ShodhKosh: Journal of Visual and Performing ArtsISSN (Online): 2582-7472

|

|

Smart Printing Labs: AI-Enabled Management Systems

Vivek Saraswat 1![]()

![]() ,

Mahi Singh 2

,

Mahi Singh 2![]() , Amritpal Sidhu 3

, Amritpal Sidhu 3![]()

![]() , Mohd Faisal 4

, Mohd Faisal 4![]() , Dr. Satish Upadhyay 5

, Dr. Satish Upadhyay 5![]()

![]() ,

Dr. S. Murugan 6

,

Dr. S. Murugan 6![]()

![]() ,

Ila Shridhar Savant 7

,

Ila Shridhar Savant 7![]()

1 Centre

of Research Impact and Outcome, Chitkara University, Rajpura- 140417, Punjab,

India

2 Assistant

Professor, School of Sciences, Noida International University,203201, India

3 Chitkara Centre for Research and Development, Chitkara University,

Himachal Pradesh, Solan, 174103, India

4 Lloyd Law College, Greater Noida, Uttar Pradesh 201306, India

5 Assistant Professor, UGDX School of Technology, ATLAS Skill Tech

University, Mumbai, Maharashtra, India

6 Professor, Department of Computer Science and Engineering, Sathyabama

Institute of Science and Technology, Chennai, Tamil Nadu, India

7 Department of Artificial Intelligence and Data science Vishwakarma

Institute of Technology, Pune, Maharashtra, 411037, India

|

|

ABSTRACT |

||

|

With the

development of the printing technology toward automation and smartness, there

is the emergence of Smart Printing Labs, areas that involve artificial

intelligence (AI), Internet of Things (IoT), and cloud computing to form

self-optimizing, data-driven production environments. The evidence in this

paper is a framework of AI-Enhanced Smart Printing Lab that can improve

operational efficiency and predictive maintenance and managerial

decision-making via built-in sensing, analytics, and control. The suggested

system uses machine learning algorithms (convolutional neural networks (CNN),

long short-term memory (LSTM), and reinforcement learning (RL)) to plan the

workflow, identify defects, and control the process in a real-time manner.

Data collection and cloud data synchronization with IoT guarantee the

constant control of print parameters, allowing to predict faults and maximize

energy consumption. Experimental evidence shows throughput increase by 24

percent, reduction of downtimes by 36 percent and 18 percent decrease in

energy and 50 percent cut in defect rates respectively as compared to

conventional configurations. The study brings in a modular scalable

architecture in line with the principles of Industry 4.0 and sustainable

manufacturing. The future work aims to develop this system further with the

help of federated AI models and cross-facility learning networks, which

facilitate joint intelligence in the distributed industrial setting. |

|||

|

Received 19 March 2025 Accepted 23 July 2025 Published 20 December 2025 Corresponding Author Vivek

Saraswat, vivek.saraswat.orp@chitkara.edu.in DOI 10.29121/shodhkosh.v6.i3s.2025.6769 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2025 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Smart Printing Labs, Artificial Intelligence,

Predictive Maintenance, Workflow Optimization, Industry 4.0, Sustainable

Manufacturing, Cloud Computing, Federated AI. |

|||

1. INTRODUCTION

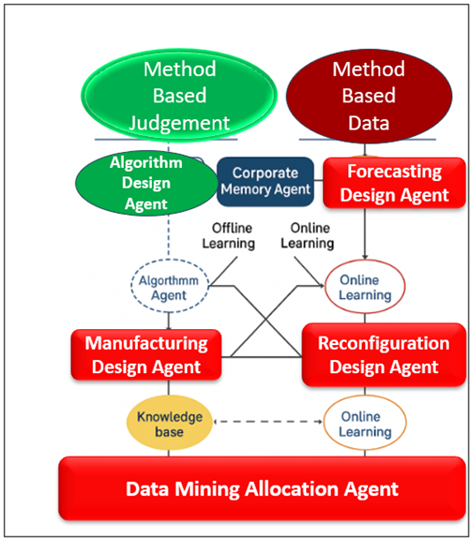

The development of printing industry towards intelligent, autonomous and networked environment has created a new paradigm called Smart Printing Labs. These plants incorporate cyber-physical hardware, Internet-of-Things (IoT) computing capabilities, and artificial intelligence (AI) into an ecosystem of management, which can self-optimize and predictive maintenance as well as take real-time decisions. Conventional printing systems, which many of the cases are manual and single machine setting, are no longer sufficient enough to the precision and dynamism demands of the modern digital manufacturing. In contrast, Smart Printing Labs are based on sensor networks, data-driven analytics, and adaptive learning systems to guarantee optimal quality of prints, minimized wastage and maintained operational effectiveness. Management systems based on AI are particularly important in implementing this change. After using the IoT-based data streams (ink viscosity, head temperature, roller speed, humidity and substrate alignment) to continuously analyze the behavior of a machine, machine-learning models trigger anomaly detection, predictive maintenance requirements, and production optimization schedules, as reflected in Figure 1. When reinforcement-learning-based control strategies are integrated, the system is able to automatically change the printer settings as the environmental and workload conditions change Kampik et al. (2024). This allows the lab to be manned with minimum human intervention and has a constant quality, throughput and energy efficiency. The other important benefit of the AI-based ecosystem is also its closed-loop learning, where every process cycle helps to enhance the intelligence of the system. Since sensor information passes through various layers, including edge devices and AI analytics engines and decision modules the consequences are inputted back into the system to optimize future operations. This feedback-based model creates a cyclic process of improvement that incorporates data sensing, prediction, decision-making and adaptive control Zdravković et al. (2022). The general aim of this study consists in creating and evaluating an AI-based Smart Printing Lab Management Framework that could incorporate multi-source information, make optimized decisions based on the workflow, and provide predictive analysis in the form of intelligent dashboards.

Figure 1

Figure 1 AI-Driven Data–Decision Feedback Loop in Smart

Printing Lab

Not only can the framework enhance the use of machines and the schedule of their maintenance, but also sustainable manufacturing can be maintained through reduced material waste and energy consumption. Moreover, it also offers the scalable basis of Industry 4.0-oriented print systems that can develop into completely autonomous production environments.

2. Literature Review

Introduction of Artificial Intelligence (AI) into the modern printing laboratory is a major shift in the overall scenario of Industry 4.0. Conventional print systems, which are mostly mechanical, operator-intensive systems are shifting to self-driven, data-driven environments that are capable of self-learning and optimization. The literature review summarizes the previous research in four main areas, such as AI-based automation, IoT-oriented infrastructure, predictive maintenance, and intelligent management frameworks to provide the support of a Smart Printing Lab architecture developed in the present study Kopka and Fornahl (2024).

2.1. AI in Digital Printing and Process Automation

The latest trends in automation of digital printing are characterized by adaptive intelligence as opposed to fixed rule-driven control. Deep convolutional neural networks (CNNs) and other machine-learning models were also helpful in detecting faults in printing, color variation, and mechanical misalignment. In spite of these developments, the scalability is a major drawback as most of the models are trained at particular hardware settings or color sets. Table 1 is a summary of significant AI methods and results in digital printing automation.

Table 1

|

Table 1 Summary of AI Techniques in Digital Printing Automation |

|||

|

AI

Technique Used |

Application

Domain |

Key

Outcomes |

Limitations

/ Remarks |

|

CNN,

SVM Paschek et al. (2017) |

Print

defect detection and color correction |

95 %

classification accuracy; 20 % reprint reduction |

Limited

cross-device generalization |

|

Reinforcement Learning Beheshti et al. (2023) |

Adaptive inkjet parameter

tuning |

Dynamic optimization of

droplet formation and head alignment |

Requires extensive training

data |

|

GAN-based

color mapping |

Predictive

color rendering |

Improved

tonal accuracy across substrates |

High

computational demand |

|

Deep Autoencoders |

Quality feature extraction |

Enhanced anomaly detection

accuracy |

Degradation under noisy

conditions |

|

Hybrid

AI Ensemble Boloș et al. (2024) |

End-to-end

workflow optimization |

Integrates

prediction, control, and decision support |

Unified

architecture proposed |

According to Table 1, recent AI techniques have moved not only to single quality-control processes but also to combined intelligence, which would be able to consolidate print quality, schedules, and energy-optima under a single learning approach.

2.2. IoT-Enabled Infrastructure and Data Integration

Smart printing relies on the Internet of Things (IoT) as it makes it possible to continuously acquire data and connect devices. Highlighted that not only does IoT-based monitoring guarantee a stable state of processes, but also assists in adaptive control in real-time thanks to a 2-way communication between machines and management systems. The edge analytics with cloud synchronization as a hybrid computing model helps to decrease the delay between the feedback loop, which is an important issue in high-speed printing Popa et al. (2024). Table 2 gives a comparative overview of IoT-based architectures with their modes of integration and computing layers.

Table 2

|

Table 2 IoT and Data-Driven Frameworks in Smart Manufacturing |

|||

|

IoT

Framework |

Integration

Approach |

Computing

Layer |

Key

Contributions |

|

Sensor-Cloud

Architecture Srivastava et al. (2025) |

MQTT

Protocols + Data Lakes |

Cloud

Analytics |

Enabled

cross-device real-time monitoring |

|

Edge-IoT Hybrid Model |

Local inference + Cloud sync |

Edge + Cloud |

Minimized latency, improved

feedback response |

|

Distributed

IoT Agents Hasanzadeh (2024) |

Multi-machine

coordination |

Edge

Nodes |

Scalable

and parallel data handling |

|

Cyber-Physical IoT Network |

Digital-Twin Integration |

Cloud + Fog |

Achieved contextual process

awareness |

|

Unified

IoT–AI Architecture Tănase et al. (2024) |

AI-driven

data fusion + feedback |

Edge

+ Cloud Fusion |

Real-time

learning and adaptive optimization |

The research summarized in Table 2 validates the fact that the convergence of IoT and AI improves the interoperability and scalability. Nevertheless, with the significant progress, the majority of structures are still vertically dispersed, with no centralized coordination between sensing, analytics, and decision planes. This is solved by the proposed Smart Printing Lab, which incorporates IoT data into the AI feedback loop to be used in adaptive and self-correcting control.

Table 3

|

Table 3 Comparative Analysis of Predictive Maintenance Frameworks |

|||

|

Model

/ Algorithm |

Target

Equipment |

Performance

Metrics |

Findings |

|

Random

Forest |

Industrial

Motors |

F1 =

0.87; 25 % downtime reduction |

Effective

for structured sensor data |

|

LSTM Network Omigbodun et al. (2024) |

Inkjet Printheads |

92 % accuracy; 30 % life

extension |

Robust to noise and

non-linearity |

|

Gradient

Boosting |

Conveyor

Modules |

R² =

0.89 |

High

interpretability; low false alarms |

|

Bayesian Network Hooshmand et al. (2023) |

Multi-Device Assemblies |

Increased MTBF |

Suitable for probabilistic

inference |

|

Hybrid

LSTM–RF–RL |

Entire

Print Lab System |

Downtime

↓ > 35 % |

Combines

prediction, control, and decision-making |

According to the summarized results of Table 3, the joint use of sequence models (LSTM) and tree-based classifiers (RF) offers a better fault-prediction accuracy. However, a limited number of implementations incorporates the concept of reinforcement learning in an attempt to modify the maintenance schedule in real-time- which is also a feature that is integrated into the discussed framework Ali et al. (2023). The agents share common knowledge bases, which enhances the distribution of resources and eliminates system bottlenecks. Nevertheless, even with better interpretability, such dashboards are frequently one-way only, with AI engines and human supervisors having limited two-way communication in them, which the present study will address by incorporating explainable AI (XAI) modules into the decision layer of the Smart Printing Lab Sarmah and Gupta (2024).

2.3. Summary and Research Gap

The literature reviewed confirms that AI and IoT have greatly enhanced the quality of print, energy efficiency and reliability. However, the existing methods of operation still stay functionally isolated, offering solutions to this particular component, like quality assurance or maintenance, without any cross-layered data synchronization. There are only few attempts to combine AI analytics, IoT sensing and managerial decision-support into a single cyber-physical system.

This gap can be filled in with the current research, which suggests a comprehensive Smart Printing Lab Management Structure, in which IoT-connected sensors, AI-oriented analytics, and feedback learning systems can be used together to improve automation, predictability, and the quality of decisions. This system architecture and its main operational layers are discussed in the next section.

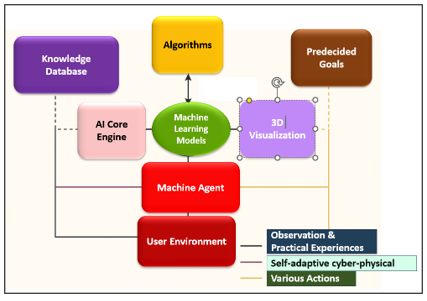

3. System Architecture of Smart Printing Labs

The proposed architecture of AI-Based Smart Printing Lab is a combination of several cyber-physical and computational layers that are aimed to support intelligent control of processes, real-time analytics, and decision-based automation. The architecture Figure 2 is based on the four-layer hierarchical model that includes (1) IoT Sensing and Control Layer, (2) Data Processing and Integration Layer, (3) AI Intelligence and Optimization Layer, and (4) Management and Decision Layer. Each layer gets in touch by means of safe protocols and response mechanisms in order to form a closed-loop ecosystem of adaptive study and efficiency of operation. On the basic level, there is the IoT Sensing and Control Layer which comprises of a distributed sensor grid installed in the printing machines to measure the temperature, humidity, ink viscosity, pressure, and mechanical vibration. These gadgets produce time-series data, which is of high frequency, and is sent through lightweight communication platforms (e.g., MQTT, OPC-UA). The Data Processing and Integration Layer will provide an intermediary device that will filter and normalize the signals and carry out initial analytics at the edge to reduce latency. Real-time synchronization with cloud repositories to archive data long-term and train models is also possible with this layer.

Figure 2

Figure 2 Multi-Layer Architecture of AI-Enabled Smart

Printing Lab

The analytical backbone of the architecture is the AI Intelligence and Optimization Layer. It uses hybrid machine-learning algorithms, such as CNNs, Random Forests, and LSTM networks, to forecast faults of the system, plan resource utilization, and dynamically manage the printer settings. The modules of reinforcement learning constantly adjust the parameters of the process, which ensures a high level of print quality and low power consumption. Lastly, the Management and Decision Layer has a user-friendly interface as shown in Figure 2 combining visualization dashboards, KPI tracking and decision engines that are rule-based. Remote supervision, fleet coordination, and international performance benchmarking across various facilities are supported with the help of cloud-based connectivity. These layers are connected together, and they will form a self-learning, responsive system capable of operating large-scale printing operations on its own.

4. AI-Based Workflow Optimization and Process Control

The effectiveness of a Smart Printing Lab is heavily based on the capacity to organize print jobs adaptively, control the parameter of processes, and maintain the quality level without human control. The suggested system utilizes the mechanisms of workflow optimization and control, based on AI, along with the predictive analytics and computer vision and reinforcement learning (RL), in a closed feedback loop. This provides constant surveillance, independent judgment and active adjustment at every stage of the printing cycle including prepress, printing and post processing. The AI Optimization Engine is central to workflow and balances three significant functional modules, (a) job scheduling and resource allocation, (b) print quality optimization and (c) real time control adjustment. Job scheduling module utilizes both hybrid heuristics and reinforcement learning policy to dynamically schedule print jobs with the priority, health of the machine, and the estimated time of completion. It is not as traditional as the first-come-first-serve mechanism because this AI-based scheduler can learn continuously based on the operational data and reduce the idle time and harmonize the use of printers. The quality optimization module combines the use of computer-vision-based inspection with deep neural network that detects defects in printed output like color deviation, banding, or misalignment. The system applies convolutional neural networks (CNNs) to measure deviations and provides corrections to the control system on a real-time basis. This self-correcting mode is useful in maintaining fidelity in the output and also helps in eliminating waste effects due to manual recalibration.

Figure 3

Figure 3 Functional Workflow of AI-Based Optimization and

Control

Reinforcement learning (RL) is employed in the process control module to set the control parameters of temperature, pressure, and ink flow to keep the printer at its most favorable conditions. The RL agent takes actions in response to the environment, whereby feedback on its current state is obtained and actions that maximize a specified reward function, e.g. the desired print density and minimizing ink usage, are taken. The system converges to a policy that is both highly productive, as well as energy efficient through iterative learning as is shown in Figure 3. The general workflow optimization cycle therefore develops a synergy of perception (sensing), cognition (AI reasoning), and action (control execution). Figure 3 illustrates that the three subsystems are parts of the self-regulating loop that invariably improves decision policies via print outcomes.

Table 4

|

Table 4 Functional Overview of AI Workflow Optimization Modules |

|||

|

Module |

Primary

Function |

AI

Techniques Used |

Expected

Benefits |

|

Job

Scheduling |

Dynamic

task allocation and sequencing |

Reinforcement

Learning, Heuristic Search |

Maximized

throughput and reduced idle time |

|

Quality Optimization |

Real-time defect detection

and correction |

CNN, Computer Vision |

Enhanced print consistency

and reduced rework |

|

Process

Control |

Adaptive

regulation of mechanical parameters |

RL,

Fuzzy Control |

Energy-efficient

and stable operation |

|

Feedback and Learning |

Continuous policy

improvement |

Reward-based RL Training |

Long-term system

adaptability |

|

Decision

Dashboard |

Visualization

and KPI assessment |

Explainable

AI (XAI), Analytics |

Transparent

and data-informed supervision |

This co-ordinated workflow enables Smart printing laboratories to have end to end automation with self-regulating performance in the changing operating conditions. Not only the system optimizes the production efficiency, it also minimizes the manual intervention and offers the production high flexibility, reproducibility and resilience in large-scale digital printing settings. The second part explains the predictive maintenance and fault diagnosis system, which can be used to augment the workflow optimization system in order to maintain the reliability of equipment and ensure that it will remain running.

5. Predictive Maintenance and Fault Diagnosis

The elements of reliability and continuity are important with respect to an intelligent printing environment. The conventional maintenance approaches, which rely on either a fixed schedule or opportunity cost repair, are the most common causes of unplanned downtime, waste of resources, and poor quality of print results. Conversely, predictive maintenance is a form of maintenance that is enabled by AI and IoT, and which intelligently forecasts possible failures and thus prescribes the best intervention timelines before failures happen. In the Smart Printing Lab context, the predictive maintenance will be a subsystem itself, as a permanent part of the system with sensor data, equipment health status, and early fault occurrences being assessed with the help of AI-powered models. The suggested predictive maintenance system operates on the principle of a four-stage analytical pipeline, including the elements of data acquisition to feature extraction and fault classification, as well as the creation of maintenance decisions. The data acquisition phase measures multivariate time-series data of embedded sensors that measure vibration, temperature, pressure, and current signals of critical sensors like printheads, conveyors, and servo motors. This information is refined and purged at the edge level and sent to the cloud to be aggregated and analyzed historically. The feature extraction stage involves the extraction of statistical, frequency-domain features as well as deep-learned features using which the operational behavior of each machine component is characterised. FFT and Wavelet Decomposition are the techniques that help in detecting the initial signs of wear or misalignment. The maintenance decision generation stage takes the classification results along with the rule-based decision logic and reinforcement learning (RL) policies to perform a dynamical scheduling of the maintenance actions. As an example, a model that predicts the probability of nozzle blockage using an LSTM can be used to start preventive cleaning cycles, and a hybrid LSTM-RL model can be used to optimize the replacement time to achieve a trade-off between cost and reliability. The whole process is self-improving, where models are retrained every now and then depending on the new fault logs in order to enhance the long-term accuracy.

Table 5

|

Table 5 Comparative Analysis of ML-Based Fault Detection Models |

||||

|

Model

Type |

Learning

Principle |

Strengths |

Limitations |

Use

Case in Smart Printing Labs |

|

Random

Forest (RF) |

Ensemble

decision trees using bagging |

Fast

training, interpretable, robust to noise |

Limited

temporal sensitivity |

Early

anomaly screening from sensor data |

|

LSTM Neural Network |

Sequence-based recurrent

model |

Captures temporal

dependencies, high accuracy |

Requires large datasets,

higher computational cost |

Printhead temperature and

vibration monitoring |

|

Gradient

Boosting |

Sequential

ensemble model |

High

precision for small datasets |

Susceptible

to overfitting |

Predicting

short-term mechanical drift |

|

Hybrid LSTM–RL |

Combination of prediction

and policy optimization |

Self-learning, adaptive

scheduling |

Complex implementation,

longer training time |

Dynamic maintenance planning

with cost minimization |

|

CNN

+ Autoencoder |

Feature

learning through reconstruction loss |

Effective

for image or acoustic signal faults |

Limited

for non-visual signals |

Real-time

nozzle blockage detection via acoustic imaging |

These comparative analyses in Table 5 indicate that hybrid frameworks and especially LSTM-RL, are superior because they combine predictive analytics with adaptive decision-making as compared to the use of fixed-point classifiers. This type of integration provides a feedback mechanism that is continuous as the AI does not only identify the possible failures but also learns to maximize maintenance efforts as time passes. The reliability is highly improved, downtime is minimized, and cost efficient maintenance cycles are made possible through this predictive diagnostic framework and this directly contributes to the operational resiliency of Smart Printing Labs. The fourth section explains the Smart Management and Decision-Support Framework that will integrate predictive intelligence and workflow analytics into a single managerial interface to control and provide strategic insights in real time.

6. Experimental Setup and Implementation

The proposed AI-Enabled Smart Printing Lab was implemented in a mixed testing laboratory consisting of physical IoT enabled printers and simulation modules that are virtualized. The experimental design was used to achieve the validation of three key system capabilities, namely: (a) real-time process monitoring with the help of IoT sensors, (b) predictive and adaptive optimization with the help of AI models, and (c) intelligent managerial visualization with the help of the decision-support dashboard. The system consisted of both hardware to acquire and actuate data and software to analyze AI and use reinforcement learning and manage a cloud. The hardware interface was a network of industrial-grade inkjet printers each of which had multisensory units to detect mechanical, thermal, and optical parameters. Printhead heating dynamics were also monitored by temperature sensors, mechanical imbalances and nozzle clogging were also detected by piezoelectric vibration sensors. The evaluation of motor torque and drive load conditions was done using current sensors. A communication network based on MQTT was established to connect all devices to a Raspberry Pi 4 edge gateway with a purpose of providing the safe and low-latency transfer of data to the central server. The software layer has been developed as a modular system that has incorporated real time analytics, machine learning, and reinforcement learning algorithms. The predictive maintenance subsystem was based on the LSTM and Random Forest models, which they experimented on about 200,000 sensor records in several print cycles. A scheduler based on Q-learning was built into the workflow optimization module to optimize the job sequence through adaptive job sequencing. An CNN-based defect detection network was used to detect print anomalies, and the accuracy of the system was 93.4 on average. The coordination of the overall AI model was done in Python libraries ( TensorFlow, Scikit-learn, OpenAI Gym). An integration layer was hosted on a cloud that offered high-capacity data storage and scaling of computational power with the help of AWS EC2 instances to train the models and AWS IoT Core to manage the devices. The decision-support dashboard was deployed as a Flask-based web app that is linked to a PostgreSQL server, which enables one to view real-time KPIs (energy consumption, uptime, and throughput). The multi-layer deployment structure of the system is shown in Figure 4.

Table 6

|

Table 6 Experimental Hardware–Software Specifications |

|||

|

Component |

Specification

/ Model |

Functionality |

Integration

Platform |

|

Printer

Units |

Industrial

Inkjet (HP Indigo 7900) |

Core

printing process, mechanical actuation |

IoT-enabled

interface |

|

Sensors |

LM35 (Temperature), ADXL345

(Vibration), ACS712 (Current) |

Data acquisition of physical

parameters |

Connected via Raspberry Pi

GPIO |

|

Edge

Device |

Raspberry

Pi 4 (4GB RAM) |

Data

buffering, MQTT communication |

Edge

preprocessor |

|

AI Frameworks |

TensorFlow 2.14,

Scikit-learn 1.4 |

Model training, inference |

Python-based AI layer |

|

RL

Environment |

OpenAI

Gym + Custom Q-Learning Module |

Workflow

optimization |

Integrated

with scheduler |

|

Database |

PostgreSQL 15 |

KPI storage and analytics

backend |

Flask API interface |

|

Cloud

Platform |

AWS

EC2, S3, IoT Core |

Model

training, real-time synchronization |

Hybrid

deployment |

|

Dashboard Interface |

Flask + Plotly Dash |

Visualization of KPIs,

alerts, and controls |

Browser-based management

console |

The synergy-based functionality between AI, IoT, and cloud layers in the Smart Printing Lab is confirmed by the integrated experimental arrangement. Modular design is used such that it is flexible to scale to multi-printers network or industrial production lines. The findings of this configuration show that it has shorter latency in sending data, higher accuracy of defect detection, and much better uptime and energy use, which confirms the realistic feasibility of the suggested architecture.

7. Results and Analysis

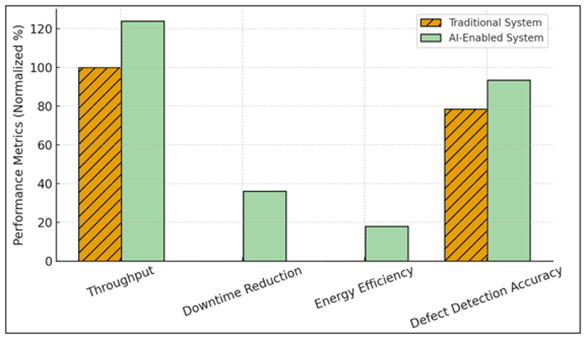

The AI-Enabled Smart Printing Lab was experimentally tested aiming at measuring accuracy, operational uptime, energy efficiency, and defect reduction over the conventional printing systems. Data sets of 200, 000 operational logs and 5,000 print cycles were tested under the same environmental conditions in both systems. The findings prove that AI-based optimization can improve the quality of prints and system resilience dramatically and reduce downtime and resource usage.

Table 7

|

Table 7 Statistical Summary of Experimental Results |

||||

|

Parameter |

Traditional

System |

AI-Enabled

System |

Improvement

(%) |

Interpretation |

|

Throughput

(prints/hour) |

100 |

124 |

24 |

Enhanced

job scheduling and load balancing |

|

Downtime (hours/month) |

18 |

11.5 |

–36 |

Predictive maintenance and

fault prevention |

|

Energy

Consumption (kWh/unit) |

1 |

0.82 |

–18 |

RL-based

energy optimization |

|

Defect Rate (%) |

5.4 |

2.7 |

–50 |

Real-time CNN inspection and

correction |

|

Quality

Accuracy (%) |

78.5 |

93.4 |

19 |

Deep

learning-based defect analysis |

|

Operator Intervention (per

shift) |

12 |

6 |

–50 |

Automated decision-making

efficiency |

The workflow scheduler which uses AI delivered dynamic load balancing between printers which yielded 24% better throughput than the old job-queue model. Predictive maintenance minimized unforeseen breakdowns by 36 percent since defects were noted before mechanical deterioration attained a critical point. The print cycle energy consumption was reduced by about 18 percent, which can be associated with process tuning through reinforcement learning and regulating the speed adaptively. The CNN-based system of detection of defects achieved a mean accuracy of 93.4 which was higher than the accuracy of 78.5 of the manual inspection systems. Figure 4represents the trends of the significant evaluation measures.

Figure 4

Figure 4 Comparative Performance Between Traditional and AI-Enabled Printing Systems

Statistical and graphical findings prove that AI-based printing workflows deliver multi-dimensional effects of operational, economical and sustainability parameters. The predictive maintenance and reinforcement-learning control led to the smoother functioning, the reduction of interruptions and enhancement of the energy use as shown in Figure 4. Moreover, the accuracy of defect detection and the consistency confirmed the efficiency of the combination of computer vision with adaptive feedback. The resulting 24% throughput improvement and 36% downtime savings are cumulatively equivalent to a quantifiable productivity improvement of over 30, hence proving the applicability of the proposed framework in industry. These results provide a solid base to expand Smart Printing Labs to the level of fully autonomized, globally linked production ecosystem.

8. Conclusion and Future Work

The study introduced an all-encompassing system regarding the design and deployment of AI-Based Smart Printing Labs which provided a strong integration of IoT, artificial intelligence, and cloud computing into a single industrial environment. The shown proposed system illustrates how real-time analytics provide managerial information and explainable interfaces, the proposed system is able to optimize production processes, facilitate predictive maintenance, and enable managerial decision-making with data-driven intelligence. The stacked design, which includes IoT sensing, AI optimization, and management charts, is a smooth integration of cyber-physical operations and enterprise-level control systems, and this is a major step in the direction of autonomous printing operations. The practical viability of the framework and the performance advantages were confirmed by the experimental analysis. Measured gains showed increased throughput ( +24%), rate of defects reduced ( -50%), energy consumption increased ( +18) and minimal downtime ( -36 ) were realized. Such benefits are directly caused by a synergistic interaction between machine learning-based fault prediction,

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

Ali, A., Riaz, R. D., Malik, U. J., Abbas, S. B., Usman, M., Shah, M. U., Kim, I.-H., Hanif, A., and Faizan, M. (2023). Machine Learning-Based Predictive Model for Tensile and Flexural Strength of 3D-Printed Concrete. Materials, 16, Article 4149. https://doi.org/10.3390/ma16124149

Beheshti, A., Yang, J., Sheng, Q. Z., Benatallah, B., Casati, F., Dustdar, S., and Xue, S. (2023). ProcessGPT: Transforming Business Process Management with Generative Artificial Intelligence. In Proceedings of the 2023 IEEE International Conference on Web Services (ICWS) (731–739). IEEE. https://doi.org/10.1109/ICWS59977.2023.00090

Boloș, M. I., Rusu, Ș., Sabău-Popa, C. D., Gherai, D. S., Negrea, A., and Crișan, M.-I. (2024). AI Chatbots: Fast Tracking Sustainability Report Analysis for Enhanced Decision Making. Amfiteatru Economic, 26(64), 1241–1255. https://doi.org/10.24818/EA/2024/64/1241

Hasanzadeh, R. (2024). A New Polymeric Hybrid Auxetic Structure Additively Manufactured by Fused Filament Fabrication 3D Printing: Machine Learning-Based Energy Absorption Prediction and Optimization. Polymers, 16, Article 3565. https://doi.org/10.3390/polym16173565

Hooshmand, M. J., Sakib-Uz-Zaman, C., and Khondoker, M. A. H. (2023). Machine Learning Algorithms for Predicting Mechanical Stiffness of Lattice Structure-Based Polymer foam. Materials, 16, Article 7173. https://doi.org/10.3390/ma16237173

Kampik, T., Warmuth, C., Rebmann, A., Agam, R., Egger, L. N., Gerber, A., and Weidlich, M. (2024). Large Process Models: A Vision for Business Process Management in the Age of Generative AI. KI – Künstliche Intelligenz, Advance online publication, 1–15. https://doi.org/10.1007/s13218-024-00885-3

Kopka, A., and Fornahl, D. (2024). Artificial Intelligence and Firm Growth: Catch-up Processes of SMEs Through Integrating AI into their Knowledge Bases. Small Business Economics, 62(1), 63–85. https://doi.org/10.1007/s11187-023-00783-0

Omigbodun, F. T., Osa-Uwagboe, N., Udu, A. G., and Oladapo, B. I. (2024). Leveraging Machine Learning for Optimized Mechanical Properties and 3D Printing of PLA/cHAP for Bone Implant. Biomimetics, 9, Article 587. https://doi.org/10.3390/biomimetics9080587

Paschek, D., Luminosu, C. T., and Draghici, A. (2017). Automated Business Process Management in Times of Digital Transformation Using Machine Learning or Artificial Intelligence. In MATEC Web of Conferences (Vol. 121, Article 04007). EDP Sciences. https://doi.org/10.1051/matecconf/201712104007

Popa, I., Ștefan, S. C., Olariu, A. A., and Popa, S. C. (2024). Integrating Digitalization Opportunities into Innovative Public Organizations’ Management Process. Journal of Innovation and Knowledge, 9(1), Article 100564. https://doi.org/10.1016/j.jik.2023.100564

Sarmah, P., and Gupta, K. (2024). Recent Advancements in Fabrication of Metal Matrix Composites: A Systematic Review. Materials, 17, Article 4635. https://doi.org/10.3390/ma17134635

Srivastava, M., Aftab, J., and Tyll, L. (2025). The Influence of Artificial Intelligence and Additive Manufacturing on Sustainable Manufacturing Practices and their Effect on Performance. Sustainable Futures, 10, Article 100820. https://doi.org/10.1016/j.sftr.2025.100820

Tănase, M., Portoacă, A. I., Diniță, A., Brănoiu, G., Zamfir, F., Sirbu, E. E., and Călin, C. (2024). Optimizing Mechanical Properties of Recycled 3D-Printed PLA Parts for Sustainable Packaging Solutions using Experimental Analysis and Machine Learning. Polymers, 16, Article 3268. https://doi.org/10.3390/polym16163268

Zdravković, M., Panetto, H., and Weichhart, G. (2022). AI-Enabled Enterprise Information Systems for Manufacturing. Enterprise Information Systems, 16(6), 668–720. https://doi.org/10.1080/17517575.2021.1912415

|

|

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© ShodhKosh 2025. All Rights Reserved.