|

|

|

|

Evaluating Key Operational Challenges in Small-Scale Construction and Fabrication Firm

Tanisha Ghadge 1![]() ,

Dr. Vishal Chavan 2, Bhawna

Sharma 3

,

Dr. Vishal Chavan 2, Bhawna

Sharma 3

1 BBA,

Amity Business School, Amity University Mumbai, Mumbai, India

2 Associate

Professor, Amity Business School, Amity University Mumbai, Mumbai, India

3 Director-International

Affairs and Programs, Officiating HOI, Amity Business School, Amity University,

Mumbai, Mumbai, India

|

|

ABSTRACT |

||

|

Small-scale fabrication businesses mostly operate on a shoestring budget, and the combination of an incomplete set of basic equipment with informal work processes may contribute to a multitude of operational problems. The main objective of this study is to identify the major inefficiencies present in a small fabrication workshop and to gauge how these affect day-to-day operations. A descriptive design was adopted for the study, and data was collected using non-participant observation over three separate visits. The observer made use of an observation checklist and field notes to document problems pertaining to labour, materials, equipment, workflow, communication, and safety. Accordingly,

some of the significant recurring problems identified are related to material

handling delays, shortages of skilled workers, frequent equipment

limitations, poorly organized workflow, weak supervision, and inconsistent

safety practices. Each of these challenges resulted in the reduction of

overall productivity and further prevented work processes from being smooth.

This study identifies needs that are easy to implement for improving

planning, tool management, worker coordination, and workplace organization.

In general, the results offer practical insights into how small fabrication

workshops can improve their operational efficiency without incurring

additional cost. |

|||

|

Received 08 May 2025 Accepted 12 June 2025 Published 30 September 2025 DOI 10.29121/ijetmr.v12.i9.2025.1695 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2025 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Operational, Fabrication, Small-Scale, Challenges |

|||

1. INTRODUCTION

Small-scale fabrication firms are especially important in the developing world for local construction and engineering needs. They can be involved in the fabrication of various metal structures, custom fittings, and on-site fabrications of different types. Penabled workshops often face a shortage of resources, poor facilities, and small crews, making them particularly susceptible to delays, disruptions to workflows, equipment constraints, and safety hazards during daily activities.

The workshop in this research is a small-scale fabrication unit involved in cutting, welding, assembling, and fabricating structural parts for residential and commercial use. While the workshop copes with its workload quite well, it faces a number of general operational difficulties like sharing equipment, limited workspace, irregular material supply, and a high reliance on human labour. These can impact productivity, quality of output, and timely completion of projects.

Understanding all these inefficiencies is very important because even small problems, such as looking for tools, waiting for machines, or correcting mistakes, can add up and slow down the general workflow. This work seeks to identify the main factors that diminish operational efficiency by observing the working environment, workflow patterns, and day-to-day challenges within the workshop and to propose practical and affordable improvements.

The following introduction sets the groundwork for the analysis of how small fabrication units work, common problems, and ways in which simple improvements in the areas of organization, resource management, and workflow can yield substantial benefits.

2. Objective of Study

A deeper level of understanding into the operational inefficiencies that affect the functioning of a small-scale fabrication workshop is aimed through this study. The research, in this case, through direct, non-participant observation, shall focus on the challenges that dislocate workflow, reducing productivity, hence contributing to daily delays. Precisely, this study seeks to find out why such settings are less productive and fail to meet deadlines. The objectives guiding this study include:

· To identify major operational inefficiencies

· Observing delays, disruptions, and recurring issues that affect daily work.

· To analyze workflows and movement patterns

· Analyzing task sequencing, worker movement, and time lost searching for tools or materials.

· Assessing equipment availability and performance

· Machine shortages, waiting time, and downtime evaluation.

· To review human-related factors

It studied skill levels, communication gaps, and supervision practices. To investigate material handling and storage Knowing how disorganized storage and small space add to delays. To assess workspace organization and safety compliance Looking at housekeeping, congestion, and use of safety gear. To recommend simple and low-cost improvements Suggesting practical changes that can improve workflow and overall efficiency.

3. Literature Review

Operational performance related to productivity, resource utilization, workflow management, and labour efficiency has been the main issues of interest in studies focusing on small-scale fabrication firms. Past studies indicate that inefficient processes and equipment constraints have a strong bearing on overall output, as most work systems are informal. This section reviews existing literature related to operational challenges in small fabrication and construction workshops.

1) Inefficient Workflow within Small Fabrication Units Poor layout planning, unstructured material movement, and lack of standardized procedures are commonly observed in small fabrication workshops, which cause interruptions in the work-flow, as stated by Deshmukh and Patil (2021). Such ineptitudes result in increased waiting time and decreased daily productivity. Their study also underlines that small units hardly follow any systematic production planning methodology, which is responsible for delays in tasks very frequently and gives rise to overlapping work activities. On the other side, Kumar (2020) has identified inconsistent process flow as one of the major time-wasting factors in metalworking and construction-based fabrication shops.

2) Equipment Constraints and Machine Downtime A study by Muchiri and Pintelon (2008) illustrates that equipment availability has a crucial effect on operational performance. Small-scale firms often depend on a limited number of welding machines, cutters, and grinders. Workers often have to wait their turn for such a machine, thus slowing the pace of the entire production line. According to Gupta and Sawant (2022), most fabrication units operate with outdated machines that need frequent repairs, leading to unplanned downtime and a negative impact on efficiency. These equipment barriers relate directly to operational bottlenecks.

3) Labour Skill Levels and Communication Gaps Human factors are a significant determinant of fabrication efficiency. According to Mishra (2022), inadequate technical training and miscommunication among the workforce result in measurement errors, reworks, and poor variability in the quality of output. For small firms, there is more use of informal skill transfer than formal training. Fernandes and D’Silva (2021) add that supervision difficulties and lack of clarity in instructions lead to mistakes at various fabrication stages, thereby reducing overall operational smoothness.

4) Material Handling and Inventory Issues Material management plays a crucial role in fabrication work. Choy and Lee (2002) have identified that small units lack proper inventory control and thus often face problems of missing materials, purchasing materials at the last minute, and constant movement to locate items. This disrupts the workflow and causes enormous waste of time. Singh (2023) again states that due to unorganized storage and poor methods of stacking the materials, retrieval and movement of raw materials are not very efficient, especially in these kinds of workshops where the area is very minimal..

4. Research Methodology

A qualitative research approach was applied to understand the operational inefficiencies present within a small-scale fabrication workshop. Since the focus of this study is on daily work routines, equipment use, and worker behavior, direct observation was deemed the most practical approach to capturing real, on-ground challenges as they naturally transpired.

1) Research

Design

A qualitative, descriptive research design was utilized. In this study design, the researcher is allowed to naturally observe the workflow, physical environment, and interaction of workers without causing an interruption to normal activities. The design is particularly suitable for patterns to be identified, including delays, bottlenecks, and issues with movement and equipment that generally characterize small workshops.

The study was based mainly on primary data collected directly from the workplace, complemented by secondary data from existing literature, research papers, and industry reports in order to contextualize the observed problems.

2) Data

Collection Methods

Non-participant observation was the primary approach to collecting primary data. The observations were made at various periods of the workday to ensure the differences in workflow, task execution, and equipment usage were recorded. The researcher documented aspects such as:

· Movement of materials and equipment

· waiting time for machines

· workspace layout and organization

· Communication among workers

· rework or measurement errors

· Safety and housekeeping practices

Recurring patterns and visible inefficiencies were recorded using field notes and an observation checklist. Additional insight into why certain delays or practices occur was gained through informal conversations with workers, which supplemented the depth of the primary data. These observed issues were compared to the existing findings through the collection of secondary data from books, journals, and related studies on small-scale fabrication operations.

3) Data

Analysis

A simple thematic analysis was performed on the data gathered. The different observations were grouped into thematic areas such as workflow issues, equipment limitations, material handling problems, and human-related factors. This grouping allowed for the identification of the greatest contributors to operational inefficiency within the workshop.

4) Scope

and Limitations

This study had a limitation in that it focused only on one fabrication workshop, focusing on daily operational activities. In addition, since the research depends mainly on primary observational data, it reflects the issues visible during work hours. It may not depict financial, administrative, or management issues that are hidden. These limitations notwithstanding, the methodology realistically and authentically presents the operating conditions of the workshop and points out its main shortcomings.

5. Analysis and Interpretation

This section highlights the findings from the observations conducted at Sai Sawant Construction and Engineering Firm. The analysis is organized according to major themes which emerged during the observation period. Each theme is then followed by its interpretation, explaining what it means to have observed such a pattern for the operational efficiency of the firm.

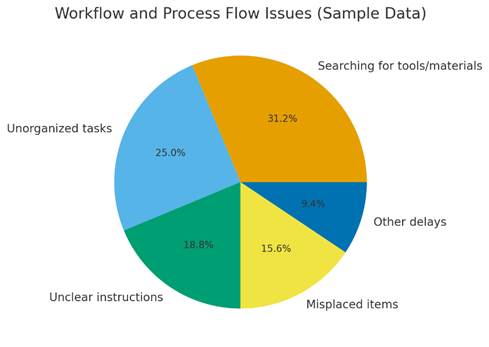

1) Workflow

and Process Flow Issues Workflow and Process Flow Issues

Analysis: The pie chart reveals that most delays-50%-happened simply because there weren't enough machines, so workers had to wait their turn. Another 30% came during busy hours when everybody needed the same tools at once. The last 20% was due to the breakdown of machines, which slowed things even further since there was no backup equipment.

Interpretation: In all, what slows this workshop most is that it does not have enough machines when the people need them. Long waits and occasional breakdowns make it hard for workers to keep tasks moving. More equipment—or better maintenance—would help reduce waiting time and improve the flow of work.

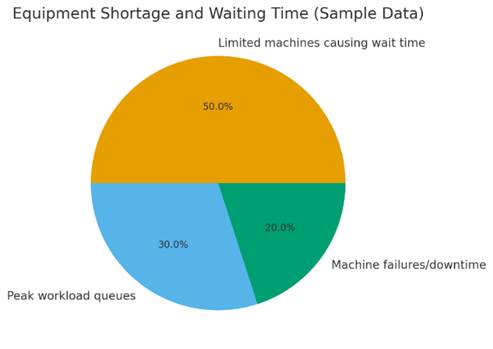

2) Equipment

Shortage and Waiting Time

Analysis: This is further explained in the pie chart, where 50% is contributed by limited machines because sometimes workers have to wait for a welding machine, grinder, or cutter. Peak workload congestion contributes 30%, during which the available equipment cannot meet the demand. Machine failures take the other 20%, with breakdowns creating additional downtime since no backup units can get the machines up and running.

Interpretation: The data indicates that the scarcity of equipment acts as a big bottleneck within the workshop. Long waiting times and occasional breakdowns reduce daily output and slow overall production. Improvement in machine availability and maintenance would greatly enhance workflow efficiency.

3) Material

Handling and Storage Problems

Analysis: Materials, like steel rods, sheets, and fittings, lay in a haphazard scatter or irregular stack. Workers wasted time searching for the right materials. Limited space meant that many incoming materials were placed randomly.

Interpretation: Poor material organization leads to waste of time and interrupts the natural flow of work. The lack of a defined area for storage increases chances of misplacement, rework, and safety hazards. This contributes significantly to overall operational inefficiency.

4) Skill

Level and Communication Gaps

Analysis: Some tasks had to be redone due to error in measurement, misalignment, or improper finishing. At times, the workers awaited instructions or explanations by the supervisor.

Interpretation: Variations in skill and breakdowns in communication increase the likelihood of mistakes and inconsistencies in the finished product. The effects are increased rework, which not only wastes time but adds to material wastage. Many of these losses could be reduced by better communication and formalized training.

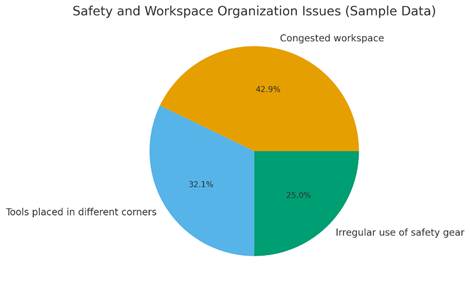

5) Safety

and Workspace Organization

Analysis: The workshop space was cramped; the rate of movement was very restricted, and this, in turn, slowed down working procedures. Tools were scattered in every corner rather than stored in a fixed location. This added to around 32% of the observed issues of safety and organization. Safety practices-such as gloves or goggles-were followed intermittently, making up about 25% of the concerns. General congestion remained the most prominent issue at about 43% as clutter blocked pathways and regular obstructions were common.

Interpretation: A disorganized, non-safe work environment is less efficient since workers are navigating through clutter to accomplish tasks and have to search for tools. Irregular safety practices also show a lack of discipline, increasing the vulnerability to accidents. Such an unstructured environment slows the pace of work, thereby negatively impacting productivity, and this calls for better organization in structure and consistency in safety habits.

6. Findings

Observations at Construction and Engineering Firm identified various operational inefficiencies, which are directly impacting the daily operations and productivity of the workshop. These are summarized under three broad categories for clarity.

1) Workflow

and Daily Operations

The workflow within the workshop was apparently unorganized. The workers were often wandering around the workshop, looking for tools, materials, or instructions. It seemed that the tasks were not planned in a sequence. Many tasks were left halfway because a required tool was not available or the workers were unclear about what to do next. This caused unnecessary waiting and hence delayed the overall work.

The workshop layout also contributed to inefficiency. Materials and tools were scattered over different areas; there was no defined pathway or specific zones for cutting, welding, or finishing work. This resulted in workers crossing over each other or obstructing the workspace of others, which created delays and occasional rework. Without standardized procedures, each worker followed their own style of working, which impacted consistency and overall coordination.

2) Resource

and Equipment Limitations

A major challenge observed was the availability of necessary fabrication equipment being at a minimal level. There were only a few welding machines, grinders, and cutting tools, and these had to be shared among several workers throughout the day. This situation caused waiting periods, especially during peak times of workload. Workers would often stop working on their tasks until one of these machines became free, thus creating bottlenecks in the workflow.

Besides, some of the machinery showed signs of wear and needed servicing. Some occasional breakdowns resulted in unplanned downtime, further delaying the job. Similarly, in material handling, steel rods, sheets, and fittings were kept without being organized properly; workers had to look for materials before starting or completing a job. This not only wasted time but also put extra physical strain on the workers.

3) Human

Factors: Skills, Communication, and Workspace Discipline

Human-related issues constituted another major source of inefficiency. The varying skill levels of workers contributed to inconsistency in measurements, alignment, and the quality of finishing. Errors were very common; these indeed led to rework, consuming both time and materials. Many workers depended on verbal instructions that at times resulted in incomplete information or misunderstandings.

Communication between workers and supervisors was not smooth. Several instances were observed when workers had to wait for either clarification or approval of ongoing tasks. The nature of supervision was unstructured, with instructions provided at the scene rather than planned. The workspace was undisciplined regarding organization and safety: the tools were laid wherever, and the area of operation became jammed as the day wore on. Poor housekeeping reduced movement efficiency and increased the chances of mistakes or small accidents. This disorganized environment significantly slowed the workflow and made coordinated work more difficult.

7. Discussion

The operational inefficiency that has been detected with regard to the performance of Sai Sawant Construction and Engineering Firm is not solely based on a single factor but rather has been due to a combination of workflow, resource, and human-related challenges. The unstructured kind of workflow observed in this workshop depicts the generally informal nature of small-scale fabrication units where the processes are experience-driven rather than system-driven. This has brought about frequent delays, as much work depends on how workers coordinate with each other rather than on an existing flow or based on a plan.

All these workflow problems are further exacerbated by equipment limitations. Workers have to wait for machines-mostly just a few in numbers-to become available, and thus reduce production even during peak hours. Besides, machine wear and occasional breakdowns contribute to the downtime. This points to the fact that small firms can barely invest in more or upgraded tools; therefore, resource shortages would persist.

Human factors also contribute to operational effectiveness. Variations in skill levels, communication gaps, and uneven supervision lead to mistakes and rework. Since fabrication involves precision work, even minor mistakes, such as incorrect measurements, result in delays and wasted materials. Informal communication systems, where instructions tend to be provided at the site of the work, also cause confusion and non-productive time.

A messy workplace, lack of certain resources, and poor human coordination add to a series of inefficiencies. Efficiency could be improved here only by better tooling or materials, but also by simple organizational changes, clearer communication, and basic work flow planning.

8. Conclusion

The issues identified in this study are particularly the operational inefficiencies observed at a Construction and Engineering Firm. The findings clearly prove that the workshop has throng difficulties in three main areas: workflow organization, resource availability, and human-related factors. Consequently, these three problems further result in delays, rework, variability in the quality of output, and low productivity.

While the firm works properly within the constraints, certain inefficiencies noted denote that small steps can make a big difference. Organizing tools and materials more systematically, some planning of tasks, clear communication, and timely maintenance of equipment can all help in improving daily activities. Even without significant investment, minor changes in layout and work process management can go a long way in streamlining the work process and avoiding wasteful delays. The inefficiencies pointed out in this work are, in fact, shared by most small-scale fabrication units. Amelioration of these factors can help in achieving higher productivity with lesser wastage and an improved working environment for the supervisors as well as workers.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

Deshmukh, R., and Patil, S.

(2021). Workflow Delays

and Production Challenges in Small-Scale Fabrication Units. Journal of Engineering Management, 14(2),

45–52.

Gupta, K., and Sawant,

M. (2022). Equipment Downtime

and Maintenance Issues in Local Fabrication Workshops. Indian

Journal of Production Research, 6(1), 23–31.

Mishra, R. (2022). Communication Gaps and Supervision Problems

in Small-Scale Manufacturing

Firms. International Journal of Management Studies, 9(2), 144–153.

National Safety

Council. (2023). Workplace Safety

in Small Industries: Annual

Report. NSC Press.

Singh, R. (2023). Material Handling and Inventory Issues in Small Construction and Fabrication Enterprises. Journal of Small Industry Research, 8(1), 27–34.

|

|

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© IJETMR 2014-2025. All Rights Reserved.