|

|

|

|

Article Citation: Dharmesh Kumar

Vishwakarma, and Prof. Harsh Gupta. (2021). A REVIEW OF STUDY OF STRENGTH AND

DURABILITY ON CEMENT WITH ADDITION OF CERAMIC WASTE AND MICRO SILICA. International

Journal of Engineering Technologies and Management Research, 8(1), 49-52. https://doi.org/10.29121/ijetmr.v8.i1.2021.861

Published Date: 31 January 2021

Keywords:

Cement

Ceramic

Micro Silica

Strength and

Durability

ABSTRACT

Silica sand smaller than 70 microns can be used as a partial substitute for cement. This study partially demonstrated the properties of cement made of ceramic scrap and micro-silica instead of sand and cement. The effect of this recycled material was investigated by compressive strength tests and durability tests such as water absorption rate, absorption test and sulfate attack test.

1. INTRODUCTION

Cement is one of the most manufactured

materials in the world. Due to the importance of cement as a building material

and the geographical abundance of its main raw materials, cement limestone is

produced in every country. Its widespread production is due to its relatively

low cost and high density of cement. However, the production of Portland

cement, the main component of concrete, emits significant carbon dioxide and

greenhouse gases (GHGs).

Fume silica is a by-product of ferrosilicon

and silicon metallic in electric arc furnaces. These by-products typically

contain more than 0 percent silicon dioxide and may contain traces of other

oxides depending on the load of the furnace and the silicon metal produced.

Figure 1: Cement

2.

MIXED

DEVELOPMENT

The main component in the production of

high-quality concrete is the low-to-cement ratio. Concrete applicability (15 to

30% by weight of cement) requires a significant amount of silica ash for

optimum applicability and relatively high-water content. When a large amount of

water is added to the mixture, it dries or shrinks upon drying as time saving

means saving money, try to reduce the mixing time. Various mixtures were

developed for the development of blends that would form mixtures with desired

properties. Combine pre-stored cement and silica. Add fume silica to the

mixture to ensure proper wetting and good dispersion during mixing.

Figure 2: Cement

and concrete work

3.

SOLID WORK

Concrete

work can be satisfying when you step back and look at a well-equipped

construction project. But even concrete tasks can be frustrating for beginners

who “sink” without adequate preparation. In the next tutorial I will discuss

concrete work tips that will help you run DIY construction projects more

smoothly for beginners.

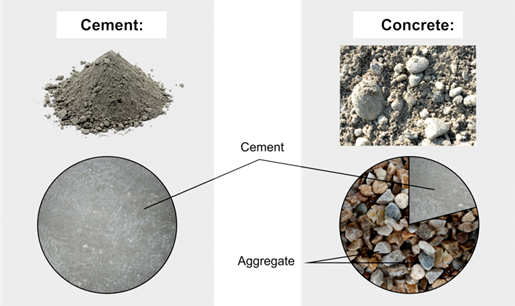

A

little vocabulary for the first sticker. Although "do" and

"cement" are often used by do-it-yourself people, in reality, the

difference between concrete and cement ("mortar" is also a part of

"mix"). Basically, this is the actual material that makes up the

building. Cement is just one component in concrete: it is a component that

combines with other components (e.g., aggregate and sand). Therefore, while it

is an important critical component of concrete, "cement" is not

synonymous with "concrete". Usually, when people say they need to buy

“cement” and go out on a DIY project, they really mean “concrete”.

Figure 3: Cement,

concrete and aggregate

4.

SILICA SAND

Silica

is a very fine material that is made entirely from silicon and oxygen, two

abundant elements in the earth's crust. Silica is rigid, chemically heavy, and

has a high melting point, which is due to the bond between the atoms. Silica

sand is not flammable, combustible or explosive. It is not known to be toxic.

This is not an environmental threat. Silica sand is insoluble in water. Silica

sand should be dried and kept outside the component.

5.

CEMENT

Common

Portland Cement confirms the 53-grade DECCN brand used in the current work of

BIS standards. Cement has been tested for various properties as per IS:

4031-1988 and found to meet the requirement as per IS: 12269-1987.

6.

CONCLUSIONS

The

concept of green concrete using complementary cement materials such as silica

sand reduces the environmental impact of concrete. The use of these waste

by-products as partial replacement of cement will further benefit the

environment by reducing environmental

pollution.

SOURCES OF FUNDING

This

research received no specific grant from any funding agency in the public,

commercial, or not-for-profit sectors.

CONFLICT OF INTEREST

The

author have declared that no competing interests exist.

ACKNOWLEDGMENT

None.

REFERENCES

[1] M. S. Shetty, Concrete

Technology‖, Year 2008

[2] Taiwan, Concrete

International‖, 1995, vol-17, pp 71-76

[3] P. J. M. Monterio,

Concrete: Microstructure, properties and Materials

[4] B. Mather, Concrete Year 2000,

Revisited‖, ACI journal, vol-144, pp31-40, 1994.

|

|

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© IJETMR 2014-2020. All Rights Reserved.