|

|

|

|

JOB SAFETY ANALYSIS (JSA) OF PILE FOUNDATION WORK AT PURBALINGGA MULTIPURPOSE BUILDING CONSTRUCTION PROJECT

Taufik Dwi Laksono 1, Dwi Sri Wiyanti 2![]()

1, 2 Civil Engineering, Faculty

of Engineering, Wijayakusuma University Purwokerto, Jl. Beji Kampus Karangsalam

Purwokerto, Indonesia

|

|

ABSTRACT |

||

|

Construction

project is a project that involved many parties and consist of various work

items that must be executed. In most cases the executed work items has

possibilities of danger and risk that threatening the worker's health and

safety. This study was carried out using Job Safety Analysis on pile

foundation work of a building and executed by direct interview and field

observation. The result is that from 4 primary steps of pile foundation work

there are indications of 10 dangers and 15 risks that may be experienced by

the workers. Preventive and control measures can be carried out to anticipate

the danger and risk potential by involving the stakeholders of pile

foundation work execution. |

|||

|

Received 10 February 2023 Accepted 09 March 2023 Published 25 March 2023 Corresponding Author Dwi Sri

Wiyanti, sriwiyanti2@yahoo.com DOI 10.29121/ijetmr.v10.i3.2023.1292 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2023 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Job, Safety

Analysis, Pile |

|||

1. INTRODUCTION

Construction projects consist of various work items that must be executed and involving many parties. Therefore, a particular management is needed so that it can be well performed without any significant obstatcles. The aspect that not less important in construction project is the health, security, and safety of project workers. Building construction project is a project that consist of various work items that must be executed and during the execution process various level of danger may occure. The worker does not realize things that may endanger their health and safety when executing a work item. Therefore, anticipatory steps are needed in order to protect the worker's health and safety. The importance of health and safety of work or Occupational Health and Safety (K3/Kesehatan dan Keselamatan Kerja) showed in Regulation number 10-year 2021 of Public Works Minister Peraturan Pemerintah (2002) about the Guidance for Construction Safety Management System. The Construction Safety Management System is used to increase the safety and health protection in construction projects.

According to H.W. Heinrich in Notoatmodjo (2007) the causes of work accident that frequently occures are unsafe behaviour of workers that is 88% and unsafe environment that is 10% or both occures together.

Sandyavitri (2009). stated that the problems of health and safety in construction project are often encountered because the factors that causing risk of health and safety work are not well identified and handled.

There are many studies that related to the execution of work in a building project, one of them is a study by Amanda (2022) that carried out in the construction of a hospital building basement with a total of 93 potential risks. Prabowo (2021) that studied wall installation finishing conclude that the most dangerous risk is fall from a height. Nuha and Efendi (2020) in their study concludes that the highest risk level faced by workers are slip or fall and hit by a sharp object. Based on several studies that carried out in work execution of building project, it shows that there are risks that endanger the worker's health and safety. Therefore, further observation that related to building project is needed to complement the previous studies.

Pile foundation is one of foundation types that is used for high stories building or tower, the pile shape can be cylindric or triangle with length around 10 to 30 m, if the depth of the foundation is more than one pile long then a splicing can be done. There are various work methods that can be used to erect pile foundation, one of them is using diesel heavy equipment. Errors that may occure in pile foundation erection is caused by the use of materials under the calculated specification so that the foundation is not strong, an error during lifting process that not in the safe spot can break the pile, tilt may occure if the uprightness is not well controlled so that decreasing the depth and strength of the foundation from the intended design.

This study is a study of pile foundation work execution. The study objective is to identify potential danger that may occure, and the effort to control and prevent it in relation to analysis of work health and safety by using Job Safety Analysis. This study is expected to provide description about the possibility of danger and what steps that needs to be done to prevent and control the danger for consruction project executor.

2. MATERIALS AND METHODS

According to Gould (2002) in Dannyanti (2010) construction project is an activity with objective to erect a building that needs various resources such as cost, workers, tools, and materials. Whereas in goverment rules number 16-year 2021, a building is physical result of construction work including its site partly or completely above and/or beneath the land and/or water that functioned as a place for human activity.

In executing construction project sometimes accidents that endanger the workers’ health and safety are occures According to Minister of Public Works Number 5/PRT/M/2014, Construction Occupational Health and Safety are activities to ensure and protect workers health and safety through attempts to prevent accidents and diseases while working in construction project.

There are several methods that can be used to analyze health and safety risks, they are:

· HIRARC (Hazard Identification Risk Assessment and Risk Controls), a guidance to identify danger, assess possibility and managing risk or hazard.

· HIRADC (Hazard Idetification Risk Assessment and Determining Controls), a method to identify danger, risk ranking, and determining danger control.

· JSA (Job Safety Analysis), An analysis or work with Construction Occupational Health and Safety insight (K3/Kesehatan dan Keselamatan Kerja Konstruksi). as an effort to eliminate and prevent the risk of work accidents.

According to Occupational Safety and Health Adminstration (OSHA) year 2002, Job Safety Analysis is a technique that focus on work duty as a tool to identify danger before work accident or incidents happens. According to National Safety Council (NSC), Job Safety Analysis (JSA) includes three important element they are :

· Specific work steps

· The danger that occure in every work step

· Management in the form of safe work procedure to decrease or even eliminate danger in every work step.

This study was carried out by doing interview and direct observation. 3 (three) source persons. were interviewed, they are site manager, caretaker of Pile work, and carteaker of K3 construction. Construction Occupational Health and Safety (K3/Kesehatan dan Keselamatan Kerja

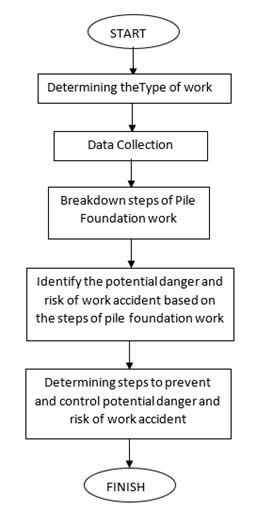

The flowchart of the study dan be seen in Figure 1 as follow:

Figure 1

|

Figure 1 Flowchart of the Study |

3. RESULTS AND DISCUSSIONS

Based on the interview, the obtained data shows a total

number of pile foundation work which is 252 points. Each point located at a

depth from 9 to 11m, whereas the length of the pile is 6m.

In general, the steps of executing pile foundation work are:

1) Bring in the materials of Pile Foundation

Figure 2

|

Figure 2 Bring in the

Materials of Pile Foundation |

2) Placing pile foundation materials at the nearest location from pile point

Figure 3

|

Figure 3 Placing Pile

Foundation Materials Near the Pile Point |

3) Setting up the pile foundation on the pile driver and erecting process.

Figure 4

|

Figure 4 Setting up

the Pile Foundation and Erecting Process |

4) Splicing the materials of pile foundation by welding.

Figure 5

|

Figure 5 Welding to Splice

the Pile Foundation Materials |

Based on the steps of pile foundation work above, identification of potential danger in every step of work was carried out. The identification results are:

Table 1

|

Table 1 The Results of Danger and Risk Identification |

|||

|

No. |

Step of Work |

Danger |

Risk |

|

1 |

Bring in the

materials of Pile Foundation |

-

Pile material carrier truck is passing

by |

-

Hit or grazed by the truck |

|

|

|

-

The pile is fell |

-

Hit by the pile. -

Grazed by the pile while being unloaded

from the truck |

|

2 |

Placing pile foundation materials at

the nearest location from pile point |

-

Sling crane is not strong enough. -

Sling crane randomly moving |

-

Grazed by the sling crane. -

Hit by the fallen pile. -

Grazed by the moving pile |

|

|

|

-

The piles are shifting and fell from

the stack |

-

Stumbled and hit by a pile |

|

3 |

Setting up pile foundation on the pile

driver and erecting process |

-

Sling crane is not strong enough. -

Sling crane randomly moving |

-

Grazed by the sling crane. -

Hit by the fallen pile. -

Grazed by the moving pile |

|

|

|

-

The pile is not correctly put on the

pile driver |

-

Hit by a pile. -

Squeezed by a pile |

|

4 |

Splicing the

materials of pile foundation by welding |

-

Welding tool shifted place |

-

Stumbled by the welding tool. -

Hit by the welding tool |

|

|

|

-

Welding sparks |

-

exposed to welding sparks |

From Table 1 it can be identified that out of 4 steps in executing pile foundation work, there are 10 (ten) potential danger and 15 potential risks from the 10 danger. This condition shows that execution of pile foundation work has danger potential that can pose risk to workers health and safety. Therefore, prevention and control of danger and risk are needed.

Below are steps of prevention and control from the identified danger and risks:

Table 2

|

Table 2 Prevention and Management of Danger and Risk |

|||||||

|

No. |

Step of Work |

Danger |

Risk |

Prevention |

Management |

Caretaker |

|

|

1 |

Bring in the materials of Pile Foundation |

- Pile material carrier

truck is passing by - The pile is fell |

- Hit or grazed by the truck. - Hit by the pile. - Grazed by the pile while being unloaded from the truck |

- Prepare the truck lane so that minimum workers are present at the

site. - Ensuring the position of pile is stable enough. - The workers wearing PPE (Protective Personal Equipment) |

-Creating signs - Assingned guards to control materials traffic and the stability

of the pile carried by truck |

- Logistics |

|

|

2 |

Placing pile foundation materials at

the nearest location from pile point |

- Sling crane is not strong enough. - Sling crane randomly moving. - The piles are shift and fall from the stack |

- Grazed by the sling crane. - Hit by the fallen pile. - Grazed by the moving pile. - Stumbled and hit by a pile |

- Ensuring that the area where the pile foundation materials will

be placed is a safe place. - Ensuring the sling crane is able/strong enough to lift pile

foundation. - Ensuring the stack of pile foundation materials is not in the

worker’s pathway. - The workers are wearing PPE (Protective Personal Equipment) |

- Creating boundary and warning signs - Regular Checking and maintenance of the sling crane - Crane operators possess expertise certificate |

- Construction

Occupational Health and Safety - Pile Supervisor |

|

|

3 |

Setting up the pile foundation on the

pile tool and erecting process |

- Seling crane is not strong enough. - Seling crane randomly moving. - The pile is not correctly put on the tool |

-

Grazed by the seling crane. -

Hit by the fallen pile. -

Grazed by the moving pile. -

Hit by a pile. -

Squeezed by a pile |

- Ensuring the sling crane is able/strong enough to lift pile foundation. - Assign a worker to control the movement of sling crane. - Assign a worker to regulate and control the placement of pile

foundation so that it will be corrrectly set on the driver. - The workers wearing PPE (Protective Personal Equipment) |

- Creating boundary and warning signs - Regular Checking and maintenance of the sling crane - Crane operator posses expertise certificate - Pile driver operator posses expertise certificate |

- Construction

Occupational Health and Safety - Pile Supervisor |

|

|

4 |

Splicing the materials of pile

foundation by welding |

- Welding tool shift place - Welding sparks |

-

Stumbled by the welding tool. -

Hit by the welding tool. -

exposed to welding sparks. |

- Ensuring the area where the welding tool placed is safe and not

in the workers pathway. - The workers are wearing PPE (Protective Personal Equipment) and

face shield |

- Creating boundary and warning signs - The welder posses expertise certificate |

- ConstructionOccupational Health and

Safety - Pile Supervisor |

|

Based on Table 2 it can be obtained that to prevent and control/manage the potential danger and risk in executing pile foundation work can be conducted in various ways. One of those is the use of self-protection gear (Alat Pelindung Diri/APD), routine control of the tools, limiting work area etc. Moreover, there are distribution of task/job for stakeholders to become the caretaker of every steps of activity in executing the pile foundation work so that prevention and management can be well applied

4. CONCLUSIONS AND RECOMMENDATIONS

Based on the result of the study it the obtained conclusions are:

1) There are 4 main steps in executing pile foundation work, bring in the materials of Pile Foundation, placing pile foundation materials at the nearest location from pile point, setting up the pile foundation on the pile driver and erecting process, and Splicing the materials of pile foundation by welding.

2) Executing pile foundation work have danger potential that may risk the health and safety of workers. There are 10 potential dangers identified and 15 risks that may occure from those 10 dangers.

3) Prevention and control measures can be carried out to anticipate potential danger and risk by involving the stakeholders to protect the worker's health and safety.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

Amanda, A. (2022). Job Safety Analysis (JSA) Konkstruksi Basement Pada Proyek Pembangunan Gedung B Rumah Sakit Umum Muhammadiyah Metro Provinsi Lampung. Jurnal Rekayasa Teknologi dan Sains, 6(1).

Dannyanti, E. (2010). Optimalisasi Pelaksanaan Proyek dengan Metode PERT dan CPM (Studi Kasus Twin Tower Building Pasca Sarjana Undip), Tugas Akhir.

Notoatmodjo (2007). Promosi Kesehatan dan Ilmu Perilaku, Rineka Cipta, Jakarta.

Nuha, U., and Efendi, R. (2020). Analisis Tingkat Risiko Keselamatan dan Kesehatan Kerja (K3) pada Proyek Pembangunan Gedung Kampus Institut Teknologi Telkom Purwokerto PT. Sandhy Putra Makmur. Science and Angineering National Seminar 5 (SENS 5), Semarang.

Peraturan Pemerintah (2002). Tentang Peraturan Pelaksanaan Undang-Undang Nomor 28 Tahun 2002 tentang Bangunan Gedung. Pemerintah Pusat.

Peraturan Perundang-undangan (2014). Peraturan Menteri Pekerjaan Umum dan Perumahan Rakyat No. 05/PRT/M/2014 tentang Pedoman Sistem Manajemen Keselamatan dan Kesehatan Kerja (SMK3) Konstruksi Bidang Pekerjaan Umum.

Prabowo, D. A. (2021). Analisis Pencegahan Kecelakaan Kerja Pada Pekerjaan Finishing Pasangan Dinding Berdasarkan Metode Job Safety Analysis (JSA). Tugas Akhir. UII. Yogyakarta.

Sandyavitri, A. (2009). Manajemen Resiko di Proyek Kosntruksi. Media Komunikasi Teknik Sipil, 17(1), 23-38. https://doi.org/10.14710/mkts.v17i1.3419.

|

|

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© IJETMR 2014-2023. All Rights Reserved.