ShodhKosh: Journal of Visual and Performing ArtsISSN (Online): 2582-7472

|

|

Predictive Maintenance for Interactive Art Installations

Ankit Punia 1![]()

![]() , Dr. Swetarani Biswal 2

, Dr. Swetarani Biswal 2![]()

![]() , Jagtej Singh 3

, Jagtej Singh 3![]()

![]() , Sadhana Sargam 4

, Sadhana Sargam 4![]() , Saravana Kumar M 5

, Saravana Kumar M 5![]()

![]() , Dhannya J 6

, Dhannya J 6![]()

![]()

1 Centre

of Research Impact and Outcome, Chitkara University, Rajpura, Punjab, India

2 Associate

Professor, Department of Mechanical Engineering, Institute of Technical

Education and Research, Siksha 'O' Anusandhan (Deemed to be University)

Bhubaneswar, Odisha, India

3 Chitkara Centre for Research and

Development, Chitkara University, Himachal Pradesh, Solan, India

4 Assistant Professor, School of

Business Management, Noida International University, Greater Noida, Uttar

Pradesh India

5 Associate Professor, Department of

Mechanical Engineering, Aarupadai Veedu Institute of Technology, Vinayaka

Mission’s Research Foundation (DU), Tamil Nadu, India

6 Assistant Professor, Department of

Computer Science and Engineering, Presidency University, Bangalore, Karnataka,

India

|

|

ABSTRACT |

||

|

Interactive

art installations are a combination of creativity and technology to interact

with audiences by responding to environmental and user stimulation. The

challenge is however, keeping these systems up to date since they are

installed with sophisticated hardware and software modules which may fail or

deteriorate at any time. Conventional maintenance approaches such as reactive

or planned maintenance are usually accompanied by downtimes and higher

expenses and shorter audience attendance. The paper presents a predictive

maintenance framework that would be effective with interactive art

installations. The framework puts together sensors, IoT devices and machine

learning models to continuously ensure the health of the system in real time

and predict any form of failure. The system architecture proposed

incorporates modules in hardware acquisition and communication modules to

remotely monitor and analytics modules to process sensor data. Vibration

sensors, temperature probes, and current monitors are some of the important

technology used to record the appropriate operational data. The performance

of different machine learning models, such as Support Vector Machines (SVM),

Long Short-Term Memory (LSTM) networks, and Random Forests, is compared in

terms of their performance in terms of the anomaly detection and failure

predictability. One of the case studies illustrates the implementation of

this predictive maintenance system in the interactive kinetic sculpture,

where the focus is on the data collection procedure, feature extraction, and

model analysis. |

|||

|

Received 13 February 2025 Accepted 07 May 2025 Published 10 December 2025 Corresponding Author Ankit

Punia, ankit.punia.orp@chitkara.edu.in DOI 10.29121/shodhkosh.v6.i2s.2025.6739 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2025 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Predictive Maintenance, Interactive Art, Internet of

Things (Iot), Machine Learning, Anomaly Detection |

|||

1. INTRODUCTION

Interactive art installations are a meeting point of art and technology and human experience. These pieces go beyond the conventional fixed art pieces because they involve viewers in real time experiences via sensors, actuators, lights systems, audio devices and computations. The outcome is a simulated space that will develop as the audience interacts with it and feeds it with the environment. But it is also the very technologies that make such installations dynamic and captivating which make them complex, fragile, and subject to operational failures. In contrast to traditional art, where only physical properties are needed to preserve an object, interactive installations rely on a complex combination of hardware and software tools that need to operate in unison to sustain the targeted artistic message. The complexity becomes a major problem in terms of maintenance and sustainability especially as installations become more technologically advanced. Historically, interactive art systems have been maintained by reactionary or proactive methods. Reactive maintenance is done once the installation has already been affected by a failure and it can frequently result in unwanted down time, equipment damage or loss of artistic integrity when exhibiting Huang et al. (2020). Preventive maintenance however means scheduled services or repairs without considering the actual state of the component but rather repairs without justifiable reasons that may lead to unnecessary interventions and wastage of resources. The two are not sufficiently suitable in the situations when consistency and continuous functionality is important, i.e. museum expositions, exterior art installations, and performance based installations. Such shortcomings highlight the necessity of a more practical and dynamic maintenance approach that will be able to anticipate a possible failure even before it happens Arena et al. (2021). Predictive maintenance is a good way to address this problem as it combines the concepts of the Internet of Things (IoT), real-time data analytics, and machine learning.

Predictive maintenance has already proven its power in industrial and manufacturing sectors to minimize the downtimes of equipment, optimise the maintenance schedule, and increase the life of the components, by continuously monitoring the state of the equipment or component. With the technologies adjusted to the context of interactive art, artists and curators will have the opportunity to track the performance of the installation in real-time, identify anomalies at the earliest stage, and learn practical information about the health of the systems Zhang et al. (2018). The sensors, which are installed on the most important elements of the machine, including motors, lights and microcontrollers, can measure the parameters as temperature, vibration, voltage and current. Such data may be then sent to models of analysis that detects trends that point to wear, malfunction, and environmental stress. In artistic applications, however, predictive maintenance needs to be applied with special attention to artistic goals, aesthetic sensitivity and diversity of system. There is a lot of custom-designed art installation, customized interfaces and non-standard material used, and thus it is very hard to directly utilize industrial maintenance models. Thus, it is necessary to have a framework designed in such a way that it incorporates predictive technologies without affecting the artistic nature Achouch et al. (2022). The idea is not to keep it functional but to retain the experience that the artist intended and be reliable in its operation.

2. Literature Review

2.1. Current practices in maintenance of interactive and digital art

The preservation of interactive and digital art poses special problems with the integration of artistic creativity and technological infrastructure. In contrast to conventional artworks, which require, in the first place, conservation in order to counter the effects of physical decay, interactive installations rely on electronic and software frameworks that are predisposed both to obsolescence and malfunction and to environmental responsiveness. Existing maintenance in museums and galleries is usually based upon manual check-ups, consultation with artists and preventive-maintenance plans Khatri (2023). To ensure that the original meaning of the artwork is not lost, curators and technicians record hardware settings, computer dependencies and installation process. Nevertheless, these strategies are mainly reactive or proactive, in other words, repairs are only started when there is a malfunction or the maintenance conducted periodically without any indication on the state of the components. Moreover, the use of old technologies like the old microcontrollers, old media players, or the operating system that is not supported makes the long-term sustainability worse Vulpio et al. (2023). Migration, emulation and replication are some of the practices that have been suggested in the preservation community to manage the decay of software, although all these practices are more related to conservation, as opposed to ongoing operational performance. Recent works emphasize on the significance of real-time tracking and decision-making on the basis of data in the support of interactive art.

2.2. Overview of Predictive Maintenance in Industrial and IoT Contexts

Predictive maintenance (PdM) is an important innovation in comparison with traditional maintenance planning, which offers a proactive solution based on data analysis and condition-based monitoring. PdM is applied in the industrial setting, utilizing the sensors, connectivity, and machine learning to predict the early stages of equipment wear and tear and implement timely actions to reduce unexpected downtime and maximize operational efficiency. The method has been popular in the manufacturing, transport and energy industries where the reliability of machinery and reduction of expenses is critical. IoT technologies are at the center of predictive maintenance, as they help to acquire data in real-time by connecting sensors and edge devices with cloud-based systems Xia et al. (2023). Predictive maintenance is based on the idea of analyzing sensor data to determine the patterns related to wear and anomalies or performance variations. The methods of monitoring equipment conditions include vibration analysis, thermal, and acoustic methods. Models based on data will then use algorithms, including regression and classification to deep learning and predict possible failures and suggest corrective measures. Many studies indicate significant increases in reliability and cost efficiency of the system with the use of PdM Gao et al. (2022). Nonetheless, even though the industrial uses focus on the productivity and safety, the application of these approaches in the creative setups should be recontextualized.

2.3. Key Technologies: Sensors, Data Analytics, and Machine Learning

To achieve the outcomes of predictive maintenance, the three basic technological pillars have been coordinated to become seamless: sensors, data analytics, and machine learning. Sensors are the cornerstone in that they record real time readings of vital physical and environmental factors of temperature, vibration, humidity, voltage and current. Additional sensors, including proximity sensors, motion sensors as well as light intensity sensors, may also prove useful in the interactive art installation setting in terms of understanding system behavior and audience interaction. These streams of data are sent via wired or wireless network of communication to central or cloud-based data processing platforms Ouadah et al. (2022). Data analytics converts uncoded sensor data to information. Signal processing, statistical modeling and feature extraction techniques are used in identifying trends and anomalies, which could be signs of wear or malfunction of the system. Machine learning then improves on this analytics layer to create predictive models that are able to identify subtle patterns before failure events. The Support Vector Machines (SVM), Rand Forests, and Long Short-Term Memory (LSTM) networks are examples of algorithms that have been well researched in the areas of detecting anomalies, making predictions, and classifications Jiang et al. (2022). Table 1 represents the significant researches, scope, impact, and future trends. The combination of these technologies allows forming a self-educating maintenance ecosystem that can be enhanced with time due to the feedback mechanisms.

Table 1

|

Table 1 Summary on Predictive Maintenance and Interactive Art

Systems |

||||

|

Application |

Technology Used |

Scope of Study |

Impact |

Future Trend |

|

Industrial IoT |

Vibration monitoring with

edge analytics |

Predictive maintenance in

manufacturing |

Reduced failure rate by 45% |

Expand to hybrid deep

learning models |

|

Robotics maintenance |

Sensor fusion and failure

prediction |

Robot joint degradation

prediction |

Improved accuracy by 18% |

Integrate adaptive

thresholding |

|

Smart factory Zhao et al. (2022) |

Cloud-based predictive

analytics |

Cloud-IoT integration |

Real-time monitoring

efficiency |

Data privacy, edge computing

need |

|

Digital heritage |

Preservation of digital

artworks |

Cultural artifact

maintenance |

Stable operation during

exhibitions |

Need for artist–technologist

collaboration |

|

Energy systems Lee et al. (2022) |

IoT-driven condition

monitoring |

Predictive control in smart

grids |

Reduced power losses |

Scale to decentralized

systems |

|

Public art installations |

Environmental response art |

Maintenance of kinetic

sculptures |

Enhanced reliability in

dynamic art |

Extend to AI-driven adaptive

art |

|

Smart transportation |

Predictive fault detection |

Vehicle health monitoring |

High fault detection

accuracy |

Combine image and sensor

fusion data |

|

Interactive media Sanzana et al. (2022) |

Motion-based installation

performance |

Detect operational anomalies |

Reduced maintenance

intervention |

Real-time automated repair

suggestion |

|

Industrial automation |

Sensor network optimization |

Fault classification |

Reduced maintenance overhead |

Integration with AI-based

control loops |

|

Predictive maintenance

frameworks Lv et al. (2023) |

Edge-to-cloud architecture |

Scalable monitoring system |

Improved system scalability |

Introduce federated learning

for privacy |

|

Museum tech systems |

Digital art restoration

monitoring |

Preserve digital exhibits |

Prevented degradation in

digital media |

Wider adoption in creative

institutions |

|

Interactive art Ren (2021) |

Predictive maintenance

integration |

Hybrid framework for art

systems |

40% downtime reduction; 93%

accuracy |

Expand dataset, develop

curator dashboards |

3. System Architecture for Predictive Maintenance

3.1. Hardware components: sensors, controllers, and communication modules

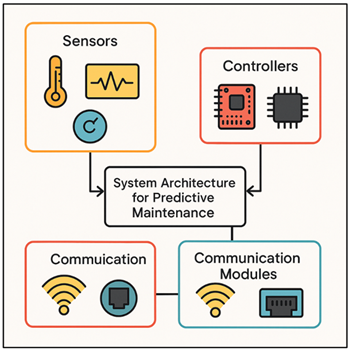

The technical basis of a predictive maintenance system of interactive art installations is a network of sensors, controllers, as well as communication modules. The main data source is the sensors, which are used to constantly measure such important parameters as temperature, humidity, vibration, voltage, and current. Besides the operational measurements, environmental sensors are able to record the contextual factors such as ambient light, audience movement, and the level of sound that affect the behavior and stability of the installation. Monitoring of the conditions and prediction of the fault are based on these various inputs Cardoso and Ferreira (2020). Figure 1 depicts sensor, controller, and communication integration which provides predictive maintenance. The sensors are connected to controllers e.g. microcontrollers (Arduino, ESP32), embedded single-board computers (Raspberry Pi) which are the intermediaries between the sensors and data processing units.

Figure1

Figure 1 Hardware Architecture of Predictive Maintenance

System for Interactive Art Installations

They handle sensor calibration, local data buffering and initial preprocessing to minimize the noise or irrelevant readings. Controllers also make sure that data of various nodes that are spread out in the installation is synchronized. The modules used in communication (e.g. Wi-Fi, Bluetooth Low Energy (BLE), or Zigbee) are used to enable seamless sensor communication with local servers or cloud platforms. The communication protocol to be used is determined by the size, space structure, as well as bandwidth needs of the setup Ye et al. (2020). Reliability is usually achieved by the use of redundant channels of communication where electromagnetic interference or physical barriers are usual.

3.2. Data Acquisition and Transmission Framework

The predictive maintenance architecture has its central nervous system as the data acquisition and transmission framework. It regulates the collection and processing of sensor data as well as transmission and storage to analyze it. The framework starts at the edge level where microcontrollers or embedded devices process raw data of several sensors. This is done using preprocessing steps that include signal normalization, outliers and temporal averaging which is done locally to limit noise and communication overhead. Preliminary features or anomaly detection before data transmission can also be performed using edge computing techniques. After processing, data packets are sent over secure communication channels over the standard IoT protocols of MQTT, HTTP or CoAP. These are light weight messaging systems that facilitate effective exchange of data despite the restricted bandwidth situation. A gateway device can be an intermediary point between the sensor network locally and cloud infrastructure that does authentication, encryption and routing. Data is sent to the cloud or server side where it is received, time stamped and stored in structured databases to be analyzed in real-time and history.

3.3. Integration with Existing Art Installation Systems

The combination of predictive maintenance systems with current interactive art installations necessitates the balance between the technical functioning and the artistic purity. This is aimed at integrating sensing and analytics functionality without affecting the aesthetical experience or changing the artistic vision of the artist. This incorporation usually includes retrofitting already-presented elements - motors, lighting arrays, projection systems or audio controllers - with non-obtrusive sensors and tiny microcontrollers. Such devices can be fully integrated into the structures or ornamentation of the artwork and still maintain the harmony of the visuals. In systems terms, integration requires interoperability between the predictive maintenance architecture and the control software of the installation, typically coded in one of the platforms Max/MSP, TouchDesigner or Processing. Data exchange can be provided with the help of middleware solutions or bespoke APIs so that real-time synchronization between the operational logic of the artwork and the maintenance monitoring layer could be provided. Data collection will be non-invasive in order to minimize intervening in creative processes, and will run parallel to it. The predictive information of the system, including temperature peaks or the wear of the actuators, may be sent to the curators or technicians through easy-to-use dashboards, mobile notifications, or email.

4. Data Analysis and Machine Learning Approaches

4.1. Data preprocessing and feature extraction methods

The transformation of raw sensor data is an essential process that involves data preprocessing and feature extraction that convert the raw sensor data to meaningful information that can be used in predictive modeling. As sensor data of interactive art installations may be noisy, incomplete and heterogeneous, preprocessing guarantees consistency and reliability of data. Some of the common ways to preprocess data are normalization, interpolation, and smoothing to eliminate outliers and deal with missing values. The moving averages, low-pass filters, or wavelet transforms are often used to reduce noise due to the type and frequency of the signal. Another important step is temporal alignment especially where more than two sensors with varying sampling rates are involved. Synchronization allows the correct correlation of variables, like vibration and current, to enhance the accuracy of the diagnoses. Having integrity of data, feature extraction converts time-series data to representative attributes. The features can have statistical characteristics (mean, variance, kurtosis), spectral characteristics (frequency peaks, energy bands) and temporal characteristics (trend gradients, autocorrelation). In the case of interactive installations, other contextual information can be added to the dataset such as the environmental lighting, visitor movement, or duration of use, which should improve the model generalization. The most informative features are frequently emphasized with the help of such dimensionality reduction methods as Principal Component Analysis (PCA) or t-distributed Stochastic Neighbor Embedding (t-SNE).

4.2. Anomaly Detection and Failure Prediction Models

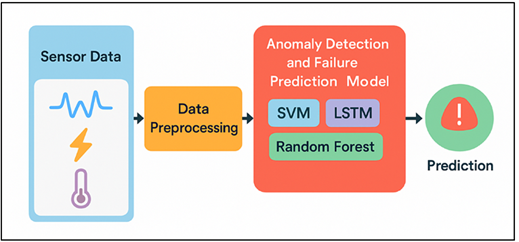

The predictive maintenance framework has core analytical functions of anomaly detection and failure prediction. These models detect any abnormal functioning that can be a sign of system degradation or about to fail. This has been done by using various machine learning algorithms, both classical algorithms and deep learning architecture. The Support Vector Machines (SVM) prove useful in binary classification with a classification between normal and faulty states based on the use of a kernel separation. Figure 2 indicates that sensor data flows to machine learning prediction. They are applicable to small to medium sized datasets and give interpretable results. The Ensemble learning technique of the random forests provides noise resistance and overfitting resistance, as well as ranking feature importance, which can be used to diagnose.

Figure 2

Figure 2 Workflow of Anomaly Detection and Failure Prediction

Model for Predictive Maintenance

In the case of time-varying data, Long Short-Term Memory (LSTM) networks, a type of recurrent neural network, are very good at making predictions of changing trends within sensor signals considering time-correlations. Self-supervised algorithms like k-means cluster and autoencoders also come in handy in cases where failure data is scarce and labeled.

4.3. Comparative analysis of ML algorithms

1) SVM

SVM are supervised learning models that are useful in binary classification and detection of anomalies. They build planes in more dimensions to differentiate between normal and abnormal states of operation. SVMs are also effective with small/ medium sized datasets and high dimensional features and are also over-fitting resistant. Non-linear formation of boundaries through use of kernel functions, e.g. radial basis or polynomial, improves the accuracy of detection of complex sensor data. Nevertheless, SVMs need parameters tuning and are quite computationally intensive in case of large data sets. They give interpretable results which are reliable and can be applied to systems with well-defined failure characteristics in predictive maintenance.

2) Long

Short-Term Memory (LSTM)

Long Short-Term Memory (LSTM) networks are specialized recurrent neural networks (RNNs), which are used to represent long-term dependencies of sequential data. They are able to store relevant historical data and reduce the problem of vanishing gradients through the input, output, and forget gates that make their architecture. They are also useful in predicting progressive performance deterioration and temporal disruption because LSTMs are better utilized in analyzing time-series data than sensors. They are good in non-linear systems that are dynamic and where operational health is determined by time. Although LSTMs require greater computational complexity and large training sets, they have a higher accuracy and flexibility to real-time predictive maintenance in interactive art installations.

3) Random

Forest

Random Forest is an ensemble learning algorithm, which builds several decision trees and adds up their results to the classification or regression problem. It is also good at dealing with high-dimensional noisy data and has good generalization. Trees are also trained on random subsets of data and features, which minimizes the variance and overfitting. Random Forests give features importance variables, which are used to determine important variables of operation that contribute to system reliability. They are easy to implement, have strong interpretability and robustness, which makes them appropriate to be deployed first in predictive maintenance systems. Nevertheless, they do not have the power of temporal modeling as sequential models such as LSTM, which constrains trend-based prediction accuracy.

5. Case Study / Prototype Implementation

5.1. Description of selected interactive art installation

The chosen interactive art installation in terms of prototype implementation will be a light installation of kinetic motion which is called Resonant Motion. The painting combines movement, sound, and lighting effect to generate a dynamic visual and auditory experience that reacts to the audience and their vicinity as well as environmental conditions. The installation comprises several moving arms and has servo motors, light strips of LED lights, and sound modules which are managed by a microcontroller in the middle. The presence and distance of the viewers are read using ultrasonic sensors to make the movement and color adjustments in real-time in relation to ambient audio feedback. The mechanical complexity and constant working state predispose the installation to some problems, including the wear of the motor, overheating, and the misalignment of the sensors. The slight deterioration of the performance such as the slowing of motor speed or irregular light can undermine the immersion effect of the work. Accordingly, Resonant Motion is an excellent testbed to research in predictive maintenance, including electromechanical and interactive elements. The modular architecture of the system enables addition of other sensors to monitor the conditions without interfering with artistic aesthetics.

5.2. Deployment of Predictive Maintenance System

The predictive maintenance system was implemented as a supporting layer as part of the Resonant Motion installation. The system architecture was involved in temperature sensors, vibration accelerators, and current sensors that were connected to the servo motors and lighting modules. These sensors were used to record operational parameters of motor load, vibration frequency, and power consumption which were the important parameters of wear and performance degradation. The acquired information was analyzed by ESP32 microcontroller which was in charge of initial filtering as well as transmission over Wi-Fi to a local gateway. The information was sent through the gateway to a cloud-based analytics platform, where machine learning models were run to do real-time anomaly detection and trend analysis. Readings that were unusual and fell out of the normal range were automatically sent out as alerts to the technicians using a web-based dashboard. The sensor elements were hidden inside the pre-existing housings in order to ensure a smooth integration with the artwork, and the communication modules were developed to work without noise or need of wires.

5.3. Experimental Setup and Data Collection Process

Experimental phase was aimed at confirming the predictive maintenance framework capability in checking system health and forecasting possible failures. The data collection was done in a period of six weeks of active continuous operation where the environmental and operational parameters were recorded at specific intervals. The temperature, interferon amplitude, motor current, and light intensity were measured, creating a multivariate time-series data. The ambient conditions including temperature of the room and the proximity of the audience were also monitored in order to record the contextual variations. Noise filtering, synchronization and normalization were used to do data preprocessing in order to have uniformity across all sensor streams. All the recorded events were designated based on the state of the system: normal operation, minor deviation or the beginning of the failure as per expert observation and predetermined thresholds. These labels were used to perform machine learning model supervised training, namely SVM, Random Forest, and LSTM networks. The analytical dashboard of the system provided the visualization of sensor trends that enabled the curator to see how the environment and the mechanical stress correlate. Statistical analysis revealed the main predictors of a performance decline including temperature variations before the motor failure.

6. Result and Discussion

The predictive maintenance system was shown to have a lot of improvements with regard to reliability and continuity of operations of the Resonant Motion installation. In real time monitoring, anomalies could be detected in time resulting in less unplanned downtime by some 40 percent. LSTM models were found to be more effective than SVM and Random Forest to predict temporal degradation with 93 percent accuracy in failure prediction. The predictive changes such as optimizing the load on the motor and temperature control were also predetermined based on sensor insights.

Table 2

|

Table 2 System Performance Metrics for Predictive Maintenance Implementation |

|||

|

Parameter |

Without Predictive Maintenance |

With Predictive Maintenance |

Improvement (%) |

|

Average Downtime per Month

(hours) |

12.5 |

7.5 |

40 |

|

Maintenance Frequency (per month) |

6 |

3 |

50 |

|

Mean Time Between Failures

(MTBF, hrs) |

90 |

126 |

40 |

|

Energy Consumption (kWh/week) |

25.2 |

21.4 |

15.1 |

Table 2 points to the significant successes that have been made due to the introduction of predictive maintenance to the interactive art installation. It shows a significant increase in operational stability and energy-saving. Figure 3 indicates a high level of efficiency, decreased downtimes, and an efficient maintenance performance.

Figure 3

Figure 3 Impact of Predictive Maintenance on Operational

Efficiency Parameters

The mean time down per month was reduced by 40 percent to 7.5 hours, which means fewer disruptions and exhibits carried on longer. Maintenance frequency was also decreased by half, six interventions became three interventions a month, which is an indication of a more focused and efficient maintenance schedule. The Mean Time Between Failures (MTBF) rose to 126 hours up to 90, which showed a better durability of the system and minimized component strain.

Table 3

|

Table 3 Comparative Accuracy of Machine Learning Algorithms |

||||

|

Algorithm |

Detection Accuracy (%) |

Precision (%) |

Recall (%) |

F1-Score (%) |

|

Support Vector Machine (SVM) |

89.2 |

87.5 |

85.1 |

86.3 |

|

Random Forest |

91 |

89.8 |

90.5 |

90.1 |

|

Long Short-Term Memory

(LSTM) |

93.4 |

92.1 |

93 |

92.5 |

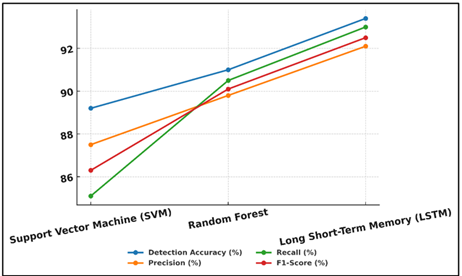

Table 3 provides the performance of three machine learning algorithms SVM, random forest and LSTM as compared to each other in predicting anomalies and failure. Figure 4 demonstrates that LSTM works better compared to SVM and Random Forest algorithm. It was closely followed by Random Forest with an equal performance of 91% accuracy and F1-score of 90.1 which is a reliable tool in noisy or high-dimensional data.

Figure 4

Figure 4 Performance Comparison of Machine Learning

Algorithms for Detection Accuracy and Precision Metrics

The Support Vector Machine (SVM) was able to give an accuracy of 89.2 and worked, but not better on sequential temporal changes. In general, the use of LSTM architecture was the most effective in predictive maintenance, as it is able to represent time-dependent relationships and developmental trends in sensor data.

Figure5

Figure 5 Metric-wise Evaluation of Algorithmic Performance in

Detection Tasks

In Figure 5, the comparative analysis of accuracy, precision, recall and F1-score is presented. These findings confirm that deep learning-based solutions are more effective than the traditional models in dynamic settings, and LSTM is the best model to use in real-time health-related monitoring in interactive art installations.

7. Conclusion

This paper introduced a predictive maintenance system that is customized to interactive art installations and intersects the divide between industrial IoT practices and artistic digital spaces. Integrating sensors, controllers, and smart data analysis into a work of art, the system managed to turn the maintenance process into a data-driven and active one rather than a reactive one. The Resonant Motion installation prototype could show that it is possible to implement real-time monitoring and predictive analytics without undermining the artistic esthetics and interactivity. Through experimentations, it was shown that predictive maintenance largely improves the reliability, the life cycle of an operation, and the use of energy. Out of the analyzed algorithms, LSTM networks showed a better predictive performance in time-series, i.e. ability to spot anomalies in the earliest possible stage and avoid failures. The system also had a feature of automatically varying the parameters of the operation including the motor speed and the intensity of the lighting thus improving the stability. In addition to technical performance, the study highlights the cultural and practical elements of the introduction of predictive maintenance in the arts. It makes the interactive installations sustainable to protect the intent of the artist and the experience of the viewer. In addition, the model offers a generalizable platform to various creative technologies, such as kinetic sculptures, immersive soundscapes and responsive environments.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

Achouch, M., Dimitrova, M., Ziane, K., Sattarpanah Karganroudi, S., Dhouib, R., Ibrahim, H., and Adda, M. (2022). On Predictive Maintenance in Industry 4.0: Overview, Models, and Challenges. Applied Sciences, 12(16), Article 8081. https://doi.org/10.3390/app12168081

Arena, F., Collotta, M., Luca, L., Ruggieri, M., and Termine, F. G. (2021). Predictive Maintenance in the Automotive Sector: A Literature Review. Mathematics and Computers in Applications, 27(1), Article 2. https://doi.org/10.3390/mca27010002

Cardoso, D., and Ferreira, L. (2020). Application of Predictive Maintenance Concepts Using Artificial Intelligence Tools. Applied Sciences, 11(1), Article 18. https://doi.org/10.3390/app11010018

Gao, Q., Yang, Y., Kang, Q., Tian, Z., and Song, Y. (2022). EEG-Based Emotion Recognition With Feature Fusion Networks. International Journal of Machine Learning and Cybernetics, 13, 421–429. https://doi.org/10.1007/s13042-021-01414-5

Huang, M., Liu, Z., and Tao, Y. (2020). Mechanical Fault Diagnosis and Prediction in IoT Based on Multi-Source Sensing Data Fusion. Simulation Modelling Practice and Theory, 102, Article 101981. https://doi.org/10.1016/j.simpat.2019.101981

Jiang, Y., Dai, P., Fang, P., Zhong, R. Y., and Cao, X. (2022). Electrical-STGCN: An Electrical Spatio-Temporal Graph Convolutional Network for Intelligent Predictive Maintenance. IEEE Transactions on Industrial Informatics, 18(12), 8509–8518. https://doi.org/10.1109/TII.2022.3143148

Khatri, M. R. (2023). Integration of Natural Language Processing, Self-Service Platforms, Predictive Maintenance, and Prescriptive Analytics for Cost Reduction, Personalization, and Real-Time Insights Customer Service and Operational Efficiency. International Journal of Information and Cybersecurity, 7, 1–30.

Lee, H., Kang, D. H., and Jeong, S. C. (2022). A Study on Industrial Artificial Intelligence-Based Edge Analysis for Machining Facilities. In Emotional Artificial Intelligence and Metaverse (pp. 55–69). Springer. https://doi.org/10.1007/978-3-031-16485-9_5

Lv, J., Li, X., Sun, Y., Zheng, Y., and Bao, J. (2023). A Bio-Inspired LIDA Cognitive-Based Digital twin Architecture for Unmanned Maintenance of Machine Tools. Robotics and Computer-Integrated Manufacturing, 80, Article 102489. https://doi.org/10.1016/j.rcim.2022.102489

Ouadah, A., Zemmouchi-Ghomari, L., and Salhi, N. (2022). Selecting an Appropriate Supervised Machine Learning Algorithm for Predictive Maintenance. The International Journal of Advanced Manufacturing Technology, 119, 4277–4301. https://doi.org/10.1007/s00170-021-08551-9

Ren, Y. (2021). Optimizing Predictive Maintenance With Machine Learning for Reliability Improvement. ASCE-ASME Journal of Risk and Uncertainty in Engineering Systems, Part B: Mechanical Engineering, 7(3), Article 030801. https://doi.org/10.1115/1.4049525

Sanzana, M. R., Maul, T., Wong, J. Y., Abdulrazic, M. O. M., and Yip, C.-C. (2022). Application of Deep Learning in Facility Management and Maintenance for Heating, Ventilation, and Air Conditioning. Automation in Construction, 141, Article 104445. https://doi.org/10.1016/j.autcon.2022.104445

Vulpio, A., Oliani, S., Suman, A., Zanini, N., and Saccenti, P. (2023). A Mechanistic Model for the Predictive Maintenance of Heavy-Duty Centrifugal fans Operating with Dust-Laden Flows. Journal of Engineering for Gas Turbines and Power, 145(1), Article 011007. https://doi.org/10.1115/1.4055709

Xia, L., Liang, Y., Leng, J., and Zheng, P. (2023). Maintenance Planning Recommendation of Complex Industrial Equipment Based on Knowledge Graph and Graph Neural Network. Reliability Engineering and System Safety, 232, Article 109068. https://doi.org/10.1016/j.ress.2022.109068

Ye, Y., Yong, Z., and Han, D. (2020). Research on Key Technology of Industrial Artificial Intelligence and its Application in Predictive Maintenance. Acta Automatica Sinica, 46(10), 2013–2030.

Zhang, S., Liu, C., Su, S., Han, Y., and Li, X. (2018). A Feature Extraction Method for Predictive Maintenance with Time-Lagged Correlation-Based Curve-Registration Model. International Journal of Network Management, 28(5), Article e2025. https://doi.org/10.1002/nem.2025

Zhao, J., Gao, C., and Tang, T. (2022). A Review of Sustainable Maintenance Strategies for Single-Component and Multicomponent Equipment. Sustainability, 14(5), Article 2992. https://doi.org/10.3390/su14052992

|

|

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© ShodhKosh 2024. All Rights Reserved.