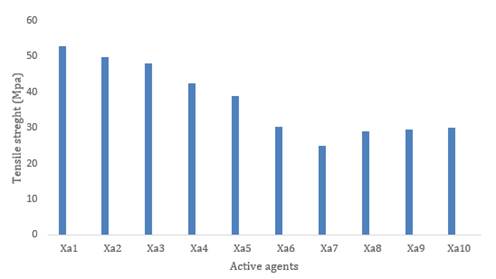

3.1. Tensile Strength

Researchers used PLA-PCL as a matrix to investigate the effect of chitosan content on the mechanical strength of bioplastic samples. The resulting tensile strength increases as the chitosan content increases. Because nanochitosan, as an immiscible component, has low ductility and is a brittle material, its addition stiffens the mixture. Furthermore, good interfacial adhesion between chitosan and PLA-PCL matrix was caused by good dispersion of chitosan particles as a result of chitosan's high solubility with acetic acid solvent. When the total amount of nanochitosan content in the mixture is considered, our results show higher tensile strength at 9% by weight of nanochitosan content. The even dispersion of chitosan particles is due to the constituent materials' good compatibility and immiscibility. Chuesiang et al. (2021)

The effect of

catechins and nanochitosan as active agents on the mechanical properties of

PLA-PCL films is dependent on the molecular structure of the Active Agents,

processing techniques, and conditions.

Figure 1

|

Figure 1 Tensile Strength of Bioplastic |

The mechanical

properties of PLA films changed more as the concentration of active agents

increased. In general, the tensile strength of PLA-PCL films decreased with

active agent incorporation. This is primarily due to the plasticizer effect,

which occurs between the PLA-PCL chains. When a agents is added, the free volume increases, chain

attachment decreases, and chain mobility and flexibility increase.

Nanochitosan, on the other hand, acts as a reinforcing filler in PLA-PCL and

limits the movement of the PLA-PCL segmental chains. Because of the stiffness

of these polysaccharide chains and the resulting interaction between PLA-PCL

and nanochitosan, the film stiffness increases. Suryani et al. (2018) This interaction can take the form of

hydrogen bonds between PLA (carbonyl or hydroxyl end groups) and nanochitosan

hydroxyl/amine/acetamide groups.

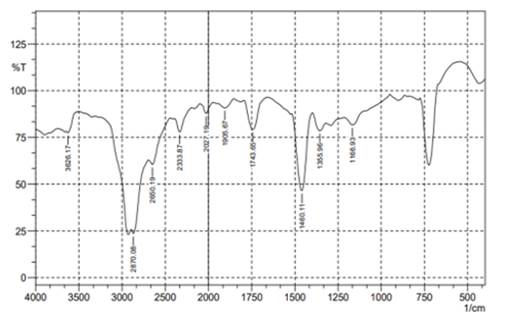

3.2. FTIR of

bioplastic

FT-IR is an instrument that uses the

principle of spectroscopy. Infrared spectroscopy/FTIR is used for

identification of organic compounds because of its very complex spectrum

consisting of many peaks (qualitative analysis). FTIR is also to determine the types

of functional groups that can indicate the general composition of a material.

Initially, tests were carried out for conventional plastic samples and for

bioplastic. For this reason, two measurements at different locations were

obtained from each bioplastic sample. These measurements are presented in Figure 2, with an offset

between them to show the true similarity. As shown, the measurements were very

consistent based on the absorption functional groups of the components.

Table 2

|

Table 2 FTIR Test Observation Data |

||

|

Sample |

Wavelength number (cm-1) |

Functional groups |

|

Neat PLA/PCL (SNI) |

3330-3500 |

O – H |

|

2840-3000 |

C – H |

|

|

1540-1820 |

C = O |

|

|

|

1000-1300 |

C – O |

|

Conventional plastic |

2870.08 |

C – H |

|

1743.65 |

C = O |

|

|

|

1166.93 |

C – O |

|

PLA-PCL/Chitosan/catechin 9,5 g - 0,5 g/ 0,9

g/ 0,1 g |

3348.42 |

O – H |

|

2927.94 |

C – H |

|

|

1163.08 |

C – O |

|

Figure 2

|

Figure 2 FT-IR Spectrum on Conventional Plastics as Comparative Data |

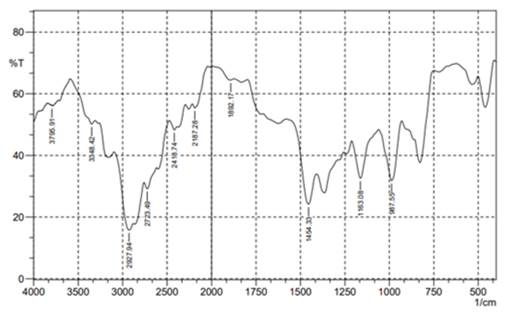

|

Figure 3 FTIR Spectrum On PLA-PCL Based Plastics |

This analysis was carried out to identify the functional groups present in

the produced PLA-PCL/Chitosan-Catechin samples and conventional plastics as a

comparison using a Fourier Transform Infrared (FT-IR) Spectrophotometer. FT-IR

is a widely used method to investigate intermolecular interactions and phase behaviour

between polymers. In Figure 1, the sample in

the form of conventional plastic as a comparison shows the characteristics of

the wave number area of 2870.06 cm-1, 1743.65 cm-1 and 1166.93

cm-1 which shows the C - H and C = O and C - O groups. In Figure 3 with samples of

PLA-PCL 0.9 g chitosan and 0.1 g catechins which are the best results from the

research that has been carried out, it shows the characteristics of the wave

number area of 3348.42 cm-1, 2927.94 cm-1 and 1163, 08 cm-1 which

shows the O – H, C – H, and C – O groups, while for the C = O group there is an

increase which should be in the range 1640-1820 but the results obtained are

1892.17 cm-1. In this study, it was shown that the addition of a new functional

group in the form of O – H which was not found in the plastic sample was used

as a comparison.

Based on the comparison between ordinary plastics and biodegradable

plastics, it was found that the FTIR results of biodegradable plastics were

very close to the plastics used as comparisons, so that the resulting products

had very similar properties to ordinary plastics, although there was a new

functional group, namely, O-H. This is because the constituent materials and

compositions used are different so that they will not produce the same

functional group and wave number.

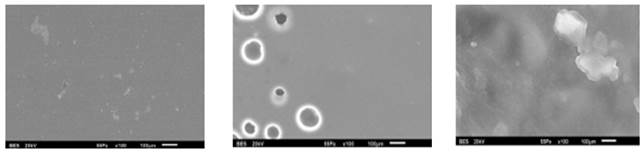

3.3. SEM CHARACTERIZATION OF BIOPLASTIC

SEM testing as

an additional test in this study aims to support the results of the best

samples taken from the main tests of tensile tests and thermal degradation

tests. The samples tested were samples with a variation of (a) Xa1, (b) Xa7,

and (Xa10) based on Table 1. This test aims to see the morphological

structure of PLA-PCL biocomposite using a microscope that relies on electron

beams to describe the surface shape of the analyzed material. The following is

a picture of the results of the analysis under an electron microscope (SEM).

Figure 4

|

Figure 4 SEM Image of Each Bioplastic (a) Xa1, (b) Xa7, and (Xa10) |

The image above

shows the sample's surface structure at x100 magnification, which shows a

smooth surface and a good interfacial bond between the matrix and filler. This

is due to the fact that when PLA polymer is combined with PCL polymer, it has

superior mechanical and surface properties, resulting in good exfoliation or

union with PLA polymer and high missibility. The ability of one liquid to

completely dissolve in another liquid solvent is referred to as miscibility. Suryani et al. (2018) When we have a miscible solution, no

distinct layer between the two liquids forms. Thus, immiscibility occurs when a

distinct layer forms in a mixed solution.

4. CONCLUSIONS AND RECOMMENDATIONS

The composition of 0.9 g Chitosan: 0.1 g Catechins with C - H, O - H, C = O, and C - O groups produced the best results. The SEM test revealed a smooth surface with good interfacial bonds formed between matrix and filler; however, there is still insoluble chitosan residue due to the inhomogeneous blending process and the use of incompatible solvents.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

Ashothaman, A., Sudha, J., and Senthilkumar, N. (2021). A Comprehensive Review on Biodegradable Polylactic Acid Polymer Matrix Composite Material Reinforced With Synthetic and Natural Fibers. Materials Today: Proceedings. https://doi.org/10.1016/j.matpr.2021.07.047.

Barone, A. S., Matheus, J. R. V., De Souza, T. S. P., Moreira, R. F. A., and Fai, A. E. C. (2021). Green‐Based Active Packaging : Opportunities Beyond COVID‐19, Food Applications, and Perspectives In Circular Economy-A Brief Review. Comprehensive Reviews In Food Science And Food Safety, 20(5), 4881-4905. https://doi.org/10.1111/1541-4337.12812.

Chuesiang, P., Sanguandeekul, R., and Siripatrawan, U. (2021). Enhancing Effect of Nanoemulsion on Antimicrobial Activity of Cinnamon Essential Oil Against Foodborne Pathogens in Refrigerated Asian Seabass (Lates Calcarifer) Fillets. Food Control, 122. https://doi.org/10.1016/j.foodcont.2020.107782.

El Assimi, T., Beniazza, R., Raihane, M., Youcef, H. B., El Meziane, A., Kricheldorf, H., and Lahcini, M. (2022). Overview on Progress in Polysaccharides and Aliphatic Polyesters as Coating of Water-Soluble Fertilizers. Journal of Coatings Technology and Research, 1-19. https://doi.org/10.1007/s11998-022-00613-1.

Firouz, M. S., Mohi-Alden, K., and Omid, M. (2021). A Critical Review on Intelligent and Active Packaging in the Food Industry: Research and Development. Food Research International, 141. https://doi.org/10.1016/j.foodres.2021.110113.

Ganewatta, M. S., Wang, Z., and Tang, C. (2021). Chemical Syntheses of Bioinspired and Biomimetic Polymers Toward Biobased Materials. Nature Reviews Chemistry, 5(11), 753-772. https://doi.org/10.1038/s41570-021-00325-x.

Joseph, S. M., Krishnamoorthy, S., Paranthaman, R., Moses, J. A., and Anandharamakrishnan, C. (2021). A Review on Source-Specific Chemistry, Functionality, and Applications of Chitin and Chitosan. Carbohydrate Polymer Technologies and Applications, 2. https://doi.org/10.1016/j.carpta.2021.100036.

Ju, J., Chen, X., Xie, Y., Yu, H., Guo, Y., Cheng, Y., Qian, H., and Yao, W. (2019). Application of Essential Oil as a Sustained Release Preparation in Food Packaging. Trends in Food Science and Technology, 92, 22-32. https://doi.org/10.1016/j.tifs.2019.08.005.

Lin, C., Liu, L., Liu, Y., and Leng, J. (2021). Recent Developments in Next-Generation Occlusion Devices. Acta Biomaterialia, 128, 100-119. https://doi.org/10.1016/j.actbio.2021.04.050

Liu, L., Xu, Y., Pan, Y., Xu, M., Di, Y., and Li, B. (2021). Facile Synthesis of an Efficient Phosphonamide Flame Retardant for Simultaneous Enhancement of Fire Safety and Crystallization Rate of Poly (Lactic Acid). Chemical Engineering Journal, 421. https://doi.org/10.1016/j.cej.2020.127761.

Liu, S., Yu, J., Li, H., Wang, K., Wu, G., Wang, B., Liu, M., Zhang, Y., Wang, P., Zhang, J., Wu, J., Jing, Y.,Li, F., and Zhang, M. (2020). Controllable Drug Release Behavior of Polylactic Acid (PLA) Surgical Suture Coating With Ciprofloxacin (CPFX)-Polycaprolactone (PCL)/Polyglycolide (PGA). Polymers, 12(2). https://doi.org/10.3390/polym12020288.

Luckachan, G. E., and Pillai, C. K. S.

(2011). Biodegradable Polymers-A Review on Recent Trends and Emerging

Perspectives. Journal of Polymers and The Environment, 19(3), 637-676. https://doi.org/10.1007/s10924-011-0317-1.

Martinez Villadiego, K., Arias Tapia, M. J., Useche, J., and Escobar Macías, D. (2021). Thermoplastic Starch (TPS)/Polylactic Acid (PLA) Blending Methodologies: A Review. Journal of Polymers and The Environment, 1-17. https://doi.org/10.1007/s10924-021-02207-1

Mohamed, R. M., and Yusoh, K. (2016). A Review on the Recent Research of Polycaprolactone (PCL). Advanced Materials Research, 1134, 249-255. https://doi.org/10.4028/www.scientific.net/AMR.1134.249.

Nabgui, A., El Assimi, T., El Meziane, A., Luinstra, G. A., Raihane, M., Gouhier, G., Thébaulte, P., Draouig, K., and Lahcini, M. (2021). Synthesis and Antibacterial Behavior of Bio-Composite Materials-Based on Poly (Ε-Caprolactone)/Bentonite. European Polymer Journal, 156. https://doi.org/10.1016/j.eurpolymj.2021.110602.

Patti, A., and Acierno, D. (2022). Towards the Sustainability of the Plastic Industry Through Biopolymers: Properties and Potential Applications To The Textiles World. Polymers, 14(4), 692. https://doi.org/10.3390/polym14040692.

Rihayat, T. (2010). Synthesis and Properties of Biobased Polyurethane/Montmorillonite Nanocomposites. International Journal of Materials and Metallurgical Engineering, 4(5), 341-345.

Rihayat, T., Hadi, A. E., Aidy,

N., Safitri, A., Siregar, J. P., Cionita, T., Irawan, A.P., Hamdan, M. H. M.

and Fitriyana, D. F. (2021). Biodegradation of Polylactic

Acid-Based Bio Composites Reinforced With Chitosan and Essential Oils as

Anti-Microbial Material for Food Packaging. Polymers, 13(22). https://doi.org/10.3390/polym13224019.

Salim, S., Rihayat, T., Riskina, S., and Safitri, A. (2021). Physical and Mechanical Properties of Bamboo/Flax Fibre Reinforced Epoxy Composite Water Absorption Behaviour and High-Temperature Conditions. Plastics, Rubber and Composites, 50(8), 415-424. https://doi.org/10.1080/14658011.2021.1910776.

Shen, Y., Ni, Z. J., Thakur, K., Zhang, J. G., Hu, F., and Wei, Z. J. (2021). Preparation and Characterization of Clove Essential Oil Loaded Nanoemulsion and Pickering Emulsion Activated Pullulan-Gelatin Based Edible Film. International Journal of Biological Macromolecules, 181, 528-539. https://doi.org/10.1016/j.ijbiomac.2021.03.133.

Sid, S., Mor, R. S., Kishore, A., and Sharanagat, V. S. (2021).

Bio-Sourced Polymers as Alternatives to Conventional Food Packaging Materials :

A Review. Trends in Food Science and Technology, 115, 87-104. https://doi.org/10.1016/j.tifs.2021.06.026.

Siracusa, V., and Blanco, I. (2020). Bio-Polyethylene (Bio-PE), Bio-Polypropylene (Bio-PP) and Bio-Poly (Ethylene Terephthalate) (Bio-PET): Recent Developments in Bio-Based Polymers Analogous to Petroleum-Derived Ones for Packaging and Engineering Applications. Polymers, 12(8). https://doi.org/10.3390/polym12081641.

Sucinda, E. F., Majid, M. A., Ridzuan, M. J. M., Cheng, E. M., Alshahrani,

H. A., and Mamat, N. (2021). Development and Characterisation of

Packaging Film from Napier Cellulose Nanowhisker Reinforced Polylactic Acid (PLA)

Bionanocomposites. International Journal of Biological Macromolecules, 187,

43-53. https://doi.org/10.1016/j.ijbiomac.2021.07.069.

Suryani, Agusnar, H., Wirjosentono, B., Rihayat, T., and Nurhanifa. (2018). Thermal Degradation of Aceh's Bentonite Reinforced Poly Lactic Acid (PLA) Based on Renewable Resources for Packaging Application. In AIP Conference Proceedings. AIP Publishing LLC, 2049(1), 020040. https://doi.org/10.1063/1.5082445.

Syafiq, R., Sapuan, S. M., and Zuhri, M. R. M. (2021). Antimicrobial Activity, Physical, Mechanical and Barrier Properties of Sugar Palm Based Nanocellulose/Starch Biocomposite Films Incorporated With Cinnamon Essential Oil. Journal of Materials Research and Technology, 11, 144-157. https://doi.org/10.1016/j.jmrt.2020.12.091.

Temesgen,

S., Rennert, M., Tesfaye, T., and Nase, M. (2021). Review on Spinning of

Biopolymer Fibers from Starch. Polymers, 13(7). https://doi.org/10.3390/polym13071121.

Termizi, M. N. H., Rasidi, M. S. M., Zainuddin, F., and Masa, A. H. (2022). Mechanical and Morphological Properties of Pure Α-Cellulose-Filled Polylactic Acid (PLA) Biocomposite. In AIP Conference Proceedings. AIP Publishing LLC, 2496 (1), 020008. https://doi.org/10.1063/5.0090708.

Tezara, C., Hadi, A. E., Siregar, J. P., Muhamad, Z., Hamdan, M. H. M., Oumer, A. N., Jaafar, J., Irawan, A. P., Rihayat, T. and Fitriyana, D. F. (2021). The Effect of Hybridisation on Mechanical Properties and Water Absorption Behaviour of Woven Jute/Ramie Reinforced Epoxy Composites. Polymers, 13(17). https://doi.org/10.3390/polym13172964.

Vieira, I. R. S., De Carvalho, A. P. A. D., and Conte-Junior, C. A. (2022). Recent Advances In Biobased And Biodegradable Polymer Nanocomposites, Nanoparticles, and Natural Antioxidants for Antibacterial and Antioxidant Food Packaging Applications. Comprehensive Reviews In Food Science and Food Safety, 21(4), 3673-3716. https://doi.org/10.1111/1541-4337.12990.

Da Costa Monção, É., Grisi, C. V. B., De Moura Fernandes, J., Souza, P.

S., and Souza, A. L. (2021). Active Packaging for Lipid Foods and

Development Challenges For Marketing. Food Bioscience. https://doi.org/10.1016/j.fbio.2021.101370.

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© Granthaalayah 2014-2022. All Rights Reserved.