ShodhKosh: Journal of Visual and Performing ArtsISSN (Online): 2582-7472

|

|

A REVIEW ON HAND BLOCK PRINTING IN INDIA

1 Assistant

Professor, Department of Home Science, Women’s Christian College, Chennai,

India

|

|

ABSTRACT |

||

|

India is well known for its art and culture which makes the country unique. There are several forms of art which have been nurtured and groomed under skilled guidance and has been inherited through generations of family traditions. Hand Block Printing is one such an art, which can be used to make every design and every piece of fabric exclusive from the other. Hence block printing is considered to be the most interesting method of designing textiles. Printing is the process of applying colour to fabric or yarn in a definite and repeated pattern. Every design created using hand block printing is very exclusive and different from each other. However, this cannot be achieved by automated printing machines where several meters of fabric can be printed with the same design and colour in a short time. India’s

block-printed fabric holds a place of pride in the world market. India is one

of the major producers and exporters of block printed fabrics. It is amazing

that each region of the country has developed variations in this traditional

craft, to name a few, Dabu print of Rajasthan which

uses the mud printing technique, Ajrakh print of

Gujarat known for geometric motifs and Kalamkari of Andra Pradesh. The

various styles of block printing are symbolic of the country’s rich heritage

and culture. This article explains the process of block printing and the

various styles of block printing methods practiced in India. |

|||

|

Received 18 September 2023 Accepted 15 February 2024 Published 09 March 2024 Corresponding Author Preetha R,

preetha@wcc.edu.in

DOI 10.29121/shodhkosh.v5.i1.2024.689 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2024 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Hand Block Printing, Natural Dyes, Steps in Block

Printing, Dabu Print, Ajrakh |

|||

1. INTRODUCTION

Textiles

is one of the most successful exports of India and as its oldest craft Hand

block printing has sustained and is thriving even in this digital age Edwards (2016).The word ‘printing’ originates from Latin,

which means ‘pressing’, this implies to the pressure applied to transfer the

design during the printing process Kiron (2012). Printing is an important step in

the textile manufacturing process. It is generally done on the fabric but

sometimes it is done on the finished garment. The process of applying colour to

a selected area which produces a design is Printing Hossain et al. (2015). This process involves the

production of images or designs of various intricacies with a range of colours.

This localised application of colour to produce the desired pattern should be

carried out carefully. The time taken to complete this process depends upon the

complexity of the design and the number of colours used in the design Wardman (2018).

In

printing, the thickened pigment colorant is applied with the help of a tool -

printing machine. The thickening agents present in the pigment prevent the

colour from spreading by capillary action on the fabric. Wooden blocks,

stencils, rollers, or silk screens are the tools which are used to do printing

on the fabric. These are used to confine the flow of the colouring paste while

printing the designs on the fabric Choudhury (2023). Of all the printing process done

on textiles, block printing is the oldest and generally considered to be the

most artistic of all. Block printing was practiced in India since 3,000 BC.

Scraps of block printed cloths were found in the ruins from Mohenjo Daro, an

ancient city of Indus Valley civilization Mandal & Jaiswal (2019).

Hand

block print is a labour-intense and painstaking process that has survived since

ancient times because of the exquisite handmade products. The early blocks were

made out of terracotta or clay, others were made out

of carved wood Choudhury (2023) Block printing is still practiced

today as a handcraft by the cottage or small-scale industry. Blocks cane either

carved out of wood or made with metal pieces which are shaped and attached

securely to the wooden base. Each block can print only one colour, so if a

design with several colours is desired a block must be made for each colour. In

preparing a wooden block, the design area remains raised while background is

carved away. The fabrics discovered earlier by the archaeologists have been

printed with small blocks no larger than 1-2 inches in diameter. By the 15th

century the blocks have grown to 12-18 inches diameter and 2.5-3.5 inches

thick. Recently blocks are also made using foam for home crafts.

Figure 1

|

Figure 1 Different Types of Blocks Source Author |

Block

printing is a centuries old art form and the essence of India which has made

India stand out in the world. Every design created using hand block printing is

very exclusive and different from other printing methods. However, this

printing technique cannot be duplicated by automated machinery where several

metres of fabric are printed in few seconds with the same design and colour.

The factory-printed (using machine) fabric are low-priced and have good

colourfastness compared to fabrics that are hand block printed. Still, hand

block printed fabrics manifests human labour and emotional response of the

artisans which can never be seen on machine-made fabric. In India hand block

printing is a skill that has been passed over many generations and provides a

sustainable income to artisans Rahman (2022).

Every

generation has contributed towards the enhancement and artistic beauty of this

art. Block printing represents cultural and social trends Qutub et al. (2022). This art is an indigenous art

because of its rich and traditional roots and the efforts taken by the

artisans. Hand block printing was traditionally done using Natural Dyes which

makes it very unique and has to be preserved. Recently

hand block printed fabric is found its use in the metropolitan cities and block

printed garments are being exported to several countries worldwide Rahman (2022).

In India

block printed fabric have been integrated into dress code and plays a key role

serving the domestic and ritual functions of the subcontinent Edwards (2016). Traditional hand block printing in

India as usually done on sarees, suits, kurtis, bedspreads,

upholstery and household articles to name a few Anjum & Kunwar (2020). Consumers are moving towards more

artistic and unique choices which will also positively influence the textile

printing market. As the demand for block printed textiles is expected to

increase globally, the growth and market for the same is believed to increase

in the coming future. Mandal & Jaiswal (2019).

2. The block printing process

Earlier the

entire block printing process was done with naturally occurring materials. The

fabric to be scoured was soaked for 24 hours in cow dung/ sheep dung mixed

water. This was done to remove the natural and added impurities from the

fabric. The fabric was then rinsed in water and dried in sunlight on bamboo

lines or spread on the ground. This made the fabric more permeable for the

printing process.

The vessels used

in the process such as copper vessels and earthen pots also had a major role in

the colour development Chouhan & Patil (2019).

In certain block printing techniques, the fabric was

Mordanted (A mordent helps to fix the colour on the fabric hence the fabric

will have good colourfastness to light and washing). The scoured fabric was

treated with harda or myrobalan (15 to 20 %

myrobalan). The mordanted fabric turns yellow after it is dried. Alum- phitkari was also used as a mordant it has minerals to fix

the colours Hada (2015).

The ancient

records show that natural dyes were largely used to colour textiles Singh (2022). Natural dyes were preferred for

their gentle shades. Printing on cotton fabric with myrobalan fruit,

pomegranate rind and catechu gave unique shades Rana et al. (2022).

1) Red is produced by combining alizarin

with alum, the colour may range from pink to dark red. Manjistha (Rubia

cordifolia) www.fibre2fashion.com. (n.d.) and Powdered Tamarind seeds with

alum also produced red Sampath (2023).

2) Indigo Blue can be extracted from the

leaves of indigo bush which is found all over India.

3) Black is obtained by using rusted

iron, nails and old jaggery the paste is prepared which is then kept in earthen

pots kept under shade for 15 to 25 days depending on the weather.

4) Green obtained when alum mordanted

fabric is dyed with pomegranate rind and heena.

5) Yellow obtained from flowers like kesula to get various shades when mixture with alum as

mordent Hada (2015) Lal Chandan (Adenanthera

pavonina) bark www.fibre2fashion.com. (n.d.) .

6) Mustard colour: Pomegranate skins

were used to produce mustard colour Chouhan & Patil (2019).

7) Brown: Catechu and Heena produced

light to dark brown shades based on the mordants used Vankar (2022).

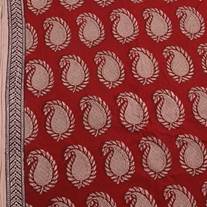

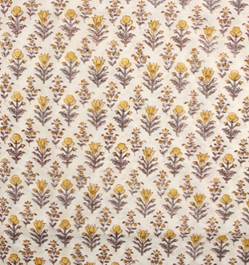

3. Motifs used in

block printing

The Indian block

printing has a diverse regional style. Each region and community in India has its unique motifs. Each motif with its cultural

significance contributes to the enduring beauty of this traditional craft.

The common motifs seen in Indian block printing are

· Floral Pattern are the most popular motif in Indian

block printing. Images of flowers like roses, lotus and jasmine are common. The

design ranges from simple petals to realistic floral images. These patterns are

also combined with leaves, vines etc.

· Paisley Motifs the teardrop-shaped motif, known as

“mango” or “ambi,” is a popular pattern of Indian

block printing characterized by curved lines and intricate designs. This is a

very distinct motif of Inia and may have originated from Persia.

· Geometric Patterns are obtained from repeating the

geometric shapes like squares, triangles, circles, and hexagons placed in a

symmetric manner. These patterns have similarities reflecting the

influence of Islamic art.

· Animals and birds motifs hold a significant place in

the Indian culture. Elephants, camels, parrots, peacocks, and sparrows are some

of the common motifs used. They are portrayed either individually or depicted

as part of larger narrative scenes.

· Figurative design represents human figures engaged in

various activities exhibiting traditional scenes, cultural practices, and

religious stories. These figures have intricate detailing on costumes and jewellery.

· Borders have geometric patterns, floral designs, or

abstract pattern which add beauty to the product Hill’s (2023).

The motifs on the

printed cloth served as social designators. The printed fabric based on the

colour, motif and pattern were used to differentiate religion, gender,

ethnicity, socio-economic status, occupation, and marital status of the people Balotra Printing. (n.d.).

4. Steps involved in Block

printing

1)

Preparation of the block

Hand-carved wooden blocks were the basis of the block

printing process. The process of carving the block is a tedious process which

requires an extraordinary skill. This

skill has been passed over generations. There are two types of blocks used to

create the desired design namely Rekh- the block used

to create an outline pattern and Gadh- the block used to create a filling

pattern. Carving the block for creating the outline is a challenging process in

block printing. As the skeleton for the design, it is the more expensive as the

block is prepared by the most skilful artisan. Blocks have a wooden handle and two or three cylindrical holes are drilled into

the block which allows the free air passage and the release of excess printing

paste. The newly carved blocks are soaked in oil for 10-15 days which soften

the grains Marigold (2020).

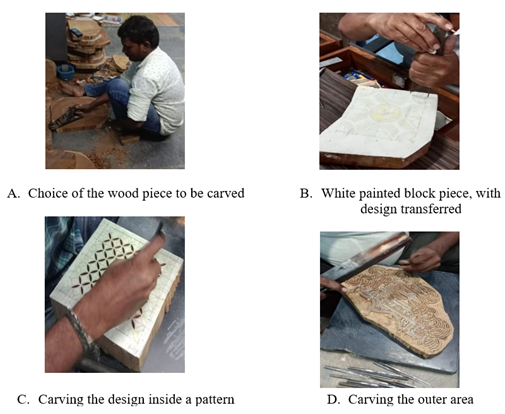

The

blocks are normally made using sheesham wood. The

first step is to draw the design or the motif on a paper. Once the design is

approved, the carver prepares the block by coating the surface of the wood with

a white paste to make the surface of the wood uniform and smooth for carving.

The carver then carves the wooden block so that the design alone remains

raised. This is done by hand using a

very small chisel. This process requires skill, experience, and patience hence

it is a labour-intensive process.

Figure 2

|

Figure 2 Steps in the Preparation of

Block Source Krishnamurthi Hand Blocks,

Chennai |

The

completed blocks are checked for accuracy after which it is soaked in oil to

cure the wood, which prevents cracks. A block can print only a single colour

hence different blocks are carved based on the number of colours to be used and

each block is designed in a manner to fit exactly into the other. Hence extra

time and attention are needed to align blocks correctly.

Figure 3

|

Figure 3 Blocks Based on the

Patterns they Produce on the Fabric Source Author |

Metallic block: The metallic blocks

are prepared from metal sheets, using manual hand beaten process. The metal is

made into wafer thin thickness and are pliable. The thin sheets are cut into

narrow strips which are even in length. The patterns required on the block is

first drawn on the wooden block and the thin metal strips are pressed onto the

pattern and gently hammered in place. The designs using the metal are done by

hand, it is done from the centre to the outside. After the design is placed in

position, the block is checked to ensure that the strips are of uniform height

from the wooden base. The brass (metallic) blocks are used for fine designs and

for high clarity in print. These blocks are more expensive as it is more time

consuming to make and it is long lasting Ganguly & Amrita (2013a).

2)

Preparation of the fabric

The

fabric to be printed should be bleached and scoured (washed) so that it does

not have any impurities. The pigment will be uniformly absorbed by the fabric

only if it is starch and impurity free.

3)

Preparation of the Printing pad

The

colouring material- printing paste is poured over a layer of sponge or felt

material kept in a tub so that there is an even spread of the pigment paste and

when the block is placed on the sponge the dye paste is evenly taken up by the

block.

4)

Preparation of the Printing table

Block

printing process requires a solid table made of either wood, stone, iron, or

concrete. The table has to be padded hence it is

covered with a back-grey plain cotton cloth which is usually stretched over the

table to help in the proper spread of colour by blocks and absorb any extra

pigment. The length of the table depends on the length, quantity, and nature of

the material to be printed.

5)

Block printing process

The

fabric is pinned on the printing table neatly without any crease. The wooden

block is pressed on the sponge (which is loaded with pigment paste) and then it

is placed on the fabric and pressed or beaten with a mallet to get the

impression of the pattern. The printing is done carefully if a continuous

pattern is desired then the process is repeated to form a proper repeat.

Individual designs or prints-buttas are done on the

body of the fabric after planning the pattern on the fabric. If different

colours are required for printing the outline is done first followed by the

filling of the pattern inside using other blocks with different colours. The

process has to be done carefully to produce a neat

design. The border design is printed first followed by the printing inside the

border of the fabric Singh (2021).

Figure 4

|

Figure 4 Block Printing Process Source Author |

6)

Curing the block printed fabric

After

printing, the cloth is sun dried as a fixing process and then subjected to

steaming to ensure that the colour has fixed well in the fabric. Finally, the

block printed fabric is washed, rinsed, and ironed.

5. Hand block printing in India

India is

famous for hand block printing and the important centres for block printing are

Madhya Pradesh, Rajasthan, Uttar Pradesh, Gujarat, Andra Pradesh, and West

Bengal.

1)

Madhya Pradesh

Bagh is a

tribal town in Madhya Pradesh, the name originated from baghs

or tigers that lived in that region. This region has the Baghini

River which has high copper content accounting for the beautiful colours

developed on the fabrics. Also, the flowing water contributes to dyeing Chouhan (2019). The Bagh printers use Natural

dyes, typically bright shades of red, indigo, and black. Bagh block prints

produce a characteristic three-dimensional effect which is not possible to be

replicated by the machine printing process or screen printing. The blocks used

in making bagh prints are made of intricate and

stylized motifs, a traditional art which has evolved over hundreds of years Ganguly & Amrita (2013b) In Indore, this traditional art of Hand Block

printing is still kept alive by the fifth generation of block printers

who have their origins from 'Nagore', a village in Rajasthan.

Figure 5

|

Figure 5 Bagh Print Sari Source theindianethnicco.com |

Nandana

is a wax resist printing and dyeing process which has 18 steps. This printing

is done on thick and heavy-duty cotton fabric.

The motifs used in this printing are few and are used in backdrop of

deep, dark, and rich colours which suit the rough use by the hard-working Bhil

and Bhilal community people who were engaged in

farming (“Nandana Hand Block Printed Textiles,” 2024). The motifs used were

Mirch (chilli), Amba (mango) and Jalam buta (creeper

web).

Figure 6

|

Figure 6 Nandana

Block Print Source “Nandana Hand Block Printed Textiles,” 2024 |

2)

Rajasthan

This

region is famous for eye-catching, colourful dressing. These are obtained from

the unique dyeing and printing techniques using vegetable colours, which is

done mostly on cotton fabric. This oldest technique of dyeing and printing are

conserved in the state. Royals in Rajasthan patronize this art of printing. The

block print patterns consist of gods, goddesses, birds, human figures, and

animals. Jaipur, Pali, Bagru, Barmer and Sanganer are

the main centers in Rajasthan which are well known

for this form of Hand Block Printing. Barmer is famous for motifs of red with

black-blue outlines, surrounded by flower-laden trees and is well known for

turbans, sarees, and traditionally worn lungis. The

villages of Jahota in Jaipur is

famous for the Jahota hand block printing Ganguly & Amrita (2013b).

Figure 7

|

Figure 7 Black Botanical Floral Jahota Hand Block Printed Cotton Fabric Source theindianethnicco.com |

“DABU”

print is one of the oldest, most famous and favoured folk form resist printing

of Rajasthan. This art is originally an Indian printing technique which was

developed centuries before the mughals invaded India.

‘Dabu or Daboo’ is a traditional mud resist

block printing done on natural fabric with dark earthy tones with fabulous

designs and traditional patterns. It is done with carved wooden

or metal blocks the stamp is done using Mud resist print techniques Kaur (2012).

Figure 8

|

Figure 8 White Bud Dabu Printed Fabric Source theindianethnicco.com |

Sanganer

and Bagru villages near Jaipur have two prominent

settlements of Hand block printers. Though the printing methods followed in

these two regions are similar, each village has its own mark on the fabric. The

availability of water in these villages plays a major role in the manufacture

of the block printed fabric. Each area has a significant design and colour

printed fabric. In Sanganer village, water is available in abundance hence

washing and printing are easily done. But the Bagru

village has scarcity of water and the reddish tinge the water leaves is a characteristic shade on the fabric (The Craft of Hand

Block Printing).

Figure 9

|

Figure 9 Bagru Print Source theindianethnicco.com |

The main

difference between Sanganeri and Bagru

styles of block printing, is the colour of background on which they are

printed. The background colour for Bagru prints is

black and red while the Sanganeri print is known for

delicate lines of bright colours printed against white background. Sanganeri print has prevailed since 12th century

and it flourished under the patronage Maharaja Sawai Jai Singh, who invited

people from Gujarat and Andhra for creating new designs Baral (n.d.).

Figure 10

|

Figure 10 Sanganeri Print Source theindianethnicco.com |

The Balotra printing is named after the city Balotra, Barmer district of Rajasthan. This block printing technique belongs to the Chhipa community. The printed fabrics are

characterized by vertical floral patterns and geometric butis in tones of earthy red, yellow, or cream, on a

background that is dyed in indigo or dark green. These butis

are generally large and are often printed without the black rekh, producing bold and simple designs

without the shades of colour. A unique feature of Balotra

printing, is printing is done on both sides of the cloth.

Figure 11

|

Figure 11 Balotra Print Source EcoFab:

Balotra Handblock

Printing: Rajasthan’s Bounty ecofabstories.blogspot.com |

The fabric, is washed to remove the impurities and to make the fibres soft. Saaj, a process in which the fabric is subjected to a mixture of castor oil, camel or goat dung, and soda ash. The fabric is then soaked in a paste of harda, while wet which gives the fabric a yellow shade and allows it to develop into deep black. When the fabric is dry, the designs are transferred to the fabric using the wooden blocks. The first step in this process is direct printing — in which the dye is applied to the block and dabbed onto the fabric and then the second step is using dabu (or dye-resist) printing Balotra Printing. (n.d.).

3)

Gujarat

Sodagiri

(trader) prints is a hand printing technique practiced by Paithapur

families in Gujarat. This is a mud resist – printing method which is used to

print textiles and intricate blocks are prepared. In Kutch the famous patterns

dancing girls, birds and animals are done using black and red colours. In

Ahmedabad and Baroda large mango motifs against the background of red or blue

are done on the saris Ganguly & Amrita (2013b).

Figure 12

|

Figure 12 Sodagiri Block Print Source rugrabbit.com |

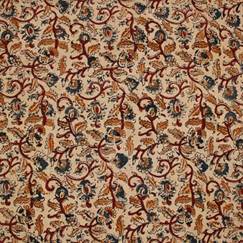

Another

famous printing technique of Gujarat is the Ajrakh, a

double sided printed textile which is considered to be

the oldest living textiles in the world. This art is considered to be

indigenous and symbolise the land, through which the river Indus flows Karolia & Buch (2008).The name Ajrakh

is derived from the Arabic word- Blue, as indigo is one of the predominant colour in this printing.

Figure 13

|

Figure 13 Cotton Fabric with Ajarkh Print Source yehaindia.com |

Figure 14

|

Figure 14 Indigo Madder Floral Ajrakh Hand Block Printed Cotton Fabric Source theindianethnicco.com |

The Ajrakh painted cloth has colours like blue, black, red, and

white in several patterns. The Ajarkh printing

comprises of the resist and mordant printing process which consists of nearly

14 to 16 stages. It produces several borders of patterns with centre filed Williamson (2016).

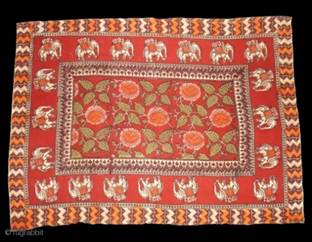

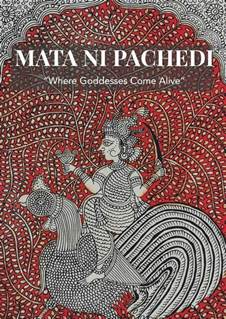

Mata ni Pachedi is also called the

Kalamkari of Gujarat which follows similar techniques of Kalamkari. It is a

craft of religious significance of the Vagri

community Kulkarani (2021)

The two

techniques followed to create the Mata ni Pachedi are wooden block-printing and painting. Block

printing is done for borders and certain figures and painting using brush for

freestyle drawing, embellishments are incorporated by the artist. The patterns include the sun and the moon, which are

generally on the two top corners; it also includes singers, musicians, sages, animals,

and birds which seem to dance and fly in celebration of the goddess. The

fineness of these patterns depend on the carving skills

of the block maker and the artistic skills of the painter How Mata ni

Pachedi is Created. (n.d.).

Figure 15

|

Figure 15 Mata Ni Pachedi Source Kulkarani,

2021 |

Gamati print originated from

Gujarat and Rajasthan. It uses lively and bold colours. The intricate designs

used in Gamati print are mainly inspiration from nature. Earlier only natural

dyes were used in this type of printing, but at present it has been replaced by

chemical dyes. The natural colours used were, henna (green), turmeric (yellow),

indigo (blue), and rusted iron (black), about 27 colours were obtained from

different parts of the plant and metals. The blocks were made from seasoned

teak wood. The designs are etched, two to three cylindrical holes are drilled

vertically and horizontally across the body of the block, which ensured free

passage of air and release of excess printing paste, which make the blocks

unique 9 types of block printing

techniques across India. (n.d.).

Figure 16

|

Figure 16 Gamati Print Source Edwards,

2016 |

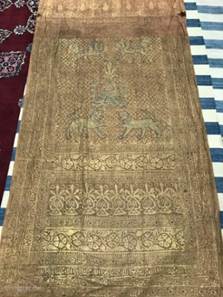

Varak

Gold And Silver Leaf Printing: In this printing gold or silver was flattened to

a fine paper like thickness which was hand printed as a prestige of the

possessor onto the flags, coats of arm, royal tents, and other emblems of

power. The traditional Varak leaf printing is employed to decorate textiles

used in temples till today. The glittering

Varak leaf prints, had a niche use because of the cost, as

these textiles do not lend itself to the rigorous washing to its fading

away over time.

Figure 17

|

Figure 17 Varak Gold and Silver Leaf Printing Source 19th Century India Gold Block Print

Textile. Gold leaf block print using the Varak technique of transferring gold

leaf from paper to block print. Made in Gujarat with symbols of the Nawab

Sahib ... | rugrabbit.com. (n.d.) |

The Varak

printed textiles can be seen in large temple towns and several past royal

cities in India Past-Continuous: Block Printing

on Textiles in India. (n.d.). The varak

block printing technique is extremely rare today and there are only two

printers who practice this printing in Jaipur Indian prints that are the face

of India’s heritage—Textile Magazine, Textile News, Apparel News, Fashion News.

(n.d.).

4)

Uttar Pradesh

Uttar

Pradesh is a center of block printing for temple

dresses or Nawabi royal attire. This state has a great influence of

Indo-Persian culture which is reflected in its art and textile industry. Uttar

Pradesh is famous for its tree like motives which is printed on either plain or

dyed cloth. The most famous motif of Farrukhabad is the “Tree of life” motif.

This motif stamped on silk fabric earns high foreign exchange. Beautiful

paisley motifs are seen in the hand block printed fabrics. Jehangirabad,

is another block printing centre, is famous for its low toned colours and bold

lines. Tanda in Uttar Pradesh is well known for its detail printing. Red and

dark blue, blend with red against an indigo background, are the main colours

used for block printing here Singh (2022).

Figure 18

|

Figure 18 Tree of Life Block Source desicraftshop.com |

5)

Andhra Pradesh

One of

the earliest but a complex technique of block printing developed in

Machilipatnam in Andhra Pradesh is Kalamkari. This craft evolved with the

patronage of the Golconda sultanate at Pedana near

Machilipatnam and the Mughals.

‘Kalam’

is only tool used in making these painted cloths. It is a brush made using

bamboo stick pointed at one end while the other end is thick. In the middle of

the stick wool or jute yarns are tied around to form of a ball and is held by

twine which is wrapped around in a crisscross manner. This craft uses only

natural dyes Divakala & Vasantha (n.d.).

Figure 19

|

Figure 19 Kalamkari Hand Printed Cotton Fabric Source theindianethnicco.com |

|

6)

West Bengal

Santiniketan is renowned for its distinct

style of block printing. This artistic tradition has deep roots in the cultural

and educational ethos. It was established by the Nobel laureate Rabindranath

Tagore which connects students with nature and traditional Indian arts. The

prints often reflect the ethos of Santiniketan, featuring nature-inspired

motifs, rural life, and themes from Tagore's literary and poetic works. The

blocks feature detailed patterns, often inspired by elements of nature,

folklore, and traditional Bengali art. Using natural dyes derived from plants

and minerals this printing produces earthy tones and vibrant hues, contributing

to the eco-friendly and sustainable nature of the craft Raman (1997).

6. Conclusion

India is well known for its hand block printing. This craft has played an important role in establishing the reputation of India for a very long time and has its market within and outside the country. Block printing is an art and a way to decorate the surface of the fabric for enhancing the appearance of the same. This traditional craft has been very much appreciated around the world because of the wonderful patterns created by hand. Each state in India has its unique style of block printing ranging from delicate patterns and lines to elaborate designs with vibrant colours, use of natural dyes. Another fascinating fact is the water in some regions producing unique colours. In spite of challenges from other modern printing techniques in the fashion industry this traditional art is still skilfully used for designing apparels and household articles, by varying combinations of motifs and colour, giving us a wide range of choices with a sense of uniqueness.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

9 types of block printing techniques across India. (n.d.). Retrieved from 2024, January 11.

19th Century India Gold Block Print Textile. Gold leaf block print using the Varak technique of transferring gold leaf from paper to block print. Made in Gujarat with symbols of the Nawab Sahib ... | rugrabbit.com. (n.d.). Retrieved from 2024, January 14.

Anjum, S., & Kunwar, N. (2020). Designs of Block Printing and Use of Techniques.

Balotra Printing. (n.d.). MAP Academy. Retrieved from 2024, January 12.

Baral, B. (n.d.). Sanganer Block Printing. D’Source Digital Learning Environment for Design.

Choudhury, A. K. R. (2023). Principles of Textile Printing—1st Edition -.

Chouhan, K. (2019). Historical View on Block Printing Technique and its Used in Bagh Print. International Journal of History and Cultural Studies, 5(4). https://doi.org/10.20431/2454-7654.0504006

Chouhan, S., & Patil, S. (2019). The Eco-Friendly Bagh Printing. International Journal of Research -GRANTHAALAYAH, 7(11), Article 11. https://doi.org/10.29121/granthaalayah.v7.i11.2019.3716

Divakala, M., & Vasantha, D. M. (n.d.). Kalamkari- The Painted Temple Cloths.

Edwards, E. (2016). Lasting Impressions: Indian Block-Prints and Global Trade.

Ganguly, D. & Amrita. (2013a). A Brief Studies on Block Printing Process in India. 41, 197–203.

Ganguly, D. & Amrita. (2013b). A Brief Studies on Block Printing Process in India. Fibre 2 Fashion, 41, 197–203.

Hada, J. (2015). Dyeing with Natural Dyes: A Case Study Of Pipad Village, District Jodhpur, Rajasthan. https://doi.org/10.13140/RG.2.1.5049.3204

Hill’s, N. (2023, May 22). Exploring the Rich History of Indian Block Printing. Nell Hill’s.

Hossain, M. A., Rahman, M., & Islam, R. (2015). Overview of Piece Printing Process in Textile Industry.

How Mata ni Pachedi is Created. (n.d.). Google Arts & Culture. Retrieved From 2024, January 12.

Indian prints that are the face of India’s heritage—Textile Magazine, Textile News, Apparel News, Fashion News. (n.d.). Retrieved From 2024, January 12.

Karolia, A., & Buch, H. (2008). Ajarkh, the Resist Printed Fabric of Gujarat. Indian Journal of Traditional Knowledge, 7, 93–97.

Kaur, J. (2012). DABU-A Unique style of Mud Printing.

Kiron, M. I. (2012, August 5). Common Printing Defects in Fabric: Causes and Remedies. Textile Learner.

Kulkarani, D. (2021). (PDF) Mata Ni Pachedi Craft Documentation.

Mandal, P., & Jaiswal, N. (2019, October 1). The Art of Block Printing. Indian Textile Journal.

Marigold, S. (2020, July 22). Block Printing: The History & Craftmanship of Indian Block Prints. Saffron Marigold.

Past-Continuous: Block Printing on Textiles in India. (n.d.). Google Arts & Culture. Retrieved From 2024, January 11.

Qutub, S., Sarfraz, S., & Naeem, S. (2022). Hand Block Printing: The Ancient Craft of South Asia. Journal of Development and Social Sciences, 3(II). https://doi.org/10.47205/jdss.2022(3-II)05

Rahman, N. (2022). Block Printing in India.

Raman, S. K. (1997). Santiniketan The making of A Contextual Modernism. With Notes. Santiniketan: The Making of a Contextual Modenism.

Rana, Md. B., Hasan, M., Islam, M. A., Rokonuzzaman, M., Khandaker, S., & Bashar, M. (2022). Printing Effects of Different Natural Colourants on Cotton Fabric. Textile & Leather Review, 5, 280–295. https://doi.org/10.31881/TLR.2022.30

Sampath, V. (2023). Indian Traditional Textiles an Overview on the State of Madhya Pradesh, India. Trends in Textile Engineering & Fashion Technology, 9(1). https://doi.org/10.31031/TTEFT.2023.08.000705

Singh, D. H. (2021). Rural Hand Block Print Fabrics in India: Introductory Review Based Study. EPRA International Journal of Research & Development (IJRD), 6(8), Article 8.

Singh, Y. (2022). Block Printing of Farrukhabad, Uttar Pradesh Academia.edu.

Vankar, D. P. S. (2022). Commercial Viability of Natural Dyes Heena, Catechu and Babool for Textile Dyeing.

Wardman, R. H. (2018). An Introduction to Textile Coloration: Principles and Practice. John Wiley Sons, Inc.

Williamson, L. (2016). Tracing Textiles, Motifs and Patterns: Historical to Contemporary.

www.fibre2fashion.com. (n.d.). Textile Printing in India – Traditional Approach. Retrieved From 2024, January 12.

|

|

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© ShodhKosh 2024. All Rights Reserved.