ShodhKosh: Journal of Visual and Performing ArtsISSN (Online): 2582-7472

|

|

Robotic Carving and Its Pedagogical Implications

Avni Garg 1![]()

![]() ,

Pooja 2

,

Pooja 2![]()

![]() , Frederick

Sidney Correa 3

, Frederick

Sidney Correa 3![]()

![]() , Indira

Priyadarsani 4

, Indira

Priyadarsani 4![]() , Akhilesh

Kumar Khan 5

, Akhilesh

Kumar Khan 5![]() , Dr.

Supriya Rai 6

, Dr.

Supriya Rai 6![]()

![]() , Kiran

Ingale 7

, Kiran

Ingale 7![]()

1 Chitkara

Centre for Research and Development, Chitkara University, Himachal Pradesh,

Solan, 174103, India

2 Assistant

Professor, Department of Development Studies, Vivekananda Global University,

Jaipur, India

3 Centre of Research Impact and Outcome, Chitkara University, Rajpura-

140417, Punjab, India

4 Assistant Professor, School of Business Management, Noida International

University 203201, India

5 Lloyd Law College, Greater Noida, Uttar Pradesh 201306, India

6 Associate Professor, Department of Management Studies, JAIN

(Deemed-to-be University), Bengaluru, Karnataka, India

7 Department of E and TC Engineering Vishwakarma Institute of

Technology, Pune, Maharashtra, 411037 India

|

|

ABSTRACT |

||

|

Robotic

carving is fast transforming the modern day

activities in the fields of design, engineering, and creative arts by

combining computer accuracy with the physical exploration in materials. The

technological, educational and pedagogical aspects of robotic carving are

discussed in the paper and it is argued that robotic

carving is a game changer in the experimental

learning. First, it provides a description of the fundamental elements,

working principles and software conditions that allow robotic carving systems

to work with high fidelity through a variety of materials. It is based on

this that the paper will discuss how these systems are being incorporated

into curricula in architecture, industrial design and fabrication programs

where they reinforce project based learning and interdisciplinary

collaboration. Based on constructivist theory and the principles of STEAM

education, robotic carving is potentially useful in the development of

cognitive and psychomotor skills that are based on the necessity to iterate,

prototype, and solve problems in real time. The case studies of universities

in the forefront show how robotic fabrication access improves student

engagement, creativity, and design agency and provides students with novel

assessment modes, which are linked to process, craft, and innovation. The

article also takes into account the new

opportunities, which are the AI-instigated toolpath generation, adaptable

fabrication processes, and ecologically conscious material approaches.

Lastly, it outlines the research directions in the future trying to perfect

the approaches to curricular integration, broadening the equitable access to

fabrication technologies, and concerning ethical aspects of automation in

creative fields. |

|||

|

Received 05 March 2025 Accepted 11 July 2025 Published 20 December 2025 Corresponding Author Avni Garg,

avni.garg.orp@chitkara.edu.in

DOI 10.29121/shodhkosh.v6.i3s.2025.6782 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2025 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Robotic Carving, Digital Fabrication, Steam

Education, Constructivist Learning, AI-Assisted Design, Experiential Learning |

|||

1. INTRODUCTION

Robotic carving has been a major advancement in the larger context of digital fabrication, and it is a combination of robotics, computational design, and material science to create very accurate and customizable shapes. With the growing number of educational institutions incorporating highly innovative technologies into their curricular programs, robotic carving is becoming a more and more popular method of creating, as well as a driver of the change of pedagogical perspectives. Its usage indicates a wider change to more towards experiential, inter-disciplinary, and technology enhanced learning environments in which students are actively involved in processes of design and fabrication that can be seen to reflect professional practice. The emergence of robotic carving can be interpreted in the development history of fabrication technologies, the history of manual work and mechanical early mechanisms, then CNC machining, and, most recently, multi-axis robotic arms. Robotic carving is flexible, adaptable, and scaled unlike the traditional subtractive methods Tang et al. (2023). It helps users to cut intricate geometries, manipulate a variety of real world materials and experiment with a form that would be hard or even impossible to realize with conventional tools. These features make robotic carving become a precious tool in a variety of uses, such as architecture, art and design, engineering, and product development. The usefulness of a robotic carving is not limited to its technical functionality in the context of education. It is now being embraced by universities and design institutes as a way of promoting more meaningful learning experiences through the involvement of students in project-based and iterative workflow Zhong and Xia (2020). Using the combination of robotic instruments, learners become directly exposed to the entire design-to-fabrication process: they can observe the digital design and modeling phases as well as the physical stages of testing and toolpath creation and execution. This participatory experience promotes problem solving, critical thinking and creative exploration as well as providing a physical correlation between digital manifestations and physical results. Robotic carving can also be closely related to the modern-day pedagogical theories, and especially to constructivism, which places the emphasis on learning through doing, reflection, and personal meaning-making. Through engaging with robotic systems, the students develop knowledge as they experiment with their designs and see what happens as a result of their design choices and use this knowledge to improve their processes Channa et al. (2021). Robotics integration into the studio and laboratory environment is another technology that can be used to support STEAM education programs, combining technical capability and artistic or conceptual growth.

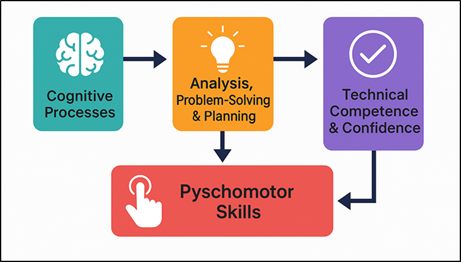

Figure 1

Figure 1 Overview of Key Components in Robotic Carving and Pedagogical Theory

Students learn a rich and varied set of skills as they encounter the technical challenges of programming and calibration with the aesthetic and functional issues; connecting the analytical and the artistic. In Figure 1, the components of robotic carving are accorded with pedagogical theory. Besides, robotic carving opens the possibilities of collaboration and interdisciplinary learning. Teamwork among students with an engineering, computer science, design, and fine arts background, is often necessary in projects. The interaction process resembles the practice of innovation in the real world, where complicated issues are solved by using the collective experience and interdisciplinary viewpoints Kubilinskiene et al. (2017). The common learning space leads to communication skills, flexibility and appreciation of the various methodologies. Simultaneously, the adoption of robotic carving raises some significant concerns in terms of security, availability, viability, and ethical utilization of automated technologies. Teachers should think about the way in which they can combine such systems in a responsible manner so that everyone can have equal opportunities and be ready to work in the future, where the role of automation will become more and more central Roberts et al. (2021). These issues underline the necessity of considered curriculum development and research that will also investigate the non-technical implications of robotic carving, as well as its consequences.

2. Technological Foundations of Robotic Carving

2.1. Components and mechanisms of robotic carving systems

Robotic carving systems are made up of an assembly of mechanical, electronic and computerized parts that interact to perform complicated subtractive manufacturing operations. The central element of these systems is a multi-axis robotic arm, which, as a rule, has 4-7 axes and can be highly maneuverable and have a long reach. The end-effectors fitted on this arm include spindle motors, milling tools, or carving bits that can cut, shape and texture materials Tercanli and Jongbloed (2022). These terminal devices can be changed or tailored to the needs of the project, which enables the robot to be used with a wide variety of materials such as wood, foam, stone, plastics, and soft metals. The arm motion is controlled precisely by the motor drivers, servo motors and encoders to allow the robot to track the toolpaths. The operational reliability is guaranteed by safety systems which include emergency stops, collision sensors and protective enclosures Baharin et al. (2018). The material being processed is held steady by a supporting structure e.g. a fixed or rotating worktable and dust-collection units assist in keeping the environment clean and under control. The latest robotic carving machines have force-feedback extruded on the machines, enabling the robot to modify its pressure and speed depending on the resistability of the material. The vision systems can include depth cameras or laser scanners, which can be used to enable a real time tracking, scanning, or adaptive carving processes. A combination of these elements creates a highly integrated system that has the potential to convert digital models to accurate physical representations, and robotic carving is an essential device in the modern design and fabrication environment Hafni et al. (2020).

2.2. Software and Programming Tools Used in Robotic Carving

Robotic carving is critically dependent upon specialized software ecosystems which interpret design intentions as machine-readable toolpaths. The design and manufacturing process of products usually starts with a 3D modeling system like Rhino, Blender, Autodesk Fusion 360 or SolidWorks through which designers produce digital geometries. The models are then sent to CAM (Computer-Aided Manufacturing) software such as RhinoCAM, Fusion 360 CAM or PowerMill, which produces initial toolpaths depending on the tool diameter, solid density, spindle velocity, and cutting plan Zizka et al. (2018). Most popular software platforms used in robotic carving include robotic programming environments such as Grasshopper (with such programs as KUKA|prc and HAL Robotics), ABB robots RoboStudio, and robotic carving simulator RoboDK, which deals with toolpath optimization and kinematic analysis. These are used by designers to simulate the movement of the robot in a virtual world and identify possible collisions as well as improving trajectories prior to real implementation. Simulation is a very risk aversive method that ensures accuracy and assists in streamlining time and material consumption Mwangi et al. (2022). Depending on the model of the robot, low-level programming can be performed with the help of such a language as RAPID (ABB), KRL (KUKA Robot Language), or Python-based APIs.

2.3. Precision, Automation, and Material Adaptability

High precision and automation of a material processing are the distinguishing features of robotic carving. The multi-axis robots can also attain sub-millimeter accuracy as a result of built-in encoders, servo controls and sophisticated kinematic systems. In contrast to classical CNC machines that are only capable of linear motion, robotic arms are able to bring a workpiece in a variety of angles and excavate complex geometries, undercuts and organic formations with very high precision. This dimensional flexibility increases the possibilities of designing and allows experimentation on complex surface textures and sculptural shapes Kerimbayev et al. (2023). Automation is very important in improving productivity and minimizing human error. When a toolpath is developed, the same could be executed in the repetitive labor intensive jobs continuously without getting tired. Robots can modify speed, pressure and tool orientation dynamically based on automated calibration, real time monitoring systems and feedback loops, making them more consistent over several iterations Baccaglini et al. (2020). In more sophisticated implementations robotic systems may be linked to material-handling systems and so autonomous loading, carving and finishing can be done. Table 1 gives a comparison of studies involving the educational and fabrication use of robotic carving. The other characteristic feature of robotic carving is the material adaptability. The type of materials that robots can machine varies greatly, including soft foams and hardwoods, dense stone and engineered composites, by changing the speed of the spindle, the feed rate and the tool used.

Table 1

|

Table 1 Comparative Review of Studies on Robotic Carving in Education and Fabrication |

||||

|

Focus Area |

Methodology |

Key Findings |

Benefits |

Impact |

|

Robotic fabrication in architecture |

Multi-axis robotic milling |

Demonstrated structural precision using robotic

carving |

Improved accuracy, novel geometries |

AI-guided structural optimization |

|

Digital fabrication pedagogy Kert et al. (2020) |

Studio-based robotic workshops |

Students gained hybrid computational–material

skills |

Enhanced design–fabrication literacy |

Integrated sensing and feedback systems |

|

Material-driven robotics Afzal et al. (2023) |

Adaptive toolpaths |

Real-time adaptability enhances fabrication

efficiency |

Reduced waste, dynamic workflows |

Autonomous fabrication pipelines |

|

Creative digital craftsmanship |

Robotic sculpting |

Artists explore non-traditional materials |

Expands artistic expression |

Cross-platform AI design assistants |

|

Robotic prototyping |

KUKA robotic milling |

Supports parametric exploration |

Expanded form-finding possibilities |

Multi-material hybrid fabrication |

|

Artistic carving Chatzichristofis (2023) |

Robotic subtractive sculpting |

Blends art and computation |

Boosts creativity and rapid iteration |

Democratized robotic access |

|

Human–robot interaction |

Collaborative carving experiments |

Students improved robotic programming skills |

Enhances problem-solving |

Safer, smarter cobot

workflows |

|

Fabrication research |

AI-enhanced robotic milling |

Increased precision and adaptability |

Better toolpath efficiency |

Predictive machine learning |

|

Computational design Valls Pou et al. (2022) |

Robotic form exploration |

Encourages conceptual–material integration |

Strengthens spatial reasoning |

Autonomous design generation |

|

Material experimentation |

Multi-material robotic carving |

Supports complex material studies |

Broader fabrication versatility |

Sustainable bio-material fabrication |

|

Design engineering Coufal (2022) |

User-centered

fabrication tasks |

Students gain hands-on systems thinking |

Faster prototyping cycles |

Real-time robotic tutoring systems |

3. Educational and Pedagogical Context

3.1. Role of robotic carving in design and engineering education

Robotic carving has emerged as a powerful instrument in design and engineering education with the potential effect of giving students firsthand experience of high-digital fabrication technologies which are presently being employed in professional practice. Robotic carving bridges the gap between theory and practice by allowing learners to perceive the mutually reinforcing nature of the relationship between computational modeling, material performance and mechanical performance in the modern design studio and engineering laboratory.

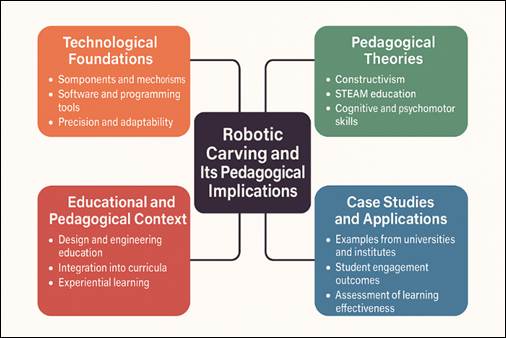

Figure 2

Figure 2 Educational Impact Pathways of Robotic Carving in

Design and Engineering Programs

Working with robots, students also acquire the understanding of motion planning, kinematics, structural concepts, and workflow optimization which are the concepts of contemporary engineering and design fields. Robotic carving is used in the field of design education to investigate the constraints of forms, geometry, and fabrication. Figure 2 has presented the paths that indicate the educational influence of robotic carving in design engineering. Students are able to test complex shapes, make prototypes, and make designs in an iterative way, thus developing an iterative attitude in solving problems Chang and Lan (2021). Meanwhile, engineering students have access to robotics, automation, and control systems and manufacturing processes that can prepare them to work in the automation, advanced manufacturing and product development industry.

3.2. Integration into Art, Architecture, and Fabrication Curricula

Robotic carving is becoming part of the field of art, architecture and fabrication programs in order to develop the use of creative expression as well as technical proficiency. In art classes, the technology has been used to enable the student to experiment with sculptural objects, surface modulation and experimentation with materials at scales and levels of detail that would have been impossible in the traditional hand-carving techniques. Artists are able to operate in a cyclic manner, by combining both digital conceptualization and physical crafting, by extending aesthetic limits with computational generated geometries Solan and Shtub (2023). Robotic carving is crucial in architecture courses by allowing intent and constructability to intersect. Robots are used by students to create complicated spatial models, components of facades, and structural prototypes that embody new architectural tendencies focusing on parametric design and digital craftsmanship. The technology can assist learners to appreciate how design decisions can play with fabrication logic and learn to respect precision, tolerances and structural behavior. The curricula in fabrics lay stress on technical mastery, which trains students in toolpath design, machine programming, material handling and workflow management. These courses emphasize the practical competencies needed in the field of construction, industrial design and highly skilled manufacturing. Robotic carving is then taught as a learning tool to educate students as to how to translate abstract design ideas into objects to be produced by automated systems.

3.3. Skill Development Through Experiential and Project-Based Learning

Robotic carving plays a major role in skill development as it complements experiential and project-based models of learning, based on hands-on engagement, iteration, and reflective practice. Students who have the direct experience with robotic systems are trained in technical skills that included computer programs, toolpath production, machine setup, and work with materials. These are skills that are developed in the process of cycle of experimentation where the learners design, make, test results and improve on their processes depending on the results of the tests. Experiential learning enhances cognitive knowledge through connecting theory with practice. The students can observe the process of conversion of digital models into physical objects and understand geometry, behavior of tools, and material properties better. This facilitates critical thinking because in this process, the learners have to anticipate possible fabrication challenges, troubleshoot and change their strategies on the fly. These problem-solving abilities form the core of the engineering as well as the creative disciplines. Project-based learning also encourages team work, team building and project management skills. Team-based working helps the students to organize tasks, share workload and to work within the complicated design-to-fabrication processes. This is similar to the professional settings where collaboration between disciplines is a crucial aspect. Psychomotor skills are also improved by robot carving, since the learners learn to control tools, set up materials, and use machinery safely and effectively. When the learners use different senses and motor skills, they develop confidence in their technical skills.

4. Pedagogical Theories Supporting Robotic Carving

4.1. Constructivism and hands-on learning

Constructivist pedagogy is based on the idea that learning is an active, experiential, process whereby people construct knowledge by means of direct interaction and reflection. Robotic carving is similar to this philosophy since it will expose students to real, practical fabrication experience that can bridge theory and practice. The design-to-fabrication cycle has learners so that they are constantly experimenting with digital models, producing toolpaths and seeing what the machine does and how the results of the physical process look. This cyclical process helps them to build their knowledge by trial and error and progression as opposed to merely consuming information. In the robotic carving world, students are allowed to be involved in owning their learning, as they are allowed to make decisions regarding the choice of tools, preparation of materials, machine settings, and design plans. This agency encourages elaborated conceptual understanding and internal inquiry. When they deal with both the digital and physical systems, learners experience a collision with the real world parameters in the form of tool limitations, material inconsistencies, and fabrication tolerances. The ability to deal with such challenges leads to resilience and supports the constructivist idea that learning is a result of useful problem-solving. Reflection is also of primary importance. The results of every attempt to fabricate something are evaluated by the students, and discrepancies between the planned and real results are measured and modified to alter processes.

4.2. STEAM (Science, Technology, Engineering, Arts, Mathematics) Education Approach

Robotic carving can be viewed as a potent stimulus in STEAM learning as it incorporates the scientific logic, fluency with technology, engineering tenets, artistic aptitude, and mathematical cognition into a unified learning process. The interdisciplinary nature of the modern design and fabrication practice can be presented as students work with robotic carving systems and simultaneously interact with several domains of STEAM. Science is developed by material experimentation where learners get to learn about the properties of density, grain structure, and resistance in machining. The process focuses on technology since students are involved in modeling, simulation, and the generation of toolpaths with the help of software tools. The concepts of engineering, such as kinematics, allocation of load, and optimization of processes, are inherent in the process of planning robotic movements and their real execution. The exploration of arts also gains the same significance because with the assistance of robotic carving, students can develop expressive shapes, sculptural texture, and aesthetically appealing artworks. Mathematics forms the basis of almost all the workflow steps, such as working out the angles and feed rates of tools, and the geometric transformations, and continuity of surfaces. The smooth connection between these areas reflects the conditions in the real world of problem-solving, where the innovation is based on the convergence of various disciplines. Teamwork and communication are other characteristics of STEAM education that are promoted by collaborative projects.

4.3. Cognitive and Psychomotor Skill Enhancement

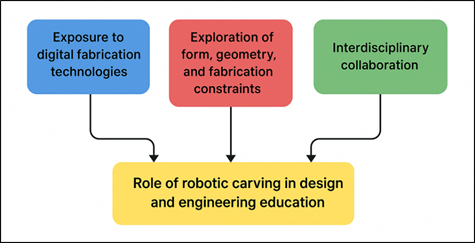

Robot carving plays an important role in the process of cognitive and psychomotor development of students, providing them with an integrated learning process involving the brain and the body. Mentally, the students will be required to examine the digital models, to foresee the machine behaviour, to design and determine issues that may occur in fabrication. These activities can develop superior level of thinking like spatial thinking, logical sequence, critical analysis and decision-making. Students are taught how to assess tradeoffs, get the best toolpaths and read the data in simulation, all of which demand longer term mental activities. Figure 3 demonstrates the way in which cognitive and psychomotor skills are improved with the help of robotic carving. Psychomotor skills are also reinforced because the robotic carving involves direct interaction between the learner and the materials, tools and machinery.

Figure 3

Figure 3 Conceptual Model of Cognitive and Psychomotor

Enhancement Through Robotic Carving

By organizing stock materials, workpieces, choice of cutting tools and setting machine parameters, the motor actions, accuracy and awareness of situations are coordinated. With practice, the students become dextrous and have fine motor skills and gain confidence in working with fabrication equipment in a safe and efficient manner. Robotic carving is characterized by interactions between thinking and acting, which is done through cognitive planning and execution.

5. Case Studies and Applications

5.1. Examples from universities and design institutes

Robotic carving is now widely seen as a key element of the digital fabrication studio in universities and design institutes throughout the world, providing students with a chance to work with high-tech manufacturing tools. Schools, colleges, and universities like the Massachusetts Institute of Technology (MIT), ETH Zurich and the Architectural Association (AA) have been the first to incorporate robotic carving into their coursework, typically with the prototyping of architectural features, sculpture and experimenting with the properties of materials, using usually multi-axis robotic arms. These centers often function as interdisciplinary centers where students of architecture, engineering, art and computer science work in teams producing projects based on research into fabrication. Examples include robotic carving taught in courses at MIT on the topic of computational design, in which students are given the opportunity to design their own toolpaths to generate some complex shape. The Digital Fabrication Lab at ETH Zurich makes use of robotic systems to be able to test new methods of construction, allowing its students to make full-sized components that combine material science and structural design. Equally, the Design Research Laboratory of the AA School promotes the investigation of emergent forms and responsive structures by students by robotic milling and experimenting with tool paths.

5.2. Student Engagement and Creativity Outcomes

Robotic carving has also shown a high potential of promoting student learning because it exposes learners to dynamic and technology-intensive environments that foster experimentation, exploration, and innovation. Students have frequently in the past, characterized work with robotic systems as an inspiring, thought provoking experience, because of the interactive quality of the technology and its capacity to yield specific concrete outputs. Robotics in the studio and laboratory environment transforms the learning process into a creative process rather than a passive process of observation, therefore leading to increased involvement and ownership of projects. Especially noteworthy are the results of creativity. Robotic carving helps students to take the limits of design to new areas that cannot be explored by normal means or traditional equipment. Learners are enabled to follow ambitious design concepts and to experiment with unconventional shapes by the ability to cut complex geometries, organic surfaces and massive components. This liberty stimulates deviant thinking which is a fundamental element of creative growth. In addition, the creative problem-solving is supported by the iterative process of robotic fabrication where students have to create more and more refined toolpaths, change parameters, and measure the results of the 3D output.

5.3. Assessment of Learning Effectiveness

To determine whether robotic carving is efficient or not, it is important to measure the process and results of interaction with students. Contrary to traditional tasks, which are mainly concerned with the final products, the robo fabrication projects are rather concerned with the process of iterative development, design rationale, and the transformation of the digital models into tangible objects. Teachers tend to use complex evaluation techniques to encompass technical mastery, creative discovery, problem solving skills and critical reflections. Among the important measures is assessing the knowledge of students in the field of digital workflows, such as modeling, simulation, and toolpath generation. The manifested skill in the maximization of robotic actions, the regulation of machine parameters, and the prediction of difficulties with fabrication can be considered the signs of profound technical education. Documentation Process documentation of various kinds, such as sketches, digital files, journals, and prototype iterations, is also important, as it shows how students explore ideas, debug their problems and perfect their approach. A different aspect of evaluation is concerned with quality and complexity of physical products. Though aesthetic triumph is taken into account, more attention is paid to craftsmanship, structural rationale, and digital-to-physical translation correction. Teachers often evaluate the ability of learners to use robotic possibilities to produce desired shapes or material actions. Team-based projects also require collaboration in terms of performance with paying attention to communication, role allocation, and integration of interdisciplinary viewpoints. Reflective essays/critiques enable tutors to evaluate conceptual development, which promotes students to explain what they have learned through both the successes and the failures of the experiment.

6. Future Directions and Innovations

6.1. Emerging trends in robotic fabrication and AI integration

The future of robotic carving is determined by the accelerated development of robots fabrication and the more refined application of artificial intelligence. A current major trend is a trend toward more autonomous and more adaptive fabrications systems that are able to make changes to toolpaths in real time depending on material behavior, environmental conditions, or sensor feedback. Robot vision algorithms are currently driven by AI, allowing the machine to identify anomalies, optimize the cutting plan and provide corrections without human intervention, minimizing the number of errors and improving performance. Machine learning is also broadening the scope of predictive modeling, whereby robots use the results of the past fabrication to optimize the future operation. The generative design tools are constantly being developed which means that the designers can design complex, optimized geometries that are fabricated by the robotic systems with a high degree of fidelity. They are the tools that combine computational creativity and robotic accuracy and are pushing the limits of design expression. The hybrid fabrication processes in a single robotic workflow that mix additive and subtractive processes are another new trend. These integrations enable the robots to construct and cut materials in stacked orders, which enhance flexibility and less waste. Robot carving is also becoming more affordable to learning institutions as collaborative robots aka cobots are becoming increasingly popular because of the user-friendly interfaces and safe workspace sharing with humans.

6.2. Curriculum Development and Research Opportunities

The further development of robotic carving has great opportunities in the development of curriculum and academic research. With digital fabrication becoming a core component of design, engineering and art education, institutions are gaining more incentive to design organized courses introducing robotic carving into both core courses and elective courses. The curricula of the future can then be focused on inter-disciplinary teamwork, whereby, the students of robotics, computer science, architecture, and fine arts can collectively work on design-to-fabrication problems. The courses will probably extend past technical teaching to encompass the conceptual and theoretical view of automation, material behavior, computational design and human-machine interaction. Practical lab lessons will remain significant, imparting students with the necessary skills like toolpath programming, machine configuration and trial and error. The capstone projects and research studios can have a specialisation on the emergent topics, such as adaptive fabrication, bio-inspired design, or AI-assisted toolpath generation. There are also good prospects in research. Researchers are able to explore new materials to be used in robotic carving, experiment with hybrid digital-physical procedures, or create new ways of sensing and feedback to improve the accuracy of fabrication. The research on education can be devoted to the investigation of the effect of robotic carving on student learning, creativity, and cognitive awareness. Differences in student results could be investigated in comparative studies of manual, CNC and robotic fabrication processes.

7. Conclusion

Robotic carving is a disruptive technology/creativity/pedagogy convergence that provides emerging opportunities in teaching and learning in designs, engineering, art, and fabrication. With the potential of digital technology becoming increasingly influential on professional practice, the introduction of robotic carving into educational settings will prepare students with the technical proficiency and the ability to think adaptively in order to becoming future-innovative. This capability of the technology to combine computational accuracy with material interaction effectively produces a very powerful experiential learning environment in which students acquire first hand experience of what it is like to translate digital models into physical reality. The value of robotic carving as a technical tool and as a pedagogical stimulus has been demonstrated in its use in the academic setting throughout the process of its implementation. It promotes constructivist learning through the possibility to experiment which allows iterative experimentation, interdisciplinary collaboration through STEAM-based frameworks, and enhances cognitive and psychomotor skills through the correlation of conceptual reasoning with embodied practice. The case studies performed in universities and design institutes show the way robotic carving improves learners engagement, creativity, and problem-solving skills, providing the real-life examples of the educational value. In the future, further developments in the field of AI integration, sensing technologies, and hybrid fabrication workflows will allow increasing the possibilities of robotic carving. Such innovations offer the possibilities in the development of curriculum, exploration of research, and more in-depth comprehension of human-machine collaboration.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

Afzal, A., Khan, S., Daud, S., Ahmad, Z., and Butt, A. (2023). Addressing the Digital Divide: Access and use of Technology in Education. Journal of Social Science Review, 3(2), 883–895.

Baccaglini-Frank, A. E., Santi, G., Del Zozzo, A., and Frank, E. (2020). Teachers’ Perspectives on the Intertwining of Tangible and Digital Modes of Activity with a Drawing Robot for Geometry. Education Sciences, 10(11), 387. https://doi.org/10.3390/educsci10110387

Baharin, N., Kamarudin, N., and Manaf, U. K. A. (2018). Integrating STEM Education Approach in Enhancing Higher Order Thinking Skills. International Journal of Academic Research in Business and Social Sciences, 8(7), 810–822. https://doi.org/10.6007/IJARBSS/v8-i7/4421

https://dx.doi.org/10.29121/shodhkosh.v6.i3s.2025.6782

Channa, F. R., Sarhandi, P. S. A., Bugti, F., and Pathan, H. (2021). Harnessing Artificial Intelligence in Education for Preparing Learners for the 21st Century. Elementary Education Online, 20(5), 3186–3196. https://doi.org/10.17051/ilkonline.2021.05.357

Chatzichristofis, S. A. (2023). Recent Advances in Educational Robotics. Electronics, 12(4), 925. https://doi.org/10.3390/electronics12040925

Coufal, P. (2022). Project-based STEM learning using Educational Robotics as the Development of Student Problem-Solving Competence. Mathematics, 10(24), 4618. https://doi.org/10.3390/math10234618

Hafni, R. N., Herman, T., Nurlaelah, E., and Mustikasari, L. (2020). The Importance of Science, Technology, Engineering, and Mathematics (STEM) Education to Enhance Students’ Critical Thinking Skill in Facing the Industry 4.0. Journal of Physics: Conference Series, 1521(1), 042040. https://doi.org/10.1088/1742-6596/1521/4/042040

Kerimbayev, N., Nurym, N., Akramova, A., and Abdykarimova, S. (2023). Educational Robotics: Development of Computational Thinking in Collaborative Online Learning. Education and Information Technologies, 28(12), 14987–15009. https://doi.org/10.1007/s10639-023-11879-2

Kert, S. B., Erkoç, M. F., and Yeni, S. (2020). The Effect of Robotics on Six Graders’ Academic Achievement, Computational Thinking Skills and Conceptual Knowledge Levels. Thinking Skills and Creativity, 38, 100714. https://doi.org/10.1016/j.tsc.2020.100714

Kubilinskiene, S., Zilinskiene, I., Dagiene,

V., and Sinkevičius, V. (2017). Applying Robotics

in School Education: A systematic review. Baltic Journal

of Modern Computing, 5(1), 50–69.

Mwangi, P. N., Muriithi, C. M., and Agufana, P. B. (2022). Exploring the Benefits of Educational Robots in STEM Learning: A Systematic Review. International Journal Of Engineering and Advanced Technology, 11(2), 5–11.

Roberts, H., Cowls, J., Morley, J., Taddeo, M., Wang, V., and Floridi, L. (2021). The Chinese Approach to Artificial Intelligence: An analysis of policy, ethics, and regulation. AI and Society, 36(1), 59–77. https://doi.org/10.1007/s00146-020-00992-2

Solan, D., and Shtub, A. (2023). Development and Implementation of a New Product Development Course Combining Experiential Learning, Simulation, and a Flipped Classroom in Remote Learning. International Journal of Management Education, 21(2), 100787. https://doi.org/10.1016/j.ijme.2023.100787

Tang, K. Y., Chang, C. Y., and Hwang, G. J. (2023). Trends in Artificial Intelligence-Supported E-Learning: A Systematic Review and Co-Citation Network Analysis (1998–2019). Interactive Learning Environments, 31(12), 2134–2152. https://doi.org/10.1080/10494820.2021.1875007

Tercanli, H., and Jongbloed, B. (2022). A Systematic Review of the Literature on Living Labs in Higher Education Institutions: Potentials and Constraints. Sustainability, 14(19), 12234. https://doi.org/10.3390/su141912234

Valls Pou, A., Canaleta, X., and Fonseca, D. (2022). Computational Thinking and Educational Robotics Integrated into Project-Based Learning. Sensors, 22(10), 3746. https://doi.org/10.3390/s22103746

Zhong, B., and Xia, L. (2020). A Systematic Review on Exploring the Potential of Educational Robotics in Mathematics Education. International Journal of Science and Mathematics Education, 18(1), 79–101. https://doi.org/10.1007/s10763-018-0992-1

Zizka, L., McGunagle, D. M., and Clark, P. J. (2018). Sustainability in STEM Higher Education: Making Social Change Together. Journal of Higher Education Theory and Practice, 18(5), 121–132.

|

|

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© ShodhKosh 2025. All Rights Reserved.