OPTIMIZATION THE PERFOMANCE OF PHOTOVOLTAIC PANELS FOR CITRONELLA OIL DISTILLATION

Nelly Safitri 1![]() , Suprihardi 1,

Ridwan 2, Teuku

Rihayat 2,

Nurhanifa Aidy 3, Een Setiawati 2

, Suprihardi 1,

Ridwan 2, Teuku

Rihayat 2,

Nurhanifa Aidy 3, Een Setiawati 2

1 Department of Electrical Engineering, Lhokseumawe State Polytechnic, Lhokseumawe,

North Aceh, Aceh 24301, Indonesia

2 Department of Chemical Engineering, Lhokseumawe State Polytechnic, Lhokseumawe,

North Aceh, Aceh 24301, Indonesia

3 Department of Renewable Energy

Engineering, Universitas Malikussaleh, Blang Pulo, Muara Satu, North

Aceh, Aceh 24355, Indonesia

|

|

ABSTRACT |

||

|

Photovoltaic

system is a module that is used to absorb heat that is exposed to sunlight

which is converted into electrical energy. The purpose of this research is to

use a solar panel with a capacity of 100 wp to absorb heat which is converted

into electrical energy as much as 100 watts/hour which is later expected to

be a substitute for conventional electricity which will be used for the

refining process. The treatment was carried out by varying the drying time of

citronella leaves 0, 1, 2 and 3 days and the time for citronella oil

distillation operation for 1.5, 3, 4.5 and 6 hours. By using a solar cell

that has a capacity of 100 wp for 6 hours a day when exposed to sunlight it

can produce power of 600 watts / day. Testing of distilled citronella oil

using the photovoltaic method, the best density was obtained at a

distillation time of 1.5 hours with a drying time of 1 day of 0.8889 kg/cm3.

Refractive index testing, drying time of 1 day with a distillation time of

1.5 hours the value obtained is 1.4655. The more the chain components with

the oxygen group are also distilled, the density of the oil will increase so

that the incoming light is more difficult to refract. The yield of lemongrass

oil at a drying time of 3 days with a distillation time of 6 hours the value

obtained was 2.30%. Drying and withering the amount of material that can be

distilled per distillation increases, so that the refining of the material in

a dry state is more efficient. The best distillation time is 6 hours, this

occurs due to the longer a material receives heat, the more evenly

distributed the diffusion process causes the distillation process to be more

efficient and greatly affects the yield and oil yield. |

|||

|

Received 23 September 2022 Accepted 24 October 2022 Published 14 November 2022 Corresponding Author Nelly Safitri, safitrinelly567@gmail.com

DOI10.29121/granthaalayah.v10.i10.2022.4831 Funding: The author

expresses his gratitude and highest appreciation to the sincere appreciation

to the Ministry of Research, Technology and Higher Education of the Republic

of Indonesia and the Lhokseumawe State Polytechnic

which has funded through grant number: 091/SPK/D4/PPK.01.APTV/VI/2022. Copyright: © 2022 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Photovoltaic, Distillation, Essensial Oil, Density, Yield |

|||

1. INTRODUCTION

Indonesia is

rich in essential oil-producing plants. As is known, essential oils are useful

as raw materials for making cosmetics, aromatherapy and so on. Essential oils

are made from distillation of plant parts such as leaves, fruit, seeds,

flowers, roots to all parts of the plant. Essential oil is a potential

agro-industry export commodity that contributes to the country's foreign

exchange. One of the essential plants that are widely available in Indonesia,

especially in Aceh, is an area that has a strategic area for cultivating

essential oil-producing plants including citronella, nutmeg, agarwood, coffee,

and patchouli. Gill et al. (2017), Rihayat et al. (2018).

Essential oil

is a commodity in the agribusiness sector that has a good market and strong

competitiveness in foreign markets. However, it seems that there are still many

plants that produce essential oils that have not been worked on to be ready for

investment. For example, citronella plant.

The results of

the distillation of essential oils are known as fragrant oil seeds. As with the

essential oil industry in Indonesia, it is still carried out by entrepreneurs

who have large capital, because the extraction and distillation processes

require expensive equipment. This is another drawback of the current system,

namely the optimization of energy has not been controlled electronically to

determine the length of distillation time. Zulkifli et al. (2018).

In the process

of refining essential oils, many energy sources come from fuel oil (BBM), fuel

gas (BBG), firewood and electricity from PLN (State Electricity Company). The

energy source that is often used is an energy source that is less

environmentally friendly and its availability can be disrupted at any time

because of its large amount of demand. Therefore, the process of refining

essential oils utilizes sufficient alternative energy sources such as solar

energy sources that can be available in the long term because the energy comes

from the sun.

In this case,

the distillation process (refining) which is often used as a source of heat or

steam in general, uses BBM, BBG and PLN which functions to heat a mixture of

substances to be separated based on differences in boiling points. However, in

this study, researchers want to replace the source of heat or steam energy from

electric heaters, by absorbing solar heat as a source of electricity using a

solar cell that will be used in this essential oil refining process, as

renewable energy that is friendly to the environment does not cause pollution

and does not require costs. There are many who can use this energy, it is

enough when procuring the equipment, the rest is only doing maintenance on the

tool as a replacement energy for fuelwood, diesel and gas. Kültürela and Tarhan

(2016)

According to

the International Renewable Energy Agency (IRENA), photovoltaic system

technology has surpassed Concentrated Solar Power (CSP) technology. As the

photovoltaic cell is exposed to direct sunlight to generate electricity, the

surface temperature of the photovoltaic panel increases, resulting in a

significant decrease in the photovoltaic output power. To optimize the use of

solar panels, a control system is needed that can control the position of the

solar panels so that they always follow the direction and position of the sun

automatically. This system is called tracking solar cell so that the efficiency

of sunlight utilization can be increased. Khudhair et al. (2018), Luyben (2017).

Advances in

solar cell technology are becoming very common nowadays. As is well known that

solar cells can convert sunlight into electrical energy. The most common use of

solar cells in calculators and replace battery functions. Usually for the

provision of power for traffic lights, telephones, house lights, roads,

electric cars and so on. In this study, researchers want to use solar power for

the process of refining essential oils, the raw material used is citronella. Pawel et al. (2018) , Rahul et al. (2016).

2. METHODOLOGY AND CHARACTERIZATION

2.1. METHODOLOGY

The

materials used are citronella plants and water. while the equipment used is a

100 wp solar panel, 12 v 100 ah battery, solar charge

control, ac-dc inverter, element heater, a set of distillation equipment, 10 kg

of citronella.

The raw materials or materials used in this study are citronella plants that have been harvested. at first the citronella leaves were dried for 3-4 hours for 1, 2, and 3 days and those without drying. after that weighed as much as 10 kg for the distillation process. furthermore, for the essential oil refining process, the kettle used for the distillation process is cleaned first, then enter 50 liters of distilled water into the kettle, enter the raw materials used into the kettle as much as 10 kg, then the heater is turned on to reach 100oc, the process is stopped when the distillation time is 1.5 , 3, 4,5 and 6 hours have been completed then the distillation process is complete, the samples obtained are put into a separating funnel and allowed to stand for 1 hour until the water and essential oil are separated. the essential oil that has been obtained will be analyzed. Ranjay et al. (2017) , Shih et al. (2017)

2.2. CHARACTERIZATION

The characterization used for the essential

oil testing process from the distillation process is calculating density,

citronella oil yield analysis and refractive index analysis.

2.2.1. DENSITY ANALYSIS

To calculate

the density, first weigh the empty pycnometer, then fill the empty pycnometer with 10 grams of citronella oil distillate, then

subtract the mass of the pycnometer that has been filled with an empty

pycnometer, then obtain the density. The results of the two values are the

density value of citronella. The treatment was carried out by varying the

drying time 0, 1, 2 and 3 days and the distillate time 1.5, 3, 4.5 and 6 hours. Yang et al. (2018), Rihayat and Suryani

(2010)

2.2.2. REFRACTIVE INDEX ANALYSIS

To perform an analysis of the refractive

index, the sample to be tested is first dripped with a refractometer sample.

Then close the lid tightly let the light pass through the solution and through

the prism so that the light on the screen in the device is divided into two.

After that, Move the boundary mark by turning the adjustment knob, so that it

intersects the point of intersection of the two diagonal lines that intersect

each other visible on the screen. Then, observe and read the refractive index

scale indicated by the needle of the scale screen through the microscope.

Furthermore, the display results in two colors that have been arranged in such

a way that it provides two colors that have clear and crisp colors. Rihayat et al. (2018) , Gavahian et al. (2018).

2.2.3. OIL YIELD ANALYSIS

Calculate the weight of citronella to be

distilled (input), then calculate the final weight of citronella oil obtained

(output).

Yield (%) = Weight of refined oil (output)

x 100%

Weight of distilled citronella (input)

3. RESULTS AND DISCUSSIONS

Citronella oil is produced from the distillation

process by utilizing sunlight using a solar cell (Photovoltaic). The

photovoltaic system used consists of an electrical element (heater) which has

an energy absorption power of 2,000 watts with varying operating times, namely

1.5 hours, 3 hours, 4.5 hours and 6 hours. Then the energy required for this

system is 3,000, 6,000, 9,000 and 12,000 (watts). The energy required for this

system is taken at the maximum energy, which is 6 hours, thus the total energy

requirement for the electrical element (heater) is 2000 watts x 6 hours =

12,000 Watts. And a pump that has an electric energy absorption capacity of 125

watts/hour, so the amount of electrical energy required for a pump is 125

watts/hour x 6 hours = 750 watts. Thus the total electrical energy requirement

for the lemongrass oil refining process is 12,000 watts + 750 watts = 12,750

watts. Analysis of the performance of the photovoltaic system regarding the

calculation of power before application will thus facilitate the process of

preparing solar cells for its application which is to calculate the total power

used x usage time. Gupta et al. (2018) , Gurung and Qiao (2018).

The sun irradiation time in a day lasts from

10.00 to 16.00 with energy absorption time for 6 hours. For the use of Solar

Cells here we use a solar cell with a capacity of 100 Wp. Taking into account

the energy required as much as 12,750 watts. Thus the energy required to set

the maximum usage is 12,750 watts. So with a power of 12,750 watts with a

irradiation time of 7 hours / day with a solar cell capacity of 100 Wp, the

number of solar cells needed is 12,750: (6 x 100) = 21.25 (22) solar cell units

needed, with consideration of energy saving 2 times the electrical energy

required. Gao and Sun (2016)

Based on the journal Experimental study of

photovoltaic panel installation configurations for lighting structures where

the energy requirement for lighting in the home garden is based on the amount

of power required, where the number of lamps used in the garden is 11 units

with energy absorption per unit of 80 watts/hour with lighting time (use ) for

10 hours, then the total electrical energy needed is 11 units x 80 watts x 10

hours = 8,800 watts. Then the need for solar cells to produce 8,800 watts of

electrical energy with the formula Scn (Solar cell needs) = Ten (total energy

needs) / (It(irradiation time) x Csc(Capacity solar cell)) = 8,800 / (5 x1000)

= 1 ,76 (2 units of solar cells needed). Garoosi et al. (2018)

For power storage using a battery (Battery)

with a capacity of 12V/100 Ah to distribute the energy produced as much as

12,750 watts, then the number of batteries needed to store electric current is

12,750: (12 x 100) = 10.6 (11) Unit batteries with 12V/100 Ah capacity. In this

case, according to the calculations contained in the journal Experimental

studies of photovoltaic panel installation configurations for lighting

structures where the battery needs as a medium for storing electrical energy,

the number of batteries used depends on the battery capacity and electrical

energy to be supplied, where the batteries they use are 24v. 250 ah so the

total battery needs / battery capacity (8,800: (24 x 250) = 1.46 (2 units of

batteries used). Hustings

et al. (2022).

In this study, the results of the tests that

have been carried out will be presented. The results of the test were carried

out using distillation products without using the photovoltaic method and

distillation using photovoltaic. The treatment determined for the product yield

was the same, with drying treatments, namely without drying (0 days), 1 day, 2 days

and 3 days. And the variation of distillation time is 1.5 hours, 3 hours, 4.5

hours and 6 hours. The following are the observations of Density Analysis,

Yield Analysis and Refractive Index obtained.

3.1. DENSITY ANALYSIS

Citronella oil was refined for 1.5 hours, 3 hours, 4.5 hours and 6 hours

with drying times of 0, 1, 2 and 3 days. From the results of the distillation

of citronella oil, it was then tested using a pycnometer. Table 1, Table 2

Table 1

|

Table

1 Results

of Distillation of Citronella Oil Without Using Photovoltaic |

||||

|

Distillation

Time |

Fragrant Lemongrass Density Fragrance |

|||

|

(Hour) |

Drying Time (Days) (Kg/cm3) |

|||

|

|

0 |

1 |

2 |

3 |

|

1,5 |

0,8568 |

0,8675 |

0,8548 |

0,8522 |

|

3 |

0,8596 |

0,8641 |

0,8535 |

0,8536 |

|

4,5 |

0,8555 |

0,8639 |

0,8553 |

0,8549 |

|

6 |

0,8574 |

0,8621 |

0,8582 |

0,8574 |

Table 2

|

Table

2 Results

of Distillation of Citronella Oil Using Photovoltaic |

||||

|

Distillation

Time |

Fragrant Lemongrass Density Fragrance |

|||

|

(Hour) |

Drying Time (Days) (Kg/cm3) |

|||

|

|

0 |

1 |

2 |

3 |

|

1,5 |

0,8778 |

0,8889 |

0,8878 |

0,8855 |

|

3 |

0,8776 |

0,8883 |

0,8875 |

0,8861 |

|

4,5 |

0,8775 |

0,8885 |

0,8873 |

0,8860 |

|

6 |

0,8774 |

0,8881 |

0,8872 |

0,8858 |

Distillation of citronella, the highest value was obtained at a

distillation time of 1.5 hours with a drying time of 1 day, namely 0.8675

kg/cm3 which was obtained from distillation without using a solar cell while a

value of 0.8889 kg/cm3 resulted from distillation using a solar cell. From the

two distillation results, both are close to the determined SNI standard, but in

distillation using a solar cell the density gain is closer to the specified

standard. This happens because the citronella leaves are not too dry, so the

oil produced can be distilled properly. The lowest value at the distillation

time of 1.5 hours and drying 3 days, without a solar cell is 0.8522 kg/cm3 and

with a solar cell is 0.8855 kg/cm3 .

Table 3

|

Table 3 Based on International Quality Standards (SNI) |

||

|

Parameter |

Distillation by Utilizing Sunlight Using Solar Cells

(Photovoltaic) |

SNI

06-3953-1995 |

|

Color |

Pale Yellow to Brownish Yellow |

Pale Yellow to Brownish Yellow |

|

Specific Gravity, 25oC (gr/cm3) |

0.862 – 0.882 |

0.875 – 0.893 |

|

Refractive Index, 20oC |

1.415 – 1.472 |

1.466 – 1.475 |

The results of the analysis of the quality of citronella oil with the

influence of various variables on the quality standard (SNI) are presented in Table 3. In Table 3 shows that most of the existing parameters

ranging from color, refractive index and density show numbers that are in

accordance with the applicable quality standards (SNI).

3.2. REFRACTIVE INDEX ANALYSIS

The refractive index of a substance is a measure of the speed of light in

a liquid compared to when it is in air. In the field of chemistry, the

measurement of refractive index is widely used, among others, to determine the

concentration of a solution and to determine the composition of the ingredients

of the solution. The refractive index can be used to determine the quality of a

solution. Table 4. Results of the refractive index of citronella

without using photovoltaic.

Table 4

|

Table

4 Results of Fragrant Lemongrass Refractive Index

Without Using Photovoltaic |

||||

|

Distillation Time (Hour) |

Citronella

Oil Refractive Index |

|||

|

|

Drying

Time (Days) |

|||

|

|

0 |

1 |

2 |

3 |

|

1,5 |

1,4362 |

1,4459 |

1,4381 |

1,4375 |

|

3 |

1,4381 |

1,4447 |

1,4393 |

1,4374 |

|

4,5 |

1,4373 |

1,4454 |

1,4411 |

1,4365 |

|

6 |

1,4425 |

1,4445 |

1,4439 |

1,4351 |

Table 5

|

Table 5 Results of the Refractive Index of Citronella Using Photovoltaic |

||||

|

Distillation Time (Hour) |

Citronella

Oil Refractive Index |

|||

|

|

Drying

Time (Days) |

|||

|

|

0 |

1 |

2 |

3 |

|

1.5 |

1.4639 |

1.4655 |

1.4625 |

1.4617 |

|

3 |

1.4636 |

1.4654 |

1.4623 |

1.4618 |

|

4.5 |

1.4635 |

1.4646 |

1.4625 |

1.4619 |

|

6 |

1.4636 |

1.4645 |

1.4624 |

1.4615 |

The refractive index of a solution is the most important characteristic

parameter and several related parameters such as temperature, concentration

etc. and refractive index measurements can be used in industry to determine the

parameters of concentration, temperature, pressure and so on. Refractive index

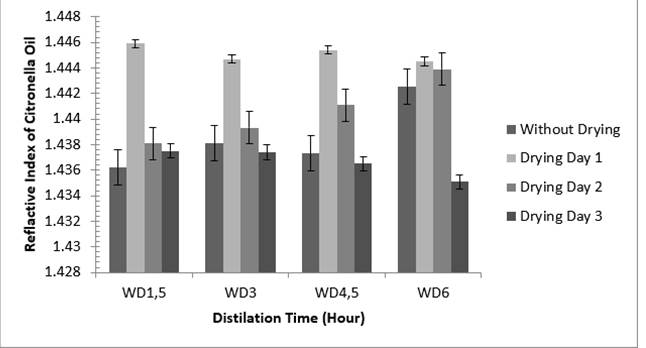

and viscosity have many benefits in everyday life Rodriguez-Gomes et al. (2022). Figure 1. Shows the Refractive Index Graph for the Aroma

Value of Citronella Oil.

Figure 1

|

Figure 1 Refractive Index Graph for Assessing the Fragrance of Citronella Oil Without Using Photovoltaic |

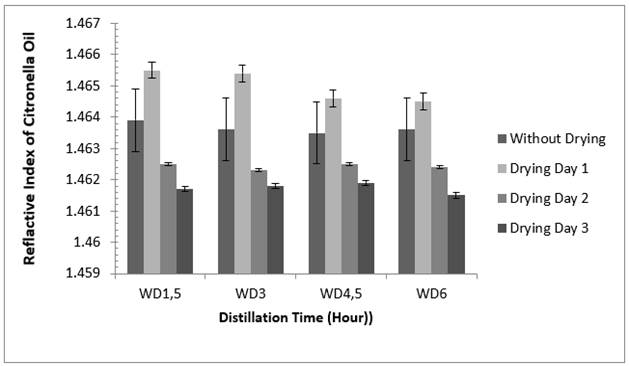

Figure 2

|

Figure 2 Graph of Refractive Index to Assess Fragrance of Citronella Oil by Using Photovoltaic |

In the two graphs above, the distillation time is 1.5 hours with a drying

time of 1 day, for the distillation process with a solar cell the value

obtained is 1.4655, while in the distillation process without a solar cell the

value obtained is 1.4459. From the acquisition of the refractive index analysis

using solar cells and without solar cells, the value obtained in distillation

with solar cells is greater than without the use of solar cells, this is

because the absorption of heat energy from the sun using a solar cell of 12,750

watts is effectively used to essential oil refining process. Eddy et al. (2020) The citronella used as raw material also needs

to be dried so that the water content contained in the citronella can be

reduced and can also keep the components of the oil produced for the better.

because the lemongrass leaves used are still fresh so the oil produced has a

better purity. Drying time for 1 day will produce a higher refractive index

value. This happens because the oil produced tends to be more viscous so that

the water content contained in it is getting less and less. And for the lowest

value in distillation with solar cells and without solar cells, it was obtained

at 6 hours with a drying time of 3 days, namely 1.4615 and 1.4351, this is

because the lemongrass leaves are too dry so that the resulting oil content is

reduced. This happens because the oil produced tends to be more viscous so that

the water content contained in it is getting less and less. And for the lowest

value in distillation with solar cells and without solar cells, it was obtained

at 6 hours with a drying time of 3 days, namely 1.4615 and 1.4351, this is

because the lemongrass leaves are too dry so that the resulting oil content is

reduced. This happens because the oil produced tends to be more viscous so that

the water content contained in it is getting less and less. And for the lowest

value in distillation with solar cells and without solar cells, it was obtained

at 6 hours with a drying time of 3 days, namely 1.4615 and 1.4351, this is

because the lemongrass leaves are too dry so that the resulting oil content is

reduced.

The refractive index of essential oils is closely related to the

components arranged in the essential oil produced. The more long-chain

components such as sequiterpenes or components with oxygen groups are also

distilled, the density of the essential oil medium will increase so that the

incoming light will be more difficult to refract. This causes the refractive

index of the oil to be larger. The more water content, the lower the refractive

index. This is due to the nature of water which is easy to refract the incident

light Dewi et al. (2017) , Nkurikiyimfura et al. (2020). Thus the use of solar

cells in the essential oil refining process is effectively used because in

addition to saving energy usage, it can also shorten the distillation time to

be more efficient with good product results.

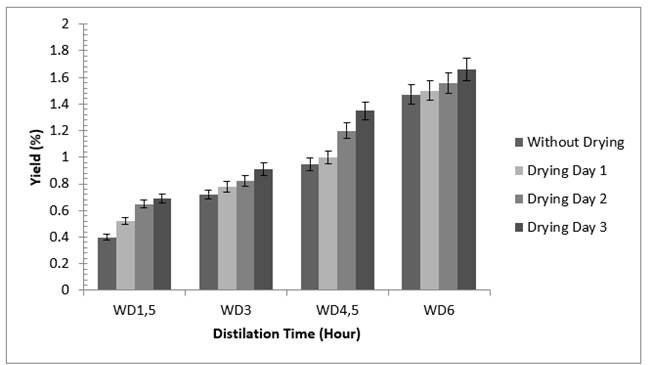

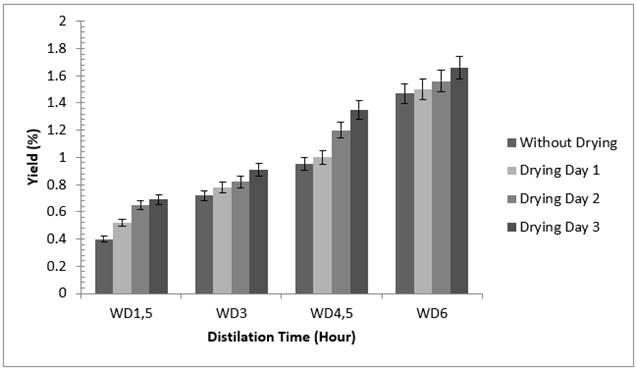

3.3. OIL YIELD ANALYSIS

From the two graphs below, it can be seen that the amount of yield

obtained fluctuated. This happened because of the drying factor on the leaves

of citronella after harvest. Suryani et al. (2018), Ridwan et al. (2018) Actually the best

quality of the oil is obtained from the distillation of fresh leaves. Drying

and withering of citronella leaves before being distilled at a certain time did

not affect the oil yield. The drying and drying process that is too long can

reduce the levels of citronella and total geraniol in the oil. However, the

amount of material that can be distilled per distillation increases, so that

the distillation of the material in the dry state is more efficient.

The highest yield in Figure 3 of the graph of distillation without using a

solar cell is 1.66% with a drying time of 3 days, while the highest yield in Figure 4 of the graph of

distillation using a solar cell is obtained at the time of drying on the third

day, which is 2.30%. The yield of distillation using a solar cell is greater

than that without a solar cell. This is because the absorption of solar heat by

the solar cell is converted into constant electrical energy so that the heat

produced is stable, therefore the use of solar cells results in greater yields

without solar cells. The yields obtained from both samples with solar cells or

without solar cells are indeed higher in product yield, however, the purity and

quality of the oil is reduced. This is evidenced by the data from the lower

density test results obtained on the third day of drying. Likewise with the

results of the refractive index test obtained for drying on the third day the

value obtained is smaller. Bisoffi et al. (2018), Esmaeili et al. (2018) The maximum increase in

yield was due to the softening of leaf tissues when exposed to sunlight, making

it easier to extract. The increase in the yield of citronella oil can be

increased by conditioning and pre-treatment of raw materials such as withering

and size reduction. Bisoffi et al. (2018) , Esmaeili et al. (2018) The maximum increase in

yield was due to the softening of leaf tissues when exposed to sunlight, making

it easier to extract. The increase in the yield of citronella oil can be

increased by conditioning and pre-treatment of raw materials such as withering

and size reduction. Bisoffi et al. (2018), Esmaeili et al. (2018) The maximum increase in

yield was due to the softening of leaf tissues when exposed to sunlight, making

it easier to extract. The increase in the yield of citronella oil can be

increased by conditioning and pre-treatment of raw materials such as withering

and size reduction.

Meanwhile, at the operating time or distillation time of 1.5 hours, 3

hours, 4.5 hours and 6 hours, the highest yield was obtained at 6 hours of

distillation, distillation without solar cells the value obtained was 1.66%

while using solar cells was 2 ,30%. The results of the distillation with

treatment of 1.5 hours, 3 hours, 4.5 hours and 6 hours, indicate the oil at the

time of distillation with a time of 6 hours of constant oil extracted. The

increase in yield at a distillation period of 4.5-6 hours has been maximally

extracted.

The yield of citronella oil depends on various factors, namely climate,

soil fertility, planting age and distillation method. The longer the time of

distillation of essential oils, the higher the yield obtained, but up to a

certain time until the maximum composition of the material. The increase in

yield is caused by the increasing amount of heat received so that the diffusion

process evaporates the oil faster. Caritte et al. (2018)

Figure 3

|

Figure 3 Graph of Effect of Drying Time and Distillation Time on Yield Produced Using Photovoltaic |

Figure 4

|

Figure 4 Graph of Effect of Drying Time and Distillation Time on Yield Produced Using Photovoltaic |

4. CONCLUSION

From the results of the research that has been done, it can be said that, refining essential oils by utilizing alternative energy sources, namely sunlight, is effectively used. The use of solar cells to absorb sunlight into electrical energy is more efficient than the use of firewood for heating lemongrass oil, but it is also more environmentally friendly. In this study also carried out the results of the analysis for testing without using sola cells, the results obtained were the density analysis with an operating time of 1.5 hours and 1 day drying of 0.8675 kg/cm3. And for the analysis of the refractive index obtained the highest value at 1.5 hours of operation with a time of 1 day with the value obtained is 1.4459. While in the analysis of the yield of citronella oil with the highest product obtained at 3 days with a distillation time of 6 hours with a value of 1.66%. Furthermore, for the results of the analysis by refining using a solar cell, the results obtained are as follows. The value of the density analysis at an operating time of 1.5 hours with a drying time of 1 day was 0.8889 kg/cm3. And to analyze the refractive index of the highest value at an operating time of 1.5 hours with a drying time of 1 day the value obtained is 1.4655. The more long-chain components such as sequiterpenes or components with oxygen groups are also distilled, the density of the essential oil medium will increase so that the incoming light will be more difficult to refract. This causes the refractive index of the oil to be larger. The more water content, the lower the refractive index. This is because of the nature of water that is easy to refract the incoming light. While the yield of lemongrass oil at a drying time of 3 days with a distillation time of 6 hours the value obtained was 2.30%. The longer the time of distillation of essential oils, the higher the yield, but until a certain time limit the composition of the ingredients is maximized. The increase in yield is caused by an increase in the amount of heat received so that the diffusion process evaporates the oil faster.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

Bisoffi, A., Forni, F., Lio, M.D, and Zaccarian, L. (2018). Relay-Based Hybrid Control of Minimal-Order Mechanical Systems with Applications. Automatica, 97, 104-114. https://doi.org/10.1016/j.automatica.2018.07.033.

Caritte, R.M., Cheung, K., and Malik, M. (2018). Alternative Approaches and Dynamic Analysis Considerations for Detecting Open Phase Conductors in Three Phase Power Systems. Electric Power Systems Research, 163, 59-65. https://doi.org/10.1016/j.epsr.2018.05.012.

Dewi, E., Irmayanti., Salfauqi, N., Purnama, S. S., Bintamat. (2017). The Effect of Withering and Distillation of Fragrant Citronella (Cymbopogon nardus) in Makmur Jaya Village, Terangun-Gayo Lues District on the Quality of Fragrant Citronella Oil. Seminar National II USM, 1, 513-517.

Esmaeili, H., Karami, A., and Maggi, F. (2018). Essential Oil Composition, Total Phenolic and Flavonoids Contents, and Antioxidant Activity of Oliveria Decumbens Vent, (Apiaceae) At Different Phenological Stages' Cleaner Production, 198, 91-95. https://doi.org/10.1016/j.jclepro.2018.07.029.

Gao, D.Z., and Sun, K. (2016). 16 : DC-AC Inverters. Electric Renewable Energy Systems. 222, 354-381. https://doi.org/10.1016/B978-0-12-804448-3.00016-5.

Garoosi, R.M., Mehrzad, T.R., and Behroch, H.H. (2018). Experimental Evaluation of Rigid Connection with Reduced Section and Replaceable Fuse. Structures, 16, 390-404. https://doi.org/10.1016/j.istruc.2018.11.010.

Gavahian, M., Lee, Y.T, and Chu, Y.H. (2018). Ohmic-Assisted Hydrodistillation of Citronella Oil From Taiwanese Citronella Grass : Impact on The Essential Oil and Extraction Medium. Innovative Food Science and Emerging Technologies, 18, 466-8564. https://doi.org/10.1016/j.ifset.2018.05.015.

Gill, D.J., Roca, L., Zaragoza, G., and Berenguel, M. (2017).

A Feedback Control System With Reference Governor for a Solar Membrane

Distillation Pilot Facility. Renewable Energy, 120, 536-549. https://doi.org/10.1016/j.renene.2017.12.107.

Guo, H., Sun, G., and Yiyon, W. (2018). Simulation of Solar

Cells by Delocalized Recombination Model and its Applications. Solar Energy.

181, 83-87. https://doi.org/10.1016/j.solener.2019.01.075.

Gupta, V.S., Singha, D.B., Mishrab, R.K., Sharmac, S.K., Guptaa, T.V.S., Singha, D.B., Mishrab, R.K., Sharmac, S.K., and Tiwarid, G.N. (2018). Development of Characteristic Equations For PVT-CPC Active Solar Distillation System. Desalination, 445, 266-279. https://doi.org/10.1016/j.desal.2018.08.009.

Gurung, A., and Qiao, Q. (2018). Solar Charging Batteries : Advance, Challenges and Opportunities. Joule, 2, 1217-1230. https://doi.org/10.1016/j.joule.2018.04.006.

Hustings, J., Fransaert, N., Vransken,

K., Cornelissen, R., Valcke, R., and Manca, J. V. (2022). Photovoltaic Photographs", Journal of Solar Energy Materials And

Solar Cell. https://doi.org/10.1016/j.solmat.2022.111917.

Khudhair, M.A., Ajeel, F.N., and Mohammed, M.H. (2018). Engineering And Design of Simple Models From Dye-Sensitive of Solar Cells and Photovoltaic Cells of Solar Applications : Theoretical Study. Chemical Physics Letters, 713, 166-171. https://doi.org/10.1016/j.cplett.2018.10.014.

Kumar, R., Sharma, S., Sharma, S., and Kumar, N. (2016). Drying Method and Distillation Time Affects Essential Oil Content And Chemical Compositions of Acorus Calamus in the Western Himalayas. Applied Research on Medicinal and Aromatic Plants, 3, 136-141. https://doi.org/10.1016/j.jarmap.2016.06.001.

Eddy, K., Nita, S., and Sulhatun. (2020). Extraction of Fragrant Lemongrass into Essential Oil. Unimal Journal of Chemical Technology.

Kültürela, Y., and Tarhan, S. (2016). A Solar Distillery of Essential Oils With Compound Parabolic Collectors (Cpcs). Agricultural Sciences, 31, 72-83.

Luyben, W.L., (2017). Control of Heat-Integrated Extractive Distillation Processes. Computer and Chemical Engineering, 111, 267-277. https://doi.org/10.1016/j.compchemeng.2017.12.008.

Nkurikiyimfura, I, Wang, Y., Safari, B., and Nshingabigwi E. (2020). Electrical and Thermal Perfomances of Photovoltaic/Thermal Systems With Magnetic Nanofluids: a Review. Particuology, 54, 181-200. https://doi.org/10.1016/j.partic.2020.04.004.

Pawel, L., Thomas, W., and Alexandros, R. (2018). The Pole Connector for Miniature Circuit Breakers Used in Photovoltaic Applications. Applied Thermal Engineering, 99, 1057-1070. https://doi.org/10.1016/j.applthermaleng.2015.12.091.

Rahul, S. S., Tejaswi, P. N., Sandeep, Y. M., and Krishna, K. H. (2016). Two Stage Operational Amplifier With a Gain Boosted, Source Follower Buffer. Engineering Trends and Technology (IJETT), 34, 256-259. https://doi.org/10.14445/22315381/IJETT-V34P252.

Ranjay, S., Bansal, R. C, and Arvind, R. S.

(2017). Optimization of an Isolated Photovoltaic Generating Unit With

Battery Energy Storage System Using Electric System Cascade Analysis. Electric

Power Systems Research, 164, 188-200. https://doi.org/10.1016/j.epsr.2018.08.005.

Ridwan,

Wirjosentono, B., Tamrin, Siburian, R., Rihayat, T. and Nurhanifa. (2018).

Modification of PLA/PCL/Aceh's Bentonite Nanocomposites as Biomedical

Materials. AIP Conference Proceedings, 2049 (1), 02008. https://doi.org/10.1063/1.5082413.

Rihayat, T., Suryani, Satriananda, Ridwan, Nurhanifa, Putra, A., Audina, N., Yunus, M. Sariadi, Safari, Jalal, R., Khan, N. S. P., and Saifuddin. (2018). Influence of Coating Polyurethane With Mixture of Bentonite and Chitosan Nanocomposites. AIP Conference Proceedings, Vol. 2049(1), 020020. https://doi.org/10.1063/1.5082425.

Rihayat, T. and Suryani. (2010). Synthesis and Properties of Biobased Polyurethane/Montmorillonite Nanocomposites. International Journal of Materials and Metallurgical Engineering, 4(5).

Rihayat,T., Suryani, Satriananda, Ridwan, Nurhanifa, Putra, A., Audina, N.,Yunus, M., Sariadi, Safari, Jalal, R., Khan, N. S. P. and Saifuddin. (2018). Influence of Coating Polyurethane With Mixture of Bentonite and Chitosan Nanocomposites. AIP Conference Proceedings, 2049 (1), 020020. https://doi.org/10.1063/1.5082425.

Rodriguez-Gomes, F., Campo-Avila, J. D., Ferrer-Cuesta, M.,

Mora-Lopez, L. (2022). Data Driven Tools to Assess The Location of

Photovoltaic Facilities In Urban Areas. Journal Expert Systems With

Applications.

https://doi.org/10.1016/j.eswa.2022.117349.

Shih, Y.M., Enriquez, A.C., Hsiao, T.Y., and Trevino, L.M.T. (2017). Improved Differential Evolution Algorithm for Coordination of Directional Overcurrent Relays. Electric Power Systems Research, 143, 365-375. https://doi.org/10.1016/j.epsr.2016.09.011.

Suryani, Agusnar, H., Wirjosentono, B., Rihayat, T. and Nurhanifa. (2018). Thermal Degradation of Aceh's Bentonite Reinforced Poly Lactic Acid (PLA) Based on Renewable Resources For Packaging Application. AIP Conference Proceedings 2049, 020040. https://doi.org/10.1063/1.5082445.

Yang, Z., Li, W., Chen, X., Su, S., Lin, G., and Chen, J. (2018). Maximum Efficiency and Parametric Optimum Selection of a Concentrated Solar Spectrum Splitting Photovoltaic Cell-Thermoelectric Generator System. Energy Conversion And Management, 174, 65-71. https://doi.org/10.1016/j.enconman.2018.08.038.

Zulkifli, Rihayat, T., Suryani., Facraniah., Habibah, U., Audina, N., Fauzi, T., Nurhanifa., Zaimahwati., Rosalina. (2018). The Process of Purifying Used Cooking Oil Using Banana Kepok Activated Charcoal. International Seminar on Chemistry, 2049. https://aip.scitation.org/doi/pdf/10.1063/1.5082427.

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© Granthaalayah 2014-2022. All Rights Reserved.