|

|

|

|

Bouthaïna Fersi Maazoun 1![]() , Mariem Ben Mabrouk 1

, Mariem Ben Mabrouk 1![]() , Mahdi Gargouri 1

, Mahdi Gargouri 1![]() , Faouzi Masmoudi 2

, Faouzi Masmoudi 2![]()

1 MODILS

Laboratory, Faculty of Economics and Management of Sfax, University of Sfax,

Tunisia

2 Professor, Department of Mechanical Engineering, University of Sfax, National School of Engineers of Sfax, Tunisia

|

|

ABSTRACT |

||

|

Manufacturing companies are constantly driven to minimize costs, maximize efficiency, and enhance production quality, as these factors are pivotal for maintaining a competitive edge in the market. Lean manufacturing is a pivotal strategy that plays a crucial role in assisting companies for achieving significant continuous improvement in performance through the elimination of all wastes of resources and time in the total business process. The main objective of this paper is to validate the results of implementing Lean manufacturing through the DMAIC concept. This study focuses on a case study conducted in a glass transformation company that aims to improve the flow within the production workshop by implementing pull systems and minimizing waste. To achieve this objective, a comprehensive literature review was conducted to examine different frameworks for applying the Lean method. The

implementation of DMAIC has provided a better structure for the entire

project, enabling the selection of appropriate improvement solutions and the

use of the right Lean tools. This approach offers several advantages that are

not present in other frameworks. The results of this implementation have

shown a significant improvement in production planning, flow efficiency, and

a substantial financial gain for the company. |

|||

|

Received 15 February 2024 Accepted 16 March 2024 Published 31 March 2024 Corresponding Author Bouthaïna Fersi Maazoun, bouthaina.maazoun@usf.tn

DOI 10.29121/ijetmr.v11.i3.2024.1406 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2024 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Lean

Manufacturing, DMAIC, Lean Tools, Continuous Improvement |

|||

1. INTRODUCTION

In today's highly

competitive business landscape, numerous companies strive to establish their

presence despite limited resources. However, in order to achieve greater

profitability, these companies often find themselves in need of more efficient

manufacturing processes. This is where the adoption of lean management

techniques comes into play. By implementing this approach, businesses across

various sectors such as manufacturing, for-profit, non-profit, education, and

healthcare can significantly enhance their effectiveness and efficiency The

lean approach has proven to be a game-changer for numerous industries, enabling

them to produce superior products in less time and with fewer efforts Dave (2020).

After the conclusion

of World War II, Japanese manufacturers, specifically those in the automotive

industry, were confronted with a significant predicament: shortages of

essential resources such as materials, finances, and manpower. It was during

this challenging period that Eiji Toyoda and Taiichi Ohno, visionaries at the

Toyota Motor Company in Japan, pioneered a groundbreaking concept known as the

Toyota Production System. Kumar et al. (n.d.).

Following its

resounding success in Japan, lean manufacturing quickly gained traction among

companies and industries worldwide, particularly in the United States Fawaz Abdullah (2003). Moreover, the lean approach fosters a culture of

continuous improvement, encouraging employees to identify and address

inefficiencies, resulting in a more agile and adaptable organization.

This document

presents a relevant Lean Manufacturing application, implemented by following

the systematic steps of the DMAIC approach to reduce the various waste forms

that involve a high inventory of work-in-process for a glass transformation

company with a complex workflow. In

order to successfully implement the Lean concept, the team used a plethora of

Lean tools like, value stream mapping, 5S, etc. For the paper’s organization,

the first part is dedicated for a literature review concerning Lean Manufacturing

and its applicability as well as the DMAIC cycle. The second part will be

focusing on the methodology used for the implementation of the Lean

Manufacturing project. The third part

will include the gain generated and the Lean application’s efficiency in this

company. A conclusion and some perspectives will be discussed in the last part.

2. Literature review

2.1. Lean concept

The Lean philosophy is centered around the reduction and elimination of non-value added activities, commonly referred to as "Mudas" in Lean terminology. By implementing Lean production techniques, companies can achieve higher levels of productivity with fewer human resources, reduced financial investment, less space, and fewer equipment requirements to manufacture the same product Salonitis & Tsinopoulos (2016).

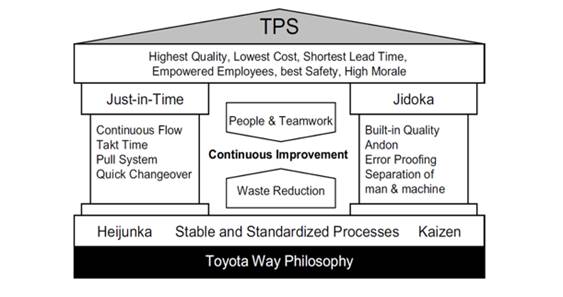

Figure 1

|

Figure

1 The Core Principles of the

Toyota Production System Romvall et al. (2010) |

Toyota, the originator of Lean, has

likened its philosophy to a temple, symbolizing the foundation of Lean project

construction and the pillars that fortify its strength (refer to Figure 1). Each component of this temple serves to define the objectives of the

methodology, highlighting the areas that require attention and the tools that

should be employed Rüttimann & Stöckli

(2016).

It also adds five principles to

improve the company's functioning: determining the product's value in the eyes

of clients, identifying, and clarifying the value stream for the product,

providing a fast and undisturbed value stream, allowing clients to elicit value

from the producer, and striving for excellence Dekier (2012).

2.2. Lean manufacturing

Lean Manufacturing was

first coined in 1991 by James P. Womack, Daniel T. Jones, and Daniel Roos in their book "The Machine That Changed the

World." They compared Japanese and American companies and found that

Toyota Motor Company, with its Toyota Production System, was the most

efficient. Dekier (2012).

The Toyota Production System (TPS)

was hailed as the first system that followed the principles of Lean. In 2001,

Womack and Jones published "Lean Thinking: Banish Waste and Create Wealth

in Your Corporation," which defined the foundations of the

Lean Philosophy. Lean Manufacturing is considered a successor of the TPS

and applies the instruments developed by Toyota. Palange & Dhatrak (2021).

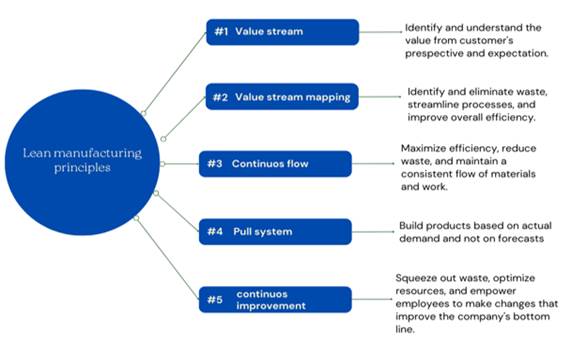

In order to effectively implement Lean

principles, companies must adhere to the principles of Lean implementation.

These principles have been extensively discussed in various books and articles,

including works by Jerry (2003), Liker (2004), Andersson et al. (2006), Su et al. (2006). For a

comprehensive overview, refer to Figure 2.

Figure 2

|

Figure

2 The Lean Manufacturing

Principles |

The implementation of Lean has been

closely linked and integrated with various other concepts, services, and

paradigms. One such example is Lean Sigma Mostafa et al. (2016) which combines Lean's focus on efficiency and speed with Six Sigma's

emphasis on accuracy and precision. By utilizing Lean principles, resources are

effectively utilized to create value, while Six Sigma ensures that tasks are

done correctly the first time.

2.3. DMAIC approach

DMAIC, inspired by Deming practices

and the Plan, Do, Check, and Act (PDCA) Cycle Gupta (2013). This process ensures continuous improvement and has proven to be

highly beneficial for numerous organizations.

DMAIC stands for the five steps:

Define, Measure, Analyze, Improve, and Control. Interestingly, DMAIC can be

operated without making reference to the Six Sigma

approach. For instance, in one study, the DMAIC cycle was exploited to improve

the supply chain Dossou & Dedeban

(2016), while in another study, it was used to analyze the root causes of

circuit breaker failure in a distribution system Popov et al. (2018).

The DMAIC Methodology is a six-step

approach used in Six Sigma projects. The first step is the Define Phase, where

the problem is identified, the project goal is established, and the customers

affected by the problem are determined. The second step is the Measure Phase,

where the existing system or process is measured and

metrics are established. The third step is the Analyze Phase, where the

defective process is analyzed to identify input variables that affect the

output. The fourth step is the Improve Phase, where solutions to the problem

are selected and implemented to improve efficiency, cost-effectiveness, and

speed. The fifth step is the Control Phase, where modifications to management

systems are made to ensure the improvements are sustainable. Continuous

monitoring is also necessary to confirm the desired improvement has been achieved Kumar and Sharma (2012).

3. Mehodology

A diagnostic is an important step in any project as it helps

identify issues within an organization. It involves observation,

identification, and analysis to establish connections between relevant

variables. In this case, a Lean assessment was used to evaluate the company's

operations and determine indicators related to costs, quality, and

timelines. Lean assessment is based on the “Genchi Genbutsu”

approach which means going to the source to check the situation for yourself

and emphasizes Gemba processes, a Japanese word meaning “where reality is”. The

Genba or Gemba walk is an activity for managers which

consists of going into the field to look for waste and opportunities for

improvement that are at the origin of added value. Loyd et al. (2020b).

Company managers were involved in the

assessment and rated the level of Lean integration using a scale from 0 to 4. A

questionnaire based on eight Lean principles was used to calculate results,

with each principle assigned a rating out of 100 points for a total evaluation

score of 800 points. The company scored 120 points, indicating deficiencies in

accountability, continuous improvement, and transparency. Due to the challenges

posed by the COVID-19 pandemic, the company chose to prioritize areas that can

be improved with minimal cost and bring added value to society, focusing on the

principles of process orientation, flow, and transparency. The Lean methodology

was implemented with the primary objective of enhancing the physical flow

within the polishing workstations and optimizing stock management. The project

team recognized that Lean Manufacturing is the most effective solution for

identifying non-value-added activities and improving overall workflow, provided

that the company is committed to eliminating various forms of waste within the

workshop.

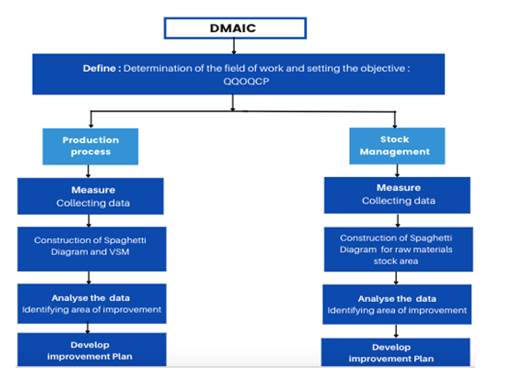

The DMAIC problem-solving methodology

has been selected to implement Lean Manufacturing like presented in the Figure 3.

Figure 3

|

Figure

3 The DMAIC Problem-Solving

Methodology |

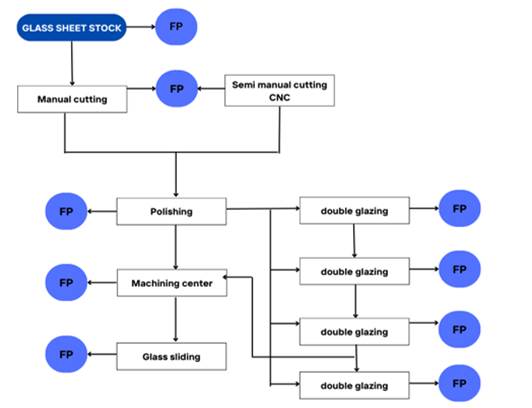

3.1. Production line

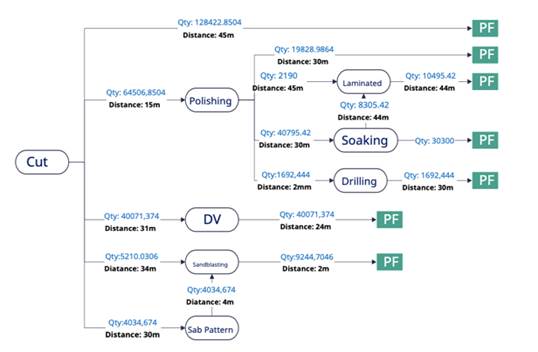

The first step is to observe the

production line and collect required information During the observation of the

production line we discovered the existence of different categories of products

that the company manufactures refer to the Figure 4 in which is represented all the process of the transformation of the

glass.

Figure 4

|

Figure

4 Glass Transformation Flow

Diagram |

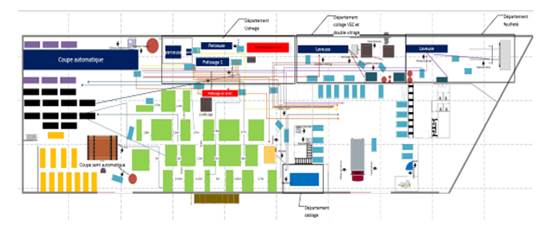

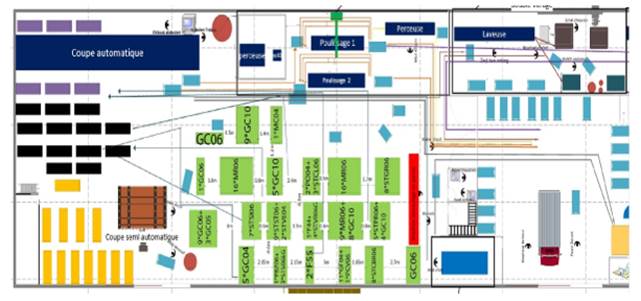

The initial layout of the production

departments has unveiled a series of challenges that warrant attention. The

primary focus was on analyzing the distance between each workstation, alongside

assessing production quantities and intermediate stock levels between each

process. This critical evaluation has been succinctly represented in the

diagram below, illustrating the spatial arrangement of workstations, the flow

of materials, and the accumulation of intermediate stocks.

Figure 5

|

Figure

5 Workstations Overview |

The Figure 5 illustrates that the automatic cutting machine serves as the main

machine in the factory, as all products go through it. The polishing station,

double glazing, sandblasting, and sandblasting pattern are directly related to

the cutting machine, while there is a significant distance between the stations

in relation to the quantity demanded. Taking the example of the double-glazing

department, it is located 31m away, and the sandblasting department is 34m

away. As shown by the spaghetti diagram (Figure 6), due to the flow intersections, operators spend between 10 and 15

minutes to bring a trolley with a frequency of 3 times per day, resulting in a

total of 45 minutes per day.

Based on this analysis, one can

observe the presence of a poor layout causes waste in

transportation, handling, and movement between workstations.

Figure 6

|

Figure

6 Diagram Spaghetti |

Among the problems encountered in the

production workshop is that of an imbalance between the production departments

and a high stock of work in progress (WIP) and given that the company does not

have any production monitoring indicators, we calculated the capacity of each

station to determine the bottleneck station by conducting timing assessments

for each workstation over a span of five days as shown the Table 1:

Table 1

|

Table 1 Workstation Capacity |

|||

|

Operations |

Machine capacity |

Number of machine |

Client orders |

|

Cut |

0.05 m/s |

1 |

0.045 LM |

|

Polishing |

0.002 m/s |

2 |

0.008 LM |

|

Double glazing

operation |

0.009 m/s |

1 |

0.005 LM |

|

Sandblasting |

0.003 m/s |

1 |

0.001 LM |

|

Drilling |

0.01 m/s |

1 |

0.0002 LM |

|

Lamination |

0.014 m/s |

1 |

0.0014 LM |

|

Soaking |

0.008 m/s |

1 |

0.005 LM |

Upon

analyzing the table, it becomes

evident that the capacity of the polishing machine falls short of meeting

customer demand. Furthermore, when comparing the capacities of the drilling,

laminating, and soaking processes with that of the polishing operation, it

becomes apparent that the latter is significantly lower. This discrepancy leads

to a substantial waiting time for work-in-progress inventory, as depicted in

the flow maps.

Consequently, the table uncovers the

presence of a bottleneck machine, namely the polishing machine.

From this analysis the focus was on

developing a comprehensive Value Stream Map (VSM) tailored specifically to the

polishing process. This strategic approach enables to

gain a deep understanding of the current state of affairs,

pinpoint areas of inefficiency, and identify opportunities for improvement.

For the polishing workstation, the

manufacturing time for a specific number of pieces was tracked, along with

calculating the linear meterage of each piece. Subsequently, the capacity of

each workstation in meters per second was determined.

All the data collected will be

presented in the tables below (Table 2) and (Table 3).

Table 2

|

Table 2 Surface Measurement

for the Glass Sheet |

|||

|

Number of glass sheet |

Lenghth |

Width |

LM |

|

1 |

0.947 |

0.662 |

3.218 |

|

2 |

0.947 |

0.912 |

3.718 |

|

3 |

0.14 |

2 |

4.28 |

|

4 |

1.16 |

0.78 |

3.88 |

|

5 |

1.16 |

0.78 |

3.88 |

|

6 |

1.16 |

0.78 |

3.88 |

|

Sum |

22.856 |

||

Table 3

|

Table 3 Timing Measurement |

|

|

|

|

|

|

|

|

Operation |

1 |

2 |

3 |

4 |

5 |

6 |

Average Value Added |

|

Verification of the dimensions

of the piece |

12 |

||||||

|

Placement of the piece on

the machine |

6 |

6 |

15 |

10 |

7 |

6 |

|

|

Passage of the piece on the

conveyor |

11 |

17 |

6 |

17 |

26 |

11 |

|

|

Polishing operation on the

side (Width) |

70 |

78 |

50 |

50 |

71 |

72 |

6,51,66,66,667 |

|

Passage of the piece on the conveyor |

15 |

17 |

15 |

18 |

24 |

23 |

|

|

Return and placement of the

piece on the machine |

10 |

14 |

17 |

15 |

15 |

12 |

|

|

Passage of the piece on the

conveyor |

17 |

10 |

9 |

11 |

28 |

14 |

|

|

Polishing operation on the

side (Length) |

78 |

78 |

54 |

51 |

81 |

80 |

7,03,33,33,333 |

|

Passage of the piece on the

conveyor |

11 |

17 |

15 |

13 |

21 |

9 |

|

|

Return and placement of the

piece on the machine |

17 |

20 |

23 |

14 |

11 |

15 |

|

|

Passage of the piece on the

conveyor |

22 |

9 |

11 |

8 |

18 |

11 |

|

|

Polishing operation on the

side (Width) |

70 |

77 |

53 |

81 |

70 |

70 |

7,01,66,66,667 |

|

Passage of the piece on the

conveyor |

10 |

17 |

16 |

18 |

23 |

24 |

|

|

Return and placement of the

piece on the machine |

14 |

14 |

26 |

15 |

15 |

9 |

|

|

Passage of the piece on the

conveyor |

20 |

12 |

11 |

13 |

11 |

14 |

|

|

Polishing operation on the

side (Length) |

78 |

77 |

54 |

81 |

81 |

81 |

7,53,33,33,333 |

|

Convyor |

16 |

12 |

6 |

20 |

12 |

33 |

|

|

Return and placement of the

piece on the machine |

13 |

||||||

|

Polishing operation |

70 |

70 |

|||||

|

Passage of the piece on the

conveyor |

36 |

||||||

|

Placement of the finished

product on the glass transport and storage trolley |

8 |

10 |

35 |

6 |

13 |

6 |

|

|

Sum of the operations |

485 |

485 |

416 |

441 |

527 |

585 |

Sum of AV |

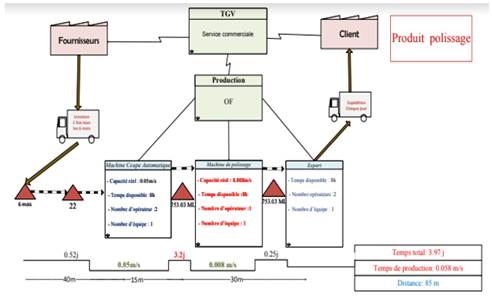

After implementing all necessary

measures, the Value Stream Mapping (VSM) for the polishing process was

designed. This map involved every step of the polishing operation, from the

initial preparation of materials to the final placement of the finished product.

By visualizing the entire value stream. Each stage was carefully analyzed to

identify potential inefficiencies, bottlenecks, and opportunities for

improvement. The VSM is represent in Figure 7.

Figure 7

|

Figure

7 Value Stream Mapping (VSM) of

the Polishing Process |

The analysis of the indicators has

revealed the following issues:

·

Problems with departmental

layout.

·

Poor synchronization

between all positions, resulting in a significant gap between the capacities of

each position and consequently, high waiting time for work-in-progress stocks.

·

The polishing machine is

causing a bottleneck at the workstation.

·

The production time for

the laminated product is very high due to the polishing machine and the

subcontractor's delivery delay (dipping operation).

With the identification of the

polishing station as the bottleneck within the production line, the improvement

plan is strategically oriented towards optimizing the flow process at this

critical juncture. Recognizing the pivotal role that efficient polishing

operations play in the overall productivity and output of the manufacturing

process, the primary objective is to streamline and enhance the flow of work

specifically within the polishing stage.

3.2. Stock

management

The storage areas at the production workshop level present

problems at the level of Organization and administrative tasks, flows and risks

for the employees.

The main objective must be the organization and optimization

of storage station flows so that they generate real added value in the

production process.

The storage area for raw materials consists of various models

of glass sheets that are stored in wooden boxes. These boxes have a width of 30

cm and a height of 2.5 m. The number of glass sheets in each box varies

depending on the model, ranging from 13 to 31 sheets as represented by the

green zone in the Figure 8.

In order to gather accurate data, we measured

the distances between the wooden boxes and the passageways, as well as the time

it takes for the operator to handle and transport the glass sheets from the

warehouse to the cutting stations. These measurements were crucial in

determining the efficiency of our operations.

By carefully analyzing these

factors, we aim to enhance our storage system, streamline our processes, and

ultimately improve overall productivity.

Figure 8

|

Figure

8 Spagetti Diagram of Glass Sheet

Stroage |

According to the spaghetti

diagram show different problems:

·

There is a

crossing of flows between the boxes, since the storage

trestles are not well arranged. Additionally, the crossover between the storage

flow and the polishing machine flow.

·

The boxes of

glass sheets presented by the green color are not organized according to any

classification despite the existence of all the names of the models. The distance between each trestle is different which has caused a disorder in terms of stock but

also the spaces for handling and moving the boxes are very narrow which shows a

loss considerable time.

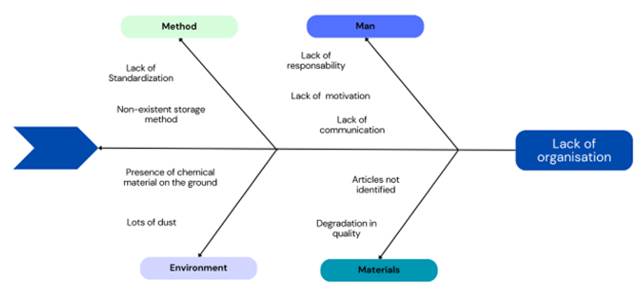

The next step is to analyze

the various issues encountered in the maintenance store and mezzanine storage

areas, the 5M method was employed. This method helped identify the root causes

of the problems (Figure 9) and facilitated their resolution.

Figure 9

|

Figure

9 Ishikawa Diagram (Storage Areas) |

The analysis reveals several

key issues contributing to the inefficiencies in stock management:

·

Inadequate Space Utilization: Storage

areas are not optimized for maximum capacity utilization, leading to wasted

space and congestion.

·

Poor Organization: Items are haphazardly stored

without a coherent organizational system, making it difficult to locate and

retrieve specific items promptly.

·

Absence of Standard Operating Procedures (SOPs): The

absence of clear SOPs for stock management leads to inconsistency and confusion

among staff members

·

Poor Organization: Items are haphazardly stored

without a coherent organizational system, making it difficult to locate and

retrieve specific items promptly leads to inconsistency and confusion among

staff members.

3.3. Improvement

plan

Optimizing operations within the production workshop,

it's imperative to address not only the efficiency of the production line but

also the effectiveness of stock management. This section outlines comprehensive

improvement plans for both aspects, aiming to streamline processes, minimize

waste, and maximize productivity. Those tables below represent the improving

plan for both production workshop and stock management.

Table 4

|

Table 4 Improving Plan (Production Flow) |

|

|

Problems detected |

Improving actions |

|

- Wasted Operator

Travel: The existing layout requires operators to traverse

unnecessary distances between workstations, resulting in wasted time and

energy. - Crossing of Flows:

Inefficient arrangement of machinery and workstations leads to the

unnecessary crossing of material flows within the department, increasing the

risk of congestion and delays. - Productivity Impacts:

Cumulative effects of inefficient layout contribute to decreased

productivity, higher operational costs, and potential quality issues. |

1. Machinery Reconfiguration Optimize the placement of

polishing machinery and equipment to minimize the distance traveled by

operators and reduce processing times. Consider reconfiguring the

layout to create a more linear workflow, allowing materials to move

seamlessly from one workstation to the next without unnecessary detours. 2. Employee Involvement Involve frontline employees

in the layout redesign process to leverage their insights and expertise. 3. Continuous Monitoring and Improvement Encourage a culture of continuous improvement within the polishing

department, where employees are empowered to propose innovative ideas and

solutions for enhancing efficiency. |

|

Machine Downtime: The unexpected stoppage of the second polishing machine halts the

production process, leading to delays and potential loss of productivity. Bottleneck Formation: The idle second polishing machine creates a bottleneck in the production

line, causing congestion and impeding the smooth flow of work. Operational Disruptions: The impact of machine

downtime extends beyond immediate production delays, affecting downstream

processes and overall operational efficiency. |

1. Repair of the Second Polishing Machine Promptly initiate the repair

process for the malfunctioning second polishing machine to minimize downtime

and resume normal production operations. 2. Improved Value Stream

Mapping (VSM) |

Table 5

|

Table 5 Improving Plan for Storage Areas |

|

|

Problems |

Improving actions |

|

- Inadequate Space

Utilization: Storage areas are not optimized for maximum capacity utilization, leading

to wasted space and congestion. - Poor Organization: Items are haphazardly stored without a coherent organizational system,

making it difficult to locate and retrieve specific items promptly. - Absence of Standard

Operating Procedures (SOPs): The absence of clear SOPs for stock management leads to inconsistency

and confusion among staff members |

1. Implementation of 5S Practices a) Sort: Remove unnecessary items from the storage spaces, disposing items that are no longer needed. b) Set in order: Establish a systematic storage system, organizing items in a logical and

accessible manner to maximize space and facilitate easy retrieval. c) Shine: Clean and maintain the storage areas regularly to ensure a safe and

hygienic working environment. d) Standardize: Implement standardized procedures for storing and

accessing items including labeling systems and storage protocols. e) Sustain: Develop a plan for ongoing maintenance and monitoring to sustain the

improvements achieved through the 5S practices. 2. Maximizing Storage

Capacity for the glass sheet Implementation of the ABC

method to standardize the stock of glass sheets, optimizing inventory levels,

and improving efficiency. 3. Optimization of Flow

Crossings Redesign layout and pathways to minimize unnecessary crossings and

optimize material flow, enhancing efficiency and reducing the risk of

accidents or delays. |

The following section will comprehensively present all

results achieved and improvements attained as a direct consequence of the

implemented actions aimed at enhancing efficiency and optimizing operations.

4.

Results and

discussion

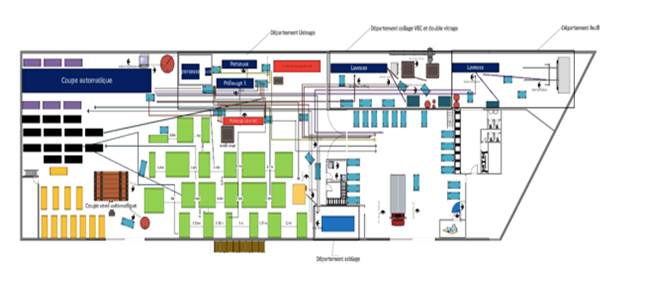

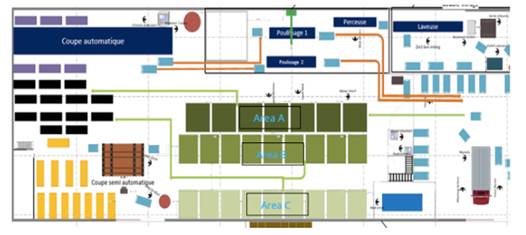

The implementation of the new layout in the machining

department has yielded several significant improvements. Most notably, the

restructuring has successfully eliminated the crossing of flows within the

department, a previously persistent issue contributing to inefficiencies and

waste. By streamlining the flow of materials and activities, we anticipate a

notable reduction in waste generation, thereby enhancing overall productivity

and cost-effectiveness. Moreover, the reconfigured layout has provided additional

space for storing trolleys adjacent to the machines, optimizing accessibility,

and facilitating smoother workflow operations. Additionally, the relocation of

the second polishing machine has resulted in the liberation of the corridor

space, creating a safer and more navigable environment for operators

maneuvering with trolleys. This newfound spatial freedom has had a tangible

impact on operational efficiency, notably reducing the delivery time of

trolleys from the cutting machine to the double glazing

department. (Figure 9)

Figure 10

|

Figure

10 Diagram Spaghetti After the Improvement Action |

Following the implementation of these initiatives,

improvements were expected within the Value Stream Mapping (VSM). In the

subsequent section, a thorough comparison was made between the indicators of

the value flow map of the polishing station before and after the application of

the improvements (Table 6).

Table 6

|

Table 6 Comparison Between

the Different Indicators Before and After the Improvement |

||

|

Indicator |

Initial

state |

Current state |

|

Production

capacity of the two polishing machines ML/days |

57.6 |

230.4 |

|

Number

of operators for one polishing machine |

2 |

1 |

|

Production

lead times for polishing products |

13.77d |

0 m2 |

|

Production

lead times for laminated products |

17,509day |

3.97 day |

|

Production

lead times for drilling products |

4.106d |

1.695 day |

|

Crowded

space in front of the polishing machine |

48m2 |

8.689 day |

The implementation of 5S principles has brought about

significant improvements in the efficiency and organization of store storage

and the mezzanine area.

·

Time savings: previously, employees spent

approximately 10 minutes searching for items, tools, or spare parts up to 10

times a day. With the 5S improvements, this time has been reduced to just 3

minutes, resulting in a daily time saving of 1 hour and 50 minutes, a remarkable

gain of 80%.

·

Elimination of losses: poor organization led to 10% of

items being unable to be found, necessitating replenishment of stock. However,

with all items now identified and visible, and with the store manager having a

tracking log for stock status, losses due to misplaced items have been

effectively eliminated.

·

Preservation of lifetime of

articles: items previously subjected to

dust and dirt suffered from degradation in quality, and clutter resulted in

destruction of some parts and tools. However, through the implementation of 5S,

all items and tools are now cleaned, well-maintained, and stored appropriately,

minimizing the risk of damage, and prolonging their lifetime.

·

Time

and Risk Reduction:

the previous lack of organization led to wasted time searching for items, while

cluttered spaces posed risks to employee safety. However, with improved

organization and easy access to desired items, time is saved, and the risk of

accidents is minimized.

The redesign of the storage space for

glass sheets, coupled with the implementation of the ABC method, has led to

several notable improvements.

1) Gain #1: Maximizing storage capacity

By strategically applying the ABC

method, we were able to categorize glass sheets based on their value and

importance, allowing us to allocate storage space accordingly. High-value

sheets are stored in easily accessible areas, while low-value sheets are placed

in less accessible locations. This optimized arrangement maximizes the

utilization of available space, ensuring that every square inch is utilized

efficiently.

2) Gain #2: Minimization of risks

The redesign of the storage space has

resulted in the creation of a new corridor, providing operators with ample room

to maneuver safely. This not only reduces the risk of work accidents but also

mitigates the risk of material loss due to breakage of glass sheets. With more

space to work in, operators can handle materials more safely and securely,

minimizing the likelihood of accidents and costly damages.

3) Gain #3: Reduction in handling times

The implementation of the ABC method

and redesign of the storage space have also resulted in a significant reduction

in handling times. The new storage layout, guided by the ABC categorization,

ensures that high-value items are easily accessible, reducing the time required

to locate and retrieve them. Additionally, the new organizational flow,

depicted in the updated "spaghetti" diagram, highlights the

improvement in material flows. With the absence of crossings and the presence

of a continuous flow, materials can move seamlessly through the production

process, reducing handling times and improving overall efficiency refer to Table 7 and Figure 10.

Table 7

|

Table 7 Measurement of Distance and Time After Improvement Actions |

|||

|

Distance |

Time |

||

|

Before |

After |

Before |

After |

|

53 |

39 |

25 |

10 |

|

42 |

33 |

21 |

10 |

|

49 |

27 |

24 |

8 |

|

25.2 |

21 |

16 |

8 |

|

19.6 |

17 |

11 |

8 |

|

15.9 |

8.2 |

9 |

8 |

|

25.3 |

12.6 |

10 |

8 |

Figure 11

|

Figure

11 The Current State of the

Production Manufacturing |

To effectively demonstrate the

impact of improvement actions from the initial state to the final state, a

comprehensive reassessment was conducted of Lean principles that were targeted

in the initiatives of the project. Through this reassessment, the objective was

to provide a clear visualization of the progress achieved. The results revealed

a significant improvement in the evaluation scores, which increased from 120 to

154 out of a total of 800 points.

This notable increase

underscores the effectiveness of the improvement actions undertaken,

highlighting tangible advancements in operational efficiency, process

optimization, and adherence to Lean principles.

5.

Conclusion

and prespectives

This paper presents a

practical application of Lean Manufacturing utilizing the DMAIC approach, a

concept often associated with Six Sigma methodologies. Through the

implementation of Lean principles, notable improvements were achieved across

various aspects of the production workshop. The optimization of physical flows

within the workshop layout led to a significant reduction in unnecessary

travel, enhancing efficiency. Additionally, the application of 5S resulted in

improving and optimizing the stock management and work organization.

Furthermore, these enhancements contributed to a positive impact on the working

environment, fostering motivation and employee engagement.

As the future of this project

is considered, several prospects emerge. One potential area of focus is the

implementation of Total Productive Maintenance (TPM) programs can optimize,

this proactive approach can help minimize downtime and ensure optimal equipment

performance. Additionally, using the concept of Just-in-Time (JIT) inventory

management to minimize waste and inventory holding costs, while establishing a

production schedule could aid in reducing work-in-progress inventory and

promoting synchronization between workstations.

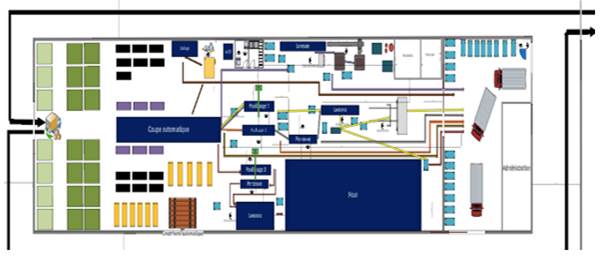

A

comprehensive proposal for the enhancement of production manufacturing has been

put forth to the company, aimed at streamlining operations and optimizing

workflow while simultaneously improving working conditions. This proposed plan (Figure 11) encompasses a

multifaceted approach, addressing various aspects of the production process to

drive efficiency and effectiveness. Central to the proposal is the optimization

of flow within the production line, achieved through strategic layout

adjustments, workflow reorganization, and the implementation of lean

principles. By reconfiguring the layout and redefining workflow sequences, the

aim is to minimize bottlenecks, reduce cycle times, and enhance overall

productivity. The ultimate goal of this proposal is to create a more efficient,

productive, and employee-friendly manufacturing environment that fosters

continuous improvement and sustainable growth. Through careful planning,

implementation, and monitoring, the company can expect to realize significant

benefits in terms of operational efficiency, product quality, and employee

satisfaction.

Figure 12

|

Figure 12 Proposal of New Workstations

Layout |

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

Andersson, R., Eriksson, H., & Torstensson, H. (2006). Similarities and Differences Between TQM, Six Sigma and Lean. The TQM Magazine, [E-Journal] 18(3), 282-296. https://doi.org/10.1108/09544780610660004

Dekier, L. (2012). The Origins and Evolution of Lean Management System. Journal of International Studies, 5(1), https://doi.org/10.14254/2071-8330.2012/5-1/6

Dossou, P., & Dedeban, G. (2016). Using DMAIC for Making Sustainable Supply Chain Efficient in a GRAI Environment. In Ecoproduction, 63-85. https://doi.org/10.1007/978-3-319-46451-0_5

Gupta, N. (2013). An Application of DMAIC Methodology for Increasing the Yarn Quality in Textile Industry. IOSR Journal of Mechanical and Civil Engineering, [E-Journal] 6(1), 50-65. https://doi.org/10.9790/1684-0615065

Jerry, K. (2003). LEAN Principles, Manufacturing Extension Partnership. Utah: Manufacturing Extension Partnership.

Kumar, N., Hasan, S. S., Srivastava, K. V., Akhtar, R., Yadav, R. K., & Choubey, V. K. (n.d.). Lean Manufacturing Techniques and Its Implementation: A Review. Materials Today: Proceedings, 64, 1188-1192. https://doi.org/10.1016/j.matpr.2022.03.481

Liker, J.K. (2004). The Toyota Way: 14 Management Principles from the World's Greatest Manufacturer. New York: McGraw-Hill.

Loyd, N., Harris, G. A., Gholston, S., & Berkowitz, D. (2020b). Development of a Lean Assessment Tool and Measuring the Effect of Culture from Employee Perception. Journal of Manufacturing Technology Management, 31(7), 1439-1456 https://doi.org/10.1108/JMTM-10-2019-0375

Mostafa, S., Chileshe, N., & Abdelhamid, T. S. (2016). Lean and Agile Integration within Offsite Construction using Discrete Event Simulation. Construction Innovation: Information, Process, Management, 16(4), 483-525. https://doi.org/10.1108/CI-09-2014-0043

Palange, A., & Dhatrak, P. (2021b). Lean Manufacturing a Vital Tool to Enhance Productivity in Manufacturing. Materials Today: Proceedings, 46, 729-736. https://doi.org/10.1016/j.matpr.2020.12.193

Panagos, P., Ford, A. L., Williams, J. A., Khoury, N., Sampson, T., McCammon, C., & Lee, J. M. (2012, February). Abstract 175: Applying Toyota Lean Manufacturing Principles to Stroke Care: Accelerating Door-to-Needle times. Stroke, 43. https://doi.org/10.1161/str.43.suppl_1.A175

Popov, I., Jenner, D., Todeschini, G. and Igic, P. (2018). Use of the DMAIC Approach to Identify Root Cause of Circuit Breaker Failure. In: 2018 International Symposium on Power Electronics, Electrical Drives, Automation and Motion (SPEEDAM). Amalfi: IEEE. 996-1001. https://doi.org/10.1109/SPEEDAM.2018.8445417

Romvall, K., Wiktorsson, M., & Bellgran, M. (2010). Competitiveness by Integrating the Green Perspective in Production – A Review Presenting Challenges for Research And Industry.

Rüttimann, B. G., & Stöckli, M. T. (2016). Lean and Industry 4.0-Twins, Partners, or Contenders? A Due Clarification Regarding the Supposed Clash of Two Production Systems. Journal of Service Science and Management, 09(06), 485-500. https://doi.org/10.4236/jssm.2016.96051

Rüttimann, B.G., & Stöckli, M.T. (2016). Going Beyond Triviality: The Toyota Production System-Lean Manufacturing Beyond Muda and Kaizen. Journal of Service Science and Management, [E-Journal] 09(02), 140-149. https://doi.org/10.4236/jssm.2016.92018

Salonitis, K., & Tsinopoulos, C. (2016). Drivers and Barriers of Lean Implementation in the Greek Manufacturing Sector. Procedia CIRP, 57, 189-194. https://doi.org/10.1016/j.procir.2016.11.033

Sharaf, I. (2019). Six Sigma DMAIC Methodology: A Powerful Tool for Improving Business Operations. https://doi.org/10.4028/www.scientific.net/AMR.488-489.1147

Shingō, S., & Dillon, A.P. (1989). A Study of the Toyota Production System from an Industrial Engineering Viewpoint. Rev. ed. Cambridge: Cambridge Mass Productivity Press.

|

|

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© IJETMR 2014-2024. All Rights Reserved.