|

|

|

|

Research on the Evaluation System for Training Field Engineers in the Manufacturing Industry of Vocational Education under the Background of New Industrialization

Haibo Yi 1![]()

![]() ,

Hao Meng 2

,

Hao Meng 2 ![]() , Li Cao 3

, Li Cao 3![]() , Qiang Fu 1

, Qiang Fu 1![]()

1 Shenzhen

Polytechnic University, Shenzhen, China

2 China

Academy of Industrial Internet, Beijing, China

3 Ministry

of Industry and Information Technology Education and Examination Center,

Beijing, China

|

|

ABSTRACT |

||

|

In the process

of promoting new industrialization, it is particularly crucial to build a

high-level team of engineers. Although China has established the world's

largest engineering education system, it still faces a talent gap of over 20

million, especially the scarcity of high-quality technical and skilled

engineers, which has become a bottleneck restricting the sustainable

development of China's industry. In this context, the on-site engineer

special training program has emerged, with the first phase focusing on the

advanced manufacturing industry, aiming to jointly cultivate at least 200000

on-site engineers through deep cooperation between vocational colleges and

enterprises. In view of this, this article starts from the demand for talents

in the manufacturing industry in China's new industrialization process, and

deeply analyzes the problems and shortcomings of the current evaluation

system for engineer training. On this basis, we actively explored and

constructed a training and evaluation system and implementation path for

vocational undergraduate on-site engineers in the manufacturing field, aiming

to provide solid talent support for the transformation and upgrading of

China's manufacturing industry towards high-end, digital, intelligent, and

green directions, and also provide strong

theoretical support for building a high-level engineering team for new

industrialization. |

|||

|

Received 19 April 2024 Accepted 20 May 2024 Published 21 June 2024 Corresponding Author Hao Meng,

menghao_2016@126.com DOI 10.29121/ijetmr.v11.i6.2024.1470 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2024 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: On Site

Engineer, New Industrialization, Evaluation System, Vocational Education,

Manufacturing Industry |

|||

1. INTRODUCTION

1.1. Urgent need to cultivate undergraduate level vocational education on-site engineers in the context of new industrialization

In the process of promoting new industrialization, the cultivation of high-level engineering teams is particularly important. Although China has the world's largest engineering education system and a total of over 20 million engineers, it is noteworthy that we still face a talent gap of over 20 million, especially the shortage of high-quality technical and skilled engineers, which has become a bottleneck restricting development. To this end, the Ministry of Education, the Ministry of Industry and Information Technology, and other five departments have jointly implemented a special training plan for on-site engineers since 2022. This plan aims to mobilize no less than 500 vocational colleges and 1000 enterprises to participate by 2025, and jointly cultivate at least 200000 on-site engineers. In the context of new industrialization, vocational colleges at the undergraduate level have more advantages in cultivating on-site engineers in the advanced manufacturing industry compared to colleges at the intermediate and vocational levels. They are more in line with the needs of the new industrialization process driven by technological innovation, and can provide strong talent support for the transformation and upgrading of the manufacturing industry towards high-end, digital, intelligent, and green directions, thereby promoting the effective improvement of quality and reasonable growth of quantity in the manufacturing industry Donovan et al. (2022), Lampon & Rivo-Lopez (2022), Sarbu (2022).

Starting from the

demand for manufacturing talents in China's new industrialization process, this

article analyzes the current situation and problems

of the engineer training evaluation system, explores and constructs a training

evaluation system and implementation path for vocational undergraduate on-site

engineers, in order to provide guidance for building a

high-level engineering team in new industrialization.

2. Current situation and problems in the evaluation of on-site engineer training

1)

Current status of research on training methods and paths for on-site engineers

The key to

cultivating on-site engineers is "on-site". No less than scholars

have explored the training of on-site engineers from the perspective of

standardized training modes Mostow & Wohlers (2022), Kuang & Li (2022), Djuniardi et al. (2022), Braglia et al. (2024), such as constructing a standardized

training mode for on-site engineers in vocational colleges, proposing the

construction of training standards for "professional certification+vocational

qualification certificates", and proposing the reconstruction of a

standardized system for integrating theory and practice courses; In terms of

training paths, we discussed the training of on-site engineers from the

perspectives of value implications and paths, and explored effective paths for

cultivating talents through the collaborative mode of industry and education

from the perspective of improving the quality of talent training; Analyze the practical experience of on-site engineer

training from the perspective of industries such as elevators, molds, and steel; Analyzed the

value, challenges, and paths of on-site engineer training from the perspective

of the skills development framework of the International Labour Organization.

2)

Current

Status and Shortcomings of Research on the Training of Field Engineers in

Undergraduate Vocational Education

Since its launch

in 2019, undergraduate vocational education has received widespread attention

from various sectors, including academia Teixeira & Tavares-Lehmann

(2023), Ramos-Maldonado &

Aguilera-Carrasco (2022), Brown (2022), Wang et al. (2024). How to carry out on-site engineer training

in undergraduate vocational colleges has also become a hot research topic. Many

scholars have proposed new ideas, models, and methods, such as systematically

constructing a "one main line, two supports, three directions, and six

key" undergraduate level vocational education on-site engineer training

path; Positioning the training standards for vocational undergraduate on-site

engineers as engineering technology oriented, ability composite oriented, and

practical innovation oriented; The proposal of the on-site engineer plan will

promote the development of vocational undergraduate majors towards matching,

distinctive, and high-quality directions; Taking 321 engineering related

professional talent training programs from the first batch of 32 vocational

undergraduate colleges in China as samples, this paper analyzes

the logical dimension, practical difficulties, and path optimization of on-site

engineer training in vocational undergraduate colleges. These studies provide

effective theoretical support for vocational undergraduate colleges to carry

out on-site engineer training, but there is still a lack of systematic research

in the evaluation of training effectiveness Kahyarara & Teal (2022), Mao et al. (2024), Kuang & Li (2022), Paek (2023).

3. Evaluation principles for on-site engineer training in undergraduate vocational education

1)

The

requirements of new industrialization for on-site engineers in undergraduate

vocational education

The flourishing

new round of technological revolution and industrial transformation has built

an immensely broad growth stage for new industrialization and endowed it with

enormous development potential. The new industrialization, with its distinctive

characteristics of high-end, digitalization, intelligence, and greenization, is gradually shaping a new appearance of

modern industry. High end development not only means the optimization and

upgrading of industrial structure, but also represents the outstanding

improvement of product quality. It requires us to continuously pursue

excellence in technology and management, and promote

the extension of the industry to the high-end of the value chain.

Digitalization represents the deep integration of industry and digital

technology. Industry digitization drives the transformation and upgrading of

traditional industries, while digital industrialization gives birth to new

economic growth points. Intelligence is the deep integration of artificial

intelligence and manufacturing industry. Through the application of intelligent

technology, the automation and intelligence of the production process are

achieved, improving production efficiency and quality. Greenization

emphasizes the harmonious coexistence between industrial development and

environmental protection, promotes low-carbon industrial development, and

achieves sustainable development.

Therefore, the

new industrialization has put forward clear and urgent requirements for the

training of on-site engineers in undergraduate vocational education. We need to

cultivate on-site engineers with high professional competence, innovative

spirit, and practical ability. They should not only have profound theoretical

knowledge, but also have practical operation ability, be able to proficiently

master and apply new technologies and processes, and

promote the rapid development of new industrialization. At the same time, they

should also have a high sense of responsibility and mission, actively engage in

the practice of new industrialization, and contribute their own strength to

promoting the modernization process of China's industry.

2)

Principles

of on-site engineer evaluation

·

Strengthen

the evaluation of craftsmanship spirit

To guide

enterprises to form their own unique comparative advantages, promote the spirit

of craftsmanship, strengthen brand building, cultivate more "century old

stores", and enhance product competitiveness. When evaluating on-site

engineers, it is important to highlight and strengthen the assessment and

evaluation of apprentices in terms of finely crafted products and pursuit of

ultimate quality. This means that we expect apprentices to demonstrate a spirit

of striving for excellence and perfection in every process of production and

every detail of products, in order to promote the

continuous improvement of industrial manufacturing level.

·

Highlight

the "on-site" attribute of evaluation

The most

prominent feature of on-site engineers compared to other types of engineers is

their "on-site" nature. Specifically, this includes a precise

assessment of their on-site operational capabilities to verify their

proficiency and accuracy in actual operations; Conduct an in-depth assessment

of their on-site process knowledge to verify whether they have rich practical

experience and a solid theoretical foundation; A comprehensive examination of

their on-site management capabilities to determine whether they can effectively

organize and coordinate on-site work; A detailed observation of their on-site

collaboration ability to evaluate their communication and collaboration

abilities in team collaboration; And conduct a survey on the satisfaction of

their on-site service recipients to understand their performance and

effectiveness in serving customers.

·

Evaluation

should follow the rules of project and task implementation

The manufacturing

industry, especially high-end manufacturing projects, has its unique and

inherent operating rules. When evaluating on-site engineers, it is important to

ensure that the evaluation process is closely linked to the actual operational

logic of the manufacturing industry. Specifically, evaluation should closely

consider the progress of the project and the specific requirements of the task,

comprehensively and comprehensively from multiple dimensions, including the

engineer's actual operational ability, process application level, management

and coordination ability, and service effectiveness. Through this evaluation

method, not only can it ensure that the evaluation process conforms to the

actual situation of the manufacturing industry, but it can also accurately

reflect the professional ability and comprehensive quality of engineers,

providing strong talent support for the sustainable development of the

manufacturing industry.

·

Reflect

the innovative orientation of evaluation results

Technological innovation is the core driving force in the process of new industrialization, injecting a continuous stream of vitality into industrial development. When evaluating on-site engineers, attention should be paid not only to their professional abilities in technical implementation and problem-solving, but also to their innovative thinking and outstanding achievements demonstrated in on-site practice. This evaluation method aims to motivate engineers to continuously explore new technologies and methods, drive the sustainable development of the manufacturing industry through innovation, and promote the industry to achieve higher levels of innovation and upgrading.

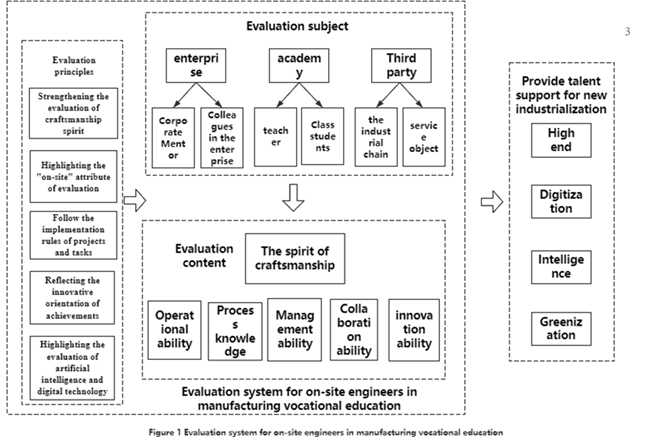

Figure 1

|

Figure

1 Evaluation

System for on Site Engineers in Manufacturing Vocational Education |

·

Highlighting

the evaluation of artificial intelligence and digital technology

Digitization and

intelligence, as significant symbols of new industrialization, have brought

unprecedented changes to modern manufacturing industry. It is necessary to

focus on assessing the professional competence and application ability of

engineers in the fields of intelligence and digitization, and deeply explore

their technological innovation and practical achievements in modern

manufacturing environments. Through this evaluation, the aim is to emphasize

the important role of engineers in promoting the transformation and upgrading

of the manufacturing industry in the digital age, in order to

better meet the urgent needs of manufacturing development.

4. Evaluation system for on-site

engineer training in undergraduate vocational education

1)

Evaluation

system framework

Based on the

principles of strengthening the spirit of craftsmanship and highlighting the

"on-site" attribute of evaluation, a undergraduate level on-site

engineer evaluation system for manufacturing vocational education is

established, with enterprises (enterprise mentors and colleagues), universities

(teachers and students), and third parties (upstream and downstream of the

industry chain, service objects, etc.) as the evaluation subjects (as shown in Figure 1), to provide high skilled talent support

for the high-end, digitalization, intelligence, and greening of new

industrialization.

2)

Evaluation

Content Framework

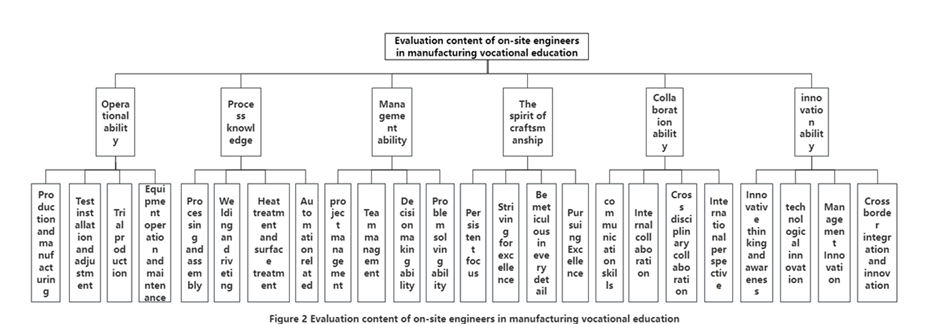

The evaluation

content of on-site engineers in undergraduate vocational education mainly

includes six dimensions: craftsmanship spirit, operational ability, process

knowledge, management ability, collaboration ability, and innovation ability

(as shown in Figure 2).

·

Evaluation

of craftsmanship spirit

The evaluation of

the spirit of craftsmanship should comprehensively consider their performance

in persistence, excellence, meticulousness, and pursuit of excellence. Through

these evaluation contents, we can more accurately grasp their level of craftsmanship

quality and literacy.

·

Evaluation

of operational ability

The evaluation of

operational ability should be based on the specific operational performance of

the apprentice in specific positions such as production and manufacturing,

testing and assembly, trial production, and equipment operation and

maintenance. The evaluation of operational ability should pay more attention to

the reflection of on-site ability.

Figure 2

|

Figure

2 Evalution

Content of On-Site Engineers in Manufacturing Vocational Education |

·

Evaluation

of process knowledge

The evaluation of

process knowledge should include related process knowledge such as processing

and assembly, welding and riveting, heat treatment and surface treatment,

automation, etc. The evaluation of process knowledge should place greater

emphasis on the depth and breadth of knowledge.

·

Management

capability evaluation

The evaluation of

management ability should include project management, team management,

decision-making ability, and problem-solving ability. The main body for

evaluating management capabilities should be corporate executives or direct

responsible persons.

·

Collaboration

ability evaluation

The evaluation of

collaborative ability should include communication skills, internal

collaboration, cross disciplinary collaboration, and an international

perspective. The evaluation of collaborative ability should focus on the

performance of apprentices in communicating and collaborating with external

enterprises and organizations.

·

Evaluation

of Innovation Capability

The evaluation of

innovation capability should include innovative thinking and awareness,

technological innovation, management innovation, cross-border integration and

innovation. The evaluation of innovation capability should be guided by

achievement innovation, such as the formation of invention patents, papers,

etc.

5. Reform measures and typical cases

The trend of

evaluation reform for field engineers in the manufacturing industry can be

summarized as follows:

1)

Classification

management and scientific evaluation

Emphasis on

classified management, and develop a more scientific

evaluation system based on the professional ability, performance and

contribution of professional and technical personnel, as well as the

innovation, achievement transformation and market application of enterprise

technical personnel. Such adjustments not only make the evaluation more

realistic, but also give every engineer a chance to show their unique value.

2)

Break

the "four-only" and focus on practical ability

In the past,

academic qualifications, qualifications, papers, and awards often became the

"hard bars" for professional title evaluation, which restricted the

development of many talented and capable engineers. The reform explicitly

breaks this tendency of "only", no longer using these factors as the

only criteria for evaluation, but paying more

attention to the actual work ability of engineers.

3)

Strengthen

supervision to ensure fairness and justice

By establishing a

system of integrity files and blacklists for professional title evaluation, we

will strictly deal with units and individuals who violate regulations to ensure

fairness and impartiality in professional title evaluation.

4)

The

evaluation criteria are more strict and comprehensive

The new

evaluation criteria not only require applicants to have a solid theoretical

foundation, but also require them to have rich practical experience and

innovative capabilities. Emphasize the importance of transforming and applying

research results, encourage applicants to combine theoretical knowledge with

practice, and promote scientific and technological innovation and industrial

development.

5)

Establish

a diversified qualification certification system

Considering

factors such as education, work experience, project experience, and

professional skills, and focusing on practical abilities, we aim to improve the

accuracy of engineer qualification certification.

6)

Improve

the career evaluation system

Include factors

such as performance results, innovation ability, and professional ethics into

evaluation indicators to achieve a comprehensive, objective, and fair

evaluation of engineers' careers. Strengthen the application of the evaluation

results of engineers' professionalism, link them with salary and promotion, and

stimulate the enthusiasm and creativity of engineers.

7)

Enhance

the development of the engineering team

We focus on

cultivating engineers with innovative spirit, practical ability and

international vision. We will increase support for training, communication, and

introduction of engineers, and improve the overall quality of the engineer

team.

8)

Promote

mutual recognition of international certification for engineers

Strengthen

cooperation with international engineer certification organizations, promote

mutual recognition of international engineer certification, and improve the

competitiveness of Chinese engineers in the international market.

In summary, the

trend of evaluation reform for on-site engineers in the manufacturing industry

is moving towards a more scientific, fair, comprehensive, diverse, and

international direction. Through reform measures such as classified management,

breaking down the "four-only" approach, strengthening supervision,

setting strict standards, establishing a diverse system, and improving the

professional evaluation system, it will help cultivate more outstanding on-site

engineers and promote the sustainable development and innovation of China's

manufacturing industry.

Shenzhen Polytechnic

University actively promotes the reform of the diversified talent training

model, deepens the integration of industry and education, and school enterprise

cooperation, laying a solid foundation for the training of on-site engineers.

Among them, the innovation and practice of the automation technology

application talent training model led by the Huichuan

Industrial Alliance began in 2017, and 7 consecutive order classes have been

held. Through the reform of the training evaluation system, more than 170

automation technology high skilled talents that meet the actual needs of Huichuan Technology Industry Alliance enterprises have been

delivered, and Huichuan technology innovation has

been transformed into new courses, new skills, and new vocational qualification

standards of the school, forming a replicable and promotable "Deep

Vocational Huichuan" model.

6. Conclusion

In the context of new industrialization, the training of on-site engineers in undergraduate vocational education has become a key measure to promote the growth of high skilled talents. This article is based on the current demand for talents in the manufacturing industry in China's new industrialization process, and conducts in-depth research and construction of a systematic evaluation system for on-site engineers in undergraduate vocational education in the manufacturing industry. The construction of this system aims to provide strong guidance and support for the construction of a new type of industrialized engineering team with high-level skills and qualities, thereby injecting new impetus into the transformation, upgrading, and sustainable development of China's manufacturing industry.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

This study was funded by National Natural Science Foundation of China (No.62202316), Special Innovation Projects for Universities in Guangdong Province (No. 2022KTSCX308), Research Projects of Shenzhen Polytechnic (No. 6022310037K), High-level Talents Research Initiation Projects of Shenzhen Polytechnic (No. 6021310026K), Shenzhen Natural Science Foundation (No. 20200821082500001).

REFERENCES

Braglia, M., Paco, F. D., Frosolini, M., Gabbrielli, R., & Marrazzini, L. (2024). Exploring the Relationship Between Project Cost Deployment and Industry 4.0 through an Industrial Application in an Engineer-to-Order Environment.Procedia Computer Science, 232, 139-148. https://doi.org/10.1016/j.procs.2024.01.014

Brown, D. A. (2022). Enhancing Graduate, Undergraduate, and Vocational School Education with Research and Development Internships and Capstone Projects. The Journal of the Acoustical Society of America, 151(4), A114-A114. https://doi.org/10.1121/10.0010825

Djuniardi, D., Jumantini, E., & Jamhari, A. (2022). Trading Volume, Earnings Per Share and Stock Returns and their Impact on Bid-Ask Spreads on Manufacturing Industry Sector Stocks Listed on the Indonesia Stock Exchange 2015-2018. JPPI (Jurnal Penelitian Pendidikan Indonesia). https://doi.org/10.29210/020221467

Donovan, R. P., Kim, Y. G., Manzo, A., Ren, Y., Bian, S., Wu, T., Purawat, S., Helvajian, H., Wheaton, M., Li, B., Li, G.-P. (2022). Smart Connected Worker Edge Platform for Smart Manufacturing: Part 2-Implementation and On-Site Deployment Case Study.Journal of Advanced Manufacturing and Processing. https://doi.org/10.1002/amp2.10130

Kahyarara, G. W., & Teal, F. (2022). General or Vocational Education? Evidences from the Returns to Education in Tanzanian Manufacturing Firms.

Kang, K., Liu, X., Jiang, Y., Ken, Lee, K. H., Wan, S. K. W., Huang, G. Q., & Zhong. R. Y. (2023). Blockchain Opportunities for Construction Industry in Hong Kong: A Case Study of RISC and Site Diary. Construction Innovation, 23(2), 443-466. https://doi.org/10.1108/CI-08-2021-0153

Kuang, Y., & Li, Z. (2022). Personal Value Orientation, Expectation Confirmation and Choice Behavior: A Perspective of Sustainable Higher Vocational Development.International Journal of Sustainable Development and Planning: Encouraging the Unified Approach to Achieve Sustainability. https://doi.org/10.18280/ijsdp.170727

Lampon, J. F., & Rivo-Lopez, E. (2022). The Effect of the Industry Technology Intensity on the Drivers of Manufacturing Backshoring. Journal of Manufacturing Technology Management, (1), 33. https://doi.org/10.1108/JMTM-03-2021-0071

Mao, W., Sun, H., Wang, W., & Luo, D. (2024). Factor Reallocation Path for Low-Carbon Transformation: A Perspective of Manufacturing Industry Ecosystem. Energy Economics, 134. https://doi.org/10.1016/j.eneco.2024.107620

Mostow, N., & Wohlers, T. (2022). Additive Manufacturing: State of the Industry. Manufacturing Engineering, (4), 168.

Paek, K. J. (2023). A Survey on the Needs of the Garment Manufacturing Industry in Busan for the Development of Fashion Major Education Program. The Research Journal of the Costume Culture. https://doi.org/10.29049/rjcc.2023.31.2.213

Ramos-Maldonado, M., & Aguilera-Carrasco, C. (2022). Trends and Opportunities of Industry 4.0 in Wood Manufacturing Processes. Chapters. https://doi.org/10.5772/intechopen.99581

Sarbu, M. (2022). The Impact of Industry 4.0 on Innovation Performance: Insights from German Manufacturing and Service Firms. Technovation: The International Journal of Technological Innovation, Entrepreneurship and Technology Management, 113. https://doi.org/10.1016/j.technovation.2021.102415

Teixeira, J. E., & Tavares-Lehmann, A. T. (2023). Industry 4.0: The Future of Manufacturing from the Perspective of Business and Economics - A Bibliometric Literature Review. Competitiveness Review: An International Business Journal, 33(2), 458-482. https://doi.org/10.1108/CR-07-2022-0091

Wang, B., Zheng, L., Wang, Y., Fang, W., & Wang, L. (2024). Towards the Industry 5.0 Frontier: Review and Prospect of XR in Product Assembly. Journal of Manufacturing Systems, 74, 777-811. https://doi.org/10.1016/j.jmsy.2024.05.002

|

|

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© IJETMR 2014-2024. All Rights Reserved.