ShodhKosh: Journal of Visual and Performing ArtsISSN (Online): 2582-7472

|

|

Investigating the challenges between designs to the reality of digitally fabricated structures

Shraddha Makarand Parange

1![]()

![]() ,

Dr. Vaishali Anagal 2

,

Dr. Vaishali Anagal 2![]()

![]()

1 Student,

Fourth Year, Dr. B. N. College of Architecture, Pune, Maharashtra, India

2 Associate

Professor, Dr. B. N. College of Architecture, Pune, Maharashtra, India

|

|

ABSTRACT |

||

|

Digital fabrication is not only the relation between design and construction but also the relation between thinking and making, which would be established by the use of modern technologies. The study aims to investigate the challenges formed between the two aspects of parametric architecture ‘Design’ and ‘Fabrication’ in India. There are various factors on which this gap depends. These factors would be the cost of construction, building material required for fabrication, and time required for construction compared with the conventional methods of construction. The objective of this study is to understand how digital fabrication will change the way of construction in India, which won’t be restricted to the classroom or only the computer-based design but will work in onsite construction with many different materials with no waste of time and money. The earlier literature focuses on a single aspect which may be either design or fabrication. There are fewer papers available that address both of the aspects comprehensively. The research would get an overview of different perspectives of people towards parametric architecture. This is done by conducting surveys of different practicing architects, students who have done their masters in digital architecture and now practicing, and contractors who are working on parametric construction. The survey was conducted by sending a questionnaire to different practicing architectural firms all over India, the students who have pursued Master’s degrees in digital architecture and professors teaching Master’s degrees in digital architecture who had an interest in parametricism. The data received was analyzed using descriptive statistics. The qualitative data received through the questionnaire was analyzed by identifying patterns and then categorized according to the different answers. |

|||

|

Received 29 August 2023 Accepted 29 December 2023 Published 03 January 2024 Corresponding Author Shraddha

Makarand Parange, shraddhaparange1608@gmail.com DOI 10.29121/shodhkosh.v4.i2

ECVPAMIAP.2023.706 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2023 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Parametric Architecture, Digital Fabrication, Parametricism |

|||

1. INTRODUCTION

The architectural magazines publish many articles about architects and their work on parametric architecture. The majority of work done in India, regarding Digital architecture, was concerned with the digital design of small-scale manufactured structures such as pavilions, public seating, elements in bungalow façades, or occasionally form exploration using parametric architecture tools (oneistoex, 22, Melih Gürcan Kutsal 22). Furthermore, the websites of architectural firms post numerous rendered images of skyscrapers and massive townships with very futuristic designs, but images of structures built using parametric designs are rarely seen. Many small-scale pavilions and installations have been observed in India, whereas many completed buildings built outside of India have been discovered to be digitally designed.

There may

be different approaches of designers and fabricators to parametricism,

which had different depending factors, and these factors generated a gap

between thinking and making. This research attempts to identify the reasons

behind the generation of this gap. The inclination towards parametricism

may involve the fascination or inclination towards technology, futuristic

forms, and different skillset of software. A questionnaire Survey was conducted

to investigate:

1)

What

is the situation of Parametric Architecture in India based on design and

fabrication aspects?

2)

How

are practicing architects responding to the term digital fabrication in India?

3)

What

is the current focus of parametric practices in India in current times?

1.1. Understanding Parametric Architecture

The term

parametric has mathematical origins, but it has a different meaning in

architecture. In Greek, para means besides, and metre

is derived from metron, which means measure. When

these two words are used together, they refer to a collection of numerical or

other measurable factors that define a system or establish the conditions for

its operation Koumari (2022). The

experimental nature of parametric modelling is known as form-finding. The

method of metric architecture is based on algorithms that enable the various

parameters. These parameters are subject to some rules, which determine the

relationship between design inputs and design outputs. This relationship

produces complex geometries and structures.

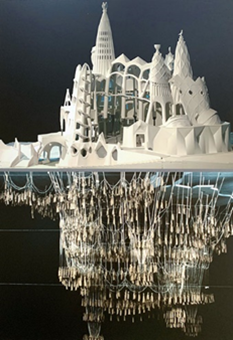

One of

the earliest examples of parametric design is Antonio Gaudi's upside-down

church models; in his designs for the churches of Colonia Guell and Sagrada

Familia, he created a string model (Figure 1). Digital fabrication was first

used to create physical models for the restorations of Saint John the Divine

Cathedral and Sagrada Familia Burry et al. (2001). That was weighted down to create

complex vaulted ceilings and catenary arches. By adjusting the weight

positions, he could change the shape of the catenary arches and see how it

affected the entire model. He then placed a mirror on the model's bottom to see

how it should appear upside down. (Figure 2).

Figure 1

|

Figure 1 Upside Down Model of Sagrada Família |

Figure 2

|

Figure 2 Visualization of Model with Mirror at Bottom of String Model |

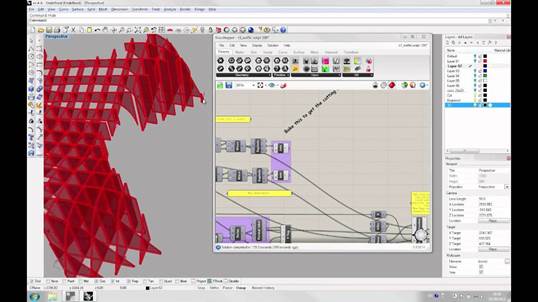

Parametric design deals with the designing of futuristic forms with help of different software. These forms mainly include forms with curvy nature, parabolic shapes, and flowing shapes of arches. There is large technical growth in the software field and now anyone with knowledge of coding can design this software. But the most used software for digital architecture is Rhino + Grasshopper designed by McNeill and associates.

Figure 3

|

Figure 3 Picture Showing Design Process of Model on Rhino Software with Grasshopper |

Structures designed with the help of parametric software are produced using a variety of digital fabrication techniques, such as additive, subtractive, and robotic fabrication. The most common digital fabrication procedures used in architecture are; additive procedures, subtractive procedures, formative procedures, joining procedures Hauschild & Karzel (2011), and robotic fabrication. Gallo & Pellitteri (2018)

3D printing, laser cutting, robotic building, and digital fabrication using AR and VR technologies are the tools used for these techniques. Digital fabrication is now being used in India, but so far it has only been for small-scale items like pavilions, benches, hangings, or furniture used for display purposes. However, parametric architecture's potential applications may completely change with digital fabrication. There are many architectural firms in this particular industry in India; these firms/studios have experience with parametric design and want to concentrate on digital design.

2. Theoretical background

A new, epochal global architectural style known as parametricism encompasses all design disciplines, including urbanism, interior architecture, product design, and furniture design, Integrating fashion design and graphic design Chokhachian (2014). Additionally, throughout the past fifteen years, many uses of digital media in architecture have had an impact on the entire area of building and design. Digital media were initially only used as a medium for representation. New digital technology has provided architecture with a new instrument for conceptual design in digital media. Schnabel (2007).

According to Luigi Moretti, the definition of parametric architecture is the Affirmation of the Architect's decision-making and expression freedom, but only if it does not interfere with the characteristics determined by the analytical investigations. In an article published in Moebius, the concept of Parametric Architecture is thoroughly developed by Moretti (1971), two years before his death, renews the need for a new architecture, rigorous in the definition of form through the use of Mathematical logic, computer techniques, and methods of operational research Viati (2010), necessary to overcome the empirical state of the current architecture.

As a result, parametric architecture is becoming increasingly popular. Geometric primitives such as squares, triangles, and circles are avoided in metric architecture, as are simple repetitions of elements and the juxtaposition of unrelated elements or systems. The key point is that parametricism requires that any element or subsystem that enters the evolving composition engage in intensive, adaptive relationships with what is already there Chokhachian (2014). Digital fabrication in architecture opens up previously unattainable possibilities for form, material, process control, and optimization in construction Kumsal et al. (2021). Which encourages both young and experienced architects to investigate these structures.

Form-finding has become an important strategy for shape determination since designers discovered that CAD programs could manage complexity beyond human capabilities. Architects can now design using a multi-parametric form-finding approach that incorporates geometry, dynamic forces, the environment, social data, and any other desired data. Kumsal et al. (2021). this new conversation between form and process has resulted in new architectural tectonics. As a result, there are various perspectives on form finding (design) and bringing these complex structures to life (fabrication). This study attempts to identify the various factors that influence the main two phases of parametric digital fabrication.

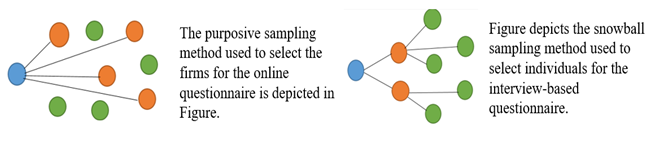

3. Methodology

At the commencement of the study, various articles were read, and a questionnaire was developed based on the articles in architecture magazines and research. There were both open-ended and closed-ended questions on the questionnaire. The qualitative questions provided a good understanding of the various thought processes of architects. Purposive sampling was used to conduct the survey, which allowed for the collection of qualitative responses from the best-fit participants, resulting in relevant data for research. The participants were chosen based on their interest in working in the design process or the construction of parametrically designed structures, as well as their post-graduate training in the parametric discipline.

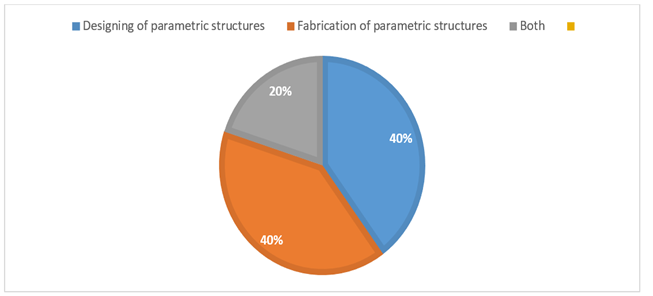

3.1. Methods and tools

The data collected from the questionnaire was based on theoretical knowledge. This data from the survey was collected from different architecture firms, professors, and master’s students who had completed a Master’s in digital architecture. The architecture firms were from all over India and professors and students were from BNCA digital architecture. A total of 65 questionnaire forms were sent to the above group of people, from which a total of 5 responses were obtained. To understand the origin of interest in whether design or fabrication questions were framed. If someone has no interest in the initial phase of design then there is no scope for fabrication. The following pie chart shows the area of interest in architects about parametric structures.

Figure 4

|

Figure 4 Pie Chart Showing Interest of Work in Parametric Architecture Related to Either Design or Fabrication Process |

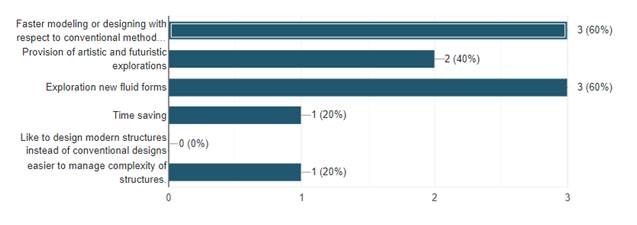

Interest developed in the design process was due to various reasons prominently because parametric designs consume less period to design concerning the conventional methods of design. Also, this helps in the exploration of new fluid forms rather than being stuck to the cuboidal geometries. Parametric software reduces time consumption while the designing process and is easier to manage the complexity of these forms. As shown in Figure 5

Figure 5

|

Figure 5 Bar Graph Showing the Interest of Respondents in Design of Parametric Structures |

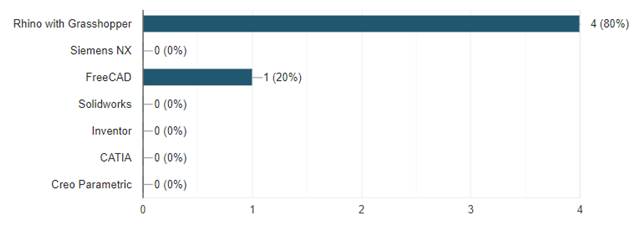

This design thinking and making process is accompanied by

software support. Many Software programs are available for parametricism

in India even so, only some of them are being utilized for designing, according

to the responses received mainly rhinoceros software

is used for designing and for fabrication process software such as free cad,

metal cut, and the coral draw is used.

Figure 6

|

Figure 6 Bar Graph Showing Use of Software in Parametric Designs |

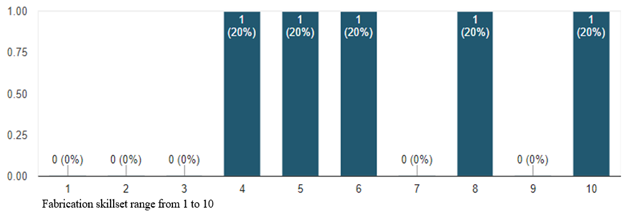

As these software are being utilized by respondents the skillset of these software has an impact on the design and fabrication process. According to the responses, on a scale of 1 to 10 the skillset ranging from 3 to 7, are mainly in the design process whereas the skillset above 7 is in the field of fabrication as well. As shown in Figure 7.

Figure 7

|

Figure 7 Bar Graph Showing

Skillset About Software |

For designing and fabricating the skillset for the

exploration of this field, prior software experience is essential. Which may

also be the cause of the lesser level of fabrication expertise. This software

has inbuilt fabrication features yet there are reasons for not building them

according to the responses received, lack of fabrication techniques and

Complicated designs are what stop users from exploring. Also, financial

constraints make it more impractical in a developing economy like India. These

constructions can only be built with experienced labour, which places

restrictions on the design.

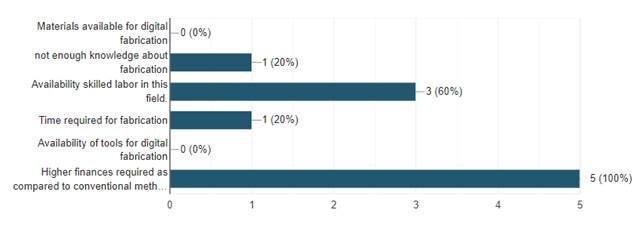

Figure 8

|

Figure

8 Bar Graph Showing Factors Restricting the Fabrication Process |

As various rendered images of these futuristic structures are seen on the websites of architecture firms (Rat Lab, Wall Makers, Ant-Block studios, etc.) different factors would limit fabrication such as economic factors and lack of technology. Some People in India still have a mentality when it comes to these non-conventional constructions, and because they still follow Vaastu Shastra, the reason project remains in the planning stages. People have started accepting these structures for public buildings, but not yet completely in the housing sector, it has been observed that in the interiors of houses parametricism is welcomed but not completely in buildings. In current times, as a status symbol or because of fancy designs a group of people tends to accept these structures. It also depends on the age group, financial condition, and locality of clients. Many people are encouraging/insisting on futuristic structures as compared to a decade back.

Respondents who had moved on to the construction phase also mentioned several problems that included the availability of experienced labor as they find difficulties in understanding drawings, clientele who would support such a financial giant, and fabrication facilities available. The choice of materials available for digital fabrication is crucial because, traditional structures were made of concrete, which was simple to work with because it was just to pour the concrete into the mold to give it shape. In terms of aesthetics, it can be cast into almost any shape, allowing architects and engineers to achieve complex geometry. Xiao et al. (2022).

However, with parametric forms, this is extremely difficult because the individual unit has a unique shape, making it challenging to achieve the desired form. And the materials available at this point such as clay, and plastic have limited structural height with the digital tools available which would not be sufficient for taller buildings. Materials that are capable of folding and bending would give the desired shape in these structures like steel. Here tools and designs are ready but due to some material constraints structure is still in the design phase only. The precision needed to fabricate these structures is attained with the aid of robots and 3D printers, which is not feasible with human precision. Robots are primarily employed in parametricism for precision.

4. Results and Discussion

The qualitative data collected from the interview of architects practicing digital fabrication, and a survey taken from students who have pursued master’s degrees in digital fabrication and Firms practicing in the field of parametricism helped to understand the factors affecting the fabrication process of parametric structures. Initially, the design process requires a moderate skillset in software.

Respondents only want to investigate parametric design and software throughout the design phase, and then they want to proceed to the fabrication stage. Since the development of computer programs such as Grasshopper and Rhinoceros, freedom in the design of parametric architecture has become available. They enable automatic simulation and optimization of problem solutions, greatly expanding the possibilities for creating complex structures and forms Pimenova et al. (2019). Modern construction concepts include the parametric field. This fascinates architects, which is why it's becoming more popular among professionals. It represents a fresh way of approaching structures. Therefore, designers seek to research forms and software in particular and want to become experts in their profession. It is not very difficult to begin the fabrication process because this software has capabilities that generate the fabrication coding while creating itself. However, there are several limitations, mostly financial capital and materials, which have limited the ability of architects to construct.

Additionally, the clientele has a distinct perspective on this structure, which also hinders large-scale fabrication. Although architects create small-scale prototype models for form exploration and models for pavilions, some ideas may not move forward with large-scale production due to cost restrictions.

Although many people now accept the parametric design, there are still some instances where the acceptable design cannot be implemented due to the materials available.

5. Conclusions

The investigation indicates that several factors cause this gap in the design and fabrication process. From the perspective of the clientele and the designer, these variables would change. Designers' key concern is that they want to first use software to study the design itself and then they want the form exploration of these structures. The financial capital needed to build these buildings is higher than for traditional structures, for example, from the fabricator's point of view, Clients aren't presently approving such large sums for these setups. Some of them agree, but not for substantial structures. Parametric designs are limited to building façades, interiors, and small-scale projects like temples, gardens, schools, railway platforms, or the roofing profile of some structures but not on large-scale buildings.

The designs and production techniques are often ready, but because of these issues, they are only available in digital form and not in reality. Numerous architects in India have already created parametric forms for pavilions, landscape features, public structures like airports, parking structures, and residential building interiors. In India, where the mentioned difficulties are constraining the design to the reality of parametric structures, this would take some time for these structures to be fully accepted. However, it's not as though people do not accept them.

Positively, digital fabrication expands the possibility for these structures to be built and appeals to many practicing architects. If these structures are constructed, they would certainly contribute to sustainable environmental changes in society.

In terms of accepting these fluid forms, India is currently in a phase of coherence. Future years will certainly bring various opportunities for large-scale digital fabrication.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

The author thanks the interviewees and respondents who contributed and responded to the questionnaire survey and for the rich insights they provided.

REFERENCES

Burry, M., Burry, J., & Faulí, J. (2001). Sagrada Família Rosascomputer-Aidedputer Aided Dialogue Between Designer and Craftsperson (Overcoming Differences in Age, Time, and Distance).

Chokhachian, A. (2014). Critical Attitude Toward the Footstep of Googie Architecture on Parametric Architecture.

Gallo, G., & Pellitteri, G. (2018). Luigi Moretti, from History to Parametric Architecture.

Hauschild, M., & Karzel, R. (2011). Digital Processes: Planning, Designing Production. Basel/Berlin/Boston: Birkhauser.

Kumsal, A., & Şen Bayram, A. (2021). Digital Fabrication Shift in Architecture.

Pimenova, E. V., Grigoryan, M. N., Ivanova, P. V. (2019). The Parametric Architecture Tall Buildings Implementation Aspects, IOP Conf. Ser.: Mater. Sci. Eng.

Schnabel, M. A. (2007). Parametric Designing in Architecture, Sydney.

Viati, N. A. (2010). Un nuovo linguaggio per il Pensiero Architettonico. Ricerca Operativa E Architettura Parametrica. In: Luigi Moretti. Razionalismo e Trasgressività Tra Barocco e Informale, Electa, Milan, 409-19.

Xiao, Y., & Hack, N., & Kloft, H. (2022). Digital Structural Design and Shotcrete 3D Printing Strategies for Lightweight Reinforced Concrete Beam-Grid Structures.

|

|

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© ShodhKosh 2023. All Rights Reserved.