|

|

|

|

Article Citation: Yong Yang, Guofang Hu, Wanxu Liang, Kang

Jin, Li Xiong, and Shuo Hou. (2020). STUDY ON MAGNETIZATION TREATMENT AND

CUTTING PERFORMANCE OF A NEW-TYPE OF TRIETHANOLAMINE BORATE CUTTING FLUID. International

Journal of Engineering Technologies and Management Research, 7(11), 17-29. https://doi.org/10.29121/ijetmr.v7.i11.2020.800

Published Date: 19 November 2020

Keywords:

Triethanolamine Borate

Water Based Cutting Fluid

Magnetization Treatment

ABSTRACT

The composition of water-based cutting fluid and emulsion is different, and it has not been reported whether the magnetization treatment will affect the performance of water-based cutting fluid. In this study, a newly developed triethanolamine borate water-based cutting fluid is used as the research object to study the magnetization treatment technology and the law of its influence on cutting performance systematically. The cutting fluid magnetization experimental system was set up based on the principle of magnetization and the influence of magnetization parameters (magnetic field strength, magnetization duration) on the results of magnetization was further studied. The experimental results are measured by force measuring instrument, temperature measuring instrument, roughness measuring instrument and scanning electron microscope, and the parameters such as milling force, milling temperature, surface roughness, cutting specific energy, friction coefficient and workpiece surface morphology are comprehensively analyzed through data processing; the performance of cutting fluid before and after magnetization is also compared. The test results show that the magnetization effect is best when the magnetic field strength is 10000GS and the magnetization time is 40 minutes. The mechanism of magnetization treatment is to change the macromolecular group into a small molecular group, and the disordered array of molecules becomes ordered.

1. INTRODUCTION

Titanium alloy has the advantages of high strength and good corrosion resistance and are widely used in aviation industry [1], [2], [3], [4]. However, titanium alloys also have the disadvantages of poor thermal conductivity, low elastic modulus and high chemical activity [5], [6], [7], which makes the processing of titanium alloy very difficult and has always been a problem in the field of aviation manufacturing [8]. Improved cutting fluid is an important means to solve the difficult machining problem of titanium alloy [9], [10]. Cutting fluid can not only form lubricating film between tools, workpieces and chips, but also reduce cutting temperature through gasification and convective heat transfer. In this way, the surface quality of workpiece and tool durability can be improved [11], [12].

At present, many scholars have adopted the method of changing chemical composition of cutting fluid to improve its performance. This method has some limitations and the developed cutting fluid is difficult to adapt to various working conditions. Therefore, it is of great significance to improve the performance of cutting fluid by studying the cutting fluid treatment device. After a long period of research, people think that magnetic field has some mysterious power. So far, magnetic field has been applied in various fields of life, including oil transportation, wastewater treatment, agricultural planting, biomedicine, etc. [13], [14]. The scholars of Harbin University of technology proposed that the particle size of the suspended particles in the emulsion after magnetic field treatment would be smaller, and the magnetization treatment could improve the performance of the emulsion through test verification [15], [16]. Emulsion is a kind of cutting fluid, which contains mineral oil, animal and vegetable oil with a serious waste of resources that can cause pollution to the environment, which lead the green and environmentally friendly water-based synthetic cutting fluid to the development direction of cutting fluid. However, the composition of water-based cutting fluid and emulsion is different. It is necessary to verify whether magnetization can affect the performance of water-based cutting fluid and it will be great significance in the field of metal processing if magnetization can enhance the effect of water-based cutting fluid.

2. MATERIALS AND METHODS

2.1. EXPERIMENTAL MATERIALS

The tool used in the test is a 68 degree 4-edge tungsten steel milling cutter imported from Switzerland. Its diameter, shank diameter, edge length and overall length are 10 mm, 10 mm, 25 mm and 75 mm respectively. The workpiece used in the test was a TC4 titanium alloy with a density of with density of 4.51 g/cm3 and the hardness is HRC31. The additive used in the experiment is triethanolamine borate, defoamer is modified polyether and bactericide is isothiazolinone. First, the base liquid is configured, and the base liquid contains 99.5 % Volume deionized water, 0.25% volume bactericide and 0.25% volume defoamer. The triethanolamine boric acid ester was mixed with the base fluid according to the volume ratio of 1:10, and then the cutting fluid was prepared and magnetized.

2.2. EXPERIMENTAL EQUIPMENT AND SCHEME

The cutting test is carried out on the Wintec MV-80 CNC machining center,

with the maximum speed of 5000r/min. The force measuring instrument used is

YDX-Ⅲ9702

piezoelectric three-way milling force measuring instrument. The thermometer

used is thermovision A20 infrared thermal imager. The cooling and lubrication

mode of cutting fluid is spray type. The physical figure and schematic diagram

of the experimental device are shown in Figure 1. A dynamometer and thermometer

are installed before the experiment. The cutting fluid spray device is

installed on the machine tool to ensure that the cutting fluid can be sprayed

into the contact area during the test; the position and spray volume of the

cutting fluid spray device are unchanged during the whole experiment. The

processing parameters used in this experiment are spindle speed 1200 r/min,

feed speed 200 mm/min, cutting depth 0.2mm, cutting width 10 mm.

Figure 1: Installation sketch of the milling test. b Installation

physical drawing of the experimental measuring device. c Physical chart

of the milling test process. (1) Milling temperature acquisition and analysis

software; (2) infrared thermal imager; (3) milling cutter; (4) workpiece; (5)

dynamometer; (6) machine tool workbench; (7) atomizer; (8) intake pipe; (9)

cutting Fluid Pipe; (10) charge amplifier; (11) data acquisition instrument;

(12) milling force acquisition and analysis software.

The

magnetization system device of cutting fluid for the test consists of three

parts: power cycle, magnetizer and temperature control system. The schematic

diagram is shown in Figure 2. The processed cutting fluid then acts on the

cutting area through the atomizer. The magnetizer is a permanent magnet type

magnetizer, and the structure diagram is shown in Figure 3.

Figure 2: Installation

sketch of magnetization system. (1) pump; (2) magnetizer; (3) temperature

control system; (4) heater; (5) air compressor; (6) nebulizer.

Figure 3: Structural diagram of magnetizer

The

roughness of the machined surface is measured by the TIME3220 roughness meter. The movement

direction of the probe is perpendicular to the feed direction of the worktable.

After ultrasonic cleaning, S-3400N scanning electron microscope was used to

observe the micro morphology of the machined surface.

Firstly,

determine the first set of experimental scheme with the magnetization time is 1

hour and magnetizers with magnetic field strengths of about 3000GS and 10000GS

are used in experiments to study the influence of magnetic field strength on

the magnetization effect. In the second experimental scheme, the magnetic field

strength which obtained from the first group of experiments is used to control

the magnetic field strength and the cutting fluid temperature is fixed. The

magnetization time is changed from 20 minutes to 40 minutes and 60 minutes

respectively, and the influence of magnetization time on magnetization effect

is studied.

3.

RESULTS

AND DISCUSSIONS

3.1. ANALYSIS OF THE EFFECT OF MAGNETIC FIELD STRENGTH

3.1.1. MILLING FORCE AND TEMPERATURE

The

combined force F is calculated according to the resultant force calculation

formula (1) [17].

![]() (1)

(1)

The milling

force and milling temperature are combined to analyze. Figure 4 shows the

relationship between the resultant force of cutting fluid and temperature after

the treatment of magnetizer with different magnetic field strength. It can be

seen from the figure that the combined force decreases with the increase of the

magnetic field strength, but the change amplitude is small. However, the

milling temperature increases with the increase of magnetic field strength. The

milling temperature of 3000gs and 10000gs is 42°C, which is 2°C higher than

that without magnetization. It is analyzed that this phenomenon is caused by

the heat generated by the motor during the magnetization process being absorbed

by the cutting fluid. The result of the combined force shows that the

magnetizer corresponding to the 10000gs magnetizer has the lowest combined

force, which has a greater impact on the performance of the cutting fluid.

Figure 4: Combined Force and Temperature of Different Magnetic Field Intensities

3.1.2. SPECIFIC ENERGY OF MILLING

The specific cutting energy is used to represent the machining efficiency, which is defined as the energy consumed to remove the material per unit volume. The ratio of the cutting energy consumption to the material removal volume is obtained. The smaller the specific cutting energy is, the higher the machining efficiency has. The calculation method of milling specific energy is shown in formula (2) [18]. U is the specific energy of cutting (J/mm3), P is the energy consumed (J), Qw is the volume of workpiece removal. ap is the axial depth, ae is the radial depth.

![]() (2)

(2)

As shown in Figure 5, the value of specific energy under different magnetic field intensities gradually decreases, which indicates that the processing efficiency increases with the increase of magnetic field intensity, and the specific energy corresponding to 3000gs and 10000gs has little difference, but is significantly lower than that corresponding to 0gs. This shows that the efficiency of magnetized cutting fluid is higher than that of unmagnetized cutting fluid, but the specific energy of magnetized cutting fluid is not affected by the magnetic field strength.

Figure 5: Cutting Specific Energy of

Different Magnetic Field Intensity

3.1.3. FRICTION COEFFICIENT

The friction coefficient can reflect the lubrication ability of cutting fluid. The smaller the friction coefficient is, the better the lubrication effect of cutting fluid has. The composite cutting force model mentioned by Milton C. Shaw [19] in 《Metal Cutting Principle》 is widely used in the analysis of cutting force, as shown in Figure 6.

Figure 6: The relationship between milling forces

In Figure 6, FC is the force along the tool surface, NC is the force perpendicular to the tool surface, FP is the force in the horizontal direction, FQ is the force in the vertical direction, and R is the combined force of FC and NC. The formula for calculating the knife chip interface friction coefficient according to the force shown in the figure is as follows:

![]() (3)

(3)

![]() (4)

(4)

![]() (5)

(5)

According to formula (5), the force measured by the force measuring instrument in Z direction is brought into force FQ, and the arithmetic square root of the sum of squares of forces in X and Y direction is brought into force FP to calculate the friction coefficient.

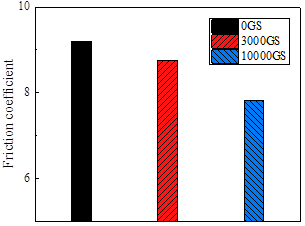

The friction coefficient corresponding to the cutting fluid treated under different magnetic field strengths is calculated, and the calculation result is shown in Figure 7. It can be seen from the figure that the friction coefficient of untreated cutting fluid is the largest, that cutting fluid treated by 3000GS magnetizer is the second, and that treated by 10000GS magnetizer is the lowest. Therefore, the lubrication ability of cutting fluid is improved after being treated by magnetizer. Among the magnetizers with different magnetic field strength studied in this experiment, the magnetizer with magnetic field strength of 10000GS has the best effect.

Figure 7: Friction Coefficient of Different Magnetic Field Intensities

3.1.4. ROUGHNESS

The roughness of the machined surface is measured by the roughness meter, and the Ra and RSm value are taken from the measured roughness signal for analysis. The Ra value is the average deviation of the contour arithmetic represented by the height characteristic parameter. The smaller its value is, the smoother the measured surface has. RSm value is the characteristic parameter of spacing, which represents the average length of contour peak and contour valley on the middle line. According to the research of Guo [20], the roughness Ra value or RSm value alone cannot fully represent the quality of the machined surface. In the roughness parameters, the weight of Ra value is 76%, and the weight of RSm value is 24%. Combined with these two parameters, the comprehensive roughness value is calculated, which is more comprehensive than single factor analysis.

Figure 8 shows the workpiece surface roughness corresponding to the cutting fluid treated with different magnetic field strength. The Ra value increases slightly with the increase of the magnetic field strength, but the variation range is not large, and the RSM value decreases gradually with the increase of the magnetic field strength. According to the comprehensive roughness value obtained from the analysis of the proportion of the two, the influence of the magnetization treatment on the surface roughness of the workpiece is very small.

Figure 8: Surface Roughness of Workpiece of Different Magnetic Field Intensity

3.1.5. SURFACE TOPOGRAPHY

The scanning electron microscope was used to observe the surface morphology of the workpiece at 100 times magnification, as shown in Figure 9. In the graph of cutting fluid without magnetization treatment, there are individual peeling phenomenon and disordered scratches, while in the graph of magnetic field strength of 3000GS, the scratches become fine and regular, but the peeling characteristics increase significantly, and when the magnetic field strength is 10000 GS, the peeling characteristics decrease, at the same time, disordered scratches appear again, and the regular scratches become obvious.

It can be seen that the surface morphology of the workpiece corresponding to the magnetized cutting fluid is higher than that of the non-magnetized cutting fluid, but the corresponding morphologies of the cutting fluid after low magnetic field strength and high magnetic field intensity are different. There are advantages and disadvantages.

Figure 9: Surface Morphology of Workpiece of Different Magnetic Field Intensity

3.2. ANALYSIS OF THE EFFECT OF DURATION OF MAGNETIZATION TREATMENT

Through the

test of changing the magnetic field strength, the parameters of combined force,

temperature, specific energy, friction coefficient, roughness and topography

are integrated and analyzed. It is found that magnetization treatment has

obvious influence on resultant force and friction coefficient, but little influence

on roughness. Considering the above parameters, the magnetizer with the

magnetic field strength of 10000GS has the greatest influence on improving the

performance of cutting fluid. Then taken the magnetizer with the magnetic field

strength of 10000GS as the research object, change the magnetization time, and

study the relationship between the performance of cutting fluid and the

magnetization time.

3.2.1. MILLING FORCE AND TEMPERATURE

Figure 10

shows the variation of milling combined force and milling temperature under the

magnetizer with magnetic field strength of 10000GS for different magnetization period.

It can be seen from the figure that the resultant force at 20 minutes is

significantly lower than that at unmagnetized time, but the change of resultant

force after 20 minutes is not obvious. However, the temperature after

magnetization is generally higher than that without magnetization, especially

reaching the highest value in 40 minutes. This shows that the longer the

magnetization time is, the better the effect has, and the longer magnetization

time is not applicable in the actual application process, so it is necessary to

further analyze and select the cost-effective magnetization time.

Figure 10: Resultant force and temperature of different magnetization time

3.2.2. SPECIFIC ENERGY OF MILLING

The milling specific energy can reflect the machining efficiency of the cutting condition. The milling specific energy corresponding to the different magnetization time length of the cutting fluid is calculated and counted into Figure 11. It can be seen from the figure that the milling specific energy corresponding to the cutting fluid without magnetization treatment is quite different from that corresponding to the cutting fluid after magnetization treatment. Among the magnetized cutting fluid, the milling specific energy is the smallest when the magnetization time is 60 minutes, that is to say, the machining efficiency is the highest. It can be seen that after a short period of magnetization treatment, the effect of cutting fluid will change significantly, but after further enhancing the magnetization time of cutting fluid, the effect will not change too much.

Figure 11: Milling Specific Energy of Different Magnetization Time

3.2.3. FRICTION COEFFICIENT

The size of the friction coefficient is the most intuitive embodiment of the strength of the lubrication effect. Figure 12 shows the corresponding friction coefficient of the cutting fluid under different magnetization duration. It can be seen from the figure that the friction coefficient becomes smaller and smaller with the increase of magnetization time, in which the friction coefficient changes greatly when the magnetization time is 20 minutes and 40 minutes, and the difference between the friction coefficient when the magnetization time is 40 minutes and 60 minutes is very small, so it can be inferred that the magnetization effect of cutting fluid can be exerted to a large extent after the magnetization treatment for 40 minutes. After further enhancing the magnetization time of cutting fluid, the effect will not change too much.

Figure 12: Friction Coefficient of Different Magnetization Time

3.2.4. ROUGHNESS

The surface roughness of the workpiece under different magnetization time is measured by the roughness measuring instrument, and the measured roughness Ra value, roughness RSm value and roughness comprehensive value are counted into Figure 13. The Ra value and RSm value respectively reflect the surface quality of the workpiece from different aspects. The comprehensive roughness value is calculated according to the weight of a value and RSm value. The following focuses on the comprehensive roughness value. It can be seen from the figure that the comprehensive roughness value decreases gradually 40 minutes before the magnetization treatment, but increases again when the magnetization treatment time is 60 minutes, which is similar to that without magnetization treatment. On the whole, the variation range of the comprehensive roughness value is not large, but the figure shows that when the magnetization time is 40 minutes, the comprehensive roughness value is the smallest, and the corresponding cutting fluid has better wear resistance effect.

Figure 13: Roughness of Different Magnetization Time

3.2.5. SURFACE TOPOGRAPHY

Observe the surface morphology of the workpiece at 100 times of magnification, and draw the surface morphology of the workpiece corresponding to the magnetization time of different cutting fluids into Figure 14. It can be seen from the figure that there are disordered scratches in the surface morphology of the workpiece corresponding to the magnetization time of 0 minutes, 20 minutes and 60 minutes, while there are no messy scratches on the surface morphology of the workpiece corresponding to the magnetization time of 40 minutes, but there are obvious peeling features in the morphology. It is difficult to distinguish which magnetization time is the highest when only considering the surface morphology of the workpiece. If the magnetization time is 40 minutes, the workpiece surface quality is the best, and the corresponding cutting fluid is easier to enter the tool workpiece contact area and play important role of friction reduction and wear resistance.

Figure 14: Surface Morphology of Workpiece of Different Magnetization Time

3.3. ANALYSIS OF MAGNETIZATION MECHANISM

By analyzing the effect of magnetic field strength on magnetization, conclusion can be drawn that when the magnetic field strength is 10000GS, the effect of magnetized cutting fluid is the best, and the reason why cutting fluid can improve its performance after passing through the magnetic field may be that the molecular group of cutting fluid becomes smaller, and the ions in the solution are orderly arranged under the effect of magnetic field. The schematic diagram of the action process is shown in Figure 15.

Figure 15: Schematic diagram of magnetization process

In the micro case, when the positive and negative particles in the cutting fluid pass through the magnetic field, their existence mode changes from disorderly distribution to orderly arrangement. Under the action of the magnetic force, all kinds of particles move at the same time and collide which causes the hydrogen bond between the molecules trends to break, and makes the original large sub cluster become small molecular cluster which is easier to penetrate into the cutting tools, workpieces and chips during the milling process. In the contact area, a temporary boundary lubrication film is formed and play an important role in the friction and wear reducing, as shown in Figure 16. At present, this assumption only belongs to the theoretical inference This experiment studies are restricted by existing equipment in detecting the molecular arrangement and particle size. It can only be proved indirectly using the results of milling test.

(a) Disordered infiltration before magnetization

(b) Orderly infiltration after magnetization

Figure 16: molecular action state of cutting fluid before and after magnetization

4. CONCLUSIONS & RECOMMENDATIONS

1) The results show that the magnetic field strength of 10000GS is better than that of 3000GS and 0GS in the three aspects of resultant force, specific energy and friction coefficient. This shows that magnetization treatment can have a favorable effect on water-based total synthetic cutting fluid, and the magnetization effect is related to the magnetic field strength. Among the three magnetic field strengths studied in this paper, 10000GS has the best magnetization effect.

2) By analyzing the parameters of friction coefficient, roughness and workpiece surface morphology, it can be found that the magnetization time has a great influence on the magnetization effect in a short period of time, and the magnetization time increases after 40 minutes has a little influence on the magnetization effect. Among the four magnetization durations studied in this paper, when the magnetization duration is 40 minutes, the cost performance of magnetization treatment is the highest.

3) Experiments shows that the performance of the magnetized cutting fluid is better, so the mechanism of the magnetization process is deduced theoretically: the macromolecule group is changed into the micromolecule group by the effect of magnetic force, and the molecules are arranged orderly, which makes the cutting fluid molecules easier to enter the cutting area to exert the lubricating effect.

SOURCES OF FUNDING

This research received no specific grant from any funding agency in the public, commercial, or not-for-profit sectors.

CONFLICT OF INTEREST

The author have declared that no competing interests exist.

ACKNOWLEDGMENT

This research was financially supported by the following Foundation items: Shandong Provincial Natural Science Foundation, China (ZR2017MEE077).

REFERENCES

[19] Shaw M C.Metal Cutting Principles [M]. second

Edition. Oxford University Press,2005.

|

|

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© IJETMR 2014-2020. All Rights Reserved.