MODERN METHODS OF MILK ANALYSIS

Ana Planinić

1 ![]()

![]() ,

Stipe Čelan 1, 2

,

Stipe Čelan 1, 2![]()

![]() , Orjana Semren 1, 2

, Orjana Semren 1, 2![]()

![]() ,

Zora Pilić 1, 3

,

Zora Pilić 1, 3

1 Faculty of Health Studies, University

of Mostar, Mostar, Bosnia and Herzegovina

2 Institute for Food and Veterinary, HB

Canton, Livno, Bosnia and Herzegovina

3 Faculty of Science and Education,

University of Mostar, Mostar, Bosnia and Herzegovina

|

|

ABSTRACT |

||

|

Milk is a product of the mammary gland obtained by proper and regular milking of healthy, properly fed cows, sheep, goats, without adding or taking anything away. This paper describes modern methods used for milk analysis and their working principle. 30 samples of raw milk were collected as follows: 10 samples of cow, 10 samples of goat and 10 samples of sheep raw milk. The obtained

results of raw milk quality parameters were processed, analyzed

and compared with the maximum permissible concentrations prescribed by the

Ordinance on raw milk. The work was written by the method of prospective

study (experimental research). Milk testing was conducted during the period

from 1 March 2020 to May 1, 2020.Samples were collected from primary

producers of raw milk from the territory of Canton 10 in the manner

prescribed by the Regulation on the method of sampling milk. They were

transported and analyzed in the Laboratory for Quality and Microbiology of

Raw Milk - Department of Food and Veterinary Medicine of Canton 10. During

this period, tests of raw milk were performed on the MilkoScan

7 device, a milk analyzer that works on the principle of close infrared

spectroscopy with Fourier transform. |

|||

|

Received 11 July 2022 Accepted 12 August 2022 Published 26 August 2022 Corresponding Author Ana Planinić, ana.planinic123@gmail.com DOI 10.29121/granthaalayah.v10.i8.2022.4724 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2022 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Milk, Milk Fat, Protein, Freezing Point,

Lactose, Casein |

|||

1. INTRODUCTION

Milk is a product of the mammary gland obtained by proper and regular milking of healthy, properly fed cows, sheep, goats, without adding or taking anything away. It is obtained by proper milking, i.e continuous and complete milking. Milk in progress has a different composition. The first jets of milk may contain less than 1% milk fat, and the last may contain more than 10% fat. Therefore, the total amount of milk should be mixed well. The name of the milk depends on its origin (woman's milk, cow's milk, goat's, sheep's, buffalo's, etc.). When there is milk on the market without essential markings, then the name means fresh cow's milk. Cow's milk may not be placed on the market if it comes from cows fifteen days before calving and eight days after calving. Cow's milk in that period is not for human consumption. The use of milk from other animals is geographically limited, and when placing such milk on the market, the milk is marked with the name of the animal from which it originates. All types of milk contain the same ingredients, but the proportions and interrelationships of the ingredients, as well as their structure, can be very different. The milk has a characteristic smell and taste. The taste of milk is slightly sweet due to the presence of lactose. In addition, the taste of milk is affected by the presence of chloride, phosphate, and other substances.

When it comes to the composition of milk, the composition of milk includes several hundred different compounds. Milk consists of dry matter, which has an average of 12.75%, and which consists of all the ingredients that do not evaporate when heated to 102 0 C and water, which has an average of 87.25%. When milk is heated, CO 2, NH 3, H 2 S, O 2, N 2, and H 2 gases and some easily volatile substances such as alcohols, fatty acids, amines, ketones, esters, aromatic compounds and else go along with the water. Table 1

Table 1

|

Table 1 Average Composition of Raw Cow's Milk |

|

|

Ingredients |

Ingredient

content (%) |

|

Water |

86.0-89.0 |

|

Dry

matter |

11.0-14.0 |

|

Fat |

3.2-5.5 |

|

Proteins |

2.6-4.2 |

|

Lactose |

4.6-4.9 |

|

Minerals

(ash) |

0.6-0.8 |

Milk that has not been subjected to a thermal process, i.e., not heated to a temperature above 400 C is called raw cow's milk. However, raw milk is a very sensitive food that is subject to rapid change if it is not handled properly and hygienically. Due to its high nutritional value, neutral pH and high-water activity, raw milk is a good medium for the growth of microorganisms.

In order to successfully conduct the research of this paper, we need to know the quality parameters of raw milk prescribed by the ordinance on raw milk (‘' Official. Gazette of BiH, number 21/11).

The ordinance describes the basic standards and criteria for the quality of raw milk. Raw milk must not contain residues above the maximum permitted values which have pharmacological or hormonal effects, as well as antibiotics, pesticides, detergents and other harmful substances that alter the organoleptic properties of milk. In addition, raw milk must not contain mechanical impurities and additional amounts of water.

The values of raw cow's, sheep's and goat's raw milk can be compared according to the data from Table 2 and Table 3.

The freezing point of milk according to the regulations is the temperature at which the milk passes from the liquid to the solid state. The freezing point is determined in order to determine whether and how much water has been added to the milk, i.e., whether the milk is counterfeited and is one of the most important measures for determining the quality of milk. Counterfeiting is any accidental or intentional change in the composition of milk.

Table 2

|

Table 2 Quality Parameters of Raw Cow's Milk Prescribed by The Ordinance on Raw Milk |

|

|

QUALITY

STANDARDS |

RAW

MILK |

|

Milk

fat |

>

3.2% |

|

Proteins |

>

2.8% |

|

Fat-free

dry matter |

>

8.5% |

|

Density

(at 2◦C temp .) |

1,028-1,034

g / cm 3 |

|

Degree

of acidity |

6.6-6.8

◦SH |

|

pH value |

6.4-6.8 |

|

Freezing

point |

<-0.520

◦C |

|

The

result of an alcohol test with 72% ethyl alcohol |

Negative |

Table 3

|

Table 3 Quality Parameters of Raw Sheep's and Goat's Milk Prescribed by The Ordinance on Raw Milk |

||

|

QUALITY

STANDARDS |

SHEEP

RAW MILK |

GOAT

RAW MILK |

|

Milk

fat |

>

4.0% |

>

2.8% |

|

Proteins |

>

3.8% |

>

2.5% |

|

Fat-free

dry matter |

>

9.5% |

>

7.5% |

|

Density (at temp 20◦C) |

1,034-1,042

g / cm 3 |

1,024-1,040

g / cm 3 |

|

Degree

of acidity |

8-12◦SH |

6.5-8.0 |

|

Ph value |

6.5-6.8 |

6.4-6.7 |

|

Freezing

point |

<-0.560

◦C |

<-0.540

◦C |

Various analytical methods (gravimetric, volumetric and titrimetric) have been developed to monitor the quality of milk and dairy products.

These methods have proved unsuitable for processing a large number of samples: it takes some time to obtain results and the costs of analysis are high. However, by applying automation to standard methods, some shortcomings have been corrected, but the biggest step forward has been made by developing measuring instruments whose work is based on testing the chemical and physical properties of milk, with or without minimal processing and sample manipulation Andersen et al. (1986), Matijević and Blažić (2008). Spectrometric techniques, in combination with chemometric methods, are used for qualitative and quantitative analysis of milk ingredients and diary products. Matijević and Blažić (2008),Karoui et al. (2007).

Spectrometry is a branch of analytical chemistry that deals with obtaining information on the chemical composition and structure of matter based on the separation, detection and measurement of energy changes occurring in atomic nuclei, atomic electron shell or molecules as a result of their interaction with electromagnetic radiation. It is of paramount importance in the analysis and research of substances.

The application of spectrometric techniques in dairy enables fast and cheap qualitative and quantitative analysis of product. Most spectrometric techniques, which allow direct study of the structure and texture of the matter in multiphase systems, are still developing Matijević and Blažić (2008), Karoui et al. (2007). Light with a wavelength of 3.5 and 5.7 μm is used to determine the amount of fat in milk, and research has obtained better results at a wavelength of 3.5 μm. Measurement of the amount of protein is performed at a wavelength of 6.5 μm, and lactose at 9.5 μm Matijević and Blažić (2008), Günzler and Gremlich(2006). The spectrometric techniques used are infrared and fluorescent spectrometry and nuclear magnetic resonance Matijević and Blažić (2008), Karoui et al. (2007). The most commonly used method for determining the content of fat, protein, lactose and dry matter in milk and milk products is infrared spectrometry, which is based on the principle of absorption of infrared light passing through the test sample. The great importance of infrared spectrometers is based on the high information value of the spectrum and on the various possibilities of measuring the sample and preparing the compounds.

Near infrared spectrometry (NIR s) is spectrometric method that uses an infrared range of the electromagnetic spectrum of 780 to 2500 nm. The advantage of this method is that no sample preparation is required, which makes the analysis simple and fast. NIRs can control milk, dairy products and the production process. It is based on the measurement of the reflection after light absorption, which is directly related to the concentration of the test substance. Fast near infrared spectrometry in routine analytics and process control replaces common, expensive and demanding classical analytical methods.

Fluorescence spectrometry is based on the measurement of the strength of fluorescent radiation and enables the quantitative determination of traces of inorganic and organic substances. This spectrometric technique is characterized by high sensitivity (100 to 1000 times more sensitive than other spectroscopic techniques), with equal selectivity, and often better. The application, however, is limited to those chemical systems that can fluoresce.

MilkoScan 7 RM is a fully automatic high-capacity milk analyser (120 samples per hour) for monitoring and analysing milk quality. The analyser works on the principle of infrared spectroscopy with Fourier transform. It works with the mid-infrared region of the spectrum 2-11 µm which corresponds to 1000-5000 cm -1.

2. MATERIALS AND METHODS

2.1. Materials

In writing the paper, the results of testing the quality parameters of raw milk from the territory of Canton 10 were used. In order to describe the composition and characteristics of milk (physico-chemical and microbiological parameters) the following literature was used: Stojanovic L. V. Katic, Milk Hygiene, Belgrade, 1998, Rulebook on raw milk-BiH Official Gazette, number 21/11, - Decree on the manner of sampling, classification and calculation of milk prices, Official Gazette of the Federation of BiH, No. 84/16.

2.2. Place and time of research

The paper was written by the method of prospective research (experimental research), milk testing was conducted in the period from March 1, 2020, to May 1, 2020. Samples were collected from primary producers of raw milk from Canton 10 in the manner prescribed by the Regulation on milk sampling. They were transported to the Laboratory for Quality and Microbiology of Raw Milk - Department of Food and Veterinary Medicine of Canton 10. During this period, tests of raw milk were performed on the MilkoScan 7 device, a milk analyser operating on the principle of close infrared spectroscopy with Fourier transform. The obtained results of raw milk quality parameters were analysed and compared with the Ordinance on raw milk quality.

2.3. Research parameters

The quality parameters of raw milk were analysed: milk fat, proteins, lactose, dry matter, non-fat dry matter, freezing point. The results of the parameters of raw milk quality of local producers obtained by analyses of raw milk conducted in the Laboratory for Quality and Microbiology of Raw Milk - Department of Food and Veterinary Medicine of Canton 10 were used. The obtained data were processed in Microsoft Office Word 2007 (Microsoft Corporation, Redmond WA, SA.) And Microsoft Excel 2007 (Microsoft Corporation, Redmond WA, SA.)

3. RESULTS AND DISCUSSION

Samples were collected from primary producers of raw milk

from the territory of Canton 10 in the manner prescribed by the Regulation on

the method of milk sampling. They were transported to the Laboratory for

Quality and Microbiology of Raw Milk - Department of Food and Veterinary

Medicine of Canton 10. During this period, tests of raw milk were performed on

the MilkoScan 7 device, a milk analyser operating on

the principle of close infrared spectroscopy with Fourier transform. The

obtained results of raw milk quality parameters were analysed and compared with

the Ordinance on raw milk quality. Collection and testing of milk samples was

conducted in the period from March 1, 2020, to May 1, 2020. Table 4, Table 5, Table 6, Graph 1, Graph 2

Table 4

|

Table 4 Results of Test Parameters of Raw Cow's Milk |

||||||

|

No |

Milk fat% |

Proteins% |

Lactose% |

Dry matter % |

Fat-free dry matter% |

Freezing point Mc |

|

1 . |

3.91 |

3.24 |

4.56 |

12.69 |

8.52 |

-520 |

|

2 . |

4.02 |

3.47 |

4.58 |

13.03 |

8.77 |

-521 |

|

3 . |

3.88 |

3.37 |

4.54 |

12.75 |

8.62 |

-516 |

|

4 . |

4.06 |

3.41 |

4.58 |

13.02 |

8.7 |

-522 |

|

5 . |

3.85 |

3.24 |

4.46 |

12.49 |

8.38 |

-517 |

|

6 . |

3.7 |

3.38 |

4.71 |

12.73 |

8.82 |

-525 |

|

7 . |

3.92 |

3.44 |

4.57 |

12.89 |

8.74 |

-517 |

|

8 . |

3.83 |

3.21 |

4.44 |

12.42 |

8.34 |

-514 |

|

9 . |

4.03 |

3.39 |

4.58 |

12.96 |

8.66 |

-511 |

|

10 . |

4.26 |

3.62 |

4.62 |

13.55 |

8.99 |

-512 |

|

average value |

3.95 |

3.38 |

4.56 |

12.85 |

8.65 |

-518 |

Table 5

|

Table 5 Results of Raw Sheep Milk Test Parameters |

||||||

|

No |

Milk fat% |

Proteins% |

Easy for% |

Dry matter % |

Fat-free dry matter% |

Freezing point Mc |

|

1 . |

7.17 |

6.13 |

4.41 |

19.37 |

11.72 |

-530 |

|

2 . |

6.58 |

5.93 |

4.42 |

18.62 |

11.5 |

-534 |

|

3 . |

6.77 |

6.11 |

4.48 |

19 |

11.76 |

-533 |

|

4 . |

6.98 |

6.33 |

4.33 |

19.44 |

11.85 |

-530 |

|

5 . |

7.47 |

5.99 |

4.44 |

19.61 |

11.59 |

-534 |

|

6 . |

5.94 |

5.73 |

4.57 |

17.82 |

11.37 |

-526 |

|

7 . |

7.25 |

6.08 |

4.35 |

19.42 |

11.62 |

-540 |

|

8 . |

4.78 |

5.67 |

4.56 |

16.5 |

11.26 |

-525 |

|

9 . |

7.22 |

6.06 |

4.33 |

19.44 |

11.59 |

-542 |

|

10 . |

6.89 |

6.21 |

4.37 |

19.26 |

11.8 |

-535 |

|

average value |

6.7 |

6.02 |

4.43 |

18.84 |

11.61 |

-532 |

Table 6

|

Table 6 Results of Raw Goat Milk Test Parameters |

||||||

|

No |

Milk fat% |

Proteins% |

Lactose% |

Dry matter % |

Fat-free dry matter% |

Freezing point Mc |

|

1 . |

3.44 |

2.88 |

4.23 |

11.62 |

7.81 |

-526 |

|

2 . |

3.52 |

2.92 |

4.25 |

11.73 |

7.85 |

-525 |

|

3 . |

3.24 |

2.86 |

4.18 |

11.33 |

7.73 |

-524 |

|

4 . |

3.9 |

2.9 |

4.27 |

12.12 |

7.87 |

-532 |

|

5 . |

3.28 |

2.81 |

4.27 |

11.45 |

7.8 |

-531 |

|

6 . |

5.8 |

6.1 |

4.46 |

18.02 |

11.78 |

-536 |

|

7 . |

4.01 |

2.98 |

4.37 |

12.54 |

8.14 |

-528 |

|

8 . |

3.33 |

3.37 |

4.17 |

11.96 |

8.3 |

-524 |

|

9 . |

3.85 |

2.9 |

4.24 |

12.15 |

7.88 |

-527 |

|

10 . |

3.51 |

2.87 |

4.26 |

11.66 |

7.79 |

-526 |

|

average value |

3.78 |

3.26 |

4.27 |

12.46 |

8.3 |

-528 |

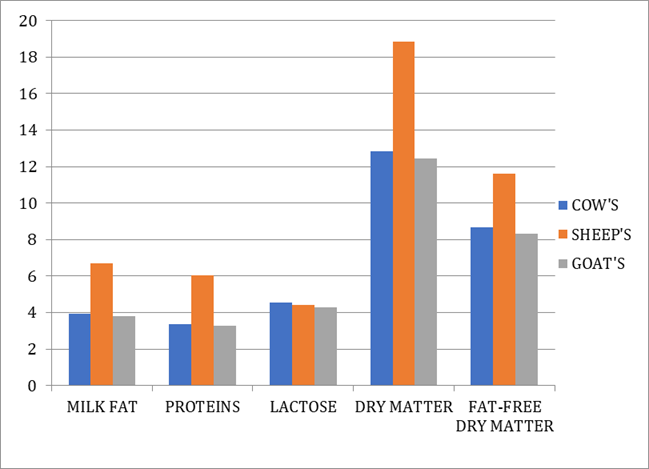

Graph 1

|

Graph 1 Representation of Average Values for Cow, Sheep and Goat Milk |

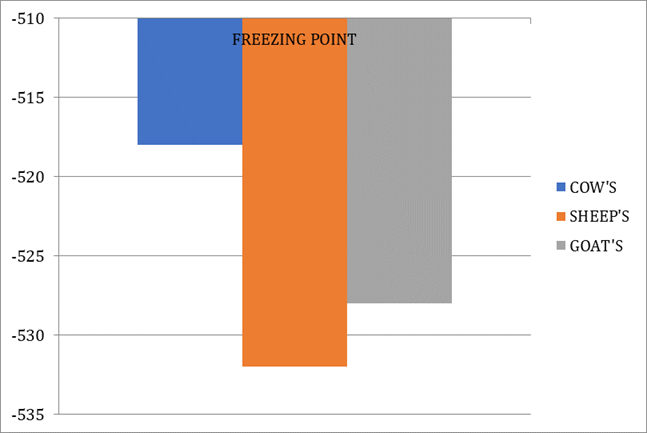

Graph 2

|

Graph 2 Representation of Average Values Freezing Point for Cow, Sheep and Goat Milk |

According to the obtained results of physico-chemical tests of cow's, goat's and sheep's raw milk conducted in the Laboratory for Quality and Microbiology of Raw Milk of the Food and Veterinary Institute of Canton 10, it was determined that all tested quality parameters of raw milk are in accordance with the Ordinance on raw milk.

Through the examination of cow's milk, it was determined that the average value of milk fat is expressed as a percentage of 3,946, while according to the rulebook on raw milk (" Official Gazette of BiH", No. 21/11), which is listed in Table 2 of this paper the milk fat of cow's milk should be greater than 3.2%. During the test, in addition to cow's milk, sheep's and goat's milk was also sampled. The study found that the average value of milk fat of sheep's milk is significantly higher than cow's milk, i.e., 6.705%, and according to the rulebook on raw milk (" Official Gazette of BiH", No. 21/11), it should be more than 4%. Goat's milk also meets the quality standards of milk as well as cow's and sheep's milk, i.e., according to the goat's milk test it was determined that the average value of milk is expressed in percentages of 3.78, while according to the rulebook on raw milk (‘' Fig. Gazette '', No. 21/11) which is listed in Table 3 of this paper, the milk fat of goat's milk should be greater than 2.8%.

Furthermore, when we talk about proteins in raw cow's milk, according to the rulebook on raw milk (" Official Gazette of BiH", No. 21/11), there should be 2.8% more. The study Table 4 found that the average value of protein in cow's milk was expressed as a percentage of 3.38. When we talk about proteins in sheep's raw milk according to the rulebook on raw milk (" Official Gazette of BiH", No. 21/11), there should be more than 3.8%. The study Table 5 found that the average value of protein in sheep's milk was expressed as a percentage of 6,020. Also, according to the research, the average value of protein in goat's milk was determined Table 6. It expressed as a percentage is 3,260. The Rulebook on Raw Milk (" Official Gazette of BiH", No. 21/11) states that the percentage of protein in goat's milk should be higher than 2.5%.

On the other hand, the conducted research determined the average value of dry matter without fat for cow (11.61%), sheep (11.61%) and goat (12.46%) raw milk. According to the Rulebook on Raw Milk (" Official Gazette of BiH", No. 21/11), which is listed in Table 2 and Table 3 of this work the fat-free dry matter should be more than 8.5% for cow's milk, 9.5% for sheep's milk and more than 7.5% for goat's raw milk.

Also, observing the parameters of the freezing point, which according to the Rulebook on Raw Milk (" Official Gazette of BiH", No. 21/11) for raw cow's milk should be <- 0.52 C °, it was found that the tested samples in accordance with quality parameters and the average value of the freezing point of the same is -0.51C °. In the case of raw sheep's and goat's milk, the freezing point is slightly higher and according to the Ordinance for sheep's milk it should be <-0.56 C °, and goat's milk has a freezing point <-0.54C °. The tested samples for sheep's milk are in accordance with the standards and the freezing point is -0.53C °, while the freezing point in goat 's milk according to the test is -0.54C °.

Regarding lactose, for which we also conducted research for raw cow's, goat's and sheep's milk, we can read from the above Tables 6, 7, and 8. that the percentage of lactose in cow's milk is 4.56, in goat's milk 4.27%, and in sheep's raw milk the lactose content is 4.43%.

When we talk about dry matter, the percentage value in the conducted research for raw cow's milk is 12.85. Goat's milk has a slightly lower value of 12.46%, while sheep's milk has a higher dry matter content (18.84%) compared to cow's and goat's milk.

4. CONCLUSION

Based on the results obtained by this study of cow's sheep and goat's milk, the following conclusions be drawn:

The tested samples of cow's, sheep's and goat's milk are in accordance with the provisions adopted in the Rulebook on Raw Milk (" Official Gazette of BiH", No. 21/11)

1) From the obtained results we can conclude that cow's and goat's milk have an approximate percentage of milk fat (cow's 3.95%, goat's 3.78%), while sheep's milk has an average milk fat value of 6.70%

2) After testing, the average protein value in cow's milk is 3.38%, in sheep’s milk 6.020%, and in goat's milk 3.260%. Given these results obtained by the research, we can conclude that the tested samples are in accordance with the provisions written in the ordinance on raw milk. ('' Official Gazette of BiH '', No. 21/11)

3) The average freezing point value of cow's, sheep's and goat's milk also corresponds to the provisions adopted in the Ordinance on raw milk.

4) According to the obtained results, we can conclude that sheep's milk, in contrast to cow's and goat's milk, has significantly higher average values in all parameters except in the percentage of lactose, casein and the number of somatic cells.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

I also thank all those who helped me in any way during my studies and making this final paper. Special thanks to the mentor prof. Dr. sc. Zora Pilić and co-mentor Master of Environmental Public Health, Stipe Čelan on the indicated trust and expert advice and Orjana Semren for facilitating the implementation of research at the Institute for Food and Veterinary HB Canton, Livno BiH.

REFERENCES

Andersen, T., Brems, N., Borglum, M.M., Kold-Christensen, S., Hansen, E., Jorgensen N, J.H., and Nygaard, L. (1986). Modern Laboratory Practice-1 : Chemical Analyses, Modern Dairy Technology: Advance in Milk Products,(Robinson, R.K.), Elsevier Applied Science Publishers, London and New York, 2, 307-343.

Günzler, H., Gremlich, H.U. (2006). Uvod u infracrvenu spektroskopiju, (preveli Meić, Z., Baranović, G.), Školska knjiga, Zagreb.

Karoui, R., Dufour, É., And De Baerdenaeker, J. (2007). Front Face Fluorescence Spectroscopy Coupled With Chemometric Tools for Monitoring the Oxidation of Semi-Hard Cheeses Throughout Ripening, Food Chemistry, 101, 1305-1314. https://doi.org/10.1016/j.foodchem.2006.01.028

Matijević, B., Blažić, M. (2008). Primjena spektroskopskih tehnika i kemometrijskih metoda u tehnologiji mlijeka, Mljekarstvo 58 (2) 151-169.

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© Granthaalayah 2014-2022. All Rights Reserved.