ShodhKosh: Journal of Visual and Performing ArtsISSN (Online): 2582-7472

|

|

Management of Digital Printing Studios with AI Tools

Dr. Angad Tiwary 1![]()

![]() ,

J. Priyadharshini 2

,

J. Priyadharshini 2![]()

![]() ,

Aarfa Rajput 3

,

Aarfa Rajput 3![]() , Dr. Monalisa Mohanty 4

, Dr. Monalisa Mohanty 4![]()

![]() ,

Dr. A. Veeramuthu 5

,

Dr. A. Veeramuthu 5![]()

![]() ,

Savinder Kaur 6

,

Savinder Kaur 6![]()

![]() ,

Aditi Ashish Deokar 7

,

Aditi Ashish Deokar 7![]()

1 Professor, Department of Management,

Arka Jain University Jamshedpur, Jharkhand, India

2 Department of Computer Science and

Engineering Aarupadai Veedu Institute of Technology,

Vinayaka Mission’s Research Foundation (DU), Tamil Nadu, India

3 Professor School of Journalism and Mass Communication, Noida,

International University, 203201, India

4 Associate Professor, Department of Centre for Internet of Things,

Siksha 'O' Anusandhan (Deemed to be University),

Bhubaneswar, Odisha, India

5 Professor, Department of Information Technology, Sathyabama

Institute of Science and Technology, Chennai, Tamil Nadu, India

6 Centre of Research Impact and Outcome, Chitkara University, Rajpura-

140417, Punjab, India

7 Department of Electronics and Telecommunication Engineering,

Vishwakarma Institute of Technology, Pune, Maharashtra, 411037, India

|

|

ABSTRACT |

||

|

Digital

printing studios have been growing at a rapid pace, which has resulted in a

pressing demand of smart, automated and scalable management tools that can

support high volume manufacturing, various materials and multiple design

types and deliver within strict deadlines. Conventional studio processes,

including job intake, color correction, resource allocation and quality check

are in most cases manualized, fragmented and liable to inefficiencies that

lower productivity and consistency. In this paper, the author suggests a

unified AI-based management system of digital printing studio, based on the

application of machine learning, computer vision, and predictive analytics to

improve workflow automation, operational intelligence, and human-machine

interaction. The system architecture has real-time data acquisition,

automated job logging, print pipeline monitoring, and dynamic scheduling

algorithms as part of it to optimize machine use and material flow. AI-based

tools assist in pre-press optimization, color correction, layout

optimization, prediction of queue and minimization of material, hence

optimizing throughput and minimizing wastage. Moreover, to provide

operational transparency and skill improvement, the design interface,

training recommendations, and human-in-the-loop decision verification powered

by AI are included in the framework. |

|||

|

Received 14 April 2025 Accepted 20 August 2025 Published 25 December 2025 Corresponding Author Dr. Angad

Tiwary, dr.angad@arkajainuniversity.ac.in DOI 10.29121/shodhkosh.v6.i4s.2025.6834 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2025 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Digital Printing Management, AI-Driven Workflow

Optimization, Predictive Maintenance, Computer Vision in Printing, Quality

Control Automation |

|||

1. INTRODUCTION

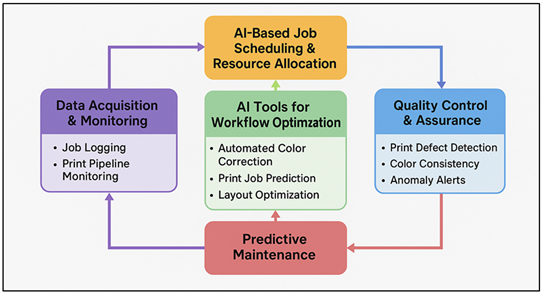

Digital printing studios have become complicated and fast-paced production facilities that need to be creative, customized, and efficient. In contrast to the traditional offset printing, digital printing can work with short-run, on-demand, variable-data and personalized jobs- hence it is the most desired choice of advertising agencies, textile studios, pack-providers, and commercial print houses. Nonetheless, this flexibility brings a lot of problems associated with scheduling, color accuracy, use of materials, pre-press preparation, machine upkeep, and quality consistency. With the growing demand of fast turnaround and high-precision printing, the manual or semi-automated workflow is not sufficient any longer. They tend to create bottlenecks, overloading of operators, unpredictability of machine down-time and poor quality output. In that regard, the implementation of Artificial Intelligence (AI) has become a revolutionary possibility of reinventing the operations of digital printing studios. AI has provided high-quality real-time decision-making, automation, and predictive analytics components, which collectively directly solve the operational limitations of the contemporary print environment. The use of machine learning can examine historical print job information, equipment performance history and environmental factors to optimize scheduling and resource usage Subeshan et al. (2024). Print defects can be automatically detectable through computer vision, and this means that quality will be better realized. The deep learning models facilitate prediction of colors, calibration and consistency across substrates and across machines. Predictive maintenance systems also contribute to minimization of operational disruptions as they are able to detect the early signs of equipment wear and tear or component failure thereby minimizing downtime and extending life of the machine. Further, the optimization of workflow is increased with the help of AI to improve the efficiency between the pre-press and post-production. Automation tools may examine inbound artwork, spot the mistakes and propose corrections and produce optimized layouts that reduce the amount of wasted material. Smart job estimation methods are able to forecast the printing time, ink usage and delivery time with accuracy Thomas (2022). AI-based queue management will make sure that priority or time sensitive jobs are automatically served without much human intervention and hence a lot better throughput is achieved. Figure 1 depicts combined AI modules that are used to optimize design, scheduling and printing processes. Another critical AI integration aspect is human-machine collaboration. AI does not substitute human skills; on the contrary, it enhances the functions of operators by offering smart recommendations, intelligent training, and personal assistance.

Figure 1

Figure 1 System-Level Architecture of AI Tools for Optimized Digital Printing Management

Artificial intelligence tools can also help designers and operators match colors, refine its layout, and correct visuals, as well as minimize many manual tasks and allow designers to make creative decisions. Recommendation systems will be able to assist the employees to acquire new skills according to the needs of the studio, as well as personal performance. The human-in-the-loop brings about the critical creative and quality-sensitive decisions that have to be made based on the professional judgment and contextual knowledge Boretti (2024). The shift to AI-driven digital printing is also motivated by the growing demand of the customers to be personalized, accurate, and fast. Quality inspection systems based on AI increase consistency of prints, thus increasing customer trust.

2. Literature Review

2.1. Traditional digital printing management practices

In traditional digital printing management, manual coordination, operator experience, and workflow sequence is a significant element. They usually involve preparation of artwork, correction of colors, substrate choice, job scheduling and machine setup; jobs that require a high level of human skills and time. In order to facilitate job intake, order tracking and print queue management, studios have separate systems, which are fragmented leading to inefficiencies. One of the most difficult areas is still color management since to ensure consistency between various printers, ink sets and substrates requires calibration routines that are often operator-dependent Metal (2023). Printing output may be subject to inconsistency and subjectivity in quality assurance by having to manually check and inspect printed output as to defects including banding, misalignment, color drift, and substrate irregularity. Also, in conventional studios, there is a tendency to use reactive maintenance, i.e. to service the machine only after the apparent problems occurred, which causes downtime, delays, as well as unforeseen repair expenses. The grounds on which jobs are scheduled are usually the intuition of the operators resulting in inefficient allocation of resources and prolonged turnaround periods. Manual optimization of material usage is also cumbersome, which leads to the increase in the amount of waste, particularly in high-volume or variable-data printing. Although the conventional systems have aided decades of digital printing process, growing customer demands of personalized products, speed, and accurate production, and the conventional systems are being limited Srivastava et al. (2025). These limitations have led to adoption of smart, automated processes that can provide more accuracy, scalability and efficiency.

2.2. AI in Print Media, Design Automation, and Production Systems

Artificial Intelligence has played a major role in the print media and digital manufacturing, bringing in automation, predictive analytics and intelligent design support. AI-based design software makes it possible to create layouts automatically, improve images, color correction, and optimized typefaces, saving time and the input efforts of pre-press processes. Before printing, computer vision models are capable of analyzing print-ready files to identify inconsistencies in designs, poor quality images, font embedding errors, and misalignment of layouts Wang et al. (2023). This robotized pre-press check helps to reduce human error as well as quicken approval-cycles. The use of AI in production systems is in real time monitoring, predictive maintenance and automated detection of defects. Machine learning algorithms compare the data produced by the printers, such as temperature, ink flow, nozzle action and motor speed to forecast the error taking place beforehand. This eliminates downtime of machines and improves on the general reliability Freeman et al. (2022). Table 1 provides significant research on AI-based workflows and quality assurance systems. Compared to human inspection, deep learning algorithms detect print flaws (streaks, smudges, color mismatch, etc.) more successfully and save resources by minimizing the amount of reprints that are associated with quality concerns.

Table 1

|

Table 1 Summary on AI Tools, Workflow Optimization, and Quality Control in Digital Printing Studios |

||||

|

Domain Focus |

AI / ML Technique Used |

Application Area |

Dataset / Input Source |

Outcome / Improvement (%) |

|

Digital printing workflow |

CNN-based detection |

Pre-press automation |

Artwork files, pre-press logs |

32% reduction in pre-press errors |

|

Color

calibration Chen et al. (2023) |

Deep Neural Networks |

Color

correction |

Color

swatches, ICC profiles |

27% improved color

accuracy |

|

Print scheduling |

Reinforcement Learning |

Job sequencing |

Print job history |

38% increase in throughput |

|

Print defect detection |

Computer Vision (CNN) |

Quality control |

Printed sample scans |

42% reduction in defect rates |

|

Material usage |

Genetic Algorithms |

Layout optimization |

Pattern layouts |

21% material savings |

|

Predictive maintenance |

LSTM + anomaly detection |

Maintenance forecasting |

Sensor logs, machine telemetry |

44% reduction in downtime |

|

Workflow automation |

ML workflow models |

End-to-end pipeline |

Studio ERP + job logs |

29% cycle-time reduction |

|

Client design Yeshiwas et al. (2025) |

GAN-based image enhancement |

Client-facing design tools |

Customer-uploaded designs |

33% faster approval time |

|

Queue optimization |

Multi-agent AI scheduling |

Resource allocation |

Multi-printer job logs |

36% better printer utilization |

|

Textile printing |

Hybrid DL calibration |

Textile print color

control |

Fabric profiles |

25% reduction in color

mismatch |

|

Print anomaly monitoring |

Autoencoder-based anomaly detection |

Real-time QC |

Sensor + vision stream |

41% faster anomaly intervention |

|

Variable data printing Zhou et al. (2024) |

ML-based error prediction |

VDP automation |

VDP template datasets |

34% drop in VDP defects |

|

Studio-wide optimization |

AI-integrated management systems |

Multi-stage optimization |

Combined logs + analytics |

40% productivity improvement |

3. System Architecture for AI-Driven Digital Printing Studios

3.1. Data acquisition, job logging, and print pipeline monitoring

An efficient AI-based digital printing framework starts with an extensive data collection, consistent job identification, and in-time pipeline surveillance. Data acquisition entails the process of gathering high frequency operational information of printers, scanners, RIP (Raster Image Processor) programs, environmental sensors, and workflow management systems. Examples of such data streams are ink levels, printhead temperatures, nozzle performance indicators, substrate type, resolution settings, file properties, and job related indicators. Intelligent analytics and automation are based on such granular data. Job logging is a significant aspect to determine historical traceability and performance benchmarking Sturm (2020). The systems with AI automatically capture the information about each print job, file metadata, operator activity, processing time, occurrence of errors, quality check outcomes, and customer requirements. This abrupt logbook allows deep learning models to identify repetitive problems, come up with performance-based insights, and facilitate the decision-making process in relation to scheduling and maintenance. Print pipeline monitoring enables each process such as pre-press, RIP processing, print initiation, finishing and dispatch to be synchronized and optimized Yampolskiy et al. (2022) . The real-time dashboards give the operators an insight into the progress, status of the queue, the approximate time of job completion, and the way of resources used. AI-based surveillance systems will be able to detect irregularities like unforeseen delays, color change, or mechanical irregularities, and send a notification or automatic remedy.

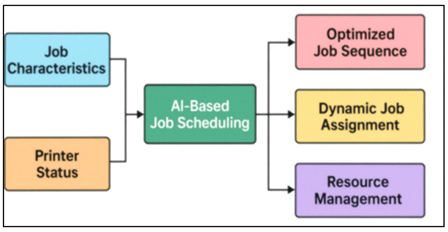

3.2. AI-Based Job Scheduling and Resource Allocation

Job scheduling and resource allocation are also very important to achieve high throughput in digital printing studios. AI-based scheduling systems are based on machine learning algorithms that are used to prioritize jobs, assign printers and optimize materials utilization through real-time and past-based information. These systems compute a wide range of variables, including job size, complexity, substrate compatibility, availability of printers, requirements of ink, and deadlines in customers. Through history, AI models would anticipate the time in processing, and optimize the scheduling plans to reduce the number of bottlenecks and improve turnaround time. Resource allocation entails the smart allocation of workloads to various printers, finishing equipment, and workstations.

Figure 2

Figure 2 AI-Driven Job Scheduling and Resource Management

Framework

AI is used to evaluate the health of the machine, the queue that is awaiting processing, the color calibration level, and the level of operator expertise to find out which resource is best to allocate to any given job. Figure 2 demonstrates how AI modules optimise job scheduling and allocation, as well as optimisation of workflow. As an instance, high-color-accuracy prints can be sent to machines that are recently calibrated and in which the environment remains constant. AI also suggests the best batch grouping of related print jobs to minimize setup and overhead of ink switching Haque and Naebe (2023). Dynamic reallocation takes place when unforeseen shocks like machine failures, shortages in supplies or emergent jobs come up. The AI systems automatically make schedule changes, reroute, operator notification, and recalculate completion estimates.

3.3. Predictive Maintenance Using ML Models

Predictive maintenance is one of the foundations of AI-based digital printing studios, as it allows the system to alert about potential equipment malfunction in time and avoid expensive downtime. Machine learning algorithms are used to detect abnormal operation conditions by analyzing continuous sensor data e.g. printhead temperature, vibration patterns, motor torque, nozzle firing behavior, and ink pressure. ML algorithms can forecast when the components will break down or fail by understanding the patterns that occur before failures happen Kennedy et al. (2025) . Such predictive insights are what enable the studio managers to plan to conduct maintenance activities, instead of responding to unforeseen failures. Indicatively, models have the ability to predict printhead clogging, roller wear or drifted alignment, which causes timely service responses. Predictive alerts can assist operators in preventing emergency repairs, interruptions in jobs, as well as prolonging the service life of machines. Scheduling of maintenance based on data also helps in optimizing inventory of spare parts and reduction of futile service process. Rather than a regular check that is done at some specific time intervals in the process of maintenance, ML-based maintenance makes sure that the intervention is done at the point of need. Digital twins improve this and simulate the performance of printers when they are loaded with various loads, stress points, and the correctness of maintenance plans Hassan et al. (2024). The print management system is also integrated so that the predicted failures automatically affect the scheduling decision. Jobs are recast off machines that indicate risks, minimizing the amount of print defects and maximizing customer satisfaction.

4. AI Tools for Workflow Optimization

4.1. Automated color correction and pre-press enhancement algorithms

AI can be extremely useful in automated color correction and pre-press enhancement, which greatly enhance the accuracy, consistency, and efficiency of printing. Conventional color management is very much dependent on operator control, ICC profiles, and manual manipulations which frequently result in human error, time consuming trial and error, and varying outcomes on substrates. The color correction systems that are based on AI surpass these restrictions by using deep learning models that are trained using massive datasets of print samples and color charts as well as device-specific calibration information. These models are trained to predict correct color outputs, correct printer variation, and reproduce consistently using materials not observed to be specific to the model. The incoming files of artwork are analyzed using AI algorithms to spot the problems of low resolution, incorrect color space conversions, font missing, or layout incorrect alignment. Automated pre-processing tools are capable of automatically adjusting tone curves, sharpening images, balancing, and fixing the occurrence of undesirable exposure differences.

4.2. Print Job Prediction, Time Estimation, and Queue Optimization

The predictive and optimization systems, which can be supported by AI, are very helpful in the digital printing studio, and assist in enhancing its efficiency by offering correct job foretelling, accurate time estimations, and clever queue resolution. Machine learning algorithms process historical job information, speed of the printer, printer resolution, substrate type, and print complexity to estimate processing times in high accuracy. This allows studios to create consistent delivery schedules and convey expectations to customers as well as organize resource allocation in a more efficient manner. The ink usage, power consumption, and wear to mechanical components can also be calculated by print job prediction models, and this allows estimating the cost and providing proactive inventory management. Knowing the difficulty of the job and the capabilities of the machine, AI systems forecast the possible bottlenecks and suggest optimal job sequences. Smart rearrangement of tasks is used to minimise idle time and maximise throughput by using queue optimization which employs reinforcement learning, genetic algorithms, or heuristic clustering. The urgent jobs or high priority can automatically be raised in queue according to the deadlines or the client priority whereas bulk print jobs may be bundled in order to minimize the cost of setting up the print job. In case of the interruptions, which can be machine failures, urgent additions, or unavailability of operators, AI dynamically changes the queue in real time.

4.3. AI-Based Layout Optimization and Material Minimization

The other significant issue with digital printing is the material wastage particularly in packaging, textile printing, signage and large format printing. AI-assisted layout optimization software can help solve this problem since it can strategically position print objects on the substrate to achieve maximum space utilization and minimized waste. Conventional algorithms of nesting use the standard rules of geometry, whereas the models of AI-enhanced nesting use deep learning, heuristic optimization, and evolutionary algorithms to ensure high efficiency in packing. Artificial intelligence programs are used to determine the dimensions of artwork, the size of the substrate, cutting, and orientation principles of prints to produce an ideal layout autonomously. They consider various nesting conditions and choose the arrangements that are the least invasive of unused area with the quality of print and the accuracy of a cut. In printing on textiles and garments, AI is used to optimize the location of patterns in order to minimize waste which improves sustainability and decreases the costs of production.

5. Quality Control and Assurance through AI

5.1. Computer vision for print defect detection

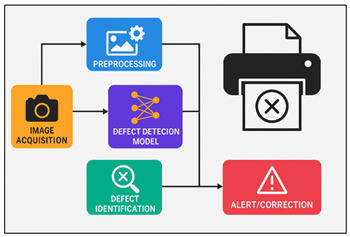

Computer vision has been applied in transforming the world of automation of print defects detection where subjective manual inspection is replaced with accurate real-time images analysis. Conventional inspection techniques are frequently not able to detect fine flaws as micro-banding, dot gain variations, streaking, registration, smudges or subtle color variations, especially at high production rates.

Figure 3

Figure 3 Computer Vision Architecture for Real-Time Print Defect Detection

Computer vision systems that are powered by AI are equipped with high-resolution cameras, scanners, and light producers to read print streams continuously. In Figure 3, the vision-based layers identify print defects in real time and with high precision. The convolutional neural networks (CNNs) that are trained to identify a vast amount of defects in different substrates and print technologies process these images. Computer vision algorithms measure deviations by a reference at the resolution of the printed output when compared to the reference of what the computer should see. They create visibility of defects that a human operator can be missing particularly when production is over a long period and the operator is tired hence cannot give full concentration.

5.2. Deep Learning for Color Consistency and Calibration

Color consistency has been a vital issue of digital printing because clients are demanding a consistency of output between dissimilar printers, batches and substrates. Deep learning also makes it possible to approach the calibration of colors more advanced and adaptive than fixed ICC profiles and manual adjustments. The AI systems can be trained to predict the physical color behavior of a specific printer by using massive datasets of printed samples, color targets and printer performance histories to learn to model realistic color behaviors, device variations, and substrate-specific color shifts. Deep Learning models are used to scan print results real-time and compare them to the reference color values. They automatically correct deviations due to aging of inks, wear on printheads and environmental variations and mechanical drift. These models also keep refining their predictions and this makes them capable of offering dynamic calibration, without necessarily having them recalibrated via manual recalibration routines. The GAN-based methods are able to generate correct color representations even without the input artwork/print conditions being similar. Cross-device consistency can also be promoted by use of AI-based calibration tools which makes sure that colors are valid under both laser and inkjet printing, as well as, textile and big-scale printing. Auto-suggestions of changing ink density, gamma values and tonal curves are advantageous to the operators. Other sophisticated systems are combined with spectrophotometers and sensors to do closed-loop color corrections.

5.3. Real-Time Anomaly Alerts During Printing

AI-based real-time anomaly detection systems are proactive systems that ensure quality by checking printing conditions as well as output during continuous process. Such systems are the ones which gather live data feeds of sensors, cameras, printhead diagnostics, environmental monitoring systems and logs. Machine learning algorithms identify anomalous tendencies (sudden changes in color, unexpected stoppage, clogged nozzles, temperature changes, misalignment of the substrates, etc.), even before they turn into significant faults. The anomaly detecting models, such as autoencoders, LSTM models, and statistical learning models, create a point of normal printing behavior. Deviations are detected and alerted to operators via dashboards, mobile applications or built-in control panels. This fast feedback mechanism enables quick corrective measures to be taken that eliminates the need to reprint and re-lost cost of production is eliminated. Other sophisticated systems can react automatically to anomalies by setting print parameters, redistributing jobs or by starting maintenance routines. As an example, when a printhead is found to be not firing at a consistent rate, the system can change ink pressure, set up cleaning cycles or reroute the job to a different printer. These programmed reactions reduce the downtimes and print accuracy. Long-term analytics is also achieved through real-time anomaly alerts. All identified abnormalities are recorded, coded, and aligned to how machines are used, the environment or the activities of the operators. This historical information is helpful in predictive maintenance and constant optimization of the workflow.

6. Human–Machine Collaboration and Skill Enhancement

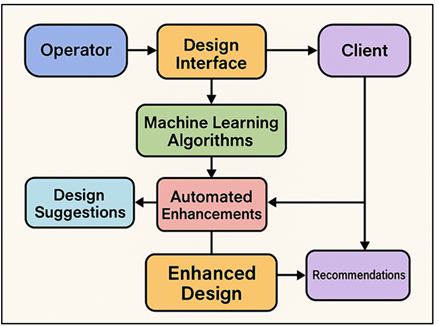

6.1. AI-assisted design tools for operators and clients

The AI-based design solutions are applicable to digital printing processes and can be used extensively to boost creativity, efficiency, and usability through helping operators and clients in the visualization of the visualization process. These applications use machine learning models, generative algorithms, and smart interfaces to take complicated tasks like layout creation, color matching, typography, and image enhancement, etc. The interactive AI tools in Figure 4 enable the collaboration of design and efficiency in creativity. To operators, AI minimizes the need to manually adjust files with artificial intelligence making automatic recommendations on how to optimize file resolution, fix distortions, sharpen files, or adjust artwork to fit a substrate and print size.

Figure 4

Figure 4 AI-Assisted Design Tools for Operators and Clients

This allows the designers to focus on greater creative decisions and not on technical corrections in routine. The AI-based interfaces also provide user-friendly customization experiences to the clients. Recommendation engines propose templates of designs, font, and color combinations, depending on the goals of the project, user choice, and previous choices. On-the-fly previews created by using deep-learning-based image synthesis enable the clients to see final print results with high fidelity, without having to print a single line before the production process starts. This eliminates the barriers of communication, accelerates the process of approval as well as guarantees customer satisfaction.

6.2. Personalized Training Using Recommendation Systems

The operational excellence in digital printing studios largely depends on training and skill development because technologies are changing at a very fast rate. AI-driven recommendation systems are critical within the context of providing individual operator-focused training routes based on their specific requirements, skills, and performance patterns. These systems examine information relating to the operator interactions, job handling efficiency, error rate, and quality assessment to identify areas that need improvement. The analysis is used to recommend specific learning modules, tutorials, practice activities, or skill-development activities based on the analysis. In new operators, recommendation systems can be used to speed up the onboarding process by discovering the underlying skills, whether handling substrates, color calibration or RIP configuration that need to be highlighted. In the case of advanced staff, the system attracts areas like machine-specific maintenance procedures, intricate layout planning, or data analytics. AI is able to adjust training intensity and frequency according to user progress as well, which will continuously allow development where the learners are not overwhelmed with it.

6.3. Human-in-the-Loop Decision Validation

In spite of the increasing potential of AI in digital printing processes, manual abilities are still needed in terms of contextual accuracy, artistic authenticity, and ethical judgment. Human-in-the-loop (HITL) decision validation is a type of decision validation system using a combination of both human judgment and machine intelligence to establish a middle ground where machine intelligence performs routine decision-making tasks but human judgment is involved in important decision making. The HITL systems also enable the operators and managers to review AI-generated suggestion like color corrections, defect classification, changed schedules, or maintenance alerts before they are implemented. This participatory approach minimizes the possibility of excessive dependence on automated outputs, particularly in a situation where creative subtlety, brand perception, or client needs need to be read very closely. To use the example, the AI might provide an alert about color differences, but the ultimate tonal curves adjustment can be determined based on the artistic inclination or the purpose of the project.

7. Case Studies and Experimental Evaluation

7.1. Performance benchmarking of AI-assisted studios vs. traditional studios

The benchmarking of performance will help to reveal the key details on the superiority of AI-assisted digital printing studios in comparison to traditional and manually controlled settings. Cases, in comparative case studies, studios that implemented AI-based workflow automation, predictive maintenance and intelligent scheduling were always found to be more efficient in their operations. Studios with AI assistants have attained high rates of machine utilization by optimization of job sequence, and minimized downtimes. The pre-press checks and color correction tools were automated so that the preparation cycles were reduced to a minimum and, therefore, the jobs could be started faster. Predictive maintenance helped to cut down the unplanned downtime as the problem in every system is detected beforehand and the proactive service interventions are planned. Conversely, the conventional studios had a massive dependence on the experience of operators during scheduling and troubleshooting which led to frequent bottle necks and inadequate turnaround time. Subjective quality assessment was also aided by manual inspection and it also took too long to detect the defect and this made rework rates higher. Also, the traditional environments did not have real-time analytics, and this incapacitated them to quickly adjust to the changing workloads or the sudden demand of customers. The throughput of AI-assisted studios was significantly upgraded by 20 to 40 percent, depending on the complexity of the job and the variety of equipment. Their rate of detecting defects was significantly better, which was due to the computer vision-based inspection. In these studios, the reproduction of colors was also more consistent and the errors associated with the substrates were reduced. The benchmarking outcomes show clearly that integrating AI increases reliability, responsiveness, and quality of print and allow a studio to work with more volumes without operational disruptions.

7.2. Quantitative Metrics: Throughput, Defect Rate, Turnaround Time

Quantitative measures of evaluation emphasize the objective benefits that AI-based printing processes present. Throughput which is determined by the number of finished print jobs per hour or per shift improved tremendously in the AI-enhanced studios. The analysis of the job distribution was optimized to minimize idle time and to make similar tasks be bundled together, based on machine learning-powered scheduling algorithms. The results of data obtained during case study indicated that throughput rose by 25-38 percent depending on the substrate material and complexity of the job. Defect rate that is a crucial measure of quality performance dropped significantly in AI-assisted operations. The computer vision systems detected slight flaws with almost human or even better accuracy, color flaws, banding, misregistration, or smudges at an early stage in the production process. The defect rates in traditional studios are 8-12 percent and in AI-assisted studios, it is about 3-6 percent, which helps to save reprints and waste of materials significantly. The automation of the pre-press facilities, job time prediction, and optimization of the queues resulted in better turnaround time. With the help of AI-based estimation systems, studios were able to better predict the length of jobs, therefore, better scheduling and more accurate commitments of delivery were possible.

8. Conclusion

The introduction of Artificial Intelligence in the management of digital printing studios is a dominating change to smarter, more resilient, and most optimized production spaces. The study shows that AI-based solutions significantly increase all parts of the printing process, including the pre-press preparation and job invitation, real-time monitoring, job defects, and post-production analysis. Using machine learning, computer vision, and predictive analytics, digital printing studios can cut inefficiencies, lessen wastage of materials and improve the print consistency and throughput. The product is an agile operational model that can address rising needs of customization, speed and accuracy in the current competitive print environment. The AI tools are not only automated but also enhance the human inventiveness and expertise. The intelligent design support, dynamic training support systems, and visible decision support systems are of help to the operators and the clients because they enhance the human machine collaboration. With human-in-the-loop validation, automated recommendations are made to be in line with the artistic expectations, brand standards, and contextual needs. Anomaly detection and predictive maintenance also increase the reliability by avoiding unforeseen downtimes and ensuring longer services of the equipment. In this work, the case studies and comparison of the results of the performance of AI-assisted studios with traditional ones suggest the obvious benefits in the form of low rates of defects, shorter turnaround time, and increased customer satisfaction.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

Boretti, A. (2024). A Techno-Economic Perspective on 3D Printing for Aerospace Propulsion. Journal of Manufacturing Processes, 109, 607–614. https://doi.org/10.1016/j.jmapro.2023.12.044

Chen, H., Liu, Y., Balabani, S., Hirayama, R., and Huang, J. (2023). Machine Learning in Predicting Printable Biomaterial Formulations for Direct Ink Writing. Research, 6, 197. https://doi.org/10.34133/research.0197

Freeman, S., Calabro, S., Williams, R., Jin, S., and Ye, K. (2022). Bioink Formulation and Machine Learning-Empowered Bioprinting Optimization. Frontiers in Bioengineering and Biotechnology, 10, 913579. https://doi.org/10.3389/fbioe.2022.913579

Haque, A. N. M. A., and Naebe, M. (2023). Tensile Properties of Natural Fibre-Reinforced FDM Filaments: A Short Review. Sustainability, 15, 16580. https://doi.org/10.3390/su152416580

Hassan, M., Misra, M., Taylor, G. W., and Mohanty, A. K. (2024). A Review of AI for Optimization of 3D Printing of Sustainable Polymers and Composites. Composites Part C: Open Access, 15, 100513. https://doi.org/10.1016/j.jcomc.2024.100513

Kennedy, S. M., Wilson, L. A., and Rb, J. R. (2025). Natural Fiber Filaments Transforming the Future of Sustainable 3D Printing. MethodsX, 14, 103385. https://doi.org/10.1016/j.mex.2025.103385

Metal AM. (2023). The Convergence of Additive Manufacturing and Artificial Intelligence: Envisioning a Future that is Closer than you Think. Metal AM.

Srivastava, M., Aftab, J., and Tyll, L. (2025). The Influence of Artificial Intelligence and Additive Manufacturing on Sustainable Manufacturing Practices and their Effect On performance. Sustainable Futures, 10, 100820. https://doi.org/10.1016/j.sftr.2025.100820

Sturm, L. D. (2020). Cyber-Physical Security for Additive Manufacturing Systems. Virginia Tech.

Subeshan, B., Atayo, A., And Asmatulu, E. (2024). Machine Learning Applications For Electrospun Nanofibers: A Review. Materials Science, 59, 14095–14140. https://doi.org/10.1007/s10853-024-09994-7

Thomas, D. J. (2022). Advanced Active-gas 3D Printing of 436 Stainless Steel for Future Rocket Engine Structure Manufacture. Journal of Manufacturing Processes, 74, 256–265. https://doi.org/10.1016/j.jmapro.2021.12.037

Wang, G., Chen, Y., An, P., Hong, H., Hu, J., and Huang, T. (2023). UAV-YOLOv8: A Small-Object-Detection Model Based on Improved YOLOv8 for UAV Aerial Photography Scenarios. Sensors, 23, 7190. https://doi.org/10.3390/s23167190

Yampolskiy, M., Bates, P., Seifi, M., and Shamsaei, N. (2022). State of Security Awareness in the Additive Manufacturing Industry: 2020 Survey. Progress in Additive Manufacturing, 2021, 192–212. https://doi.org/10.1520/STP164420210119

Yeshiwas, T. A., Tiruneh, A. B., and Sisay, M. A. (2025). A Review Article on the Assessment of Additive Manufacturing. Journal of Materials Science: Materials Engineering, 20, 85. https://doi.org/10.1186/s40712-025-00306-8

Zhou, L., Miller, J., Vezza, J., Mayster, M., Raffay, M., Justice, Q., Al Tamimi, Z., Hansotte, G., Sunkara, L. D., and Bernat, J. (2024). Additive Manufacturing: A Comprehensive Review. Sensors, 24, 2668. https://doi.org/10.3390/s24092668

|

|

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© ShodhKosh 2025. All Rights Reserved.