ShodhKosh: Journal of Visual and Performing ArtsISSN (Online): 2582-7472

|

|

Management of Printing Curriculum in AI Era

Anchal Gupta 1![]()

![]() ,

Ujwalla Gawande 2

,

Ujwalla Gawande 2![]() , Rohit Chandwaskar 3

, Rohit Chandwaskar 3![]()

![]() ,

Nuzhat Ahmad Yatoo 4

,

Nuzhat Ahmad Yatoo 4![]()

![]() ,

Richa Srivastava 5

,

Richa Srivastava 5![]() ,

,

Pooja Abhijeet Alone 6![]()

1 Centre

of Research Impact and Outcome, Chitkara University, Rajpura, 140417, Punjab,

India

2 Professor

and Dean R and D, Department of Information Technology, Yeshwantrao Chavan

College of Engineering, Nagpur, Maharashtra, India

3 Assistant

Professor, Department of Fashion Design, Parul Institute of Design, Parul

University, Vadodara, Gujarat, India

4 Assistant

Professor, Department of Computer Science and Engineering, Aarupadai Veedu

Institute of Technology, Vinayaka Mission’s Research Foundation (DU), Tamil

Nadu, India

5 Associate

Professor, School of Business Management, Noida International University, India

6 Department

of Engineering, Science and Humanities, Vishwakarma Institute of Technology,

Pune, Maharashtra, 411037, India

|

|

ABSTRACT |

||

|

The rapid

adoption of Artificial Intelligence (AI) in printing technologies is changing

the work of industries and the educational paradigm. This research paper

explores the manner in which the printing curriculum can be efficiently

managed and re-engineered in order to address the changing needs of

AI-powered production space. It follows the development of printing education

throughout history and determines how AI can transform design, workflow, and

quality management, and suggests a competency-based structure in which

curriculum is redesigned. The study is based on the international

case-studies that indicate that those institutions which integrate AI-enabled

technologies, including predictive analytics, computer vision, and generative

design, can attain the quantifiable efficiency, student engagement, and

creative innovation. It discusses the necessity of the faculty development,

modernizing the infrastructure, and the robust industry-academic partnership

to guarantee the topicality and sustainability of the curriculum.

Socio-technical and ethical aspects are also tackled in order to encourage

responsible AI usage in education. The results bring in a strategic

representation of creating adaptive, information-based and innovation-driven

printing programs that fulfill the technological progress with the capacity

to be creative and ethically accountable. |

|||

|

Received 13 June 2025 Accepted 27 September 2025 Published 28 December 2025 Corresponding Author Anchal

Gupta, anchal.gupta.orp@chitkara.edu.in DOI 10.29121/shodhkosh.v6.i5s.2025.6888 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2025 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: AI in

Education, Printing Technology, Curriculum Management, Digital

Transformation, Generative Design, Adaptive Learning |

|||

1. Introduction

The

printing business that used to be based on the artisan and mechanical focus and

accuracy is currently experiencing a paradigm shift with the introduction of

Artificial Intelligence (AI), automation, and data-driven processes. With the

world entering Industry 5.0, printing is not limited to operations of

conventional presses anymore but it has become a smart, connected ecosystem

that incorporates digital creation, smart production, and responsive workflow

operations. This change requires a subsequent adjustment in the education

systems especially in handling printing courses to equip students with the

requirements of the AI-enhanced work environment Southworth et al. (2023). Both

technical and creative skills needed by graduates in the field are being

redefined by the development of machine learning, robotics and predictive

analytics into printing processes. Traditionally, printing education focused on

manual skills (calibration by color, composition of layout, maintenance of a

press, etc) Soliman et al. (2024). Although

these competencies are still pertinent, the contemporary printing world demands

other skills in algorithmic intelligence, data visualization, process

optimization, and sustainable utilization of materials.

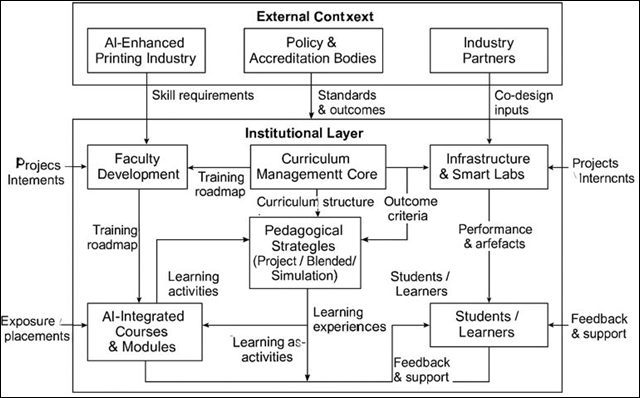

Figure 1

Figure 1 Conceptual Framework for AI-Integrated Printing Curriculum Management

From

the advent of intelligent prepress systems, self-checking quality and computer

vision to inspect defects are only some of the examples of how AI is changing

the working process. This has forced schools and colleges to reform their one

to include both traditional education as well as computational intelligence as

shown in figure 1 and consequently, schools must also design a curriculum that

will not just impart craft knowledge to students but they must also impart

technological literacy and innovation oriented attitudes Wang (2022). The printing

curriculum management during the AI age would not simply be reduced to the

introduction of new courses. It consists of methodical restructuring which

comprises pedagogical orientation, staffing, modernization of infrastructure

and continuous industry partnership. As the high paced technological changes

continue to change, institutions ought to adopt flexible and outcome based

structures that easily conform to the changes. Curriculum management with AI

also enables making decisions by data, which will enhance the educators to

monitor the advances of learners, determine the skill deficiencies, and deliver

individual learning experiences using smart learning systems. Moreover, the

adoption of academic-industry partnerships is also used to ensure that

education programs are not out of touch with practice and emerging skills that

are required in the real world Tlili et al. (2023)

In

its turn, the current research paper is aimed at studying how the principles of

AI integration may be applied in a systematic fashion in order to modernize and

manage the printing curriculum in an efficient way. The gap in the traditional

and AI-enabled production environment will be addressed in the paper through

discussion of the history of printing technologies, methods of teaching, and

use of practical examples to develop a holistic framework that could enhance

the comprehension and allow bridging the gap between the traditional and modern

printing environment. The ultimate target of the research is to achieve a

creative and future-oriented learning environment whose role balance is between

creativity, technology, and sustainability in the printing sector.

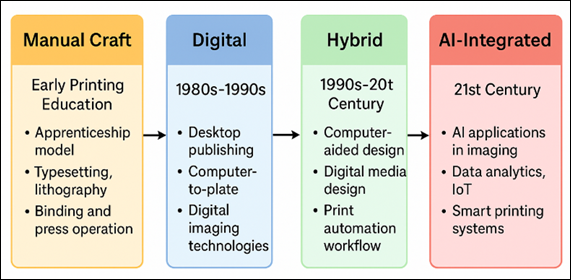

2. Historical Evolution of Printing Education

The

history of printing education resonates with overall technological and cultural

changes that have influenced the communication and manufacturing sectors. In

early days of its development, printing was rather a manual art based on the

art of typesetting, lithography, bookbinding, and operation of the press.

Precision, discipline and material knowledge were the main features of

apprenticeship models Solimanb et al. (2025).

Late 19th and

early 20th century educational institutions incorporated new workshop-based

pedagogies in which learners were taught by repetition and by solving

mechanical problems. The curriculum was based on process efficiency, color

accuracy and quality control skills that were important in the early

development of the industrial printing industry Zawacki-Richter et al. (2019). But, as the

digital revolution in the late 20th century, the range of printing education

started to enlarge to cover not physical processes but digital prepress and

computer-aided design and workflow automation.

Figure 2

Figure 2 Evolutionary Trajectory of Printing Education

In

the 1980s, with the advent of desktop publishing (DTP), and in the 1990s, with

the advent of digital imaging technologies, the idea of curriculum began to

change. The computer-to-plate and computer-to-print systems were becoming

increasingly popular to replace traditional presses thus making it mandatory

that institutions learn to incorporate digital literacy and software

proficiency into their curriculum as shown in Figure 2 .The area of

pedagogical orientation changed to the innovative design thinking and digital

management Scuotto et al. (2017),De Bernardi et al. (2019). Higher

education institutions started to introduce classes on digital color theory,

learning on the art of vector graphics, typography automation and print media

design. This shift also resulted in an interdisciplinary overlap of

communication design, information technology, and print engineering which

formed the basis of the hybrid educational ecosystem that is experienced today.

With the advent of Industry 4.0, which is the smart manufacturing, robotics,

and Internet of Things (IoT) in the 21st century, automation and scale data

analytics were implemented in the printing sector. Printers turned into smart

systems that could self-calibrate and predictively maintain themselves along

with cloud-based workflow synchronization Altun et al. (2025),Habib et al. (2025). However, the

curricula tended to be behind this industrialization and most curriculums had

traditional modules on print mechanics and not data-driven operations.

Realizing this void, some of the first institutions started to offer courses in

AI application in imaging, machine-learner print defect detection and print

design with the help of augmented reality Hamzat et al. (2025)

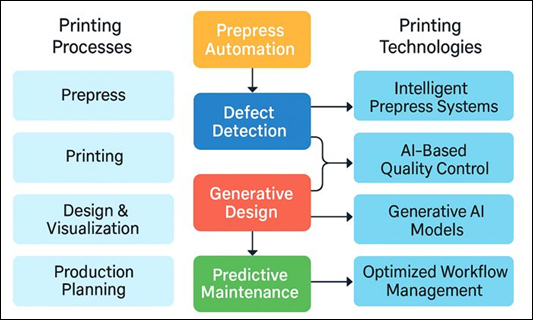

3. AI Transformation in Printing Technologies

The

use of Artificial Intelligence (AI) in printing technologies has changed the

manner in which it is applied in the production process, design process and

quality control. The traditional printing was usually done manually on

calibration and matching of the colors manually and inspecting manually to

identify defects. The convergence of machine learning and computer vision with

intelligent automation has however transformed these operations to data-driven

agile ecosystems. AI-based printing systems can now learn by its own with input

data on production, streamline processes in real time and predict system

problems before they occur, bringing in a new age of accuracy, speed and

sustainability. The most important aspect of this revolution is a smart prepress

automation, according to which using a computer program, digital artwork is

measured to maximize colors, layout positioning or ink position Subeshan, B., Atayo, A., and

Asmatulu, E. (2024),

Altun (2025). These systems

employ predictive analytics that modify settings in real-time and ensure that

they reduce waste and do not need to print a test repeatedly. Similarly,

computer vision and deep learning models can also be used to carry out quality

assurance. High-resolution images of printed materials are captured and

analyzed by cameras fitted in the printing units and the microscopic defects of

the printed materials, including variation in color, streaking, or

misalignment, are detected. The system will automatically recalibrate or

shutdown production, which maintains the same quality with a minimum of human

interventions as shown in Figure 3. Another

important development is AI-based workflow management that combines the process

of job scheduling, machine use, and material logistics into a single digital

system. The reinforcement learning algorithms consider various variables that

include print volume, type of paper, drying time and the workload of the

operator to create the best production sequences Altun (2025). This has

increased the efficiency in the operations and also reduced downtimes between

commercial printing systems. Moreover, AI is changing predictive maintenance

whereby sensors can be used to detect the vibration, temperature, and the flow

of ink and even tell when a potential breakdown will occur before it disrupts

production. The above predictive models are directly associated with cost

saving and sustainability in terms of extending the life of the machines and

minimizing resource wastage Al’Aref (2018).

Figure 3

Figure 3

AI

Transformation Map in Printing Processes

The

use of generative AI models has brought about new opportunities in the sphere

of print design and visualization in the artistic world. The tools, which are

grounded on diffusion models, GANs, and transformer-based architecture, enable

the designers to create complex and personalized compositions using natural

language prompts. Individualized packaging or marketing content that is created

by the use of variable data printing systems using AI can serve an example. On

the same note, AI application combined with augmented and virtual reality

(AR/VR) would allow displaying a design in three-dimensional forms before

printing it on paper, increasing efficiency and interaction with clients Al’Aref (2018). All these

inventions have reinvented the skill pool in the printing industry. The

contemporary printing specialist is not just a specialist in materials and

equipment, he/she should be a fluent reader of analytics dashboard, a user of

trains artificial intelligence, an ethical operator of automatic tools. In

turn, the use of AI in the printing technologies will serve as the foundation

of the re-imagination of the curriculum design that will force teachers to

consider the concept of computational literacy, data interpretation, and

sustainability as the part of the printing education systems in the future.

4. Curriculum Design for AI-Integrated Printing Education

The

AI era in the field of printing presupposes the development of an effective

curriculum that can be designed only through a comprehensive reorganization of

learning outcomes, learning content and evaluation systems. This transformation

entails the integration of AI principles into the main printing topics, the

introduction of new interdisciplinary courses, and the matching of the outcomes

with the requirements of the industry and accreditation systems. The principle

of AI-based curriculum design is to use competency mapping determining the

technical, cognitive, and ethical skills needed in future printing careers Thomas (2022). Cognitive

competencies revolve around thinking critically, solving problems in an

adaptive manner, and making innovation design-driven, whereas ethical

competencies surround responsible practices with AI, knowledge of intellectual

property, and environmental awareness Boretti (2024). These

competencies mapped are to be used in the sequencing of subjects, project-based

learning modules, and evaluation rubrics in order to balance theory and

application.

Figure 4

Figure 4 Framework for AI-Integrated Printing Curriculum

Design

To

realize these competencies, the curriculum designers can use a three-level

model. The Foundational Modules level is the introductory level that teaches

learners about the basics of digital printing, the basics of computer vision

and machine learning in imaging Metal (2023). The next

layer is the Applied Intelligence Modules, which involve the implementation of

AI tools in production planning, workflow optimization, and design automation,

which allows students to use algorithms in real-world scenarios as shown on Figure 4. The third is

Capstone and Research Projects tier, which is the most innovative and involves

interdisciplinary teamwork, during which learners engage in creating

prototypes, like an intelligent quality control system or a generative design

software to package. This is progressive to ensure that the learning process

begins with theoretical knowledge that brings about the practical

implementation. Besides, the curriculum must emphasize on the experiential and

adaptive learning. With the help of AI-based simulation environments, the

models of digital twin, and even virtual print laboratories, students will be

able to be exposed to the real-time visualization and simulation of production

scenarios. Personalized learning analytics based on AI have the ability to

track the performance patterns, provide adaptive feedback, and recommend

learning resources that are guided by the strengths and weaknesses of a

particular student. Such systems can transform the teaching approaches into a

dynamic feedback system, which enhances the degree of engagement and retention.

There is also the necessity to collaborate with the industry and research

centers, which is institutional. Co-designed modules, joint certifications, and

AI-oriented internships will aid in ensuring that the curricular relevance is

achieved and that employability is created. The accreditation agencies will

also be combined, which will guarantee both compliance with the education

standards, and the flexibility of innovation. Lastly, the curriculum must be not

only infused with the technical competencies but also with the mentality of

innovation which enables the graduates to lead the revolution in the printing

industry by being innovative, ethical and technologically proficient.

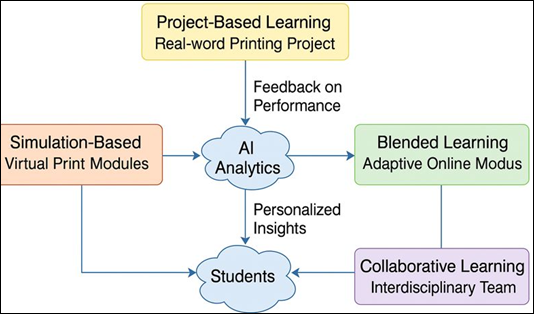

5. Pedagogical Strategies and Learning Models

The

implementation of the Artificial Intelligence (AI) in the sphere of the

printing education presupposes the paradigm shift of the teaching process: it

is not the teacher-oriented, but the learner-oriented, information-driven and

adaptive approaches. Pedagogical strategies will be forced to transform to

incorporate experiential learning, critical thinking, interdisciplinary

learning in such a way that students are prepared to work in a rapidly evolving

print ecosystem that is a blend of automation, creativity and sustainability.

The key secret to successful management of the printing curriculum in the AI

age is thus to not only redesign the content, but also reinvent the learning

process itself. One of the main approaches is the project-based and experiential

learning, according to which students can use AI technologies in real-life

printing situations. Using real world projects like creating smart quality

inspection systems or predictive maintenance dashboards the learners interact

with the industry grade tools as they work on their practical issues. These

experiences enhance the conceptual knowledge and facilitate self-directed

learning. These projects may also be used as personalized learning datasets,

when they are filled with AI analytics where an educator can assess competency

development and detect skill deficiencies over time. Similarly relevant is the

existence of learning environment through simulation as shown in Figure 5. These systems

embrace trial and error and feedback which are similar to the actual industrial

setting. As an example, a student will be able to visualize the influence of

machine learning parameters on the ink flow, print density, or defect frequency

in real-time and develop a better understanding based on the experiential

reinforcement.

Figure 5

Figure 5 AI-Enabled Pedagogical Ecosystem for Printing Education

Another

important dimension provided by blended learning models is the integration of

face-to-face learning and online learning modules which are supported by AI.

Adaptive platforms have the ability to process the data about each learner,

e.g. engagement time or quiz scores or error rates, and dynamically change the

complexity of the content. This form of continuous feedback guarantees

differentiation instruction that is consistent with the advancement and

cognition type of each learner. In addition, AI-based tutoring systems can be

used to complement faculty support by providing immediate clarifications,

computerized simulations, or contextual materials depending on their

interactions with learners. Through interdisciplinary teamwork, co-creation

between designers and engineers, and virtual tools of collaboration, students

are able to acquire the valuable soft skills in addition to the technical

skills. The AI tools can also improve collaboration even further, by monitoring

the group dynamics, making sure that everyone is equally active, and offering

analytics on the balance of communication efficiency or creative output.

Lastly, there should be an ethical and reflective pedagogy that should go hand

in hand with these innovations. Since AI technologies are becoming the part of

creative decision-making, educators need to develop awareness regarding the

transparency of algorithms, intellectual property, and cultural representation.

Integrating reflective debates and design ethics workshops is a guarantee that

the technological literacy would be developed concurrently with the ethical

sensitivity.

6. Faculty Development and Institutional Readiness

The

integration of AI in the field of printing education is largely reliant on the

readiness of the members of the faculty and on the institutional ecosystem,

which underpins them. Although technological innovation is transforming the

learning environment, human skill is the main ingredient of successful

curriculum implementation. Thus, it is vital to prepare teachers with the

essential digital, analytical, and pedagogical skills so that the shift to

AI-driven education does not mentioned in vain and can be maintained.

Development of faculty in this regard is not restricted to technical training

but it is a complete change in instructional roles. To integrate AI tools and

be more creative and engaging in the learning process, teachers will need to

change into more than mere providers of information, data interpreters, and

co-learners. There are three broad areas to which structured professional

development programs should be targeted:

1)

AI and information literacy, which allows teachers to learn and

apply the concepts of machine learning to real-life print situations;

2)

Innovation in pedagogy, in which they will create interactive and

AI-assisted teaching programs;

3)

Ethical and socio-technical awareness to equip them to deal with

bias, authorship, and automation anxiety in the classroom.

In

addition, a culture of ongoing improvement and joint experimentation may be

cultivated in peer learning communities and interdepartmental hubs of

innovation on a university campus.

Figure 6

Figure 6

Institutional

Readiness Model for AI-Integrated Printing Education

On

an institutional level, preparedness implies the strategic alignment of policy,

leadership vision and infrastructure. Smart laboratories that have intelligent

printing solutions, cloud-based analytics software, and digital simulations

should be invested in institutions. Those facilities will be used as living

laboratories where both students and faculty may learn about applied AI methods

in design, workflow automation and quality optimization. At the same time, the

administrative schemes should be re-organized to accommodate the data-driven

decision-making processes as shown in figure 6, dynamic curriculum revision,

and teacher performance analytics. The institutional policies need to promote

innovation where the contributions made by faculty in teaching research based

on AI and the participation in technology based pedagogical research should be

rewarded. Industry collaboration is also another important issue of

institutional readiness. Co-designing curriculum, sharing of resources, and

internships in real-world industrial environments can be made possible by

alliances with printing technology companies, scientists of AI solutions, and

professional associations. These interactions are beneficial as they keep

educators abreast of the new AI tools, predictive models and sustainability

models that are currently being implemented in practice.

7. Case Studies of AI Implementation in Printing Programs

The

introduction of Artificial Intelligence (AI) into the field of printing has

already started to change the academic programs of universities and training

wards all over the world. Such applications will be informative in terms of how

AI-based technologies and pedagogical innovations may transform the process of

curriculum delivery, improve results, and keep education abreast with the

changes in the industry. The case studies below can demonstrate how AI-enabled

printing programs can be applied practically, proving various approaches in an

academic and industrial setting.

Case

Study 1: Smart Printing Laboratory Initiative – Finland Polytechnic Institute

Finland

Polytechnic Institute, in the Department of Media Technology, introduced a

Smart Printing Laboratory which has AI-enabled digital presses, computer vision

modules, and predictive analytics systems. The project was meant to educate

students on intelligent production processes and management of materials

sustainably. The AI models were applied by the students to study print quality,

optimize the use of ink, and predict the need of maintenance.

Table 1

|

Table 1 Smart Printing Laboratory

Initiative – Finland Polytechnic Institute |

||||

|

Parameter |

AI Tool / Technique Used |

Observed Improvement (%) |

Learning Outcome |

Remarks |

|

Print Quality Optimization |

Computer Vision + CNN-based Defect Detection |

30 |

Students achieved higher accuracy in color

calibration and print alignment |

Demonstrated real-time quality analytics |

|

Material Efficiency |

Predictive Analytics for Ink and Paper Usage |

25 |

Enhanced understanding of sustainable printing

processes |

Reduced waste across lab projects |

|

Workflow Automation |

Reinforcement Learning Scheduler |

40 |

Students learned process sequencing and job

optimization |

Improved production turnaround |

|

Machine Health Prediction |

Sensor Data + Regression Models |

20 |

Exposure to predictive maintenance concepts |

Increased equipment uptime and reliability |

|

Faculty Training Impact |

AI Literacy Workshops |

Faculty gained technical and pedagogical AI

competence |

Supported integration across courses |

|

The

program also cited a decline in material waste by a factor of 25, as well as

the workflow efficiency that had improved by 40 percent. Educators who had

undergone ongoing AI upskilling trainings incorporated these tools in their

education practices and this created a balance between technical skills and

environmental awareness.

Case

Study 2: AI-Driven Curriculum Redesign – Indian Institute of Printing

Technology

Indian

Institute of printing technology (IIPT) adopted an AI based curriculum

management system in order to customize learning journeys. The platform tracked

progress of students, and suggested adaptive learning modules, using machine

learning analytics, and based on performance data.

Table 2

|

Table 2 AI-Driven

Curriculum Redesign – Indian Institute of Printing Technology (IIPT) |

||||

|

Curriculum Component |

AI System Functionality |

Measured Impact |

Quantitative Indicator |

Outcome Description |

|

Adaptive Learning Platform |

Machine Learning–Based Performance Prediction |

Enhanced student engagement |

+35% engagement rate |

Personalized content and pacing for each learner |

|

Assessment Analytics |

NLP-Based Essay Evaluation |

Improved grading accuracy |

+22% scoring consistency |

Automated rubric alignment and reduced evaluation

bias |

|

Skill Gap Monitoring |

Bayesian Knowledge Tracing |

Early identification of weak learners |

-18% failure rate |

Allowed proactive remedial sessions |

|

Industrial Collaboration |

Real-Time Data Integration APIs |

Strengthened academia–industry interface |

+3 new partnerships |

Improved relevance of practical modules |

|

Faculty Decision Support |

AI Dashboards for Class Analytics |

Improved curriculum agility |

Updated every semester |

Data-driven course redesign cycles |

The

system was also used to predict student successes in particular technical

fields whereby instructors could intervene. The institute found higher

participation rates among the students (by 35 percent) and better completion

rates (by 20 percent) in advanced courses of digital printing in two academic

cycles. In addition, partnership with local printing companies offered students

with access to real time industrial information which enhanced

academia-industry relationships.

Case

Study 3: Generative Design and Print Innovation – Tokyo University of Art &

Technology

The

application of generative AI models including diffusion-based visual synthesis

tools to print design education was first made by Tokyo University School of

Design. Students experimented with innovative automation, creating complicated

textures, patterns and layouts of packaging and digital art prints.

Table 3

|

Table 3 Generative

Design and Print Innovation – Tokyo University of Art & Technology |

||||

|

Creative Domain |

AI Technique Applied |

Evaluation Metric |

Student / Faculty Feedback |

Innovation Outcome |

|

Print Design |

Diffusion Models for Pattern Generation |

Creative Diversity Index = 0.87 |

84% of students reported increased design

exploration |

Introduced cross-disciplinary AI art module |

|

Typography |

Transformer-Based Style Adaptation |

Consistency Score = 0.91 |

78% of faculty noted precision improvement |

Enhanced design coherence in print layout |

|

Packaging |

GAN-Based Visual Enhancement |

Visual Appeal Rating = 8.6 / 10 |

81% of students preferred AI-assisted design |

Enabled real-time prototyping |

|

Cultural Integration |

AI Semantic Embedding for Aesthetics |

Cultural Authenticity Score = 0.82 |

Strong acceptance from art departments |

Bridged cultural heritage with computational

creativity |

|

Learning Experience |

Interactive AI Feedback Interface |

Engagement Uplift = +28% |

Faculty noted improved interdisciplinary dialogue |

Reinforced innovation-oriented pedagogy |

The

course combined computational creativity and cultural aesthetics, whereby the

ownership of AI-generated art has an ethical basis. According to the surveys,

82 percent of students said they felt more confident in their creativity, and

the faculty said there was better collaboration between design and engineering

departments, which were now cross-disciplinary.

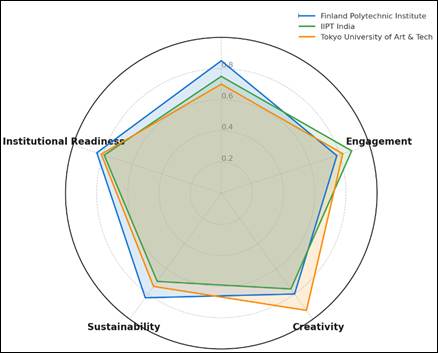

All

these case studies point to one conclusion that the adoption of AI in the

printing programs does not only result in more effective technical operations,

but also in the re-invention of creativity, pedagogy, and collaboration. The

major lessons learned are that institutional readiness is important, faculty

flexibility is important, and unremitting collaboration with industry

ecosystems as shown in Figure 7. The results

show that an AI-driven curriculum produces innovation-driven professionals who

have both analytical and creative intelligence that can enable them to succeed

as leaders in the changing printing industry. Figure 7 is a comparative radar

analysis of the outcomes in implementing AI in three institutions. The Finland

Polytechnic Institute has a high efficiency and sustainability level which can

be explained by the fact that it manages to streamline its working processes

and minimize waste of materials by using AI-based processes.

Figure 7

Figure 7 Comparative Overview of AI Implementation

Case Studies

8. Discussion

This

study reveals that the printing curriculum management in the AI age needs

paradigm shift in the contents and delivery. Embracing Artificial Intelligence

in the entire printing operations that have started with automating prepress,

up to generative design have changed the skills and competency required in the

current printing workforce. The findings of the case studies demonstrated that

AI-driven pedagogical practices can be implemented in the institutions that

will experience the apparent benefits in terms of efficiency, engagement and

innovation, which explains the need to systematic redesign of the curriculum.

The relationship between technological integration and pedagogical innovation

is one of the patterns that are also similar in all the implementations and is

a symbiotic relationship. The AI-powered personalization tools help to enhance

the learning process, and the data analytics enable educators to be able to

track the progress and dynamically adjust the content. The results suggest the

importance of capacity building of faculty and institutional capacity to uphold

such reform. Particularly, the success of the Finnish Polytechnic and IIPT also

show that successful curricula need the well-developed faculty and strong

digital communities, yet Tokyo University is also concerned with the new uses

of AI, and it is an indicator of the even greater divide between the technology

and design education. The other notable implication is the strengthening of

industry-academia cooperation as a main factor of relevance of the curriculum.

Collaborations with AI solution vendors and printing companies will mean that

the students will receive a practical learning experience on how things work in

the real-life scenario, closing the gap between the educational experience and

the industry. Nevertheless, it still has difficulties especially in the ethical

fronts regarding the biasing of data, the fear of automation and intellectual

property in AI-created print materials. In general, the discussion highlights

that the management of an AI-infused printing curriculum needs to be balanced

as the person needs to improve technical expertise in it, creative expression,

and moral consciousness. The introduction of adaptive and data-driven,

interdisciplinary models within institutions will place those institutions in

the best position to produce a new generation of professionals who will

spearhead the smart revolution of the printing industry across the globe.

9. Conclusion

The

reconfiguration of printing education in the sphere of AI age will be the

significant turn to the paradigm of off-the-shelf craftsmanship to the

framework of smart-based, information-driven, and multipolar learning. The

existing curriculum management is based on how well the AI technologies are

implemented in design, production, and pedagogical systems to present the

automated, adaptive, and creative environment to the industry to the students.

The case findings and analysis of the study indicate that the AI-enabled tools

adoption in the institutions can make visible considerable efficiency,

engagement, and innovation yield, which can reveal the real-life advantages of

the digital transformation in the education sector. The long-term success

though is to be attained through the faculty readiness of holistic

preparedness, the robust infrastructure and the current practice of partnership

with the industrial partners. The use of the generative and predictive AI

systems also requires the use of ethics and cultural sensitivity. With the

education of printing being advanced, the universities ought to have a balance

between the use of technology and the human creativity and responsibility. What

lies ahead of the printing curriculum is the best ability to create adaptive,

ethically focused as well as futuristic professionals who will be in a position

to project the industry to a viable as well as intelligent future.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

Altun, F. (2025). Mechanical and Surface Properties of 3D-Printed Ti6Al4V Alloy Parts Fabricated by Selective Laser Melting under Extreme Conditions (Master’s thesis, Wichita State University, Wichita, KS, USA).

Altun, F., Altuntas, G., Asmatulu, E., and Asmatulu, R. (2025). Additive Manufacturing of Ti-6Al-4V: Influence of Cryogenic and Stress-Relief Heat Treatments on Electrical Conductivity. In Proceedings of the 7th International Trakya Scientific Research Congress, 219–226.

Altun, F., Bayar, A., Hamzat, A. K., Asmatulu, R., Ali, Z., and Asmatulu, E. (2025). AI-Driven Innovations in 3D Printing: Optimization, Automation, and Intelligent Control. Journal of Manufacturing and Materials Processing, 9(10), 329. https://doi.org/10.3390/jmmp9100329

Al’Aref, S. J. (2018). 3D Printing Applications in Cardiovascular Medicine. Elsevier. https://doi.org/10.1016/C2016-0-01941-6

Boretti, A. (2024). A Techno-Economic Perspective on 3D Printing for Aerospace Propulsion. Journal of Manufacturing Processes, 109, 607–614. https://doi.org/10.1016/j.jmapro.2024.01.063

De Bernardi, P., Bertello, A., and Shams, S. M. (2019). Logics Hindering Digital Transformation in Cultural Heritage Strategic Management: An Exploratory Case Study. Tourism Analysis, 24, 315–327. https://doi.org/10.3727/108354219X15511864843867

Habib, M. A., Subeshan, B., Kalyanakumar, C., Asmatulu, R., Rahman, M. M., and Asmatulu, E. (2025). Current Practices in Recycling and Reusing of Aircraft Materials and Equipment. Materials Circular Economy, 7(12). https://doi.org/10.1007/s42824-025-00112-6

Hamzat, A. K., Murad, M. S., Adediran, I. A., Asmatulu, E., and Asmatulu, R. (2025). Fiber-Reinforced Composites for Aerospace, Energy, and Marine Applications: An Insight into Failure Mechanisms under Chemical, Thermal, Oxidative, and Mechanical Load Conditions. Advanced Composites and Hybrid Materials, 8, 152. https://doi.org/10.1007/s42114-025-00652-9

Metal AM. (2023). The Convergence of Additive Manufacturing and Artificial Intelligence: Envisioning a Future That Is Closer Than You Think. Metal AM.

Scuotto, V., Santoro, G., Bresciani, S., and Del Giudice, M. (2017). Shifting Intra- and Inter-Organizational Innovation Processes towards Digital Business: An Empirical Analysis of SMEs. Creativity and Innovation Management, 26, 247–255. https://doi.org/10.1111/caim.12221

Soliman, M., Ali, R. A., Khalid, J., Mahmud, I., and Ali, W. B. (2024). Modelling Continuous Intention to Use Generative Artificial Intelligence as an Educational Tool among University Students: Findings from PLS-SEM and ANN. Journal of Computer Education, 12, 1–32. https://doi.org/10.1007/s40692-024-00278-3

Soliman, M., Ali, R. A., and Noipom, T. (2025). Unlocking AI-Powered Tools Adoption among University Students: A Fuzzy-Set Approach. Journal of Information and Communication Technology, 24, 1–28.

Southworth, J., Migliaccio, K., Glover, J., Glover, J., Reed, D., McCarty, C., Brendemuhl, J., and Thomas, A. (2023). Developing a Model for AI across the Curriculum: Transforming the Higher Education Landscape via Innovation in AI Literacy. Computers and Education: Artificial Intelligence, 4, 100127. https://doi.org/10.1016/j.caeai.2023.100127

Subeshan, B., Atayo, A., and Asmatulu, E. (2024). Machine Learning Applications for Electrospun Nanofibers: A Review. Materials Science, 59, 14095–14140. https://doi.org/10.1007/s10853-024-09432-1

Thomas, D. J. (2022). Advanced Active-Gas 3D Printing of 436 Stainless Steel for Future Rocket Engine Structure Manufacture. Journal of Manufacturing Processes, 74, 256–265. https://doi.org/10.1016/j.jmapro.2021.12.032

Tlili, A., Shehata, B., Adarkwah, M. A., Bozkurt, A., Hickey, D. T., Huang, R., and Agyemang, B. (2023). What If the Devil Is My Guardian Angel: ChatGPT as a Case Study of Using Chatbots in Education. Smart Learning Environments, 10(15). https://doi.org/10.1186/s40561-023-00237-x

Wang, N. (2022). Application of Artificial Intelligence and Virtual Reality Technology in the Construction of University Physical Education. In Proceedings of the 3rd International Conference on Electronic Communication and Artificial Intelligence (IWECAI) (pp. 343–346). https://doi.org/10.1109/IWECAI55315.2022.00075

Zawacki-Richter, O., Marín, V. I., Bond, M., and Gouverneur, F. (2019). Systematic Review of Research on Artificial Intelligence Applications in Higher Education: Where Are the Educators? International Journal of Educational Technology in Higher Education, 16(39). https://doi.org/10.1186/s41239-019-0171-0

|

|

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© ShodhKosh 2025. All Rights Reserved.