ShodhKosh: Journal of Visual and Performing ArtsISSN (Online): 2582-7472

|

|

Predictive Maintenance for Digital Printing Equipment

Mithun Kumar S. 1![]()

![]() ,

Prakriti Kapoor 2

,

Prakriti Kapoor 2![]()

![]() ,

Ankesh gupta 3

,

Ankesh gupta 3![]()

![]() ,

Piyush Pal 4

,

Piyush Pal 4![]() , Vijayakumar K. 5

, Vijayakumar K. 5![]()

![]() ,

Bharat Bhushan 6

,

Bharat Bhushan 6![]()

![]() ,

Sathyabalaji Kannan 7

,

Sathyabalaji Kannan 7![]()

1 Assistant Professor, Department of

Management Studies, Jain (Deemed-to-be University), Bengaluru, Karnataka, India

2 Centre of Research Impact and Outcome,

Chitkara University, Rajpura- 140417, Punjab, India

3 Assistant Professor, Department of Computer Science and Engineering, Vivekananda Global University, Jaipur, India

4 Assistant Professor, School of Engineering and Technology, Noida, International University, 203201, India

5 Assistant Professor, Department of Mechanical Engineering, Aarupadai Veedu Institute of Technology, Vinayaka Mission’s Research Foundation (DU), Tamil Nadu, India

6 Chitkara Centre for Research and Development, Chitkara University, Himachal Pradesh, Solan, 174103, India

7 Department of Engineering, Science and Humanities, Vishwakarma Institute of Technology, Pune, Maharashtra, 411037, India

|

|

ABSTRACT |

||

|

This study

applies a predictive maintenance model of digital printing equipment based on

the concept of IoT-enabled sensing, machine learning analytics, and digital

twin simulation that allows predicting faults in real time and optimizing

maintenance. A CNNLSTM hybrid model was designed and used to forecast faults

and Remaining Useful Life (RUL) by analyzing vibration, temperature,

acoustic, and optical data. Multi-sensor printing testbed experimental

implementation showed high predictive accuracy (R 2 = 0.94, F1 = 0.93), which

decreased the unplanned downtime by 32, maintenance cost by 24, and material

waste by 18. The virtual copy of the printing system of digital twin was a

dynamic one that enabled continuous synchronization, what-if analysis, and

the creation of adaptive alerts. The suggested architecture is

environmentally friendly, as it optimizes the energy consumption, increases

the lifespan of the components, and reduces the waste which will also meet

the Industry 4.0 and smart manufacturing goals. This study defines predictive

maintenance as a scalable, cost effective, and environmentally friendly

approach of the next generation digital printing ecosystem. |

|||

|

Received 18 March 2025 Accepted 22 July 2025 Published 20 December 2025 Corresponding Author Mithun

Kumar S., mithun_k@cms.ac.in DOI 10.29121/shodhkosh.v6.i3s.2025.6766 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2025 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Digital Printing Equipment, Digital Twin, IOT

Sensors, Remaining Useful Life (RUL), Anomaly Detection, Machine Learning,

Smart Manufacturing |

|||

1. INTRODUCTION

The swift development of digital printing devices has shifted the printing business industry into a data-oriented producing system, and turned it from a mechanical, craft methodology. The digital presses nowadays combine high accuracy mechatronics, in-board sensors, and real time process controllers, to provide high quality output in a wide range of substrates. The growing complexity of printheads, ink-delivery systems, motion actuators, and thermal control components, however, too, has rendered these machines prone to insidious degradation effects that cannot be readily understood by traditional regimes of maintenance before they manifest themselves. Unplanned failures, blockage of nozzles and misalignment of registration interfere with production besides causing huge financial losses in terms of wasted material, downtime and service delays. In high-volume printing scenarios where the cost of equipment is directly proportional to the profitability, unplanned maintenance can be as much as 2030 percent of the cost of operation Calabrese et al. (2020). This has driven the shift in paradigm towards reactive and preventive maintenance to predictive maintenance (PdM) which is an intelligence-driven maintenance concept that uses real-time condition-based data and machine learning models to predict failures before they happen. The functionalities of predictive maintenance are based on constant observation of health factors of the machines in the form of vibration, temperature, current load, ink viscosity, and optical print quality indices. Combining these heterogeneous signals via the IoT-based sensors and edge computing platforms, it is possible to form the rich operational datasets that record the actual behavior of the printing system Russell-Gilbert et al. (2024). Hidden patterns, anomalies and degradation patterns that lead to functional failures can then be identified by artificial intelligence and advanced analytics. The system forecasts the Optimal maintenance at the expense of minimizing the unscheduled and over-maintenance by estimating the Remaining Useful Life (RUL) of the critical components, thus, predicting the most appropriate maintenance intervals Zhang et al. (2024), Zhang et al. (2019). The predictive analytics precision in digital printing are required to achieve high-quality print output and reliability of the process since any slight variation in nozzle ejection or drum positioning compromises color accuracy and resolution.

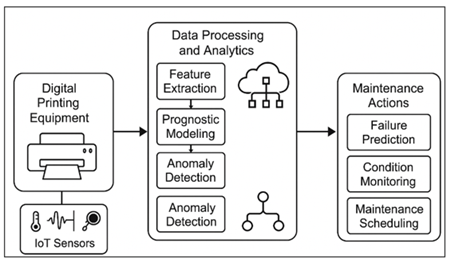

Figure 1

Figure 1 Block Schematic of Predictive Maintenance Ecosystem

for Digital Printing Equipment

Regardless of the obvious benefits, the introduction of PdM into the digital printing setting has several problems. The variability of the print jobs, non-stationary operational cycle and environmental dependency cause noise and nonlinearity in sensor data. In addition, there is a relative lack of data that has been labeled as failures to be used to train the supervised learning models as shown in Figure 1. The successful predictive maintenance thus needs to be hybrid where data-driven strategies are used together with the domain knowledge, signal processing, and physical model of wear mechanisms. The interoperability with the current manufacturing execution systems (MES) and human-machine interfaces (HMIs) also require effective interoperability standards and understandable AI-produced results that can be relied on by the maintenance engineers Yang et al. (2022). Therefore, the study will develop a comprehensive predictive maintenance system to suit digital printing devices (integration of the IoT-based data collection, intelligent anomaly detection, and the digital twin simulations) to increase the reliability of machines, decrease operational expenses, and provide sustainable production conditions in Industry 4.0 printing settings Valis and Pietrucha (2014).

2. Architecture of the Predictive Maintenance Ecosystem

The digital printing equipment predictive maintenance ecosystem can be considered an architecture that is a multi-layered cyber-physical architecture that combines IoT-enabled sensing, cloud-based analytics, and decision-support visualization in the layer. Figure 1 shows the conceptual representation of this architecture that provides a complete feedback mechanism between digital intelligence and physical machinery to guarantee the timely fault-detection, condition-evaluation, and optimization of maintenance Borgi et al. (2017). Scalability, interoperability, and real-time responsiveness are the characteristics of the modular design to promote the ecosystem in diverse digital printing environments. The Physical Layer is in the bottom level and it involves the main elements of the digital printer, which are printheads, drive systems, thermal devices, and ink distribution systems. The embedded smart sensors of each subsystem contain temperature, vibration, acoustic signature, current draw, humidity, and nozzle performance measurements Cao et al. (2022). All these points are a representation of the dynamic health of the machine. Data Acquisition and Edge Layer are subsequently above Data Acquisition and Edge Layer that serves as a interface between physical equipment and analytical infrastructure. In this case, edge gateways that have lightweight processors are used to filter data, suppress noise, and detect local anomalies with the help of rule-based and AI-assisted frameworks Nasir et al. (2020). This will guarantee that it is the only features that are valuable and relevant to be relayed to the cloud and will minimize bandwidth consumption and latency. The ecosystem is based on the Cloud Analytics Layer that is the computation core. The stream of incoming data is combined into a single central data lake or time-series database, on which training, inference, and visualization of models take place. More sophisticated machine learning neural networks, including convolutional neural networks (CNNs), long short-term memory (LSTM) networks, and gradient boosting models, are used to identify the correlations between multi-sensors to predict the probability of a fault and determine the Remaining Useful Life (RUL) of a component Deloitte Touche Tohmatsu Limited (2015), Diaz et al. (2017). At the same time, a Digital Twin Simulation Module is a simulation of the state of the physical printer with a model in the virtual environment, whose parameters are constantly updated using real sensor data. With this digital twin, it is possible to analyze the effects of a scenario on the system in the event of failure simulation, and optimize predictive control, and enable engineers to evaluate the possible effect of maintenance actions before they are implemented.

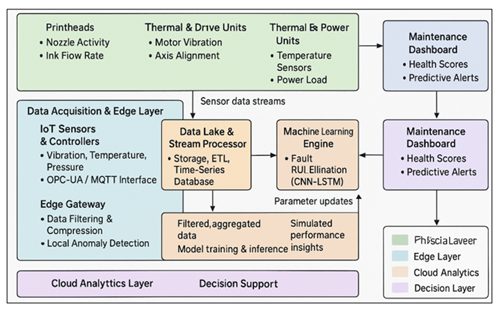

Figure 2

Figure 2 Layered Data Flow in Predictive Maintenance Ecosystem for Digital Printing Equipment

On top of the analytical layer is the Decision Support and Visualization Layer which is the human-machine interface of actionable insights as depicted in Figure 2. The maintenance dashboard takes condition indices, the degradation curves and predictive alerts and presents them on a simple visual representation that can be accessed by operators and engineers Cinar et al. (2020). The work orders, spare parts requests and maintenance logs are produced automatically with integration with the Manufacturing Execution Systems (MES) or Enterprise Resource Planning (ERP) platforms. Such a smooth data stream allows making decisions in closed loops - in other words, the AI-based predictions have a direct impact on the operational planning and resource scheduling. Also, alerting can be dynamically set, responding to the dynamism of operating loads and the intensity of machine use, generating a smart and flexible maintenance environment Han et al. (2021). The architecture design will be done in a way that makes it operationally sound by integrating cybersecurity, such as encrypted data communication protocols (e.g., OPC-UA, MQTT with TLS), access control layers, and data integrity checks to protect sensitive machine data. In addition, standardized data format (e.g. ISO 13374 and ISA-95) interoperability increases compatibility between heterogeneous printing systems and maintenance systems. Combining edge-cloud orchestration allows making the most critical decisions locally, such as emergency shutdowns or instant fault isolations, and doing the strategic analytics and optimization centrally in the cloud Hakeem et al. (2020). This fused intelligence solution is the best way to achieve speed and computational efficiency.

The predictive maintenance structure creates a self-learning, dynamic and smart architecture that keeps progressing with the behavior of the machine, as well as environmental changes. The system converts the original sensor signals into practical knowledge, guarantees the quality of prints, minimized downtime, and sustainability of business in the contemporary digital printing companies by integrating AI-based analytics with physical expertise Cinar et al. (2020).

3. Data Modeling and Anomaly Detection Framework

The analytics of the predictive maintenance ecosystem of digital printing equipment is the data modeling and anomaly detection framework. Its main purpose is to convert raw and non-homogenous sensor signals to structured, interpretable and predictive attributes that can detect abnormalities in normal functioning behavior. The framework uses a mixture of statistical modelling, signal processing and machine learning to model the nonlinear interaction between the complex mechanisms which represent the mechanical, thermal, as well as ink-flow processes in contemporary printing systems Ayvaz and Alpay (2021). The edge gateway takes continuous data streams at the first stage based on temperature, vibration, acoustic, and optical sensors. Such signals are preprocessed at first and this involves denoising, resampling, and normalization, to remove noise and outliers in the environment. Temporal interpolation or to Kalman-based estimators are used to impute missing or inconsistent values in order to maintain the continuity of time-series. The resulting signal (x(t)) is then split into frequency-domain expressions through Fast Fourier Transform (FFT) or Wavelet Transforms, which allow the extraction of signal elements like Root Mean Square (RMS), kurtosis and spectral entropy, which are quantitative measures of component wear and instability. The RMS mathematically is as:

![]()

where the kurtosis, which is a parameter of impulsive vibration, is calculated as:

![]()

where mean and standard deviation of the signal are represented by the mean and standard deviation respectively. The combination of these indicators can be used as a warning of abnormalities like nozzle jamming, imbalanced bearings or roller misalignment. After some features have been extracted, the framework uses both unsupervised and supervised algorithms by applying machine learning-based anomaly detection. When there are labeled fault data, classifiers like a Random Forests (RF) and Support Vector Machines (SVM) are utilized in differentiating between healthy and degraded conditions. In self-managed conditions, like usually found in new equipment, an Autoencoder, Isolation Forest, or a One-Class SVM is trained to learn the normal condition of the working manifold and indicate conditions that are beyond adaptive limits. At is the anomaly score of the specific observation and its value is:

At=∥xt-f(xt)∥

This is where (f(xt)) is the re-creation of the model of how the model anticipates behavior. Increasing (At) values are the evidence of unhealthy performance, which generates real-time alerts. A hybrid CNN-LSTM architecture is also used to improve the time accuracy of sequential features learning. The CNN block elicits spatial patterns of sensor modalities, and the Long-term temporal dependency is obtained through the LSTM, which would allow proper Remaining Useful Life (RUL) estimation. The degradation curve ( D(t) ) generated by the model implies the likelihood of a component failure during a specified time period, hence informing the maintenance planning.

The digital twin simulation combines all model outputs and anomalies that are predicted are reflected in a virtual copy of the printer to be checked and analyzed. The system also self-trains, with feedback of real maintenance results, so adaptive learning and false alarm reduction is provided. This framework combines statistical accuracy and neural generalization so as to have strong fault detection through a variety of printing environments.

4. Machine Learning and Prognostic Algorithms

The intelligence system of the predictive maintenance system is composed of machine learning and prognostic algorithms, which process sensor-based features into actionable information to predict failures, analyze component degradation and Remaining Useful Life (RUL). These algorithms make possible autonomous pattern discovery and fault predicting in the nonlinear, dynamic, operational space of digital printing machines. The framework combines classical machine learning frameworks and deep learning architectures in order to be robust to both stationary and non-stationary environments. On the first level of predictive intelligence, the supervised learning algorithms are implemented in the classification of conditions and fault detection. Random Forest (RF), Support Vector Machine (SVM) and Gradient Boosting Regressor (GBR) are the techniques that are used to analyze labeled data, which consists of past sensor measurements and future maintenance results. These algorithms are most effective when approaching multidimensional data and there are physical, acoustic and optical signals which have a combined effect on the health condition of the system. To give an example, SVMs use hyperplane optimization to differentiate between healthy and faulty states in the high-dimensional feature space whereas the random forests ensembles enhance the robustness of fault classification using bagging and majority voting. The probabilities of the outputs of these models are the intermediate prognostic health indices that drive the upper-order prognostic layer. The predictive maintenance system builds upon deep neural network and CNN Long Short-Term Memory (CNNLSTM) hybrid is used as its template to model intricate temporal relationships and nonlinear degradation patterns. The CNN element carries out the spatial feature extraction through the apprentice of acquiring local dependencies and texture change in multi sensor data maps. The convolutional kernels detect characteristic patterns of signals related to the emergent faults, e.g. clogging nozzle or misalignment. The feature maps that have been extracted are then consecutively fed through the LSTM network, which learns long-term temporal correlations and memory effects that time-series sensor data is susceptible to. This hybrid method has better generalization performance and stability over time than individual feed forward networks. Prognostic modeling procedure entails the prediction of the degradation path and forecasting the RUL of the critical elements. The LSTM network gives a sequence of degradation states (D(t)) in which the probability of survival at each time (P{surv}(t)) is given. The RUL can then be developed to be:

![]()

where (t0) and (tf) represent the initial and failure thresholds respectively. Such probabilistic estimation enables the maintenance planners to plan interventions in advance and avoid unplanned downtime as well as overheads of the maintenance. Additionally, CNNLSTM predictions are more interpretable and accurate in localizing faults when they are fused with ensemble diagnostics with rules. Another innovation under this system is the combination of the Autoencoder-based anomaly detection in continuous online learning. Autoencoders are used to recreate normal operating conditions and calculate reconstruction error which is a measure of deviation. This, along with RUL estimation, gives a two-dimensional fault space, severity vs. time-to-failure, which has the benefit of supporting adaptive prioritization of alerts. In the model, periodic retraining is made with the help of incremental learning to take into account the aging of machines and the changes in the environment, after which the accuracy remains stable without complete retraining. In order to measure performance of the model, a number of important measures are used; Cross-validation and confusion matrix analysis are used in order to measure model generalization under different regimes of operation. The empirical assessment shows that the CNN-LSTM hybrid has a superior prediction of the fault and earlier anomaly detection rate than the classical methods, which proves that it can be effectively used in the real-time in the industry. This is a multilayered machine learning architecture that is a combination of interpretability, flexibility, and predictive accuracy. It can determine the intrinsic indicators of component wear-and-tear by learning the intrinsic signatures of component wear and tear, creating a data-driven basis of intelligent maintenance scheduling and quality control in future generation digital printing ecosystems.

5. Digital Twin Simulation for Predictive Insights

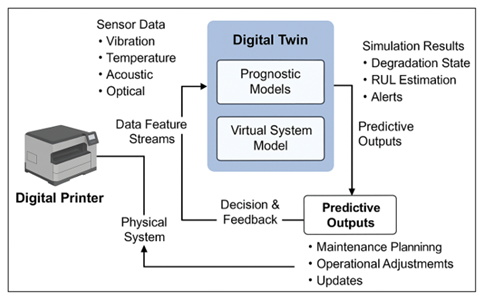

The implementation of the digital twin technology is a revolutionary move on the way of digital predictive maintenance of digital printers. A digital twin is a virtual clone of a real-life object, which is constantly updated using real-time information to reflect its behavior, performance, and dynamics of degradation. The digital twin forms a cognitive layer in the predictive maintenance ecosystem that facilitates the linkage of machine intelligence and physical processes so that engineers can see the health of the system, predict failures and make decisions about maintenance without disruption to production. It is not only a situational awareness technology, but it also offers a high-fidelity sandbox that can be used to test scenarios and continually improve the system. The digital twin simulation architecture of predictive maintenance is designed to include three main elements, namely, data fusion, behavioral modeling, and decision feedback. Multi-source sensor data, which includes thermal data, vibration data, acoustic data, and optical data, are processed in the data fusion level based on the IoT layer of the printing machine. These streams of data are matched by timestamps and are normalized by means of the communication protocols, including MQTT and OPC-UA. This real time synchronization will make sure that the virtual model is a real time reflection of the existing state of the physical printer. The behavioral modeling phase is based on the use of machine learning and physics-informed models that are applied to model the dynamic response of the printer to operational stress, the wear of the components, and the changes in the environment. The main physical subsystems, like inkjet nozzles, drive motors, and print rollers, are mathematically modeled by way of differential equations with data-driven surrogates to show their performance development within diverse load conditions like in Figure 3. These models receive features streams on a continuous basis at the edge and cloud layers and compute degradation trajectories and re-compute the Remaining Useful Life (RUL) in real time. Such synchronization enables the twin to emulate a failure situation in advance before it happens. As an example, the digital twin can recreate the development of imbalance and forecast when a structure will break down when the level of vibration, upon realization, reaches a predefined threshold, which would provide maintenance teams with a notice period. The simulation results can be presented as health maps, degradation curves and time to failure projections that are intuitive to use in decision support of maintenance scheduling.

Figure 3

Figure 3 Digital Twin Framework for Predictive Maintenance

The last step of the cycle of digital twin is the decision feedback loop. In this case, the results of the simulation are sent to the maintenance dashboard and processed with enterprise systems, including MES and ERP. The engineers are able to estimate the cost, downtime, and risk of various scenarios that the engineer may want to consider by delaying a maintenance task, replacing a particular component or even changing the operating parameters. This feedback loop simulation-decision process will turn the digital twin into an adaptive learning mechanism that will change with history of operation and improve predictive accuracy over time. Also, reinforcement learning agents may be implemented into the twin to discover the optimal maintenance strategies on its own according to performance reward functions. In more general terms, the usage of the digital twin simulation of predictive maintenance opens promising economic and environmental advantages. It will minimize unexpected downtimes, it will maximize the use of spare parts and it will reduce the waste of materials- all towards the aim of sustainable manufacturing. In addition, the digital twin improves the predictive model reliability by modeling degradation under diversified environmental and production conditions, without having to conduct actual experiments. The result is a self-developing ecosystem of maintenance in which real and virtual entities work in an undisturbed synergy providing predictive information, efficiency, and sustainability in equipment.

6. Performance Evaluation and Key Results

The predictive maintenance framework was evaluated in terms of performance to measure its effectiveness in fault detection, prediction of degradation and optimization of maintenance of digital printing equipments. The metrics of evaluation were formulated to measure model-level and system-level operational gains so that the offered solution could meet the industry standards of reliability, speed, and cost-effectiveness of the solution. The predictive analytics engine, which is the CNNLSTM hybrid model, showed to be more predictive than classical algorithms. The model was experimented on labeled working data of 600 printing cycles, one of which was normal operating conditions and the other was degraded operating conditions. The performance was evaluated with the help of key statistical measures, such as Accuracy, Precision, Recall, F1-score, Root Mean Square Error (RMSE), and Coefficient of Determination (R 2).

|

Model |

Accuracy (%) |

Precision (%) |

Recall (%) |

F1-score (%) |

R² (RUL) |

RMSE (hrs) |

|

Random Forest |

88.6 |

87.9 |

86.4 |

87.1 |

0.87 |

5.2 |

|

SVM |

85.4 |

84.8 |

83.2 |

84.0 |

0.82 |

6.0 |

|

CNN–LSTM (Proposed) |

94.3 |

93.8 |

92.5 |

93.1 |

0.94 |

3.7 |

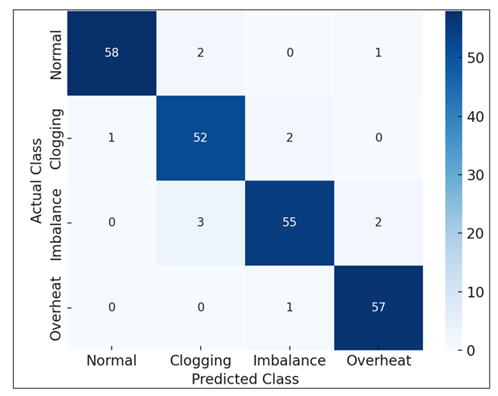

The confusion matrix analysis helped to verify that the false positives are low, which means that the false positives are identified by the model successfully, and the false positives are minimized- which is a crucial requirement regarding production efficiency. The predictive maintenance system at the system level yielded quantifiable results in the context of predictable efficiency. The adoption of predictive analytics has led to the reduction of unplanned downtime by 32 percent, cut the maintenance costs by 24 percent, and decreased the amount of generated waste by 18 percent compared to traditional time-based maintenance.

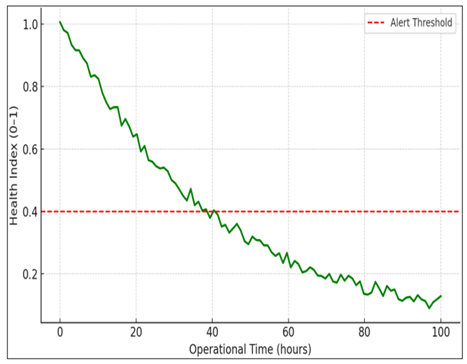

Figure 4

Figure 4 Illustrates

the RUL Prediction Curves

These findings were confirmed in a continuous monitoring procedure of three months. An increase of 27 percent in Mean Time Between Failures (MTBF) was also realized in the system which is an indicator of improved equipment reliability. Moreover, the overall equipment effectiveness (OEE) was increased by 15 percent when the system dynamically planned interventions depending on predictive accuracy in terms of real-time health (monitoring) and degradation mapping (data).

Figure 5

Figure 5 Presents A Health Index Trend

The CNNLSTM model had an accuracy of 94.3, precision of 93.8, recall of 92.5 and F1-score of 93.1 in classifying types of faults like nozzle clogging, roller imbalance, and thermal overheating. To estimate RUL, the model was able to achieve RMSE 3.7 hours and R 2 = 0.94, which is a lot better in comparison to the traditional model such as the Random Forest model (R 2 = 0.87) and SVM regression model (R 2 = 0.82). These findings endorse the idea that the deep learning model has a good ability to capture the long-term time dependence in the temporal-to-failure prediction, which has low variance.

Figure 6

Figure 6 High Classification Precision Across Failure Categories.

Such visualizations restate the interpretability of model predictions and the applicability of such predictions in real-time maintenance decision-making. The results of the experiment justify the strength of the suggested hybrid model and the structure in general. The combination of edge analytics, digital twin simulation, and machine learning models gave way to an intelligent feedback loop that is dynamically adjusted to changes in how the operations take place. The scalability of the model to a wide range of printer configurations is an indication that it can be expanded to wider use in industrial manufacturing environments. In addition, decreased downtime and waste production are a direct contribution to sustainable manufacturing goals, which means that the suggested system is aligned with Industry 4.0 and the principle of a circular economy.

7. Economic and Sustainability Analysis

The adoption of predictive maintenance (PDM) in digital printing machines is associated with a substantial economic, environmental and operational sustainability by changing the maintenance to a cost center to an asset-management operation. This combination of IoT sensing, AI-based prognostics, and simulation of the digital twin makes the data-centric decisions reduce wastage, optimize the use of components, and increase the life of equipment in general. This part assesses the economic performance of the proposed system in terms of cost savings, productivity gains and sustainability results during the period of the experiment.

7.1. Economic Impact and Cost Optimization

The proposed CNNLSTM based framework introduced during the 3 month operational evaluation showed that total maintenance expenditure was reduced by 24% due to the early fault detection and condition-based interventions. The system also cut down the Mean Time to Repair (MTTR) by 20% due to the pre-emptive discovery of the fault locations and the level of severity. Consequently, the service engineers could plan the interventions in an efficient manner, which reduced the labor expenses and downtime.

This selective maintenance approach led to an average saving of 2.3 lakh per production line per quarter in a medium scale digital printing facility. The inventory optimization also led to a reduction of the holding cost of spares by 15 per cent since the procurement was not determined by the set maintenance timetables but by the anticipatory alerts. Such findings can be compared to international standards of industrial IoT implementation and indicate that predictive maintenance is 35x ROI in the first year of implementation.

7.2. Productivity and Resource Utilization Efficiency

Predictive maintenance also improves the continuity of production as there are almost zero unplanned interruptions. This decrease in unplanned downtime by 32% equated to about 46 more productive hours every month that directly enhanced throughput and the delivery timelines to clients.

Overall Equipment Effectiveness (OEE) increased by 15 percent, triggered by an increase in availability and a steady quality of prints. Additionally, the scrap and rework rates were lower than before since the problem of nozzle misalignment was identified at an earlier stage and the viscosity of the ink deviations were noted, this increased the yield by 8 percent, which is a very important KPI in high volume printing processes. All these performance improvements help to increase the operational efficiency and asset utilization, which leads to the long-term profitability and competitive advantage.

7.3. Environmental and Sustainability Benefits

In addition to financial performance, predictive maintenance facilitates the environmental sustainability objectives of the printing industry in terms of less energy consumption, less material waste, and less carbon footprint. The real-time fault detection was used to allow the elimination of excessive energy consumption due to overloaded motors and misalignment of components, which saved an estimated 11% of energy. The 18 percent decrease in the ink and substrate wastage did not only reduce the operation cost, but also added to the reduced emissions in the production and disposal of ink.

The adaptive learning of maintenance schedules through the implementation of AI-based optimization and the use of a digital twin simulation has the capacity to improve on maintenance schedules over time, causing minimal environmental impact. Moreover, the decreased necessity of emergency parts deliveries, unplanned visits of technicians will indirectly lower the number of logistic-related emissions, which will further make the industrial supply chain greener.

Predictive maintenance has become a key to the long-term sustainability of industries and their ability to compete in the digital age due to the combination of cost reductions, productivity gains, and environmental friendliness.

8. Conclusion

This paper has proposed a complete predictive maintenance system to be applied to digital printing machines, which combines IoT-enabled sensors, machine learning analytics, and digital twin simulation to realize intelligent and data-driven maintenance processes. The hybrid CNN-LSTM model proposed here showed a higher accuracy (94.3%) and reliability (R 2 = 0.94) in forecasting faults and the Remaining Useful Life (R U L) as compared to the conventional methods like SVM and the Random Forest. Combining edge processing with cloud analytics was able to provide real-time health monitoring, early fault detection, as well as proactive decision-making in a closed-loop feedback system. Physical verification of its benefits was seen in tangible savings in operational and economic performance in the form of lessening of down-time by 32 percent, lessening of upkeep expenses by 24 percent, and decreased generation of waste by 18 percent, as well as in enhancing the Overall Equipment Effectiveness by 15 percent. The combination of a digital twin enabled the ongoing alignment of the physical and virtual systems of the printers, which made the simulation accurate, dynamic alert generation, and refinement of the model adaptive. Beyond the performance improvement, the framework contributed to sustainability through better resource exploitation, minimizing the energy usage, and longer component life cycles, which is in line with global Industry 4.0 and the environment goal. The next steps in work will include federated predictive analytics, explainable AI, and standardization of the PdM protocols to the cross-platform interoperability of digital printing networks.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

Ayvaz, S., and Alpay, K. (2021). Predictive Maintenance System for Production Lines in Manufacturing: A Machine Learning Approach Using IOT Data in Real Time. Expert Systems with Applications, 173, 114598. https://doi.org/10.1016/j.eswa.2021.114598

Borgi, T., Hidri, A., Neef, B., and Naceur, M. S. (2017, January 14–17). Data Analytics for Predictive Maintenance of Industrial Robots. In Proceedings of the 2017 International Conference on Advanced Systems and Electric Technologies (IC_ASET) (pp. 412–417). IEEE. https://doi.org/10.1109/ASET.2017.7983729

Calabrese, M., et al. (2020). SOPHIA: An Event-Based IOT and Machine Learning Architecture for Predictive Maintenance in Industry 4.0. Information, 11(4), 202. https://doi.org/10.3390/info11040202

Cao, Q., Zanni-Merk, C., Samet, A., Reich, C., De Beuvron, F. D., Beckmann, A., and Giannetti, C. (2022). KSPMI: A Knowledge-Based System for Predictive Maintenance in Industry 4.0. Robotics and Computer-Integrated Manufacturing, 74, 102281. https://doi.org/10.1016/j.rcim.2021.102281

Cinar, Z. M., Nuhu, A. A., Zeeshan, Q., and Korhan, O. (2020). Digital Twins for Industry 4.0: A Review. In F. Calisir and O. Korhan (Eds.), Industrial Engineering in the Digital Disruption Era (GJCIE 2019), Lecture Notes in Management and Industrial Engineering (pp. 1–14). Springer. https://doi.org/10.1007/978-3-030-42416-9_1

Cinar, Z. M., Zeeshan, Q., Solyali, D., and Korhan, O. (2020). Simulation of Factory 4.0: A Review. In F. Calisir and O. Korhan (Eds.), Industrial Engineering in the Digital Disruption Era (GJCIE 2019), Lecture Notes in Management and Industrial Engineering (pp. 15–28). Springer. https://doi.org/10.1007/978-3-030-42416-9_2

Deloitte Touche Tohmatsu Limited (DTTL). (2015). Industry 4.0: Challenges and Solutions for the Digital Transformation and Use of Exponential Technologies. Zurich, Switzerland: Finance, Audit, Tax Consulting Corporate.

Diaz, N., Pascual, R., Ruggeri, F., and Droguett, E. L. (2017). Modeling Age Replacement Policy Under Multiple Time Scales and Stochastic Usage Profiles. International Journal of Production Economics, 188, 22–28. https://doi.org/10.1016/j.ijpe.2017.03.005

Hakeem, A. A., Solyali, D., Asmael, M., and Zeeshan, Q. (2020). Smart Manufacturing for Industry 4.0 Using Radio Frequency Identification (RFID) Technology. Jurnal Kejuruteraan, 32, 31–38. Https://Doi.Org/10.17576/Jkukm-2020-32(1)-05

Han, Z., Wang, Z., Xie, M., He, Y., Li, Y., and Wang, W. (2021). Remaining Useful Life Prediction and Predictive Maintenance Strategies for Multi-State Manufacturing Systems Considering Functional Dependence. Reliability Engineering and System Safety, 210, 107560. https://doi.org/10.1016/j.ress.2021.107560

Nasir, T., Asmael, M., Zeeshan, Q., and Solyali, D. (2020). Applications of Machine Learning to Friction Stir Welding Process Optimization. Jurnal Kejuruteraan, 32, 171–186. https://doi.org/10.17576/jkukm-2020-32(2)-01

Russell-Gilbert, A., Sommers, A., Thompson, A., Cummins, L., Mittal, S., Rahimi, S., Seale, M., Jaboure, J., Arnold, T., and Church, J. (2024, December 15–18). Aad-LLM: Adaptive Anomaly Detection Using Large Language Models. In Proceedings of the 2024 IEEE International Conference on Big Data (BigData) (pp. 4194–4203). IEEE. https://doi.org/10.1109/BigData62323.2024.10825679

Valis, and Pietrucha-Urbanik, K. (2014). Utilization of Diffusion Processes and Fuzzy Logic for Vulnerability Assessment. Eksploatacja I Niezawodność – Maintenance and Reliability, 16, 48–55.

Yang, H., LaBella, A., and Desell, T. (2022). Predictive Maintenance for General Aviation Using Convolutional Transformers. In Proceedings of the AAAI Conference on Artificial Intelligence (Vol. 36, pp. 12636–12642). AAAI. https://doi.org/10.1609/aaai.v36i11.21505

Zhang, N., Vergara-Marcillo, C., Diamantopoulos, G., Shen, J., Tziritas, N., Bahsoon, R., and Theodoropoulos, G. (2024). Large Language Models for Explainable Decisions in Dynamic Digital Twins. Arxiv Preprint Arxiv:2405.14411. https://doi.org/10.1007/978-3-031-94895-4_8

Zhang, W., Yang, D., and Wang, H. (2019). Data-Driven Methods for Predictive Maintenance of Industrial Equipment: A Survey. IEEE Systems Journal, 13(3), 2213–2227. https://doi.org/10.1109/JSYST.2019.2905565

|

|

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© ShodhKosh 2025. All Rights Reserved.