|

|

|

|

Development of SOLAR HEAT Concentration Box Dryer and LM 35 Sensor, A tool for TEMPERATURE MEASURING Device

Umukoro, E 1![]() , Alebu, O 2

, Alebu, O 2![]() , Okocha, G.O 3

, Okocha, G.O 3![]() , Esekhaigbe, I. F 4

, Esekhaigbe, I. F 4![]()

1,2,3,4 Department

of Science Laboratory Technology, Auchi Polytechnic, Edo State, Nigeria

|

|

ABSTRACT |

||

|

The solar heat

concentration box is a system which convert the solar energy to heat energy

in a closed system for farmers to dry their farm produce. The system uses an

electronic system which is made up of LM 35 sensor enclosed in the dryer. The

LM 35 is interfaced with an Ardiuno MEGA microcontroller. The microcontroller

converts the analog signal output generated from the sensor to a digital

output signal which is been display on visual system. The analog device will

be used to measure the temperature inside the heat concentration box at a

particular time or period of the day. The system will enable farmers to dry

perishable farm produce which is seasonal. This will reduce food shortage and

increase per capital income of farmers during the off-farming season. |

|||

|

Received 09 May 2022 Accepted 10 June 2022 Published 27 June 2022 Corresponding Author Umukoro E,

DOI 10.29121/ijetmr.v9.i6.2022.1152 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2022 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Energy Conversion, Closed System, Heat Energy, Solar Energy, Sensor, And Temperature |

|||

1. INTRODUCTION

Energy generated reaching the earth’s surface from the Sun is wasted to the surrounding or environment in the form of heat. Forson et al. (2007) This form of heat energy cannot be manually measured directly with any device. Heat energy can be used to remove moisture from crops and as fuel for domestic purpose. Farming contributes ninety-five percent of the food consumed by the citizen of a Nation. Akachukwu (2014) Most of the farm produces are perishable due to the presence of water. The solar heat concentration box can be use channel heat which will most of the water content present in the farm produce when confined in an isolated system. Umukoro et al. (2021) This will reduce waste of farm produce in the farmyard before reaching the final consumers and processing factories in urban area of settlement due to inadequate road and transportation system. Chand et al. (2015) There are no good roads and inadequate transportation system to carry harvested farm produce from the farmyard to marketplaces and processing factories. Also, farm produce is seasonal, and this makes the produce unavailable to the consumers throughout the year. most farm produce is better preserved when the moisture content has low percentage of about 10 % and this can only be achieved with good drying system that will not exceed the drying temperature of such farm produce. Andritsos et al. (2003) All the same, the temperature of most body is measured manually, and the data recording is inconsistent and liable to error. Therefore, there is need to measure the temperature generated in the heat energy concentration box system to actualize the purpose of drying. The solar energy concentration box will enable farmers dry their farm produce and preserve the farm produce for a period of time before further processing. Selvaraj and Sadago (2017) The temperature of the system is measure and monitor using an analog sensor device. The interfacing of an electronic device will enable farmers not to exceed the required maximum drying temperature of the harvested produce. The heat energy generated in the concentration box is used to remove moisture from the farm produce. The system will be installed in the farm yard. The solar energy concentration box will also prevent food contamination and control spread of diseases when compared to conventional methods of farm produce drying. Okonkwo and Okoye (2005)

1.1. MATERIALS/METHODOLOGY

Materials

1) Lm 35 sensor

2) Resistor

3) Variable resistor

4) LCD

5) Arduino MEGA board

6) Connecting wire

2. METHODOLOGY

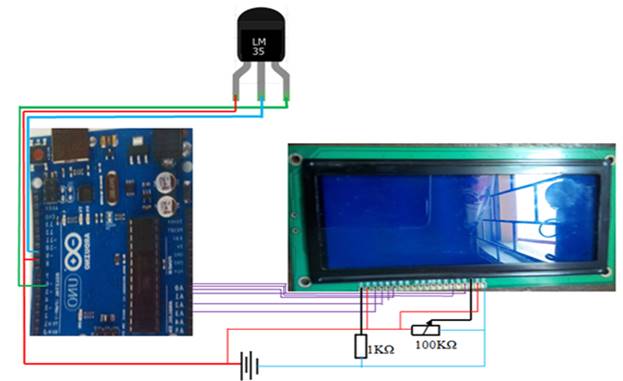

The solar heat concentration dryer was designed and constructed using transparent solar collector, aluminum foil and wooden board for the heat closed system. The LM 35 temperature sensor was inserted into the drying chamber and interfaced with Arduino MEGA microcontroller. The LM 35 device senses the heat generated in the system, and it serves as input to the analog sensor. The sensor analog output is connected as an input signal to the analog pin of the microcontroller. The analog output of the sensor is converted to voltage which can be decoded by the microcontroller. The microcontroller which has been programmed converts the input voltage signal of the sensor to temperature as digital output signal. The digital output pin of the microcontroller was connected to a liquid crystal display (LCD). The display system provides a visual digital output of the processed data from the microcontroller. The processed data can be stored for further process. The complete circuit of the solar heat concentration dryer with LM 35 Sensor interfaced with Arduino MEGA for measuring temperature in the drying chamber is shown in Figure 1

Figure 1

|

Figure

1 Complete Circuit |

2.1. LM 35 SENSOR

The LM 35 temperature sensor is a contact sensor with an analog output. The device and was introduced into the drying chamber. The system converts the heat energy inside the drying chamber to temperature in Degree Celsius (oC) at different hour of the day. The sensor detects the heat and changes it into an analog signal output as an input for the microcontroller. The amount of heat detected by the sensor in the dryer will be converted to temperature by the microcontroller as digital output data. The interfacing of LM 35 heat sensor with Arduiino UNO is shown in Figure 1

2.2. RESISTOR

The resistor opposes the current/voltage flowing across the terminals of the connecting points. In the circuit, the resistor is used to pull-down any high voltage to the ground. This will prevent any damage of unwanted voltage at such point for effective and efficient performance of the temperature measuring device.

2.3. VARIABLE RESISTOR

The variable resistor is an electronic component that varies the amount of current that flows through a circuit. It operates by sliding a wiper terminal across a resistive material such as thin film or chunk of carbon or a resistive wire made of nickel chromium or tungsten alloys. After being set to the appropriate location, the wiper's position remains fixed on the circuit board. The variable resistor is used in the circuit to reduce the backlight of the liquid crystal display to enable the digital output of the Arduino microcontroller to visualize.

2.4. ARDUINO BOARD MICROCONTROLLER

Arduino is the complete board that comes with GPIO pins, analogue pins, and a microcontroller as the heart of the board. A microcontroller, on the other hand, is a chip where all the necessary parts like microprocessor, ram, and flash memory are incorporated into a single chip. The Arduino MEGA board operates with a voltage of 5V and projects the microcontroller on the board and its associated circuitry operates at 5V. It is an open-source hardware and software platform which can be programmed as digital output for the temperature sensing device.

2.5. LIQUID CRYSTAL DISPLAY (LCD)

A liquid-crystal display (LCD) is a flat-panel display or other electronically modulated optical device that uses the light-modulating properties of liquid crystals combined with polarizer. Liquid crystals do not emit light directly, instead using a backlight or reflector to produce images in colour or monochrome. An LCD panel is made of many layers. These consist of a polarizer, polarized glass, LCD fluid, conductive connections etc. Since liquid crystals do not produce light of their own, they need an external light source to work. An LCD panel has sets of polarized glass consisting of liquid crystal materials in between them. When the external light passes through one of the polarized glasses and electric current is applied on the liquid crystal molecules, they align themselves in such a way that polarized light travels from the first layer to the second polarized glass, causing an image to appear on the screen. The LCD is used to display sensor readings as the microcontroller converts it to digital output.

2.6. CONNECTING WIRES

The connecting wires are metallic materials which are either single or stranded copper that links one terminal to another proper flow of signals in the circuitry.

3. RESULTS AND DISCUSSION

The designed and constructed temperature measuring device was interfaced with the solar heat concentration box for farm produce drying during the months of May and November. The system was able to reduce the moisture content under test to a low percentage as shown in Table 1 and Table 2. Also, the temperature of the different hours of the day was measured as shown in Table 3 and Table 4 respectively.

Table 1

|

Table 1 Dried Sample Weight in the Month of May 2021 |

||

|

Yam weight(g) |

Plantain

weight(g) |

|

|

Day1 |

622.5 |

331.5 |

|

Day2 |

455.5 |

288.5 |

|

Day3 |

134.2 |

108.4 |

Table 2

|

Table 2 Dried Sample Weight in the Month of November 2021 |

||

|

Yam

Weight(g) |

Plantain

Weight(g) |

|

|

Day1 |

520.1 |

204.3 |

|

Day2 |

213.2 |

86.2 |

|

Day3 |

92.4 |

41.1 |

Table 3

|

Table 3Temperature Measured

in the Month of May |

||

|

Day 1 |

Time (hrs.) |

Temperature

(oc) |

|

4 |

25 |

|

|

8 |

27 |

|

|

12 |

40 |

|

|

16 |

38 |

|

|

20 |

32 |

|

|

Day 2 |

Time(hrs.) |

Temperature

(oc) |

|

4 |

27 |

|

|

8 |

29 |

|

|

12 |

43 |

|

|

16 |

40 |

|

|

20 |

37 |

|

|

Day 3 |

Time(hrs.) |

Temperature

(oc) |

|

4 |

26 |

|

|

8 |

32 |

|

|

12 |

45 |

|

|

16 |

42 |

|

|

20 |

38 |

|

Table 4

|

Table 4Temperature Measured

in the Month of November |

||

|

Day 1 |

Time(hrs.) |

Temperature

(oc) |

|

4 |

26 |

|

|

8 |

29 |

|

|

12 |

43 |

|

|

16 |

41 |

|

|

20 |

38 |

|

|

Day 2 |

Time(hrs.) |

Temperature

(oc) |

|

4 |

28 |

|

|

8 |

31 |

|

|

12 |

45 |

|

|

16 |

42 |

|

|

20 |

39 |

|

|

Day 3 |

Time(hrs.) |

Temperature

(oc) |

|

4 |

29 |

|

|

8 |

36 |

|

|

12 |

47 |

|

|

16 |

44 |

|

|

20 |

40 |

|

4. DISCUSSION

The developed temperature measuring device using LM 35 sensor performance was evaluated when the sensor was inserted into the solar heat concentration box. It was found that as the solar irradiance increases at different hour of the day, the temperature measured also increases and as the Sun sets, the temperature sensed decreases gradually as shown in Table 3 and Table 4 for a maximum of twenty hours (20 hrs) per day for three consecutive days in the months of May and November 2021. The month of May depicts wet season which have an average measured temperature of 42.7 oC as shown in Table 3 during the peak hours of the periods. Also, during the dry season in the month of November, an average temperature of 45 oC was recorded as shown in Table 4 during the peak hours of the days.

5. CONCLUSION

The developed temperature measuring device was able to convert the heat generated in the solar heat concentration system to temperature using LM 35 sensor. This measured temperature will enable researchers and farmers to determine the efficiency and effectiveness of the dryer system. The moisture content of the farm produce is reduced to a minimal percentage without causing any damage to the nutrient content of the harvested crops. When the solar heat concentration box is interfaced with the temperature sensing device, it will enable farmers to dry farm produce. This will help to improve scarcity of seasonal farm produce and increase per capital income for farmers.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

Akachukwu, B. E. (2014). Investigation of Low Cost Solar Collector for Drying Vegetables in Rural Areas. Agric. Eng. Intl. Journal, 16(1), 118-125.

Andritsos, N. Dalampakis, P. and Kolios, N. (2003). Use of Geothermal Energy for Tomatoes Drying. Oregon Institute of Technology, Geo-heat Center bulletin, 24(1), 1-9.

Barrett, D. M. and Latapi, G. (2006). Tomatoes Attributes and their Correlation to Peelability and Product Yield. Journal of the Science of Food and Agriculture, 54(2), 65-73.

Bolaji, B. O. Olokode, O.S. and Olalusi, A. P. (2008). Development of a Wind-ventilated Box-type Absorber Solar Air Collector. Asset international journal, 7 (1), 18-29.

Chand, T. k. Mohanty, M. K. and Mohanty, R. C. (2015). An Overview of Solar Energy and its Application in Solar Dryers with Brief Concept of Energy and Energy Analysis. International journal of Research, 2(1), 870-875.

Forson, F. K. Nazha, M. A. A. Akuffo, F. O. and Rajakaruna, H. (2007). Design of Mixed-mode Natural Convection Solar Crop Dryer ; Application of Principles and rules of thumb. Renewable energy, 32(14), 2306-2319. https://doi.org/10.1016/j.renene.2006.12.003

Jithinraj, T. and Aftab, A. K. (2014). Experimental Analysis on Multi Pass Flat Plate Collector Solar Air Dryer. International Journal of Engineering Engineering Research and Technology, 2(7), 1-11.

Okonkwo, W. I. and Okoye, E.C. (2005). Performance Evaluation of a Pebble Bed Solar Crop Dryer. Nigerian Journal of Technology, 24(2), 68-73.

Santos, B. M. Queiroz, M. R. and Borges, T.P.F. (2005). A Solar Collector Design Procedure for Crop Drying. Brazilian Journal of Chemical Engineering, 22(2), 277-284. https://doi.org/10.1590/S0104-66322005000200016

Selvaraj, M. and Sadago, P. (2017). A Review of Solar Energy Drying Technology with Air Based Solar Collector. Advances in Natural and Applied Science, 11(4), 472-478.

Umukoro, E. Alebu, O. Efosa, J. and Odion-Owase, E. (2021). Development of Renewable Energy Farm Produce Drying System using Solar Collector. International Journal of Energy and Environmental Research, 9(3), 10-20.

|

|

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© IJETMR 2014-2022. All Rights Reserved.