DESIGN, BUILD, AND TESTING TRANSPORTATION WHEELS FOR TRANSPORTATION OF PALM OIL FRUIT IN PEATLAND

Abstract

Abstract: To increase the collection of oil palm yields on peatlands, the team made a design and tested the fruit vehicle using a double garden jeep. The design that is done is to make an iron wheel equipped with fins made of angled profile iron. To increase the diameter of the wheel, the standard wheels are given spokes from a 0.5 mm strip plate and are welded to the outside of the wheel with fins. The stress analysis results in the critical area show that the stress that occurs is lower than the allowable stress. The shear stress on the strip plate connected to the wheel is much less than the allowable shear stress(3 kg/cm2 ≤300 kg/cm2). Then the compressive stress that occurs is also smaller than the allowable stress (200.5 kg/cm2 ≤ 300 kg/cm2) however, the bending stress that occurs in the fins is much greater than the allowable stress (1413 kg/cm2 ≤ 400 kg/cm2), it is necessary to make additional reinforcement part fins every 10 cm. After the wheels are produced, testing is carried out by transporting 1100 kg of the palm fruit. From the results of these trials, it can be concluded that the wheel design fulfills the needs.

Keywords

Wheel, Peatland, Transportation

INTRODUCTION

The development of oil palm agriculture is very rapid in Indonesia, because of limited land, a lot of peatlands is used for oil palm cultivation. Peatlands are also suitable for planting oil palm, but workers harvesting oil palm fruit have difficulty moving the fruit to the loading truck so that the harvesting costs are relatively large because harvest workers lift the fruit from the peatlands using carts and motorbikes after all 4 - wheeled vehicles do not can enter the location, if a 4-wheeled vehicle enters the location, the wheels of the vehicle will be partially immersed and will not be able to run. In relatively small community gardens, the above matters are not a problem because the transport distance is not far, but if the land is large, problems will arise because the cart distance can reach 1000 m or more.

MATERIALS AND METHODS

Peatlands

Peat soil is a wetland formed from piles of organic matter from tree residues, grass, moss, and rotting animal remains. Generally, peat has water content, but making drainage will result in peat subsidence which lasts almost rapidly in the first 4-10 years. After improved drainage and tillage the peat decomposition rate will increase. (Rizaldi, Hermawan, Mandang, & Pertiwi, 2015) The area of peatland in Indonesia is estimated to be between 14.95 million hectares with around 44.6% having been degraded or 6.66 million hectares. The province on the island of Sumatra, which has the largest peatland area, is Riau. Riau has 3.89 million hectares of land 6.49 million hectares of the total peatland area on the island of Sumatra. However, around 2.31 million hectares have been degraded. Most of the peatlands or almost half of them are used by the community, mostly for the cultivation of plantation crops including rubber and oil palm. 934,130 ha of degraded peatlands that have not been utilized, around 585,217 ha are potential to be developed for horticulture, food, and plantation crops.

Critical Location of Material Strength

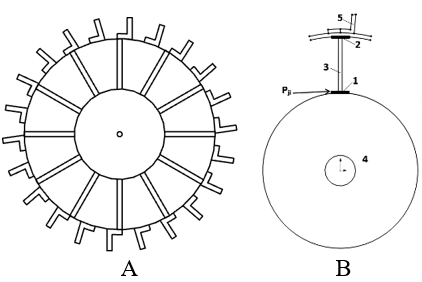

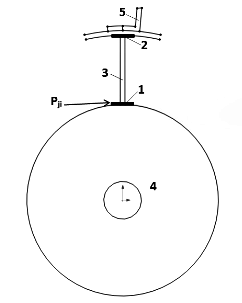

The calculation of the strength of this modified wheel is only carried out at points that are considered to experience critical loading, namely at point 1 and point 2. Meanwhile, to anticipate the collision of hard objects on the fin (5) which might cause the hoe to deform, a reinforcement is made every 10 cm. (Sudarsono & Dewanto, 2003)

Caption

Pict. A : modified wheels

Pict. B

-

Additional fingertip welding locations to the original wheels

-

Finger welding locations with fin wheel mounts

-

Additional fingers

-

Original wheels

-

Wheel fin of the vehicle so that it does not slip

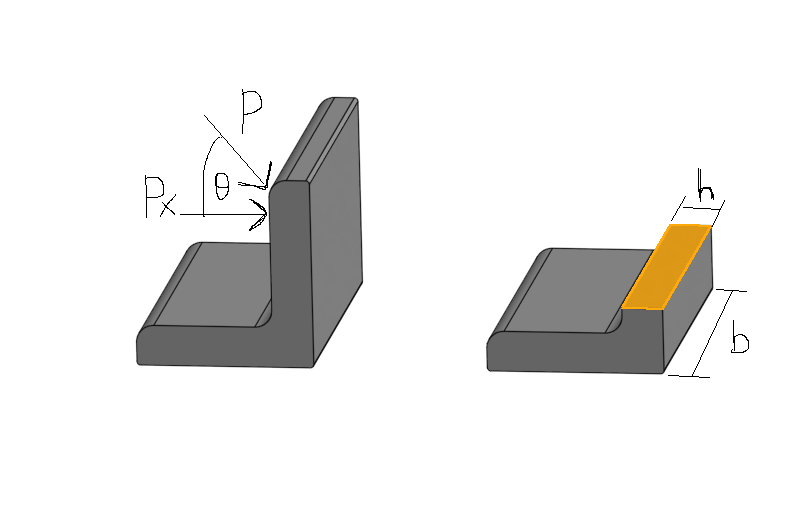

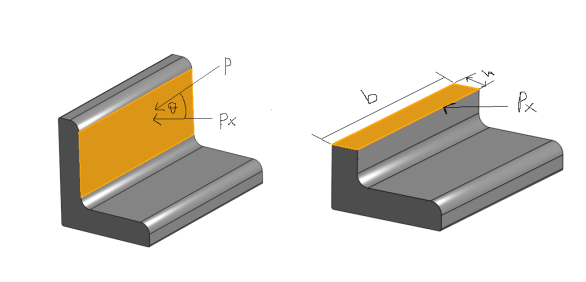

The fins on this wheel function to prevent slip on the wheel, but there will be a collision if it hits hard objects, such as wood or wood roots. The force acting at point A-A is the bending moment caused by the shock, in this case, it is marked as the force P. The magnitude of this force P is the weight of the entire vehicle. (Cebro, 2006)

RESULTS AND DISCUSSIONS

-

This design uses an iron wheel instead of a car wheel, so it can be said that this design is a modification of a car wheel to be able to carry fruit on peatlands.

-

The vehicle used for the trial was "a jeep Daihatsu Taft 4 x 4", where the power of the car: 72 hp / 2765 cc with 170 Nm of torque at 2,200 rpm.

-

For field testing, a car is needed according to the design criteria so that the results obtained are according to the plan.

-

In the manufacture of wheels, it is necessary to use car wheels that match the specifications of the car used so that you do not experience difficulties in installation.

-

Wheel making was carried out at the Mechanical Engineering Laboratory of the Christian University of Indonesia.

-

Field testing was carried out on community oil palm lands in the Riau.

Calculation o f Material Strength

The calculation of the strength of this modified wheel is only carried out at points that are considered to experience critical loading, namely at point 1 and point 2.

Overview at point 1. Point 1 has a distance of 16 cm from the center of the wheel, so the shear force that occurs at that point is torque divided by distance.

Assuming only the rear wheels are used, the torque generated by the engine is halved so that each wheel experiences a torque of 85 Nm = 8500 Ncm. Then the shear force at point 1 :

Moment of Torque

The moment of force or torque is the rotation of the force over distance 71620 = 71620 = 2.343 kg.m, Power (P) = , τ = kgm = = 23,45 kg.m. If the torque is 1 wheel = kg.cm = 1172 kg.cm, so Pg1 = = 73,28 kg. Design factor (Pd12) = 88 kg. The radius that is worked on is 24 pieces with sized iron material 0.5 cm x 2.5 cm=1.25 cm2, so the total area of the tire is 24 radius x 1,25 cm2. This can be found in the shear stress (Pg1). The shear stress that occurs σg = = = 3 kg/cm2. Compressive stress: σ = with P is vehicle weight with load 1800 kg , assuming the load is only on 2 wheels, namely the rear wheels, then one wheel becomes 900 kg. If the area of the radius (Ar) is: the sum of the area of the radius outside + the radius of the radius (2 x 1,25 cm2) + (0,2 cm x 10 cm)= 4,5 cm2. Then σt = = 200 kg/cm2. Then the total compressive stress value is :

σi =

=

= 200,5

The material used is mild steel with σi = 300 kg / cm2, so the material will be safe against loading.

Force Analysis on Fin

The force P on one wheel is the weight of the car plus the load ( 980 kg + 1020 kg) = 2.000 (6). The load is carried by the 2 front wheels and 2 rear wheels, but the rear wheels hold much more weight. Assuming that the load with the rear wheels is 80%, then the load for 1 wheel becomes : 0,8 x 2000 kg / 2 = 800 kg. Then, Pd = 1,1 P = 1.1 . 800 kg = 880 kg, but the force acting on the fins forms an angle 45o, so that the real Px is Px = P cos ᾴ = 0,707 . 880 kg = 622 kg. The twisted moment that happened is

= P.L = 622 kg . 3,5 cm = 2177 kgcm

h = 0,5 cm and b = 37 cm , = 1413 kg/cm2. This figure exceeds the allowable bending stress, so it is necessary to make an additional reinforcement every 10 cm.

Wheels Manufacture

The manufacture of wheels was carried out at the Mechanical Engineering Laboratory of the Christian University of Indonesia Jakarta - Jalan Mayjen Sutoyo no 2 Cawang, East Jakarta which was carried out by Mechanical Engineering Students.

In Figure 5 , student working on making wheels and in 3b

Wheel size is made: wheel outer diameter 74 cm, width 37 cm (the wider the wheel, the greater the load-bearing capacity).

Wheels Testing

After completing the assembly, the wheel trials were carried out on the Gambaut land located in Batin Batuah Village, Mandau District, Bengkalis Regency - Riau.

In Figure 7 above, a Daihatsu Taft car that uses an iron wheel which is being tested carrying 1,100 kg of palm fruit. In the video below, it is shown that the car is walking through the peat so that it appears that the surface of the ruts has dropped (becomes solid).

CONCLUSIONS AND RECOMMENDATIONS

-

The use of the designed iron wheel can be used on peatlands that have been planted with oil palm.

-

On land where there is still a lot of wood with a relatively small size, it is necessary to install an iron wheel on the front wheel, so that it can help to pull it out if there is an obstacle due to the wood that blocks it.

-

Peat soil that has been passed over and over again will automatically experience compaction, so that the land can be used for motorbikes to pass through.