|

|

|

|

THE INFLUENCE OF VEHICLE MILEAGE ON BRAKE FLUID TURBIDITY AND WATER CONTENT

Wen-Kung Tseng 1![]() , Jian-Liang Lin 1

, Jian-Liang Lin 1

1 Graduate

Institute of Vehicle Engineering, National Changhua University of Education,

Taiwan R. O. C.

|

|

ABSTRACT |

||

|

Brake fluid is

the indispensable "blood" in the brake system. The brake fluid is a

water-soluble liquid that easily absorbs water. When the water content in the

brake fluid is too high, the brake fluid boiling point becomes lowered,

causing vaporization, resulting in slow brake response or even brake system

failure. Also the particles produced from brake

system wear accumulate in the brake fluid is called "Sludge". When

there is too much sludge, the color of the brake fluid will become dark. In

severe cases the brake system fluid passage will be blocked. The brake system

will then partially or completely fail. Therefore

this study investigated the effect of the mileage on the brake fluid

turbidity and water content. An infrared turbidity sensor was used in this

study to measure the brake fluid turbidity. The relationship between mileages

(0, 30,000, 60,000, 90,000, 120,000 Km) and brake fluid turbidity was

investigated in this study. It is found that when the mileage exceeds 30,000

kilometers, the turbidity of the brake fluid would increase rapidly. Also the water content in the brake fluid would also

exceed the dangerous value. |

|||

|

Received 12 August 2024 Accepted 16 September 2024 Published 30 November 2024 Corresponding Author Wen-Kung

Tseng, andy007@cc.ncue.edu.tw DOI 10.29121/ijetmr.v11.i11.2024.1514 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2024 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Brake Fluid,

Water-Soluble, Sludge, Turbidity, Mileage |

|||

1. INTRODUCTION

Brake fluid is synthesized by polyethylene glycol base, and it has many specifications, such as SAE70R2 (moderate duty brake fluid), SAE70R1 (heavy duty brake fluid), SAE70R3 (extra duty type), ISO4952. There are also BPNo.6, BPNo.7, BPNo.8 released by BP laboratory. The standards issued by the Transportation Division of the National Highway Safety Standards Administration are FMVSS No116 DOT3, DOT4, DOT5 and DOT5.1 Bosick & Newbold (2015) Brake fluid is the medium that transmits pressure in the brake system. These are the important properties that it should have high boiling point to avoid vaporization in the brake system at high temperature. The water content in the brake fluid must be low (less than 2%) so as not to greatly reduce the boiling point. The viscosity should be low. The compressibility should be low, and the effect of temperature and pressure on the compressibility should be small. The brake fluid also has a lubricating effect, so that the moving elements can work for a long time. The chemical reaction with the rubber element is normal, no shrinkage effect, and only a small amount of fluid expansion is allowed. The color is appropriate to prevent the brake fluid from being misused for other purposes. Hon (2009),Ministry of Environmental Protection Taiwan, Terminology List, (2020)

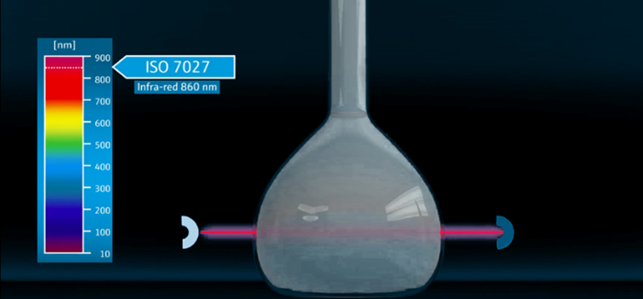

Turbidity is the degree to which light is scattered when it enters liquid. The sources of turbidity include clay particles, granules, fine organic matter, plankton, and microorganisms. The measurement of turbidity is based on the light scattering principle. The measuring tool is a turbidity meter. The unit of turbidity is generally the standard turbidity unit. (Nephelometric Turbidity Unit, NTU) NSAI Standards, IS EN ISO7027-1:2016 National Standards Authority of Ireland, (2016). The instrument for measuring turbidity is called a turbidimeter. Its design concept is derived from the Tyndall effect. This effect describes that when light passes through a colloidal solution, it will collide with micro particles with a particle size smaller than the wavelength of light, causing the light to change its direction of movement to form a scattering phenomenon. This in turn produces a light path visible to the naked eye. Turbidimeters vary according to the measurement angle, light source type and wavelength, and must follow different testing standards. The most common ones include USEPA 180.1 in the United States and ISO 7027 in the European Union, While ISO 7027 specifies infrared sources in the invisible wavelength range. Infrared measurements are not affected by the color of the medium since color only occurs in the visible range as shown in Figure 1 Redwan et al. (2019), Rudolf Limpert, Brake Design and Safety, 2nd ed, Chen Yan Book Co., (2004).

Figure 1

|

Figure 1 ISO 7027

infrared measurements NSAI Standards, IS EN ISO7027-1:2016

National Standards Authority of Ireland (2016) |

The infrared turbidity sensor has an infrared pair tube inside. When the light passes through a certain amount of water, the light will be absorbed or scattered to different degrees. After linear correction and calibration, the corresponding voltage is generated. The material used for the infrared light-emitting diode is GaAs, and the turning voltage is about 1v. This transition voltage is easily affected by temperature, and when the external temperature increases, the voltage decreases Sunday et al. (2019). Bako Sunday et al. introduced five kinds of brake fluid pollution, among which sludge is the tiny solid particles Trevathan et al. (2020). Sludge will contaminate the brake fluid, resulting in brake system failure. They also introduced the importance of the brake fluid color. If the fluid color turns dark brown, it means that it has not been replaced for a long time, and should be replaced as soon as possible. Fahim et al. introduced the formula for converting the output voltage of the infrared turbidimeter into turbidity Wan (2006), Wu (2010), Yang (2006).

If the brake fluid is not replaced for a long time, sludge will easily accumulate, causing some brake system parts to be blocked, resulting in partial brake failure or insufficient braking force, or even brake seizures. Therefore, this study investigated the effect of the mileage on the turbidity of the brake fluid and the water content, and suggested a reasonable time to replace the brake fluid.

2. METHODS

This study is divided into two stages. The first stage involves collecting DOT4 brake fluid samples from Toyota and Mercedes-Benz cars with different mileages as shown in Figure 2 After recording the mileage and water content in the samples, the samples are placed into a vacuum storage tank. The vacuum button is pressed 10 times, so that the collected samples are in a vacuum state to ensure samples originality. The equipment used in the first stage is shown in Table 1 below.

Table 1

|

Table 1 Equipment Used in the First Stage |

|

|

Name |

Model |

|

Negative pressure brake fluid replacement machine |

WH-507B |

|

Vacuum storage tank |

none |

|

Brake fluid water content detector |

JTC-1538A |

The second stage used the Arduino Uno board with the infrared turbidity sensor to measure the brake fluid turbidity at different mileages (0, 30,000, 60,000, 90,000, 120,000 Km) and different car series (Toyota, Mercedes-Benz) as shown in Figure 3. The data measured by the turbidity sensor were used to investigate the effect of the mileage on the brake fluid turbidity and the water content. The equipment used in the second stage is shown in Table 2。

Table 2

|

Table 2 Equipment Used in the Second Stage |

|

|

Name |

|

|

Infrared Turbidity Sensor |

DFR-sen0189 |

|

Arduino Uno plate |

Rev3 |

|

DB-XAB heating table |

DB-XAB |

|

Infrared Thermometer |

GE-5032A |

|

Bimetallic thermometer |

none |

Figure 2

|

Figure 2 Brake Fluid

Samples Taken from Real Vehicles |

Figure 3

|

Figure 3 Measuring the

Brake Fluid Turbidity and Water Content |

3. EXPERIMENTAL RESULTS

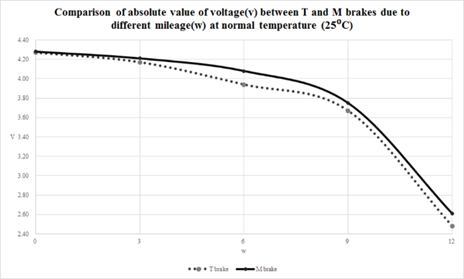

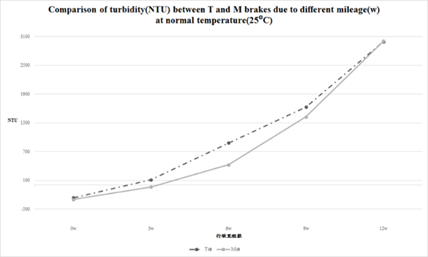

Figure 4 shows the relationship between the turbidity sensor voltage of the T brand and M brand brake fluid and the mileages at room temperature. It can be seen that the voltage of T brand and M brand brake fluid decreases when the mileage increases. Also the voltage decreases rapidly with the mileage over 30000 Km, and this curve is inversely proportional to the turbidity. The output voltage of the turbidity sensor was converted into turbidity NUT as shown in Table 3. Figure 5 shows the relationship between the turbidity and the mileages. As can be seen from the figure the turbidity increases with the mileages. Also the turbidity of the T brand and M brand brake fluid is quite low at the mileage between 0 and 30000 Km, and it increases rapidly at the mileage over 30000 Km. The results showed that the brake fluid must be replaced at the mileage of 30000 Km. The water content and the sensor output voltage are also shown in Table 4. From the table we can see that the water content is 2% at the mileage of 30000 Km, which is within the acceptable range. Therefore, the turbidity and the water content of the brake fluid are not within the acceptable range at the mileage over 30000 Km. When the mileage is over 30000 Km, the brake fluid can be found to have obvious turbidity by naked eye observation, and the water content has also reached the dangerous range. If the brake fluid is not replaced at the mileage over 30000 Km, the brake system is likely to have leakage or blockage problems. The brake system will not work properly, because the brake system may have been slightly blocked in the high turbidity case. Therefore, it is recommended that the maintenance factory can routinely replace the brake fluid before the mileage over 30000 Km to maintain the normal brake system operation.

Figure 4

|

Figure 4 Comparison of Voltage Absolute Value Between T Brand and M Brand Brake Fluid Due to Different Mileages st Normal Temperature (25⁰C) |

Table 3

|

Table 3 Brake Fluid Turbidity at Different Mileages |

|||||||

|

Milage |

Column1 |

Column2 |

3W |

6W |

9W |

12W |

|

|

T Brake Fluid (NTU) |

-261.42 |

4.17 |

109.96744 |

109.98 |

879.12 |

1630.78 |

2997.1 |

|

M Brake Fluid (NTU) |

-299.79 |

|

|

-35.9 |

425.06 |

1425.1 |

3002.23 |

Figure 5

|

Figure 5 Comparison

of Turbidity (NTU) Between T Brand and M Brand Brake Fluid Due to Different

Mileage(W) at Normal Temperature (25℃) |

Table 4

|

Table 4 Brake Fluid Output Voltage and Water Content with Different Mileage |

|||||

|

Milage |

0 |

3W |

6W |

9W |

12W |

|

T Brake Fluid (v) |

4.27 |

4.17 |

3.94 |

3.67 |

2.48 |

|

M Brake Fluid (v) |

4.28 |

4.21 |

4.08 |

3.75 |

2.61 |

|

T brake fluid water content |

0% |

2% |

3% |

4% |

4% |

|

M brake fluid water content |

0% |

2% |

3% |

4% |

4% |

4. CONCLUSIONS

This study investigated the influence of the vehicle mileage on the brake fluid turbidity and the water content. The experimental results showed that the brake fluid turbidity would increase rapidly at the mileage over 30,000 kilometers. Also the water content of the brake fluid would be too high at the mileage of 30000 Km. Therefore, it is best to replace the brake fluid at this mileage. If the brake fluid is not replaced at the mileage over 30000 Km, the braking system is likely to fail. Although there were only two brands of the brake fluid in this study, the results could be a recommendation for replacing the brake fluid.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

Bosick, A., & Newbold, D. (2015). A Practical Approach

to Motor Vehicle

Engineering and Maitenance, 3rd ed,

Cao Li Book Co.

Hon, W. (2009). Vehicle maintenance, Fong

Book Co.

Ministry of Environmental

Protection Taiwan, Terminology List, (2020).

NSAI Standards, IS EN ISO7027-1:2016 National Standards Authority of Ireland,(2016).

Redwan, F., Rafid, S., Abrar, A.H., & Pathik, B.B. (2019). An exploratory approach to monitor the quality of supply-water through IoT technology, 2019 International Conference on Automation, Computational and Technology Management (ICACTM). 137-142. https://doi.org/10.1109/ICACTM.2019.8776805

Rudolf Limpert,

Brake Design and Safety,

2nd ed, Chen Yan Book Co., (2004).

Sunday, B., Usman, T., Ezra P. Minagawa, & Ibex S. (2019). Ityokumbul, An overview of hydraulic brake fluid contamination, STEAMS International Multi-disciplinary Conference, DOI:10.22624.

Trevathan, Jarrod, Read,W., & Schmidtke, S. (2020).Towards the development of an affordable and practical light attenuation turbidity sensor for remote near real-time aquatic monitoring, Sensors 20, no. 7. https://doi.org/10.3390/s20071993

Wan, H. (2006). The Study of Turbidity

Sensor Compensation, Master Thesis,

National Don Hwa University.

Wu, S. (2010). The Study of Turbidity,

Mater Thesis, National Taiwan University.

|

|

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© IJETMR 2014-2024. All Rights Reserved.