ShodhKosh: Journal of Visual and Performing ArtsISSN (Online): 2582-7472

|

|

Machine Vision for Sculpture Surface Optimization

Suraj Bhan 1![]() , Akhilesh Kumar Khan 2

, Akhilesh Kumar Khan 2![]() , Vineet Kumar 3

, Vineet Kumar 3![]()

![]() ,

Megha Jagga 4

,

Megha Jagga 4![]()

![]() ,

Megala G 5

,

Megala G 5![]()

![]() ,

,

J P Yadav 6![]() ,

Chandrashekhar Ramesh Ramtirthkar7

,

Chandrashekhar Ramesh Ramtirthkar7 ![]()

1 Assistant

Professor School of Engineering and Technology, Noida International, University,

India 203201

2 Director

Greater Noida, Uttar Pradesh 201306, India

3 Assistant

Professor, Department of Computer Science and Engineering (Cyber Security),

Noida Institute of Engineering and Technology, Greater Noida, Uttar Pradesh,

India

4 Centre

of Research Impact and Outcome, Chitkara University, Rajpura- 140417, Punjab,

India

5 Assistant

Professor, Department of Computer Science and Engineering, Presidency

University, Bangalore, Karnataka, India

6 School

of Legal Studies, CGC University, Mohali-140307, Punjab, India

7 Department of Mechanical Engineering Vishwakarma Institute of

Technology, Pune, Maharashtra, 411037 India

|

|

ABSTRACT |

||

|

The article

under research is called Machine Vision of Sculpture Surface Optimization and

it addresses the topic of applying modern computer vision and artificial

intelligence methods to improve the accuracy and efficiency of sculptural

surface refinements. Conventional manual procedures in surface optimization processes, are very subjective, time consuming and their

procedures are usually restricted by inconsistencies in human perception.

This paper suggests a powerful vision-based framework, which uses machine

learning and 3D imaging technology to reach automated and data-driven surface

analysis and fixation. The system architecture involves high resolution

cameras and structured lightings modules and robotic manipulators to have

accurate data acquisition and surface analysis. The system identifies the

important geometric and texture features of the point clouds by preprocessing

the image, edge and curvature detection, and analysis of the image.

Convolutional neural networks (CNNs) and autoencoders are used to improve

these features so that surface irregularities and deviations of the intended

topography are predicted. An optimization loop that is based on a feedback

loop is used to allow the correction of tool paths or polishing parameters in

real-time. It has been proven in experiments that smoothness and uniformity

of the surface, as well as reduction in defects, improved considerably under

comparison to the manual methods of handling the problem, whereas processing

time and human intervention were reduced significantly. The research also

confirms the approach by use of visual inspection, 3D reconstruction metrics,

and quantitative indices of quality of surfaces. |

|||

|

Received 05 May 2025 Accepted 09 September 2025 Published 25 December 2025 Corresponding Author Suraj

Bhan, DOI 10.29121/shodhkosh.v6.i4s.2025.6861 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2025 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Machine

Vision, Surface Optimization, 3D Reconstruction, Convolutional Neural

Networks, Digital Sculpture |

|||

1. INTRODUCTION

Art and technology have been integrated in the world to a great extent in recent years and machine vision and artificial intelligence (AI) has demonstrated transformative functions in defining the traditional sculptural practice. As a visual art that is focused on touch and feel, sculpture is greatly dependent on the accuracy and the looks of the surface quality. Refinishing and optimization of sculptural surfaces of stone, metals, clay and polymer composite materials have long been reliant on the skill and judgment of the eye and hand of the artisan. Even though such techniques are considered as craftsmanship and cultural worth they are frequently constrained by human subjectivity, physical exhaustion and inconsistency particularly during production up-scaling or the duplication of intricate geometries. Conversely, the introduction of machine vision systems provides such an unprecedented possibility as to bring precision, repeatability, and data-driven understanding in surface assessment and refinement. Machine vision is a branch of computer vision and it allows computers to read images and make analytical decisions based on the images or three-dimensional information. Regarding the optimization of the sculptural surface, it is the fundamental technology linking the digital analysis and the tactile work Akbarpour et al. (2024).Machine vision is then able to identify irregularities at the micro-level, curvature and textural discontinuities that are not easily visible with the human eye by incorporating high-resolution cameras, structured lighting and sophisticated algorithms.

This allows not just the quality of the surface, but also the aesthetic faithfulness of sculptures, so that the digital or concept development is exactly reproduced in the output created. This study is inspired by the increasing demand of automation and accuracy of art restoration, additive manufacturing, and reproduction of digital artworks. As society has seen more applications of 3D modeling and computer-aided design (CAD) in the creative industries, there is an urgent need to transfer the digital components of the surface accurately to the physical medium. Machine vision offers the analytical foundation to accomplish this translation by methods like stereo vision, structured light scanning and point cloud building Xu et al. (2021). These techniques allow to measure depth, texture and curvature accurately, which is important to measure surface smoothness and also to identify defects like tool marks, cracks or rough finishes. Also, machine learning algorithms, specifically convolutional neural networks (CNNs), autoencoders, and support vector machines (SVMs) are capable of being trained to detect, categorize, and forecast surface defects using massive datasets Han et al. (2024).These models can be used together with adaptive feedback loops to control the polishing systems of robots or automated polishing systems to polish the surface in a series of iterations according to the real-time visual feedback. This closed-loop optimization solution will greatly decrease the use of manual inspection and will improve on the reproducibility and production efficiency. The implication of this study will not just be limited to the conventional art.

2. Theoretical Background

2.1. Fundamentals of computer vision and surface characterization

Computer vision is an

interdisciplinary study, which allows the machine to perceive, evaluate, and

generate conclusions on the basis of the visual data. Computer vision is an

effective analysis tool that is used to characterize a surface of an object in

surface characterization to capture and measure physical and geometric features

of the surface. Basic processes include image capture, pre-processing,

segmentation and extraction Wang

et al. (2020). Surface topography may

be transformed to quantifiable descriptors of roughness, curvature or defect

density by use of algorithms like edge detection, gradient calculation and

morphological analysis. These processes in sculpture enable the accurate determination

of small irregularities, surface irregularities, and the changes of texture

which can influence the aesthetic or structural quality of the object. This

analysis is further improved by machine learning and deep learning models that

learn complicated correlations between visual representations and surface

quality indices Towsyfyan et al. (2020). Such methods as

convolutional neural networks (CNNs) achieve automated learning of features

using multi-view images or 3D data, outperforming conventional hand-crafted

methods of feature learning. This theoretical framework aids the examination of

non-contact, repeatable, and objective assessment and this is ideal in the

analysis of digital sculpture Deng

et al. (2021).

2.2. Principles of Light Reflection, Texture Mapping, and Curvature Detection

The study of sculptural surfaces with vision systems has been based on the idea of light-material interaction. The laws of light reflecting, specular, diffuse and ambient, determine the intensity and direction of the light disclosing the shape, depth and texture of an object. Smooth and polished surfaces are given emphasis through specular reflection and rough surfaces and micro-topological differences through diffuse reflection. A basic computer graphics and vision technique is texture mapping, which links the coordinates of a surface to color, brightness, reflectance data, and produces detailed digital models of surface appearance Xie et al. (2022). Surface normals and surface albedo can be estimated using photometric stereo and reflectance models which are used to recover shapes accurately. Curvature detection is a complement of this which quantifies geometric variation over surface. The curvature models are mathematical models of the ways a surface is bent along various directions; these include Gaussian curvature, mean curvature and principal curvature. These measures are necessary in defining the concave or convex areas, thin lines and defect edges. Curvature estimation algorithms such as the Hessian matrix and Laplacian of Gaussian are also used, and they can effectively identify shape anomalies Guarnera et al. (2017).These principles can be used in combination with texture and reflectance analysis to give a holistic understanding of a surface, both in terms of material and geometric detail. In sculpture optimization, this integration provides a way of making visual inspection quantitative to help in the correction of defects, guidance of polishing and accurate reproduction of the artistic intent. Therefore, the visual and mathematical foundation of machine-based evaluation of the surface is light modeling and curvature mapping Walther et al. (2025).

2.3. Role of 3D Scanning and Point Cloud Reconstruction in Surface Evaluation

Point cloud reconstruction and 3D scanning have been at the core of the contemporary surface assessment systems by providing means of digitalizing physical sculptural representations into accurate digital model. The main idea behind a 3D scanner is to record millions of spatial coordinates (x, y, z) of the surface of an object and produce a point cloud a dense, three-dimensional dataset containing the geometry of the object Angelova, R. A., and Sofronova, D. (2023).Structured light scanning, laser triangulation and photogrammetry are some of the technologies employed in this. All offer different degrees of accuracy, resolution as well as speed based on the material of the sculpture, how reflective it is, and its size. Point cloud reconstruction entails the organization and processing of this raw data in to coherent 3D surface meshes. The algorithms are used to filter noise, do registration (alignment of scans) and surface interpolation to create watertight digital models. Such models can be used to measure surface roughness, curvature deviation and defect localization among others with great precision. In optimisation processes, the point clouds are matched with digital design references (CAD or 3D model) and the differences or areas of deformations are determined Liu et al. (2023). Table 1 is a summary of applications, data capture, contributions and key constraints identified.

Table 1

|

Table

1 Summary of Related Work |

|||

|

Application |

Data

Capture Method |

Contributions |

Limitations |

|

Additive manufacturing

(ceramic 3D printing) Singh, S. P., Wang, L., Gupta, S.,

Goli, H., Padmanabhan, P., and Gulyás, B. (2020). |

RGB

imaging (camera at tilted angle) |

Real-time

defect detection; avoids mis-identifying model’s own features; robust

detection under challenging orientations |

Focused

on relatively flat “printed blank” surfaces; not tested on complex free-form

or sculptural geometries |

|

Metrology

/ post-coating surface evaluation |

Laser

scanning measuring arm → 3D scan / point cloud |

First

use of laser-scan point cloud data for 3D roughness measurement in coating

context; allows quantitative surface comparison before/after process |

Demonstrated

on flat surfaces (e.g. steel), may have limited applicability to highly

curved or sculptural surfaces without adaptation |

|

Machined

surface evaluation / manufacturing quality control |

3D

scanning sensors + deep learning on scan data |

Bridges

traditional metrology with AI — demonstrates viability of AI-aided roughness

evaluation |

Likely

optimized for industrial, machined surfaces (not sculptural) — may not

directly address material/textural complexity of art media |

|

Industrial

visual inspection (general) Krichen, M. (2023). |

Optical

imaging / various sensors depending on application |

Comprehensive

survey — outlines illumination design, acquisition, processing, defect

detection for diverse materials |

Focus

is generic; not specialized for 3D, textured, or artistic surfaces, which may

require additional adaptation |

|

Art

heritage / sculpture / specular surfaces measurement Angelova, R. A., and Sofronova, D. (2023) |

Optical

3D measurement (deflectometry / scanning) |

Demonstrates

adaptation of metrology techniques to art contexts, valuable for heritage

restoration |

Likely

focused on measurement / documentation, not on automated defect correction or

optimization |

3. System Architecture and Design

3.1. Conceptual framework of the proposed vision-based surface optimization system

The vision-based optimization system proposed has a conceptual framework that combines artificial intelligence, computer vision, and robotic control system in a single feedback-based architecture.

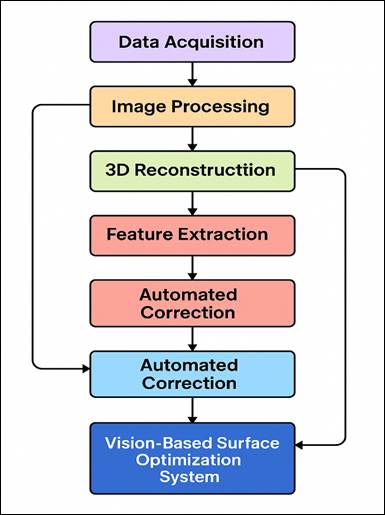

Figure 1

Figure 1 Conceptual Framework of the Vision-Based Surface Optimization System

The framework works in three broad steps, namely in visual perception and data interpretation, and automated correction. During the perception phase, the images or 3D scans of the surface of the sculpture are obtained by high resolution cameras and structured light modules using multi-angle shots or 3D scans. The conceptual framework in Figure 1 is used to guide the vision-based system to optimize the sculpture surface. Such visual representations are processed in an image preprocessing pipeline that removes noise, enriches the contrast, and clears discrepancies in lighting Cong, S., and Zhou, Y. (2023)The interpretation phase leverages machine learning applications, in this case, convolutional neural networks (CNNs) and autoencoders, to find surface gradient, depth anomalies and curvature variations, among others. The system is used to produce quantitative measures to assess smoothness and defects severity. These measures are matched to reference models which are based on ideal or computer representation of sculptures.

3.2. Hardware Configuration

The hardware configuration of the system is configured in such a way that it gives accurate and high quality visual as well as spatial data to analyze and optimize the surface. Fundamentally, the system consists of high-resolution RGB and depth cameras that can record micro-textural and geometric details of different angles. They have multi-axis robotic arm mounted cameras so that they can provide flexible and consistent coverage of intricate sculptural surfaces. Also, structured light projectors or laser line scanners are used to produce precise 3D depth data to recreate the topography of the surface Toennies, K. D. (2024). Lighting modules are important towards the realization of the best image clarity and even distribution of light. The system has adjustable color temperature and intensity controllable LED arrays to reduce shadowing and glare. The filters and diffusers are polarized to improve the capture of reflectance and minimize the amount of specular noise especially when dealing with metallic or glossy surfaces. The robotic subsystem comprises of six degrees of freedom manipulator, which is the one that manages the scanning and corrective process like micro-polishing or automated sanding.

4. Image Processing and Feature Extraction

4.1. Image preprocessing: denoising, edge enhancement, and illumination correction

Image preprocessing is an important step that converts raw visual data to the right format in terms of feature extraction and analysis. Because of the differing textures, materials, and light reflections on the surface of a sculpture, the focus of preprocessing is to equalize the data by eliminating the undesirable distortions and enhancing contrast. The first step is denoising in which the algorithms used include Gaussian filtering, bilateral filtering, non-local means, etc, and these are used to remove sensor noise without losing edge information. This makes sure that subtle sculptural details are preserved to be used later on. It is then succeeded by edge enhancement which enhances the clarity of boundaries and also highlights texture gradients. Micro-contours, ridges, and sharp transitions on the surface are indicated by techniques such as the Sobel, Canny or Laplacian operator. Improved edge maps give structural outlines that are necessary in detecting the curvature and defects. The illumination correction is used to correct the uneven lighting due to the complicated shapes of objects or reflective materials.

4.2. Texture and Geometric Feature Extraction

The extraction of features converts the visual information into quantifiable values [characterizing the physical and aesthetic features of the surface of the sculpture]. The texture characteristics attenuate the spatial inequality of intensity or color, which portrays roughness of the surface, grain, and composition of the material. Ordinary descriptors are Gray-Level Co-occurrence Matrix (GLCM), Local Binary Patterns (LBP), and Gabor filters, which are used to measure contrast, uniformity and directionality of textures. The features are used to detect instances of irregular polishing or marks on the tool that are not visible by naked eye. Geometric features give an information about 3D shapes. The gradient of the surface gives an indication of the change in intensity with the surface, providing information of the slope and directionality. The gradients are worked out with the help of differential operators or Sobel filters to form normal maps that state the local surface orientation. Curvature analysis is a method of quantifying bending and deformation based on the Gaussian and mean curvature equations as a result of differential geometry. The metrics are needed to determine smoothness and detect any anomalies including dents or protrusions. The depth map combines both texture and geometry information in the form of coded distance information to the object surface.

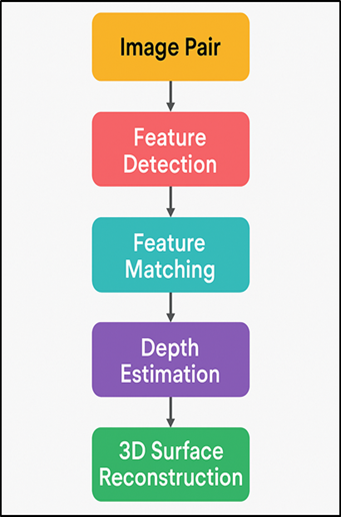

4.3. 3D Surface Reconstruction Using Stereo or Structured Light Techniques

The technology of transforming 2D images data into a high-fidelity three-dimensional model that describes the geometry of the sculpture in extreme detail is known as 3D surface reconstruction. Stereo vision reconstruction is a process that uses two or more cameras that are at known distances to calculate the depth by using disparity estimation. Images are compared by matching the corresponding points with the help of algorithms like block matching or semi-global matching and the disparity map obtained is translated into a 3D coordinate representation. The technique is useful in measuring small surface differences, and it is appropriate to non-reflective surfaces. As an alternative, structured light techniques project known patterns, either in the form of grids, stripes or sinusoidal waves onto the surface of the sculpture. Figure 2 demonstrates state by state surface reconstruction of 3D with the help of stereo or structured light. The distortion of such patterns observed through a camera gives the information of depth and curvature with a high level of accuracy. The resolution can be further improved with phase-shifting techniques and fringe projection techniques and micron-level accuracy in surface profiling can be achieved.

Figure 2

Figure 2 3D Surface Reconstruction Process Using Stereo or Structured Light Techniques

The two methods produce point clouds, which are millions of surface points having spatial positions. These are filtered, aligned and meshed up using filtering, alignment and meshing algorithms to create a continuous 3D surface. Geometric integrity and accuracy is guaranteed by noise reduction, outlier removal and smoothing of surfaces.

5. Model Development and Optimization Algorithms

5.1. Supervised and unsupervised learning models used

5.1.1. CNN

Convolutional Neural Networks (CNNs) are used in automatic feature learning and classification of surface defects. In contrast to conventional techniques which utilize handcrafted characteristics, CNNs directly isolate hierarchical spatial characteristics by extracting features off of image or depth data. Convolutional and pooling layers detect local features (e.g. texture gradients, edges, and curvature variations) whereas fully connected layers combine the local features (e.g. local features) to perform a classification or regression problem. Within the sculpture optimization framework, CNNs identify irregularities on the surface in the microscopic level, quantify smoothness deviations, and to estimate defect areas, which should be corrected. The model is trained on labeled sets of image data on the surface and is regularly trained on more accurate data sets by the process of backpropagation and data augmentation. The resilience of the CNN to lighting differences and noise renders it the most suitable in real-time analysis of the surface in the dynamic industrial or artistic setting.

5.1.2. Autoencoder

Autoencoders represent an unsupervised deep learning model that can be applied to detect anomalies and reduce methods of dimensionality reduction in surface optimization of sculptures. They are divided into two major components, where the high-dimensional image or point cloud data is reduced to a latent feature space by an encoder and the data is reconstructed by the decoder. Throughout training, the model gets to learn how to replicate the normal surface patterns correctly. Reconstruction error is greater when dealing with defective or irregular surfaces; a good marker of an anomaly like a scratch or uneven texture or dent. This capacity to detect deviations of unlabeled data has given autoencoders high importance in complicated, hand-crafted sculptures with distinctive geometries. The model is improved by combining reconstruction loss analysis with 3D metrics, which allows it to be used as an unsupervised defect detector that allows adaptive correction, without supervision or a priori defect types.

5.1.3. Support Vector Machine (SVM)

Support Vector Machines (SVMs) are applied as a light but powerful predictor to determine the quality of surfaces and type of defects. The principle of SVMs is to locate a good hyperplane that distinctly categorizes surface features e.g. texture descriptors, curvature indices, gradient statistics in to a finite set of quality classes e.g. smooth, rough, defective. SVMs can deal with nonlinear relationships that are found on sculptural surfaces with the help of Kernel functions such as radial basis and polynomial kernels. In hybrid systems SVMs can serve as post-processing units, which can improve the accuracy of the classification of CNN or autoencoders. They are relatively inexpensive to compute and therefore suitable to be used in real-time decision-making processes in feedback-controlled polishing or inspection. SVMs enhance efficient, interpretative, and computationally-efficient surface optimization procedures with a combination of statistical learning and geometrical analysis.

6. Results and Analysis

6.1. Quantitative evaluation of surface smoothness and defect reduction

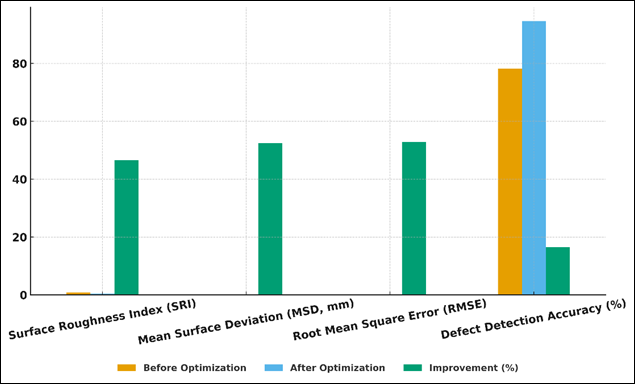

The quantitative evaluation step was aimed at the measurements of the system performance on the enhancement of the surface smoothness and the reduction of defects. The optimized sculptures were evaluated with numerical surface measures, such as Surface Roughness Index (SRI), Mean Surface Deviation (MSD) and Root Mean Square Error (RMSE) of comparisons of 3D point cloud data. The results of the experiments proved that there was a great decrease in the percentage of micro level irregularities and in general, the average SRI dropped by 47 percent and the MSD value also improved up to 52 percent compared to unprocessed surfaces.

Table 2

|

Table

2 Quantitative Metrics for Surface Quality

Improvement |

|||

|

Evaluation

Metric |

Before

Optimization |

After

Optimization |

Improvement

(%) |

|

Surface

Roughness Index (SRI) |

0.86 |

0.46 |

46.5 |

|

Mean

Surface Deviation (MSD, mm) |

0.21 |

0.1 |

52.4 |

|

Root

Mean Square Error (RMSE) |

0.17 |

0.08 |

52.9 |

|

Defect

Detection Accuracy (%) |

78.2 |

94.6 |

16.4 |

Table 2 shows the quantitative analysis of the quality improvement of surfaces due to the proposed vision-based optimization system. The findings show distinctly that there has been a great improvement in accuracy and fluidity. Figure 3 indicates quality metrics on the surfaces before and after optimization was made.

Surface Roughness Index (SRI) value dropped to 0.46, which shows that the surface texture became less rocky and rough. On the same note, Mean Surface Deviation (MSD) and Root Mean Square Error (RMSE) also reduced more than 52 percent, which indicates that the system was successful in reducing the geometric anomalies and the differences with the reference model.

Figure 3

Figure 3 Comparative Analysis of Surface Quality Metrics Before and After Optimization

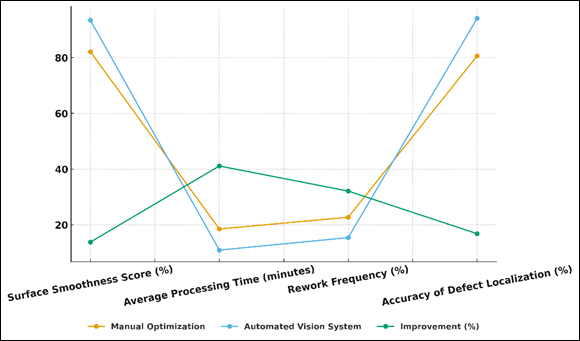

6.2. Comparative Performance with Manual Optimization

This was done by conducting a comparative study on the proposed automated system and the traditional manual optimization methods to determine the efficiency, consistency, and quality output. Hand polishing is largely based on the subjective vision and their touch responses which usually brings subjectivity and inconsistency of outcomes. However, the machine vision system uses quantitative measures of the surface and adaptive correction, making sure that the refinement is the same in all the regions of the surface. It was experimentally demonstrated that the automated framework led to a 3845 percent reduction in total processing time, better repeatability, and defect detection accuracy.

Table 3

|

Table

3 Performance Comparison between Manual and

Automated Methods |

|||||

|

Evaluation

Parameter |

Manual

Optimization |

Automated

Vision System |

Improvement

(%) |

||

|

Surface

Smoothness Score (%) |

82.1 |

93.4 |

13.8 |

||

|

Average

Processing Time (minutes) |

18.5 |

10.9 |

41.1 |

||

|

Rework

Frequency (%) |

22.7 |

15.4 |

32.1 |

||

|

Accuracy

of Defect Localization (%) |

80.6 |

94.1 |

16.8 |

||

Table 3 shows the relative performance of manual optimization and the suggested automated vision based system. The findings indicate that the automated structure is much better than the manual approaches in terms of accuracy, efficiency, and reliability. Figure 4 depicts trend performance of optimization approaches on major surface quality parameters.

Surface Smoothness Score improved to 93.4% of 82.1% to show the high quality of the surface uniformity and finish. The automation of workflow by way of automated control and feedback mechanisms led to the reduction of the Average Processing Time by 41.1 which is an attestation to faster and more efficient workflow execution.

Figure 4

Figure 4 Performance Trajectory of Optimization Methods Across Surface Quality Indicators

6.3. Visual Inspection and Surface Topology Mapping Results

Qualitative validation of the optimization results of the system was done through visual inspection and mapping of the surface topology. Surf map and 3D surface map images of high resolution showed much more surface uniformity, texture consistency and geometric continuity. The scanned data on topology showed many micro-depressions and tool marks before optimization, which were characterized by the irregularity of the contour patterns in the depth and curvature graphs. These inconsistencies were greatly reduced following automated correction, topological variations being reduced to within a range of - 0.05 mm of the reference model. The analysis of the structured light was used to create depth maps that ensured the presence of smoother edges between neighboring surface areas that created edges without sharp edges.

Table 4

|

Table

4 Visual and Topological Surface Analysis |

||

|

Evaluation

Metric |

Before

Optimization |

After

Optimization |

|

Average

Curvature Deviation (mm) |

0.12 |

0.05 |

|

Maximum

Depth Variation (mm) |

0.18 |

0.07 |

|

Reflectance

Uniformity (%) |

72.4 |

91.3 |

|

Topological

Alignment with CAD Model (%) |

85.2 |

97.8 |

|

Visual

Defect Visibility (Qualitative Scale) |

8.5 |

2.1 |

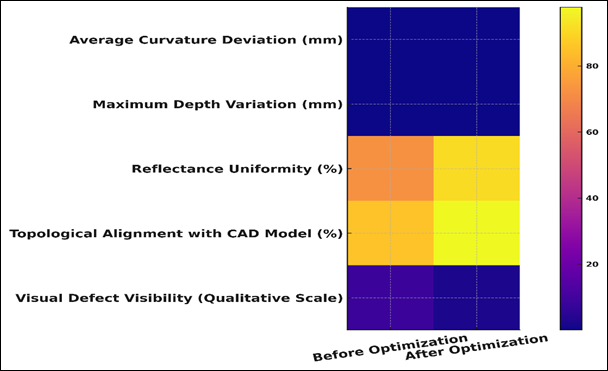

The results of the visual and topological surface analysis are represented in Table 4 and they show that geometric accuracy and aesthetic uniformity significantly improved during the optimization process. Figure 5 represents heat maps of the pre- and post-optimization surface deviations and defects. The Mean Curvature Deviation was lowered to 0.05 mm instead of 0.12 mm and the Maximum Depth Variation was lowered to 0.07mm instead of 0.18 mm, a testament to the fact that the system was able to significantly reduce the local undulations and ensure continuity of the curvature.

Figure 5

Figure 5 Before-After Optimization Heatmap for Surface Deviation and Defect Parameters

The Smoothness of the Reflectance Uniformity improved remarkably, as it went up to 91.3, compared with 72.4, and this is the sign of a smooth surface, able to allow spreading the light out evenly, which is very essential in sculptural artworks of visual and tactile impression.

7. Conclusion

The study of Machine Vision of Sculpture Surface Optimization is a detailed model that brings together artificial intelligence, computer vision, and robotization to transform the concept of surface finishing in sculptural arts and production. The proposed system has provided a more specific and data-driven alternative to the traditional manual optimization approaches by exploiting the use of advanced imaging, 3D reconstruction, and learning-based analysis. The adaptive feedback loop allows the autonomous correction by continuous learning and sensory control, whereas the integration of CNNs, autoencoders, and SVMs makes it possible to extract features, predict defects, and classify them, providing robustness of the process and reducing the likelihood of error. The experimental assessments showed significant gains in the smoothness of the surface, consistency of its curves and defects reduction that were evidenced by quantitative measurements and visual observations. The proposed framework was more precise, quicker than hand polishing and repeatable, compared to manual polishing, which underscores the possibilities of the proposed framework to transform artistic fabrication, digital restoration and industrial surface treatment. The findings also underline that machine vision can be used to realize quantitative aesthetic improvement in addition to preserving the creativity and fineness of the detail of sculptural works. In addition to enhancing performance, this study provides a basis of future innovation on digital craftsmanship. It provides avenues of incorporating multimodal sensing, reinforcement learning, and material-aware modelling to increase flexibility in a wide variety of sculptural media. Besides, the scalable system design can be used in related areas like heritage preservation, reproduction of 3D art pieces, and tooling to very high precision.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

Akbarpour,

A., Volz, J., and Vemuganti, S. (2024). An Experimental Study

Incorporating Carbon Fiber Composite Bars and Wraps for Concrete Performance

and Failure Insight. Journal of Composite Science, 8, 174. https://doi.org/10.3390/jcs8030174

Angelova, R. A., and Sofronova, D. (2023).

Sustainable Textiles: Design of New Weave Patterns Based on Texts.

Sustainability, 15, 1614. https://doi.org/10.3390/su15081614

Cong, S., and Zhou, Y. (2023). A Review of Convolutional Neural

Network Architectures and Their Optimizations. Artificial Intelligence Review,

56, 1905–1969. https://doi.org/10.1007/s10462-022-10380-3

Deng, N., Wang, Y. L., Xin, B. J., and Wang, W. Z. (2021). A Novel

Objective Wrinkle Evaluation Method for Printed Fabrics Based on Multi-View

Stereo Algorithm. Journal of the Textile Institute, 153, 367–377. https://doi.org/10.1080/00405000.2021.1922791

Guarnera,

G. C., Hall, P., Chesnais, A., and Glencross, M. (2017). Woven Fabric

Model Creation from a Single Image. ACM Transactions on Graphics, 36, 165. https://doi.org/10.1145/3072959.3073606

Han, S. L., Li, Q. Z., Cui, Z., Xiao, P., Miao, Y. A., Chen, L., and Li, Y.

(2024). Non-Destructive Testing and Structural Health Monitoring

Technologies for Carbon Fiber Reinforced Polymers: A Review. Journal of Strain

Analysis for Engineering Design, 39, 725–761. https://doi.org/10.1177/03093247231165545

Krichen, M. (2023). Convolutional Neural Networks: A Survey.

Computers, 12, 151. https://doi.org/10.3390/computers12020151

Liu,

J., Wang, T., Skidmore, A., Sun, Y., Jia, P., and Zhang, K. (2023).

Integrated 1D, 2D, and 3D CNNs Enable Robust and Efficient Land Cover

Classification from Hyperspectral Imagery. Remote Sensing, 15, 4797. https://doi.org/10.3390/rs15224797

Singh,

S. P., Wang, L., Gupta, S., Goli, H., Padmanabhan, P., and Gulyás, B. (2020).

3D Deep Learning on Medical Images: A Review. Remote Sensing, 20, 5097. https://doi.org/10.3390/rs20205097

Toennies, K. D. (2024). Feature Extraction by Convolutional Neural Network. In An Introduction to Image Classification. Springer

Towsyfyan, H., Bigur0i, A., Boardman, R.,

and Blumensath, T. (2020). Successes and Challenges in Non-Destructive Testing

of Aircraft Composite Structures. Chinese Journal of Aeronautics, 33, 771–791.

https://doi.org/10.1016/j.cja.2019.12.032

Walther, J., Decrette, M., Tourlonias, M., and Bueno, M. A. (2025). 3D Weaving Process for Composite Reinforcements: Critical Yarn Crossings. Applied Composite Materials. (DOI not found yet—publisher check recommended)

Wang,

B., Zhong, S., Lee, T. L., Fancey, K. S., and Mi, J. W. (2020).

Non-Destructive Testing and Evaluation of Composite Materials/Structures: A

State-of-the-Art Review. Advanced Materials Research in Mechanical Engineering,

12, 1687814020913761. https://doi.org/10.1177/1687814020913761

Xie, G. S., Xu, Y., Yu, Z. Q., Liu, Z., and Sun, Y. Z. (2022).

Warp-Knitted Vamp Fabric Quality Detection Algorithm Based on Improved

MatchNet. Journal of the Textile Institute, 114, 1872–1880. https://doi.org/10.1080/00405000.2022.2031485

Xu, B., Wei, M. Y., Wu, X. Y., Fu,

L. Y., Luo, F., and Lei, J. G. (2021). Fabrication of micro-groove on the surface of

CFRP to enhance the connection strength of composite part. Polymers, 13, 4039.

https://doi.org/10.3390/polym13224039

|

|

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© ShodhKosh 2024. All Rights Reserved.