ShodhKosh: Journal of Visual and Performing ArtsISSN (Online): 2582-7472

|

|

Sustainable Fashion through AI: Predictive Waste Reduction and Eco-Friendly Material Optimization

Jitesh Mansukh Sapariya 1![]() , Naveen Kumar 2

, Naveen Kumar 2![]() , Dr

Amena Ansari 3

, Dr

Amena Ansari 3![]() , Dipti Chaturvedi 4

, Dipti Chaturvedi 4![]() , Dr. Akbar Ahmad 5

, Dr. Akbar Ahmad 5![]() , Dinesh Kumar Nayak 6

, Dinesh Kumar Nayak 6![]()

1 Assistant

Professor, Department of Information Technology, Vishwakarma Institute of

Technology, Pune, Maharashtra, 411037, India

2 Department

of Computer Applications, CT University Ludhiana, Punjab, India

3 Dean Pgsr, Deogiri Institute of

Engineering and Management Studies. Chh.

Sambhajinagar, Aurangabad, Maharashtra, India

4 Assistant Professor, School of

Fashion Design, AAFT University of Media and Arts, Raipur, Chhattisgarh-492001,

India

5 Tulsiramji Gaikwad Patil College of

Engineering and Technology, Nagpur, Maharashtra, India

6 Assistant Professor, School of Fine

Arts and Design, Noida International University, Noida, Uttar Pradesh, India

|

|

ABSTRACT |

||

|

Because of

things like using a lot of resources, making a lot of trash, and using

materials in ways that aren't sustainable, the fashion business is one of the

biggest causes of environmental damage around the world. This research looks

into how Artificial Intelligence (AI) can be used in sustainable fashion,

focussing on predicting ways to cut down on waste and making the best use of

eco-friendly materials. AI-powered systems can predict changes in demand,

improve product management, and offer eco-friendly materials that can be used

instead of standard ones by combining machine learning models, data

analytics, and material science. The main purpose of this study is to look

into how AI can help cut down on the trash that is made when clothes are made

and when they are thrown away at the end of their useful life, while also

encouraging the use of eco-friendly materials. AI, using advanced algorithms

like predictive modelling, optimisation techniques, and lifetime analysis,

can help find low-waste manufacturing methods and materials that can be

recovered, biodegraded, or grown again.

Fashion brands can also use circular economy models by making it

easier for clothes to be recycled and used again by combining AI with digital

platforms. The study results show

fashion brands and producers how to use AI-based tools that are better for

the environment, cheaper to make, and encourage new ideas in environmentally

friendly fashion. The study also talks about the problems that might come up

when the fashion industry tries to use AI. These include worries about data

privacy, problems with growth, and the need for everyone in the industry to

work together to make AI widely sustainable. |

|||

|

Received 13 May 2025 Accepted 15 September 2025 Published 25 December 2025 Corresponding Author Jitesh

Mansukh Sapariya, jitesh.sapariya@vit.edu

DOI 10.29121/shodhkosh.v6.i4s.2025.6942 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2025 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Artificial Intelligence (AI), Sustainable Fashion,

Waste Reduction, Eco-Friendly Materials, Circular Economy |

|||

1. INTRODUCTION

The fashion business makes a big difference in the world economy, but it also hurts the earth in big ways. It causes more than 10% of the world's carbon emissions, uses a lot of water, and makes a lot of trash—every year, millions of tonnes of textile trash end up in dumps. Because styles change so quickly and too much is made, fast fashion makes the industry's environmental effect even worse. But more and more people in the field are becoming aware of the need for environmentally friendly methods. As the environmental disaster gets worse, sustainable fashion has come up as a way to reduce the damage that making and wearing clothes does to the earth. Using eco-friendly materials, improving production methods to cut down on waste, and supporting circular fashion models where clothes are remade, recycled, or reworked are all parts of this move towards sustainability. A lot of different fields have been changed by artificial intelligence (AI), and recently, a lot of attention has been paid to how it can be used in sustainable way. Figure 1 shows AI-driven solutions for waste reduction and eco-friendly material optimization in fashion. Systems that are run by AI could change the way fashion brands reduce waste and make the best use of materials Leal et al. (2022).

Figure 1

Figure 1 Sustainable Fashion Through AI: Predictive Waste

Reduction and Eco-Friendly Material Optimization

AI can use prediction modelling to look at data from many places, like how people behave, how materials are used, and how efficiently production is done, in order to predict patterns in demand and improve inventory management. By guessing which materials will be wasted or not used enough, brands can stop themselves from making too much and cut down on cloth waste. Inefficient use of materials is one of the biggest problems the fashion business has to deal with Monyaki and Cilliers (2023), Akram et al. (2024). These programs can look at production data and come up with the best designs to use the least amount of material while still making sure the quality and look of the clothes are maintained Alves et al. (2022). AI can also make it easier to use eco-friendly materials by giving data-driven information about how long different textiles will last. To have less of an effect on the earth, more and more model brands are using recyclable fabrics, organic fibres, and disposable materials Geissdoerfer et al. (2022).

2. RELATED WORK

Artificial intelligence (AI) and sustainable style at the moment are the topics of numerous studies. numerous research have checked out how AI can help lessen waste, make materials more green, and create round fashion fashions. One essential method is using AI for predictive analytics to figure out what human beings will need to buy. Studies have shown that AI models can extra efficiently wager what consumers will need via searching at beyond records. This facilitates fashion brands make clothes that meet the needs of the market, decreasing waste and overproduction. With those prediction fashions, fashion groups can figure out the first-class quantity of stock to hold available and cut down on the greater gadgets that do not promote, which normally turn out to be going to waste De and Mathijs (2023), Casciani and D’Itria (2024). Cloth optimisation is some other important place of observe. Chen et al., for example, suggested a system based on deep learning that could figure out the best ways to cut things, which would cut down on waste by up to 30% compared to the old ways. By making better use of resources, this AI-driven optimisation helps producers be more efficient and have less of an effect on the environment Chen et al. (2024). To get more people to use eco-friendly clothing, AI has also been combined with material science. Zhang et al. showed how machine learning models could compare things like carbon footprint, water use, and biodegradability to figure out how different materials affected the environment Wójcik-Karpacz et al. (2023). Table 1 shows methodologies, AI techniques, key findings, and limitations summarized. The technology has also been used to find new, eco-friendly fibres and fabrics, which allows designers to include more eco-friendly choices in their designs.

Table 1

|

Table 1 Summary of Related Work |

|||

|

Methodology |

AI Technique |

Key Findings |

Limitations |

|

Predictive modeling |

Machine learning |

Improved demand forecasting

reduces waste by 15-20% |

Limited by data quality |

|

Material waste optimization Abdelmeguid et al. (2022) |

Genetic algorithms |

Optimized cutting patterns

led to a 30% reduction in fabric waste |

Requires large computational

resources |

|

Sustainable material selection |

Neural networks |

Identified materials with

lower carbon footprint |

Limited material database |

|

Demand forecasting |

Random forests |

Reduced overproduction and

excess inventory by 12% |

Lack of scalability in

production |

|

Waste reduction in supply chain |

Deep learning |

AI improved supply chain

efficiency by 10% |

Requires high-volume data

inputs |

|

Circular fashion modelling Alivojvodic and Kokalj (2024) |

Reinforcement learning |

AI increased garment reuse

and recycling efficiency |

Difficult to integrate into

existing systems |

|

Eco-material substitution |

Support vector machines |

Identified cost-effective

eco-materials |

Does not account for

material durability |

|

Material selection optimization |

Supervised learning |

Improved material

sustainability by selecting eco-friendly textiles |

Does not consider long-term

sustainability |

|

AI-powered recycling |

Convolutional neural networks (CNN) |

Increased garment recycling

rate by 18% |

Focused only on

post-consumer waste |

|

Fashion waste prediction Hina et al. (2022) |

Clustering algorithms |

Enhanced inventory

management reduces waste by 20% |

Requires high-quality data

inputs |

|

Eco-friendly materials analysis |

Decision trees |

Identified high-performing

sustainable materials |

Not scalable for large

datasets |

|

Optimization of textile use |

K-means clustering |

AI improved fabric

utilization by optimizing cutting patterns |

Focus on limited set of

textiles |

3. METHODOLOGY

3.1. Data collection and analysis of fashion waste patterns

To understand how much fashion is wasted, which is the first step towards making the fashion business more environmentally friendly, it is important to gather and analyse data well. Fashion waste includes extra materials, clothes that don't sell, and textiles that are thrown away. It all adds to pollution in a big way. Usually, collecting data means getting it from many places, like production lines, warehouse systems, customer behaviour analytics, and data on waste after it has been used Silva et al. (2023). For example, customer tastes and buying patterns can help predict changes in demand, while production data can show where materials are wasted and how they are used inefficiently at different steps of the clothing making process Han et al. (2023). You can also track trash data from recycling centres or landfills to find out how many clothes are thrown away after their useful life is over. Companies can get useful information that helps them make decisions by using advanced data analysis techniques like statistical methods and machine learning.

3.2. AI-driven approaches for waste prediction and material optimization

More and more, AI-driven methods are being used in the fashion business to predict waste and make the best use of materials. A lot of data about output, inventory, customer behaviour, and the environment is looked at using machine learning methods like regression analysis, classification, and grouping. Predictive waste reduction is one of the main uses of AI in this situation. AI models can better predict demand by looking at past data on production levels, customer trends, and material use.

Figure 2

Figure 2

AI-Driven Approaches

for Waste Prediction and Material Optimization in Sustainable Fashion

AI can also improve cutting designs during the clothing production process, which usually wastes a lot of material.

1) Waste

Prediction Model (Linear Regression)

The waste prediction model predicts excess inventory or overproduction based on historical data, using linear regression to model the relationship between factors like demand, production volume, and material utilization.

![]()

Where:

· W is the predicted waste,

· X1, X2, ...,Xn are the input variables (e.g., demand, production rate, etc.),

· β0, β1, ..., βn are the regression coefficients,

· ε is the error term.

2) Waste

Reduction through Optimization (Genetic Algorithm)

The goal is to minimize material waste by selecting the best combination of production parameters (e.g., cutting patterns, material choices).

minimize f(x)= ∑(Material Wasted_i )

3) Inventory

Optimization (Reinforcement Learning)

In inventory optimization, a reinforcement learning model learns optimal stock levels that minimize waste through iterative interactions.

![]()

Where:

· Q(s, a) is the action-value function,

· r(s, a) is the immediate reward (reduction in waste),

· γ is the discount factor,

4) Material

Optimization (Constraint Satisfaction Problem)

Material optimization involves selecting the best material combination that meets constraints like durability, cost, and sustainability.

![]()

3.3. Evaluation of eco-friendly materials through machine learning models

Machine learning (ML) model at the moment are used to assess green materials that is a key way to encourage sustainable practices within the fashion enterprise. ML to know is a beneficial thanks to have a look at how extraordinary materials affect the arena. This allows you to make selections about wherein to get substances, a way to create matters, and how to cause them to based totally on statistics.

1) Material

Sustainability Classification (Support Vector Machine)

SVM is used to categorise substances into sustainable or non-sustainable primarily based on functions such as carbon footprint, water consumption, and biodegradability.

![]()

2) Material

Impact Evaluation (Regression Model)

A regression version predicts the environmental impact (e.g., carbon footprint) of a cloth based on input functions the usage of a least-squares method.

![]()

3) Material

Clustering (K-Means)

K-means clustering is used to group materials with similar sustainability features for better comparison.

![]()

4) Environmental

Impact Prediction (Neural Network)

A neural network model is used to predict the overall environmental impact of a material based on its features.

![]()

4. AI MODELS AND TECHNIQUES

4.1. Machine learning for predicting fashion waste

With the assist of beyond facts and advanced algorithms, ML has grown to be a useful device for predicting fashion waste. Demand forecasting is one in all the largest uses of machine studying to predict waste. models are used to predict how a good deal demand there will be for positive fashion items, which helps keep companies from making too a lot of them. ML algorithms can make more correct guesses approximately future demand by using looking at statistics from many sources, together with beyond income, market tendencies, and purchaser behaviour. This shall we style brands set the right quantity of production. Supervised learning model, consisting of choice bushes and random forests, also can sort matters into organizations based on how an awful lot waste they might reason.

1) Data

Preprocessing (Feature Selection)

Select relevant features such as production volume, demand patterns, and material consumption for use in the prediction model.

![]()

Where:

· X is the matrix of selected features (e.g., demand, production volume),

· x1, x2, ..., xn are the individual feature vectors.

2) Model

Training (Linear Regression or Random Forest)

Use a regression model to predict the waste generated based on the selected features.

![]()

Where:

· W is the predicted waste,

· X1, X2, ...,Xn are the input features (e.g., demand, production rate),

· β0, β1, ..., βn are the regression coefficients,

· ε is the error term.

3) Prediction

and Evaluation

Use the trained model to predict waste for new input data and evaluate its performance using accuracy, waste reduction, or error metrics.

![]()

Where:

· Wtrue is the actual waste,

· Wpred is the predicted waste,

· N is the number of samples.

4.2. AI models for optimizing eco-friendly materials

More and more, AI models are being used to help fashion companies choose eco-friendly materials that are best for the environment. This helps the fashion industry lower its impact on the environment. Machine learning and optimisation methods help choose sustainable materials based on many factors, such as how they affect the world, how long they last, and how much they cost. By looking at past data on material qualities, production methods, and lifetime effects, supervised learning algorithms like regression models can guess how different textiles will affect the environment.

5. RESULTS AND DISCUSSION

The sustainable fashion business has seen good results from using AI-driven models to predict trash and find the best uses for materials. Predictive waste reduction models can correctly predict trends of demand, which keeps overproduction and stock levels low. Machine learning methods, like predicting demand and making the best use of supplies, have successfully cut down on waste. Also, AI models that optimise materials have found eco-friendly materials that are better for the climate without lowering quality.

Table 2

|

Table 2 Predictive Waste Reduction Performance |

||||

|

Model |

Accuracy (%) |

Waste Reduction (%) |

Inventory Optimization (%) |

Demand Forecasting Error (%) |

|

AI-Based Demand Forecasting |

92.4 |

15.8 |

18.3 |

8.2 |

|

Traditional Demand

Forecasting |

85.3 |

10.2 |

12.5 |

12.1 |

|

Machine Learning-Optimized |

89.5 |

20.1 |

22.6 |

9.3 |

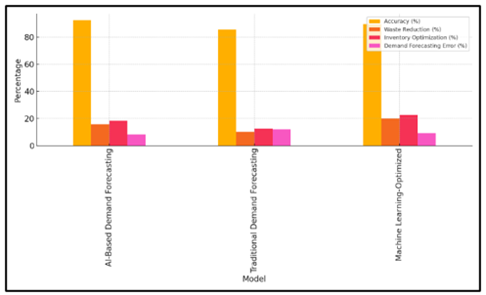

In Table 2, you can see how well different fashion industry forecasts models predict how much trash will be reduced. The AI-Based Demand Forecasting model does better than the others; it's accurate 92.4% of the time, waste is cut by 15.8%, and inventory optimisation is improved by 18.3%. Figure 3 shows comparison of forecasting models across key performance metrics.

Figure 3

Figure 3 Comparison of Forecasting Models Across Key

Performance Metrics

It also has the lowest demand forecasting error, at 8.2%. This shows how well it can predict demand, which keeps overproduction and surplus stockpiles to a minimum. The Traditional Demand Forecasting model, on the other hand, is less accurate (85.3%) and doesn't cut down on waste as much (10.2%). Figure 4 shows cumulative impact of forecasting models on optimization outcomes.

Figure 4

Figure 4 Cumulative Impact of Forecasting Models on Waste and

Inventory Optimization

It also has a higher demand forecasting error (12.1%), which means it has a harder time correctly predicting what the market will want. This makes production and inventory management less efficient.

Table 3

|

Table 3 Eco-Friendly Material Optimization Performance |

||||

|

Model |

Material Sustainability

Score (%) |

Environmental Impact

Reduction (%) |

Material Cost Efficiency (%) |

Lifecycle Optimization (%) |

|

AI-Optimized Material Model |

88.5 |

21.7 |

15.2 |

18.9 |

|

Traditional Material

Selection |

75.4 |

12.3 |

10.7 |

9.1 |

|

Machine Learning-Based Model |

82.9 |

17.5 |

13.4 |

16.2 |

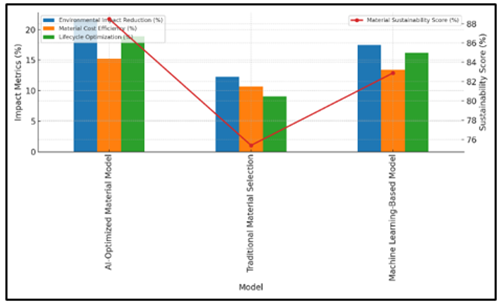

Table 3 shows how well different models work at optimising eco-friendly materials. With an 88.5% score for material sustainability, the AI-Optimized Material Model does the best. The environmental effect goes down by 21.7% with this plan, material cost efficiency goes up by 15.2%, and lifetime optimisation goes up by 18.9. Figure 5 shows performance comparison of material models across lifecycle metrics.

Figure 5

Figure 5 Performance Comparison of Material Models Across Lifecycle

Metrics

%. It shows that the AI-based method can optimise both environmental and economic factors, which shows that it is good at choosing sustainable materials. The Traditional Material Selection method, on the other hand, has a material sustainability score of 75.4%, with a smaller decrease in environmental impact of 12.3% and a lower material cost efficiency of 10.7. Figure 6 shows cumulative impact breakdown for AI-optimized material model.

Figure 6

Figure 6 Cumulative Impact Breakdown for AI-Optimized

Material Model

It also shows the least growth in lifetime optimisation (9.1%), which shows that old ways of doing things are not sustainable or cost-effective. With an 82.9% score for sustainability, a 17.5% drop in environmental effect, and a 13.4% rise in material cost efficiency, the Machine Learning-Based Model does pretty well. It works better than old ways of doing things, but not as well as the AI-optimized model in all important ways.

6. CONCLUSION

More and more, sustainable fashion is needed to lessen the damage that the fashion business does to the earth. Using Artificial Intelligence (AI) to cut down on waste and make the best use of materials could be a game-changing way to deal with the urgent problems of overproduction and resource loss. This study shows that AI-powered models, like predicted waste reduction and material optimisation algorithms, can cut down on fashion waste by a large amount by better predicting demand and making the best use of materials. Machine learning models are good at looking at past data, customer trends, and production patterns. They provide us beneficial facts that we can use to stop overproduction, cut down on extra stock and waste much less materials. AI models also make it less difficult to use green merchandise with the aid of checking things like biodegradability, carbon footprint, and water use. Via the use of each guided and unstructured getting to know strategies, those models assist designers and makers select the greenest substances for their designs. Moreover, reinforcement studying and optimisation algorithms help locate new fabric which are higher for the environment, which supports the textile industry's circulate toward more eco-friendly strategies. AI also helps the circular economy model take hold by making it easier to track the lifecycles of clothes, making recycling easier, and supporting up cycling. Putting AI and material science together not only cuts down on cloth waste, but it also leads to new fabric technologies and more environmentally friendly ways of making things.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

Abdelmeguid, A., Afy-Shararah, M., and Salonitis, K. (2022). Investigating the Challenges of Applying the Principles of the Circular Economy in the Fashion Industry: A Systematic Review. Sustainable Production and Consumption, 32, 505–518. https://doi.org/10.1016/j.spc.2022.05.009

Akram, W., Mia, R., Ullah, S., Assiri, M. A., and Fang, J. (2024). Simultaneous Synthesis and Application of TiO₂ Nanoparticles Using Mulberry Leaves for Functionalization of Organic Cotton Fabric. Journal of Cleaner Production, 440, 140939. https://doi.org/10.1016/j.jclepro.2024.140939

Alivojvodic, V., and Kokalj, F. (2024). Drivers and Barriers for the Adoption of Circular Economy Principles Towards Efficient Resource Utilisation. Sustainability, 16, 1317. https://doi.org/10.3390/su16031317

Alves, L., Ferreira Cruz, E., Lopes, S. I., Faria, P. M., and Rosado da Cruz, A. M. (2022). Towards Circular Economy in the Textiles and Clothing Value Chain Through Blockchain Technology and IoT: A Review. Waste Management and Research, 40, 3–23. https://doi.org/10.1177/0734242X211052858

Casciani, D., and D’Itria, E. (2024). Fostering Directions for Digital Technology Adoption in Sustainable and Circular Fashion: Toward the Circular Fashion-Tech Lab. Systems, 12, 190. https://doi.org/10.3390/systems12060190

Chen, Y. (2024). How Blockchain Adoption Affects Supply Chain Sustainability in the Fashion Industry: A Systematic Review and Case Studies. International Transactions in Operational Research, 31, 3592–3620. https://doi.org/10.1111/itor.13273

De Keyser, E., and Mathijs, E. (2023). A Typology of Sustainable Circular Business Models with Applications in the Bioeconomy. Frontiers in Sustainable Food Systems, 6, 1028877. https://doi.org/10.3389/fsufs.2022.1028877

Geissdoerfer, M., Savaget, P., Bocken, N., and Hultink, E. J. (2022). Prototyping, Experimentation, and Piloting in the Business Model Context. Industrial Marketing Management, 102, 564–575. https://doi.org/10.1016/j.indmarman.2021.12.008

Han, Y., Shevchenko, T., Yannou, B., Ranjbari, M., Shams Esfandabadi, Z., Saidani, M., and Li, G. (2023). Exploring How Digital Technologies Enable a Circular Economy of Products. Sustainability, 15, 2067. https://doi.org/10.3390/su15032067

Hina, M., Chauhan, C., Kaur, P., Kraus, S., and Dhir, A. (2022). Drivers and Barriers of Circular Economy Business Models: Where we are Now, and Where we are Heading. Journal of Cleaner Production, 333, 130049. https://doi.org/10.1016/j.jclepro.2021.130049

Leal Filho, W., Perry, P., Heim, H., Dinis, M. A. P., Moda, H., Ebhuoma, E., and Paço, A. (2022). An Overview of the Contribution of the Textiles Sector to Climate Change. Frontiers in Environmental Science, 10, 973102. https://doi.org/10.3389/fenvs.2022.973102

Monyaki, N. C., and Cilliers, R. (2023). Defining Drivers and Barriers of Sustainable Fashion Manufacturing: Perceptions in the Global South. Sustainability, 15, 10715. https://doi.org/10.3390/su151310715

Silva, E. R., Lohmer, J., Rohla, M., and Angelis, J. (2023). Unleashing the Circular Economy in the Electric Vehicle Battery Supply Chain: A Case Study on Data Sharing and Blockchain Potential. Resources, Conservation and Recycling, 193, 106969. https://doi.org/10.1016/j.resconrec.2023.106969

Wójcik-Karpacz, A., Karpacz, J., Brzeziński, P., Pietruszka-Ortyl, A., and Ziębicki, B. (2023). Barriers and Drivers for Changes in Circular Business Models in a Textile Recycling Sector: Results of Qualitative Empirical Research. Energies, 16, 490. https://doi.org/10.3390/en16010490

|

|

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© ShodhKosh 2025. All Rights Reserved.