0B0BMEASUREMENT OF THE DETERIORATION OF THE DIESEL ENGINE OIL USING THE IDT CAPACITOR SENSORYoun Joung Cho 1, Tae Ho Sin 1, Jae Hyeon Jeon 1, Sang Hoon Lee 1 1B1B1 Department of Mechanical and Automotive Engineering, Seoultech, Seoul, Republic of Korea. |

|

||

|

|

|||

|

Received 6 December2021 Accepted 17 December2021 Published 30 January2022 Corresponding Author Sang

Hoon Lee, hyla@seoultech.ac.kr DOI 10.29121/granthaalayah.v10.i1.2022.4449

Funding:

This

research received no specific grant from any funding agency in the public,

commercial, or not-for-profit sectors. Copyright:

© 2022

The Author(s). This is an open access article distributed under the terms of

the Creative Commons Attribution License, which permits unrestricted use, distribution,

and reproduction in any medium, provided the original author and source are

credited.

|

ABSTRACT |

|

|

|

A

capacitor-type engine oil sensor is designed and fabricated to measure the

property of the diesel engine oil depending on the vehicle mileage. This

sensor has flat structure with the interdigitated (IDT) electrodes for the

smooth oil flow and is constructed using printed circuit board (PCB) for the

fabrication convenience. For the increased capacitance, the smaller spacing

between the electrodes is preferred and determined with 0.5 mm based on the

fabrication limit. The device is applied to actual trucks with diesel engine.

From the experiment, the capacitance of vehicle A is initially constant and

then increased upto approximately 6,000 km. And

then, the output is dramatically decreased, which indicates that the engine

oil has been degraded and should be replaced. The interval at which the

reduction in capacitance occurs varies depending on each vehicle, which means

the exchange interval of engine oil is different from each other. The degree

of deterioration of the oil is also measured with the viscosity tests and

total acid number (TAN) tests, and the results are compatible with the

measurement of capacitance. From these results, it has been confirmed that

the fabricated IDT capacitor sensor can measure the engine oil conditions

depending on the mileage. |

|

||

|

Keywords: Engine

Oil, Capacitance, Dielectric Constant, Oil Deterioration, Interdigitated

(IDT) Capacitor Sensor 1. INTRODUCTION The engine oil forms a

thin oil film inside the engine, minimizes abrasion and friction between

metals, and serves to keep the engine clean and cool Kim et al. (2017), Raposo

et al. (2019). Since the

engine oil is an additive and makes the engine run smoothly, it should be

changed in the proper time. If the engine oil exchange is delayed, the

viscosity may be increased due to the depletion of the oil liquidization agent or be reduced by changes in the

components caused by metal debris and shear forces caused by continued engine

running. For this reason, a change in the viscosity of the engine oil can

significantly reduce the efficiency and performance of the engine, which can

damage the vehicle Guan et al. (2011), Akbiyik

et al. (2022), Agoston

et al. (2005). On the other hand,

frequent replacing of engine oil causes social problems such as economic

loss, waste of resources, and environmental pollution caused by the

generation of large amount of waste oil Agoston

et al. (2005). Therefore,

changing the engine oil at the correct time is very important. According to the

instruction manual of automakers, the proper exchange of engine oil is around

10,000 to 20,000 kilometers, and also recommended to

be changed every 12 months Kim et al. (2014). However,

because the timing |

|

||

of the change of engine oil depends on the characteristics of the driver, driving environment, and mileage, drivers need to change the engine oil according to their individual driving characteristics. Therefore, it is necessary to detect the status of engine oil in order to check the appropriate exchange cycle. From early 2000s, various research has been performed with the viscosity Agoston et al. (2005), Yanaseko et al. (2019), dielectric constant Dingxin et al. (2011), Kim et al. (2014), and TAN of engine oil Kim et al. (2001) for the proper exchange time.

In this study, an interdigitated (IDT) capacitor sensor was developed that can detect the condition of the oil by using the capacitance value to determine the characteristics of the engine oil. The designed sensors were simply fabricated using a lithography process with a PCB board, and they measured the capacitance value of the engine oil. Prior to actual vehicle application, preliminary experiments were conducted in the laboratory to determine the basic characteristics of the sensors, and to check the temperature effect on the engine oil. Based on these results, we applied the sensors to the engine oil collected from actual transported vehicles and performed the experiments to measure the degradation state with the capacitance change.

2. THEORETICAL BACKGROUND

2.1. PRINCIPLE OF SENSOR MEASUREMENT

There are many ways to measure the degradation of engine oil. First, there is a method using viscosity. The viscosity changes due to the change of additives and oil composition during operation. This value can be used to determine the degradation of the engine oil. Another way is to measure the total amount of acid (TAN) in the engine oil. The oil (hydrocarbons) reacts with the oxygen and is gradually oxidized during the operation. Oxidization reduces the performance of engine oil, and the degree of oxidation can be measured with TAN value. The TAN value is represented with the amount of Potassium hydroxide (KOH in mg) to neutralize the acid. However, the measurements with viscosity and TAN requires the expensive equipment or long-term verification. To solve these problems, we used a capacitive measurement method. The capacitance is the value of accumulated charge when the voltage is applied to the separated conductors. The capacitance is related with the permittivity of engine oil and can be simply measured without additional equipments. Moreover, the capacitor can be easily fabricated with standard lithography process.

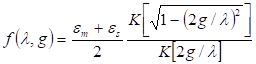

The various types of capacitors have been used like a co-axis circular capacitor, a parallel plate capacitor, and IDT capacitor with multiple finger electrodes. In this study, the IDT capacitor form was adopted because the spacing between electrodes can be precisely defined with the conventional fabrication process, and the engine oil can pass over the capacitor with less resistance. Figure 1 shows the schematic view of the designed sensor with the IDT capacitor. In the IDT capacitor, the total capacitance is known as equation (1) and (2) Liu et al. (2015),

|

|

|

Figure 1 Schematic view of the designed

IDT capacitor sensor |

![]() (1)

(1)

(2)

(2)

where C, ε0, εm, and εs represents the capacitance of engine oil, dielectric constant of air, relative dielectric constants of oil and substrate, respectively. The dimensions of IDT capacitor are also considered in equation (1) and (2) using the length (L), height (h), and spacing of fingers (g). The width (W) is used in the form of wavelength (λ). The number of fingers, N are also involved.

For the device design, the analysis was carried out to identify the overall trend of the variables. The equation (1) and (2) have the primary elliptical integration, and we use the commercial engineering tool, MATLAB. As shown in Figure 2, the function f in equation (1) increases as the spacing between the fingers decreases. Since the equation (1) is proportional to equation (2), reducing the spacing between fingers increases the capacitance value. It is also shown that increasing N and L values through equation (1) results in a large capacitance value as shown in Figure 3. Therefore, the size of the sensor should be as large as possible, and the spacing between the fingers should be minimized in order to increase the capacitance value for the stability of the sensor.

|

|

|

Figure 2 The capacitance graph in IDT sensor with finger spacing |

|

|

|

Figure 3 The capacitance graph with

finger number (left) and finger length (right) |

2.2. PRELIMINARY INVESTIGATION ON DIESEL ENGINE OIL

The moisture can be contained in the engine oil during the engine operation. In that case, the composition of engine oil is changed, and the accurate measurement of the capacitive change can be interfered Qiang et al. (2012). Therefore, the temperature should be increased by more than 80 oC for the less influence of the moisture. And the temperature of the engine oil in the vehicle is maintained between 80 and 95 oC by the cooling system of the vehicle Kim et al. (2017). As the engine oil may have different characteristics depending on temperature, the temperature of the engine oil needs to be specified based on that of actual vehicle. Therefore, prior to the experiments of engine oil taken from the actual vehicle, the test should be conducted to determine the characteristics of the engine oil according to the temperature. The experiment was performed using the new oil and the capacitance change was measured every 10 oC from 40 oC to 80 oC. As shown in Figure 4, it can be seen that the capacitance value increases proportionally with the temperature and represents a certain range of capacitance values for each temperature.

|

|

|

Figure 4 Capacitance measurement results with respect to temperature |

From these results, the temperature should be remained constant in the experiments, since the value of the capacitance of the engine oil changes with the temperature. In this study, all experiments were conducted by setting the temperature of 80 oC, which was in the temperature range of the actual operating engine.

3. EXPERIMENTAL SETUP

3.1. FABRICATION OF IDT CAPACITOR SENSOR

Like Figure 5, an IDT capacitor sensor was manufactured to measure the capacitive change of the engine oil to determine the deterioration characteristics. It was made from PCB substrate through the lithography and etching processes.

|

|

|

Figure 5 The

photos of fabricated IDT capacitor sensor and assembly |

According to the electrostatic capacitance formula (1), the smaller the spacing between electrode fingers, the higher capacitance value can be achieved. The various spacing were designed as 0.4 mm, 0.5 mm, 0.6 mm and 0.7 mm. However, in the case of 0.4 mm intervals, the sensor pattern was not clearly patterned as shown in Figure 6 due to the the limitation of the PCB fabrication system. In comparison, the sensors with over 0.5 mm gap were fabricated with the correct dimensions. Based on these results, the spacing between electrodes of the IDT capacitor sensors was selected as the manufacturing limit of 0.5 mm. If the improved lighography system like commercial MEMS fabrication system is applied, the spacing can be reduced to the micrometer scale. The length and number of fingers were also to be maximized for the increased capacitance. The minimum inner diameter of the dipstick tube was 8 mm, and the width of sensor was limited as 7 mm for the actual vehicle application. According to those dimensions, the number of fingers were set to be 6 sets. And, after the wire connections, the lower part of the sensor was fixed to prevent the wire movement using a plastic tube.

|

|

|

Figure 6 Fabricated devices with

different electrode spacing |

3.2. EXPERIMENTAL METHOD WIH IDT CAPACITOR SENSOR

In this study, the engine oil in the actual vehicle was used, which are around six liter. For the measurement, some amount of oil was extracted, and the fresh oil was replenished to maintain the constant volume. However, the added oil may change the characteristics of measured engine oil. Therefore, considering the 10 times extractions, the total adding amount of engine oil should not be exceed some portion of the engine oil. As a results, 80 ml of oil was extracted and supplemented so that even 10 times does not exceed one sixth of the total oil volume. The engine oil was extracted every 900 km, which was carried out up to 10,000 km.

The experimental setting is shown in Figure 7. During the experiments, the temperature of the engine oil is kept at 80 oC through the heater. To check the condition of the engine oil, the capacitance value was measured using an Arduino circuit.

|

|

|

Figure 7 Experimental setup for

measurement of engine oil deterioration |

The principle of measuring the capacitance value through the Arduino circuit is as shown in Figure 8. There are several ways to measure the capacitance, and here, the time constant (TC) expression was used as shown in equation (3). When voltage is applied and removed on capacitor connected to resistance, the voltage decreases smoothly. The TC means the time that the voltage reaches 63.2% of the initial value. The fabricated sensor acts as the capacitor, and the TC can be measured with the pull-up resistor in the Arduino circuit.

![]() (3)

(3)

|

|

|

Figure 8 Block diagram of capacitance

measurement |

3.3. EXTRACTION OF DIESEL ENGINE OIL

The experiments have been performed with three one-ton trucks. One truck drove through the city, while the rest of the test vehicles mainly operated on highways. The measurement cycle was performed at an average of 900 km. As mentioned earlier, the minimum amount, 80 ml, was extracted and replenished, that was assumed to have no significant impact taking into account the oil volume of 6 L.

4. RESULTS AND DISCUSSIONS

4.1. MEASUREMENT RESULTS WITH IDC CAPACITOR SENSOR

The graphs on Figure 9 shows the measurement results of three one-ton trucks. In the case of three subject vehicles, the degradation of the engine oil causes the capacitance to rise and decrease rapidly, depending on the vehicle's mileage.

|

|

|

Figure 9 The

capacitance measurement results with respect to vehicle mileage |

The deterioration of the engine oil can be divided into two main steps Chun (2006). In case of stage 1, the oil itself is oxidized. The oxidation is initially inhibited by the effects of additives such as antioxidants. However, oxides continue to occur after the exhaustion of antioxidants, resulting the increase of capacitance Cho and Park (2010). In the step 2, the oxidizing speed is reduced due to the concentration of oxides and limited contact with oxygen in the oil. This leads to a reduction in the capacitance, which means the complete deterioration of the engine oil. This is similar to the previous result 1 and can be found to be the end of the life of the engine oil. This indicates that vehicle a has reached the end of life of the engine oil after approximately 6,000 km, vehicle b after about 2,600 km, and vehicle c after about 4,200 km. Although the used vehicles were of the same type, each time of oil deterioration was different. Therefore, it was apparent that the timing of the engine oil exchange was different for each vehicle.

In the case of vehicle, A in Figure 9, there was a slight decrease in the capacitance at the beginning of the operation. This may temporarily decrease if the antioxidants contained in the engine oil are activated, even in the first stage described earlier Chun (2006). However, as a whole, after a temporary decrease, the capacitance value is increased and then rapidly decreased due to deterioration of the engine oil, which is consistent with the previous oil life characteristics.

4.2. MEASUREMENT RESULTS OF VISCOSITY

To verify the reliability of the capacitance measurement, the viscosity is measured using the engine oil sample of vehicle a. It is carried out with the Brookfield viscometer (DV-III Ultra, Brookfield AMETEK Inc.) like Figure 10. The viscometer measures viscosity using the the torque required to turn the cylinder in the oil. The temperature is maintained with heater and the overall operation is computer controlled.

|

|

|

Figure 10 Viscosity

measurement system |

During the operation, the viscosity of engine oil can be increased or decreased. Generally, the degradation point is known as the time when the viscosity increases over 20% or decreases less than 15% compared with that of fresh oil (Hanyu Energy Co., http://www.hanyuenergy.co.kr/kr/technique/actual_1.asp?ptype=4).

As shown in Table 1, as the operation mileage increases, the viscosity value of engine oil gradually decreases. At the 5,586 km operation, the viscosity decreases about 11.6 % from 6.72 cp of new oil to 5.94 cp. The viscosity value becomes 5.47 cp, which means around 18.6% variation at 7,463 km operation. Considering that the deterioration criteria in viscosity is 15 % reduction, we can know that it is located in between 5,586 km and 7,463 km. This result corresponds to the result of around 6,000 km from the measurement test of capacitance.

|

Table 1 Measurement results on viscosity of engine oil |

|||

|

Unit |

Viscosity

measruement result |

||

|

New oil |

5,586 (km) |

7,463 (km) |

|

|

cp |

6.72 |

5.94 |

5.47 |

4.3. MEASUREMENT RESULTS OF TAN VALUE

To compare the results of vehicle a, the TAN value of engine oil is measured. The testing method was carried out by the Korea Testing Certification (KTC), and the testing method was conducted using KS M ISO 6618: 2003. Generally, if the TAN value of diesel engine oil reaches around 2.0 mg KOH/g variation, the oil is considered to become the deterioration state Kim et al. (2017). According to the measurements, the TAN value increased by 0.96 mg KOH/g from 1.56 mg KOH/g at new oil to 2.52 mg KOH/g at 3,493 km. The TAN value reaches 3.38 mg KOH/g at 6,017 km with 1.82 mg KOH/g increment. Although it is not up to the 2.0 mg KOH/g value as the deterioration criteria, the close value is obtained, and it can be inferred that the exchange period has reached. In conclusion, the measurement results with TAN value were found to be in the range of about 6,000km and the same as the results of measurement of the capacitance and viscosity.

5. CONCLUSIONS AND RECOMMENDATIONS

In this study, we designed and fabricated the IDT capacitor sensor, and measured the degradation characteristics of a diesel engine oil. The results are summarized as follows.

1) In this study, an IDT capacitor-type diesel engine oil sensor, which can be mounted on an engine oil level gauge, was developed using PCB board. The sensor measures the deterioration characteristics by measuring the change in the capacitance of the engine oil.

2) Since the capacitance of engine oil increases with temperature, it is necessary to specify the measured temperature. The experiments about temperature effects were performed, and 80 ̊C was adapted to measure the characteristics of engine oil, considering actual operation conditions.

3) After comparing the capacitance values of three subject vehicles according to the distance travelled, the time of deterioration of the engine oil was 6,000 km for vehicle A, 4,400 km for vehicle b, and 2,600 km for vehicle c. Therefore, the point of deterioration becomes different according to the vehicle types and driver-specific factors.

4) The viscosity of the engine oil for a vehicle was 6.72 cp for 0 km but decreased to 5.94 cp at 5,586 km and finally reached to 5.47 cp at 7,463 km. The 15 % reduction point is approximately 6,000 km, and the viscosity result is consistent with the measurement of the capacitance.

5) In case of TAN vale, it has increased by 1.82 mg KOH/g at 6,017 km compared to the new oil. This value has almost reached the point of degradation at about 6,000 km. Consequently, it can be seen that the results are similar to those of capacitance measurement.

6) To prevent damage to the sensors caused by vibration and impact of the vehicle, research on the sensor attachment method and the sensor material should be conducted to ensure durability.

REFERENCES

Agoston, A., Otsch, C., and Jakoby, B., (2005) Viscosity sensors for engine oil condition monitoring-Application and interpretation of results, Sensors and Actuators A : Physical, 121, 327-332. Retrieved from https://doi.org/10.1016/j.sna.2005.02.024

Akbiyik, T., Kahraman, N., Taner, T., (2022) Investigation of the effect of boron additive to lubricating oil on engine performance, exhaust, and emissions, Fuel, 312, 122931 Retrieved from https://doi.org/10.1016/j.fuel.2021.122931

Cho, J., and Park, S., (2010) Capacitive sensor for automotive engine oil degradation using wireless network, 2010 International Symposium on Advanced Packaging Materials : Microtech (APM), Cambridge, USA, 88-91. Retrieved from https://ieeexplore.ieee.org/abstract/document/5441375

Chun, S. M., (2006) Study on Mutual Relation between the Level of Deterioration Influenced by the Changes of Chemical and Physical Properties and the change of Dielectric Constant for Engine Oil - diesel Engine Oil, The Korean Society of Tribologists & Lubication Engineers, 22(5), 290-300. Retrieved from https://www.koreascience.or.kr/article/JAKO200604623618467.page

Dingxin, Y., Zheng, H. and Jianwei, X., (2011) Research on capacitive sensor for online oil monitoring, 2011 Prognostics and System Health Managment Confernece, Shenzhen, 1-4. Retrieved from https://ieeexplore.ieee.org/abstract/document/5939536

Guan, L., Feng, L. X., Xiong, G., and Xie, J. A., (2011) Application of dielectric spectroscopy for engine lubricating oil degradation monitoring, Sensors and Actuators A : Physical, 168, 22-29. Retrieved from https://doi.org/10.1016/j.sna.2011.03.033

Hanyu Energy Co., http://www.hanyuenergy.co.kr/kr/technique/actual_1.asp?ptype=4

Kim, M. J., Lee, W. S., and Lee, S. H., (2014) Study on Electric and Magnetic Characteristics of Engine Oil in Transport Truck, The Transactions of the Korean Society of Automotive Engineers, 22(3), 166- 170. Retrieved from https://doi.org/10.7467/KSAE.2014.22.3.166

Kim, M. J., Sin, T. H. and Lee, S. H., (2017) Measurement of the Engine Oil Deterioration of the Diesel Vehicle Using the Engine Oil Level Gauge, The Transactions of the Korean Society of Automotive Engineers, 25(1), 60- 65. Retrieved from https://doi.org/10.7467/KSAE.2017.25.1.060

Kim, Y. D., Chung, K. W and Kang, S. C, (2001) The Study on Field Test of the New Formulated and Commercial Diesel Engine Oils, Transaction of the Korean Society of Automotive Engineers, 9(3), 51-59.

Liu, Y., Huang, Y., Tang, R., and Wang, B., (2015) Application of Interdigital Capacitive sensors for Detecting Power Cable Insulation Damage, proceedings of 2015 IEEE, International Conference on Mechatronics and Automation (ICMA), August 2-5, Beijing, China, 1795-1799. Retrieved from https://doi.org/10.1109/ICMA.2015.7237758

Qiang, L., Jiang, W., Lili, C., and Xiaowei, L. (2012) A Study of Moisture Content of Lubricating Oil Based on Impedance Analysis, Proceedings of 2012 International Conference on Mechanical Engineering and Material Science, 406-409. Retrieved from https://doi.org/10.2991/mems.2012.50

Raposo, H., José T. F., Inácio F., and Ferreira, L. A., (2019) Condition Monitoring with Prediction Based on Diesel Engine Oil Analysis : A Case Study for Urban Buses, Actuators, 8(1), 14-27. Retrieved from https://doi.org/10.3390/act8010014

Yanaseko, T., Sato, H., Kuboki, I., Mossi, K., & Asanuma, H., (2019) Vibration Viscosity Sensor for Engine Oil Monitoring Using Metal Matrix Piezoelectric Composite. Materials (Basel, Switzerland), 12(20), 3415. Retrieved from https://doi.org/10.3390/ma12203415

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© Granthaalayah 2014-2022. All Rights Reserved.